Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 07:27AM |

Registered: 8 years ago Posts: 46 |

Thanks all for the help in setting the Z offset on my BLTouch. I was having an issue being a noob and trying to use the Repetier UI to try to move below 0. Once I used your examples and used g-code direct it worked fine.

I originally had a power problem similar to what's just been mentioned. I found having the BLTouch connected to the servo pins caused really funky things. When I cycled the probe tip the LC display would flicker and sometimes the heat bed led would flash. I put a scope on the +5 line and it was dropping to about 4.2 volts. I have a semi-permanent fix unless I find something better. I mounted a TO-220 style 7805 voltage regulator using one of the existing holes in the acrylic board mount and wired it right to the +12 on the power supply. I brought the +5 output line up to a single pin connector and plugged it into a unused +5 pin on a servo connector. That solved my issues (well, maybe not all). I didn't even bother to put a filter cap at the +5 output and things seem fine.

One thing I have noticed is if the BLTouch is flashing when I try to home all the Z stage will go up rather than down. I reset the printer, the BLTouch stops flashing and homing works fine. The BLTouch seems to have a couple of different flashing modes. I'd like to determine what it's trying to tell me.

I originally had a power problem similar to what's just been mentioned. I found having the BLTouch connected to the servo pins caused really funky things. When I cycled the probe tip the LC display would flicker and sometimes the heat bed led would flash. I put a scope on the +5 line and it was dropping to about 4.2 volts. I have a semi-permanent fix unless I find something better. I mounted a TO-220 style 7805 voltage regulator using one of the existing holes in the acrylic board mount and wired it right to the +12 on the power supply. I brought the +5 output line up to a single pin connector and plugged it into a unused +5 pin on a servo connector. That solved my issues (well, maybe not all). I didn't even bother to put a filter cap at the +5 output and things seem fine.

One thing I have noticed is if the BLTouch is flashing when I try to home all the Z stage will go up rather than down. I reset the printer, the BLTouch stops flashing and homing works fine. The BLTouch seems to have a couple of different flashing modes. I'd like to determine what it's trying to tell me.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 09:17AM |

Registered: 8 years ago Posts: 93 |

Quote

sonnylowe

Quote

GrouchoDuke

Quote

sonnylowe

Quote

tjnamtiw

Still working to get the BLTouch to work with my 2020 and RC3. I tried the settings on the Wikia as well as those on Bert's git page. My Z axis goes up instead of down, which it never did before. Strange.

The biggest head scratcher is that with the laptop hooked up via USB, the BLTouch goes through it's self test and then solid red waiting for a probe. If I unhook the USB and go strictly off of the power supply, I get no self test and just flashing on the BlTouch. Any idea what that might be? Searches yield nothing.

Thanks! I WILL PREVAIL!!!! Grrrrrrrrrr.

Is your BLt getting power directly from the Ramps, if so there could be a lack of power from the ramps, usually the BLt can run off the lower current on those contacts!?!? Does it go into alarm mode when you unplug the laptop? In that case the simple fix might be to unplug the BLt power leads from the Ramps to reset it. These is a command prompt that will do that as well but I can't think of it off the top of my head!?!?

Here's my config-h

I'm seeing pretty much the same thing on mine...except my BLTouch gives me a fast flashing LED no matter what I do. Is that a power issue? If so, where besides the servo pins is good to get power to it?

I'm honestly not sure as I never had a power problem, I just know it's not recommended to drive a servo from the board due to low current. However the current draw on the BLt is super low, so mine always worked...I beleive the draw on the White version is even lower!?!?

As far as 5V from elsewhere, you could just use a phone changer and hack the connect...although I wouldn't use a cheap wimpy one, maybe one from a table would be better...

The other option would be a step-down circuit, just like dropping the voltage on the Prox Sensors...Tom's guide shows you how to do that, then you could pull power directly from the PS or the aux 12V pins.

I am currently running a different sensor, but if I went back, I'd use a Tablet Charger to be on the safe side

I've not had any problems running the BLTouch from the servo pins, nor did I have a problem running the mini servo I had before. It should work, and not cause any problems. Does the pin move freely in your BLTouch? Have you adjusted it up or down? I've heard you can adjust it too far up or down and it won't work right. Also since it isn't just a switch, there is polarity on the two pin connector, and it matters if you have ground and signal oriented right where it plugs into the endstop pins, unlike a simple non-powered switch.

I am not using the original Fogler Tech RAMPS or Arduino board, but they are still just spare ones I got off ebay, but I don't think there are any differences between them and the folger tech version.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 09:29AM |

Registered: 8 years ago Posts: 22 |

I searched around a bit, and saw some (couldn't find many posts) also had some questions with the y carriage assembly. I guess my question is pretty simple, is the bed supposed to glide smoothly without resistance along the rails or should there be a little bit of friction? i just finished putting the frame and bed on, but there is some resistance when sliding the bed back and fourth - its sounds like a grinding noise. i found this video and it kind of sounds like this (starting at 4:16), its not folgertech, but i thought it might be applicable here. [www.youtube.com]

Just wanted to see if this is what it should be doing so i can forward.

Also, are there any guides out there for align the y-carriage? The documentation is not very clear on how i'm supposed align, and where to put the rails.. i'm assuming the center, so each of the sk8s are equal distance from the side of the printer?

thanks!

Just wanted to see if this is what it should be doing so i can forward.

Also, are there any guides out there for align the y-carriage? The documentation is not very clear on how i'm supposed align, and where to put the rails.. i'm assuming the center, so each of the sk8s are equal distance from the side of the printer?

thanks!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 10:19AM |

Registered: 8 years ago Posts: 285 |

Quote

thebabymaker

I searched around a bit, and saw some (couldn't find many posts) also had some questions with the y carriage assembly. I guess my question is pretty simple, is the bed supposed to glide smoothly without resistance along the rails or should there be a little bit of friction? i just finished putting the frame and bed on, but there is some resistance when sliding the bed back and fourth - its sounds like a grinding noise. i found this video and it kind of sounds like this (starting at 4:16), its not folgertech, but i thought it might be applicable here. [www.youtube.com]

Just wanted to see if this is what it should be doing so i can forward.

Also, are there any guides out there for align the y-carriage? The documentation is not very clear on how i'm supposed align, and where to put the rails.. i'm assuming the center, so each of the sk8s are equal distance from the side of the printer?

thanks!

Yes, it is normal for the bed to have a slight grindy noise when sliding it. As long as the bed slides downwards by itself when you tilt the printer and it is not making too much noise, you should be fine. The way I aligned my linear rods was to find out how far each sk8 should be from each side of the printer (which is about 95mm on mine), tighten the rods on one side of the printer, and then slide the bed back and forth allowing the other rod to find its place in the position where there is the least friction.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 10:57AM |

Registered: 8 years ago Posts: 541 |

After a good night's sleep, I addressed my problems with the BLTOUCH with a 'semi' fresh mind. I can raise and lower the probe giving the M280 p0 s10 or s90 commands. When the probe is down, if I push it up, it goes into the fast flash mode. I took your advice and just unplugged the BLT to reset it. Much faster than disconnecting and then reconnecting the USB and Repetier. I did verify that if the probe is in the up position with light on and I disconnect the USB, it remains in the up position with the main power on.

I also verified that I have 4.96 volts on the servo rail in both cases and yes, as you said, the power draw on the new BLT is very small. At this point, I homed the printer and it zeroed X and Y and then moved to the center and came down and tripped the BLT. I had my pointer on Emerg Stop and verified it kept going down so I killed the power. I have the switch cable in the Zmin position where I removed the old Z stop switch. It is between the ground pin and the signal pin. I took off that connector and measured resistance between the connectors. I got 143 ohms whether the pin was up or down! At that point I decided it was time to start adjusting the set screw. I watched the ohm reading as I moved the set screw but it never changed. This leads me to believe that my Hall Effect switch in the BLT is bad. I guess it's time to relate all this info back to the manufacturer and see what he says.

Oh, I did have both of those boolean settings false and I had to reverse the Z direction. It appears that everything will work IF I had a working BLTOUCH.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

I also verified that I have 4.96 volts on the servo rail in both cases and yes, as you said, the power draw on the new BLT is very small. At this point, I homed the printer and it zeroed X and Y and then moved to the center and came down and tripped the BLT. I had my pointer on Emerg Stop and verified it kept going down so I killed the power. I have the switch cable in the Zmin position where I removed the old Z stop switch. It is between the ground pin and the signal pin. I took off that connector and measured resistance between the connectors. I got 143 ohms whether the pin was up or down! At that point I decided it was time to start adjusting the set screw. I watched the ohm reading as I moved the set screw but it never changed. This leads me to believe that my Hall Effect switch in the BLT is bad. I guess it's time to relate all this info back to the manufacturer and see what he says.

Oh, I did have both of those boolean settings false and I had to reverse the Z direction. It appears that everything will work IF I had a working BLTOUCH.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 11:11AM |

Registered: 8 years ago Posts: 38 |

Quote

DaveA

I originally had a power problem similar to what's just been mentioned. I found having the BLTouch connected to the servo pins caused really funky things...

I'm glad to hear you got it working. I'll power mine another way and see how that goes.

Quote

Bert3d

I've not had any problems running the BLTouch from the servo pins, nor did I have a problem running the mini servo I had before. It should work, and not cause any problems. Does the pin move freely in your BLTouch? Have you adjusted it up or down? I've heard you can adjust it too far up or down and it won't work right. Also since it isn't just a switch, there is polarity on the two pin connector, and it matters if you have ground and signal oriented right where it plugs into the endstop pins, unlike a simple non-powered switch.

Thanks Bert. I haven't adjusted the pin, so I'm guessing that's fine. I was going to adjust it because the mount I printed (I think the same mount you use) had it sitting a little too low. I tried to turn it, but it didn't seem to want to move easily (Locktite maybe?). So, I just modified & reprinted the mount to be about 3mm taller to get the extra spacing I wanted.

The pin does move freely by hand, but it doesn't respond to manual M280 commands. No matter what I do, I get a fast flashing (very dimly lit) LED in the BLTouch. I haven't tried a servo on my printer, but I may do that just to see what happens.

I think 3 people with new BLTouch's this month have had power-related issues (if mine is a power issue too, that is). I wonder if they changed the power requirements of it recently...or maybe Folger Tech changed something. Who knows!?

Anyway, I'll keep hunting on my setup. I have plenty of 5V regulators around here, so getting the right power to it shouldn't be a problem. If power issues are a common trend with the BLTouch and the FT printer, a wiki blurb about a good way to do it would ease some pain.

There are also people in other threads who've reported issues on certain servo pins when they're running Marlin 1.1 RC3. I've only tried the BLTouch on servo 0 & 1. That might be something else I can try too.

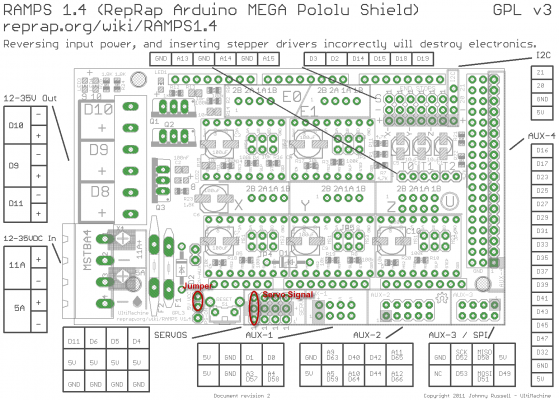

One more question though...On an older BLTouch Google+ post, they posted a picture with a line through the 5V & VCC pins near the RAMPS servo connectors. My RAMPS doesn't have anything on those pins. Do I need to do something with those to properly power up the servo power pins?

Thanks everybody!

EDIT: Some quick Google...It looks like this person has a jumper on the VCC-5V pins by the servo connectors. Mine doesn't...sooo...Do I need one? 5V VCC jumper picture

EDIT 2: There's a note on the Marlin github page that says those pins need to be jumped to get 5V on the servo pins. Sweet - something to fix. I'll try that tonight.

Edited 2 time(s). Last edit at 01/29/2016 11:28AM by GrouchoDuke.

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 01:09PM |

Registered: 8 years ago Posts: 93 |

Quote

tjnamtiw

After a good night's sleep, I addressed my problems with the BLTOUCH with a 'semi' fresh mind. I can raise and lower the probe giving the M280 p0 s10 or s90 commands. When the probe is down, if I push it up, it goes into the fast flash mode. I took your advice and just unplugged the BLT to reset it. Much faster than disconnecting and then reconnecting the USB and Repetier. I did verify that if the probe is in the up position with light on and I disconnect the USB, it remains in the up position with the main power on.

I also verified that I have 4.96 volts on the servo rail in both cases and yes, as you said, the power draw on the new BLT is very small. At this point, I homed the printer and it zeroed X and Y and then moved to the center and came down and tripped the BLT. I had my pointer on Emerg Stop and verified it kept going down so I killed the power. I have the switch cable in the Zmin position where I removed the old Z stop switch. It is between the ground pin and the signal pin. I took off that connector and measured resistance between the connectors. I got 143 ohms whether the pin was up or down! At that point I decided it was time to start adjusting the set screw. I watched the ohm reading as I moved the set screw but it never changed. This leads me to believe that my Hall Effect switch in the BLT is bad. I guess it's time to relate all this info back to the manufacturer and see what he says.

Oh, I did have both of those boolean settings false and I had to reverse the Z direction. It appears that everything will work IF I had a working BLTOUCH.

I don't think the signal from the BLTouch is the direct output of the hall effect sensor. I believe it is a digital output signal from the chip in the BLTouch, and that chip is reading the hall effect sensor. That's why the polarity of the signal wire matters - it is not a dumb switch, but a signal. Hooking it up backwards, with the BLTouch signal connected to the ground pin on the ramps, and the ground from the BLTouch to the Z-Min signal pin on the RAMPS probably won't work, and might even damage your BLTouch. I'm not sure reading the resistance across it was harmful, but it definitely wouldn't tell you anything useful.

You do have to make sure the jumper is on the RAMPS board to provide power to the servo pins. It doesn't come that way. I suspect people who are having power problems may have missed that step. There is a note about it here: [github.com]

Here is an image of how to hook up the jumper:

Edit: GrouchoDude beat me to this point. You can see a photo of the jumper in his post above.

Edited 2 time(s). Last edit at 01/29/2016 01:13PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 01:36PM |

Registered: 8 years ago Posts: 38 |

Quote

Bert3D

Edit: GrouchoDude beat me to this point. You can see a photo of the jumper in his post above.

*high five* Thanks for posting the photo. Hopefully that's all my problem was. (Well, my problem with BLTouch anyway.)

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 01:55PM |

Registered: 8 years ago Posts: 541 |

More on my BLTOUCH > I wrote to Charles and filled him in on our problems.

I failed to mention that I, like others, experience the flashing red light IF I initially power on with the main power rather than USB. If I start with USB and then power up the machine, the red light stays steady even if I remove the main power. If I push up the pin, the light with start and continue to flash until it is reset.

As mentioned, there is power on the 'switch' output. I measure 4.5 volts with the core pin in any position.

The new version of BLTOUCH uses a max of 300 ma while the old version uses 800 ma max. Normally the old one used 15ma and the new one uses the same 15 ma so the servo bus should have no problem handling the new one.

Another thing I noticed was that while the M280 commands make the pin go out and in, if I give a M401 or 402 command to deploy the servo as is done with the RC servo types, the Z carriage goes up!

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

I failed to mention that I, like others, experience the flashing red light IF I initially power on with the main power rather than USB. If I start with USB and then power up the machine, the red light stays steady even if I remove the main power. If I push up the pin, the light with start and continue to flash until it is reset.

As mentioned, there is power on the 'switch' output. I measure 4.5 volts with the core pin in any position.

The new version of BLTOUCH uses a max of 300 ma while the old version uses 800 ma max. Normally the old one used 15ma and the new one uses the same 15 ma so the servo bus should have no problem handling the new one.

Another thing I noticed was that while the M280 commands make the pin go out and in, if I give a M401 or 402 command to deploy the servo as is done with the RC servo types, the Z carriage goes up!

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 02:03PM |

Registered: 8 years ago Posts: 541 |

Quote

DaveA

Thanks all for the help in setting the Z offset on my BLTouch. I was having an issue being a noob and trying to use the Repetier UI to try to move below 0. Once I used your examples and used g-code direct it worked fine.

I originally had a power problem similar to what's just been mentioned. I found having the BLTouch connected to the servo pins caused really funky things. When I cycled the probe tip the LC display would flicker and sometimes the heat bed led would flash. I put a scope on the +5 line and it was dropping to about 4.2 volts. I have a semi-permanent fix unless I find something better. I mounted a TO-220 style 7805 voltage regulator using one of the existing holes in the acrylic board mount and wired it right to the +12 on the power supply. I brought the +5 output line up to a single pin connector and plugged it into a unused +5 pin on a servo connector. That solved my issues (well, maybe not all). I didn't even bother to put a filter cap at the +5 output and things seem fine.

One thing I have noticed is if the BLTouch is flashing when I try to home all the Z stage will go up rather than down. I reset the printer, the BLTouch stops flashing and homing works fine. The BLTouch seems to have a couple of different flashing modes. I'd like to determine what it's trying to tell me.

Mine goes up as well under those conditions. I hope that Charles Lee can make this device suitable for our machines without us having to supply separate power and jump through hoops. When you supplied your external 5 volts to the servo rail, I assume you removed the jumper that was supplying power to the servos..??

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 03:34PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 03:39PM |

Registered: 8 years ago Posts: 367 |

I bought window glass from a local store. I think it's about 3mm, maybe slightly less. People say don't use 2mm as it may crack. If you want to go fancier, buy some borosilicate glass.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 03:44PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 03:45PM |

Registered: 8 years ago Posts: 541 |

Quote

Bert3D

Quote

tjnamtiw

After a good night's sleep, I addressed my problems with the BLTOUCH with a 'semi' fresh mind. I can raise and lower the probe giving the M280 p0 s10 or s90 commands. When the probe is down, if I push it up, it goes into the fast flash mode. I took your advice and just unplugged the BLT to reset it. Much faster than disconnecting and then reconnecting the USB and Repetier. I did verify that if the probe is in the up position with light on and I disconnect the USB, it remains in the up position with the main power on.

I also verified that I have 4.96 volts on the servo rail in both cases and yes, as you said, the power draw on the new BLT is very small. At this point, I homed the printer and it zeroed X and Y and then moved to the center and came down and tripped the BLT. I had my pointer on Emerg Stop and verified it kept going down so I killed the power. I have the switch cable in the Zmin position where I removed the old Z stop switch. It is between the ground pin and the signal pin. I took off that connector and measured resistance between the connectors. I got 143 ohms whether the pin was up or down! At that point I decided it was time to start adjusting the set screw. I watched the ohm reading as I moved the set screw but it never changed. This leads me to believe that my Hall Effect switch in the BLT is bad. I guess it's time to relate all this info back to the manufacturer and see what he says.

Oh, I did have both of those boolean settings false and I had to reverse the Z direction. It appears that everything will work IF I had a working BLTOUCH.

I don't think the signal from the BLTouch is the direct output of the hall effect sensor. I believe it is a digital output signal from the chip in the BLTouch, and that chip is reading the hall effect sensor. That's why the polarity of the signal wire matters - it is not a dumb switch, but a signal. Hooking it up backwards, with the BLTouch signal connected to the ground pin on the ramps, and the ground from the BLTouch to the Z-Min signal pin on the RAMPS probably won't work, and might even damage your BLTouch. I'm not sure reading the resistance across it was harmful, but it definitely wouldn't tell you anything useful.

.

I did have the signal to the signal pin and ground to ground. It could very well be that when you hit the power switch, everything is starting up at once including the LCD screen and the BLTOUCH self test, which drags the voltage down enough to fault out the BLT. This stinks! It would be nice to have the code sequence things on so the voltage isn't pulled down.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 03:49PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

You guys are using a 8x8 sheet of glass for the print bed right? How thick is it? Im assuming 1/2 inch or less would be OK?

I am using a 8x8 aluminum plate

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 03:49PM |

Registered: 8 years ago Posts: 171 |

Quote

animoose

I bought window glass from a local store. I think it's about 3mm, maybe slightly less. People say don't use 2mm as it may crack. If you want to go fancier, buy some borosilicate glass.

I used some 8x10 picture frame glass from Home Depot and it worked fine. That is until my son bumped it when it was hot and it broke into some nasty fragments. I went with the (right sized) borosilicate. (call me fancy.

lol)

lol)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 03:52PM |

Registered: 8 years ago Posts: 25 |

Quote

UltiFix

You guys are using a 8x8 sheet of glass for the print bed right? How thick is it? Im assuming 1/2 inch or less would be OK?

I just bought an 8 x 8 x 1/8 piece of glass and asked them to sand down the edges and corners so they weren't sharp.. but I had to go to a glass shop, Lowes didn't have anything that thick

New Wikia page: [folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 04:02PM |

Registered: 8 years ago Posts: 131 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 04:03PM |

Registered: 8 years ago Posts: 93 |

Quote

UltiFix

You guys are using a 8x8 sheet of glass for the print bed right? How thick is it? Im assuming 1/2 inch or less would be OK?

You don't want it too thick, or it will be difficult, if not impossible, to heat properly. I'd say 3 to 5mm at most. Mine came from Lowes, and is 8 inches by 8-1/2 inches. I had one panel cut into 4 pieces that size. I think it was less than $10. I sanded the edges myself so nothing was sharp.

I tried the borosilicate glass, but the one I got was not flat, and made it impossible to level the bed well. It also didn't stick as well. I stopped using it and went back to the regular glass. The borosilicate plates are typically 213mm x 200mm x 3mm. A friend of mine tried two different borosilicate plates from different vendors and both had an uneven surface too. After hearing that, I decided not to bother to try getting a different one.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 04:15PM |

Registered: 8 years ago Posts: 25 |

Regarding the BLTouch, how long did it take to get it? My has been sitting here since the 20th?

2016-01-20 13:52 Departure from outward office of exchange, Dispatch number : 13

2016-01-20 13:43 INCHEON, Flight number : PO214

I tried looking up the tracking number on the USPS website and it recognized it as an item from Korea but it didn't have any information.

New Wikia page: [folgertech.wikia.com]

2016-01-20 13:52 Departure from outward office of exchange, Dispatch number : 13

2016-01-20 13:43 INCHEON, Flight number : PO214

I tried looking up the tracking number on the USPS website and it recognized it as an item from Korea but it didn't have any information.

New Wikia page: [folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 04:19PM |

Registered: 8 years ago Posts: 314 |

Im currently stuck mounting the PSU, he bolts they gave me are to short because im using a washer to keep the head from going through the 2020 corner brackets... I wonder if I can just use the 11mm bolts instead of 8mm, just not sure if im going to need the 10mm bolts. Does anybody remember?

Actually there happen's to be 2 extra of those 10mm bolts

Thanks!

Sam

Edited 3 time(s). Last edit at 01/29/2016 05:23PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 04:37PM |

Registered: 8 years ago Posts: 93 |

Quote

john-i

Regarding the BLTouch, how long did it take to get it? My has been sitting here since the 20th?

2016-01-20 13:52 Departure from outward office of exchange, Dispatch number : 13

2016-01-20 13:43 INCHEON, Flight number : PO214

I tried looking up the tracking number on the USPS website and it recognized it as an item from Korea but it didn't have any information.

You can track Korean packages using [www.17track.net]

I've found the tracking stops when it leaves Korea. I saw no further updates after the flight. It appeared in my mailbox 10 days after the flight date. Tracking still shows the flight as the last activity.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 04:56PM |

Registered: 8 years ago Posts: 46 |

Quote

john-i

Regarding the BLTouch, how long did it take to get it? My has been sitting here since the 20th?

2016-01-20 13:52 Departure from outward office of exchange, Dispatch number : 13

2016-01-20 13:43 INCHEON, Flight number : PO214

I tried looking up the tracking number on the USPS website and it recognized it as an item from Korea but it didn't have any information.

I ordered mine via Ebay on Jan 10, it was shipped on the 11th and arrived on the 25th. I was fortunate to be home when it was delivered as it was sent signature required. If I wasn't here I'd have to find the time to take a trip to the PO to pick it up.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 05:30PM |

Registered: 8 years ago Posts: 314 |

My goodness, you guys weren't joking about those ramps boards.... Should I even risk using it?

IMHO It looks messy but usable. Also my ramps and arduino came pre attached, im assuming they already put jumpers on it as there are none it the bag.

Those heat sinks don't conduct electricity do they? Otherwise I might short something because there huge! The ones that go on the stepper drives.

Edited 3 time(s). Last edit at 01/29/2016 05:37PM by UltiFix.

IMHO It looks messy but usable. Also my ramps and arduino came pre attached, im assuming they already put jumpers on it as there are none it the bag.

Those heat sinks don't conduct electricity do they? Otherwise I might short something because there huge! The ones that go on the stepper drives.

Edited 3 time(s). Last edit at 01/29/2016 05:37PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 05:32PM |

Registered: 8 years ago Posts: 25 |

Quote

Bert3D

Quote

john-i

Regarding the BLTouch, how long did it take to get it? My has been sitting here since the 20th?

2016-01-20 13:52 Departure from outward office of exchange, Dispatch number : 13

2016-01-20 13:43 INCHEON, Flight number : PO214

I tried looking up the tracking number on the USPS website and it recognized it as an item from Korea but it didn't have any information.

You can track Korean packages using [www.17track.net]

I've found the tracking stops when it leaves Korea. I saw no further updates after the flight. It appeared in my mailbox 10 days after the flight date. Tracking still shows the flight as the last activity.

Thanks Bert3D and DaveA, looks like I am within the window of receiving it.

New Wikia page: [folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 05:38PM |

Registered: 8 years ago Posts: 285 |

I wonder who is running FT, or at least their components department. From what I have been seeing on this thread recently, It seems the parts have gotten worse than how they were back when I bought my printer.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 05:52PM |

Registered: 8 years ago Posts: 314 |

In the guide it says to plug in the motor wires like this, [prntscr.com]

Thats backwards right? And It's so weird that the x carriage motor plug is backwards compared to the rest lol

Edited 1 time(s). Last edit at 01/29/2016 05:52PM by UltiFix.

Thats backwards right? And It's so weird that the x carriage motor plug is backwards compared to the rest lol

Edited 1 time(s). Last edit at 01/29/2016 05:52PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 05:54PM |

Registered: 8 years ago Posts: 314 |

I might shoot them an email and see what they say. the boards were packed awful, totally not acceptable... Tons of pins were bent...Quote

Mach

I wonder who is running FT, or at least their components department. From what I have been seeing on this thread recently, It seems the parts have gotten worse than how they were back when I bought my printer.

EDIT:

Done, lets see what they say.

Edited 1 time(s). Last edit at 01/29/2016 05:58PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 05:55PM |

Registered: 8 years ago Posts: 541 |

Quote

UltiFix

My goodness, you guys weren't joking about those ramps boards.... Should I even risk using it?

IMHO It looks messy but usable. Also my ramps and arduino came pre attached, im assuming they already put jumpers on it as there are none it the bag.

Those heat sinks don't conduct electricity do they? Otherwise I might short something because there huge! The ones that go on the stepper drives.

Pull out the stepper drivers and make sure all the jumpers are ACTUALLY jumping the pins. One of mine for the extruder was offset and I was getting really strange numbers when I calibrated my extruder. As a last resort, I checked under the driver and found the mistake. I worried about those heat sinks too so I made sure they were not touching the little pot that you adjust the current with. There is voltage on there.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 06:00PM |

Registered: 8 years ago Posts: 367 |

Those heatsinks have always bothered me too. At one point, I took them off and covered the whole of the top of the stepper driver with kapton tape except for a little hole over the chip where the heatsink sticks on.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

Sorry, only registered users may post in this forum.