Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 06:01PM |

Registered: 8 years ago Posts: 314 |

I already have it screwed in and wired, im a bit afraid to pull it apart... They are so crappyily made it might pull out the pins! One of the pin sets arent even soldered straight!Quote

tjnamtiw

Quote

UltiFix

My goodness, you guys weren't joking about those ramps boards.... Should I even risk using it?

IMHO It looks messy but usable. Also my ramps and arduino came pre attached, im assuming they already put jumpers on it as there are none it the bag.

Those heat sinks don't conduct electricity do they? Otherwise I might short something because there huge! The ones that go on the stepper drives.

Pull out the stepper drivers and make sure all the jumpers are ACTUALLY jumping the pins. One of mine for the extruder was offset and I was getting really strange numbers when I calibrated my extruder. As a last resort, I checked under the driver and found the mistake. I worried about those heat sinks too so I made sure they were not touching the little pot that you adjust the current with. There is voltage on there.

Is it worth double checking? I don't want to break the ramps. But if you think it's worth it I will definietely do it.

Edit:

Oops, I took off the arduino board then noticed that the jumpers are under to stepper drives.

Facepalm

Edited 1 time(s). Last edit at 01/29/2016 06:22PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 06:25PM |

Registered: 8 years ago Posts: 541 |

Quote

UltiFix

In the guide it says to plug in the motor wires like this, [prntscr.com]

Thats backwards right? And It's so weird that the x carriage motor plug is backwards compared to the rest lol

According to the instruction manual, The plug for the X motor should have the red wire to the left. Put it just like the picture shows. The instructions call this the 'Z' motor again. Also these things need to be done that are different from the instructions.>>

Change the following in configuration.h

#define INVERT_X_DIR true to #define INVERT_X_DIR false

#define X_HOME_DIR -1 to #define X_HOME_DIR 1

With the printer off PHYSICALLY move the x-axis stop plug to the left one set of pins (this makes it so it's the x max instead of x-min)

Now if you are using rep host, you need to go to printer settings > printer shape and change home X: from min to Max.

One big glaring mistake in the build manual is putting the X stop plug in the wrong place on the board. It should be right next to the Y stop plug, not two over as the manual says. Also, for the X motor plug wires, keep them as you see. It's not a mistake to have them reversed from the others. I DID end up reversing the extruder motor plug because it was pushing the filament out the top!

The new spring design extruder has a brass feed gear that, for me, was rubbing inside the motor housing and causing it to drag and skip steps

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 06:27PM |

Registered: 8 years ago Posts: 541 |

Quote

UltiFix

I already have it screwed in and wired, im a bit afraid to pull it apart... They are so crappyily made it might pull out the pins! One of the pin sets arent even soldered straight!Quote

tjnamtiw

Quote

UltiFix

My goodness, you guys weren't joking about those ramps boards.... Should I even risk using it?

IMHO It looks messy but usable. Also my ramps and arduino came pre attached, im assuming they already put jumpers on it as there are none it the bag.

Those heat sinks don't conduct electricity do they? Otherwise I might short something because there huge! The ones that go on the stepper drives.

Pull out the stepper drivers and make sure all the jumpers are ACTUALLY jumping the pins. One of mine for the extruder was offset and I was getting really strange numbers when I calibrated my extruder. As a last resort, I checked under the driver and found the mistake. I worried about those heat sinks too so I made sure they were not touching the little pot that you adjust the current with. There is voltage on there.

Is it worth double checking? I don't want to break the ramps. But if you think it's worth it I will definietely do it.

Edit:

Oops, I took off the arduino board then noticed that the jumpers are under to stepper drives.

Facepalm

When you calibrate your motor and print your test cube, you'll soon see if the jumpers are in the right positions.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 06:54PM |

Registered: 8 years ago Posts: 131 |

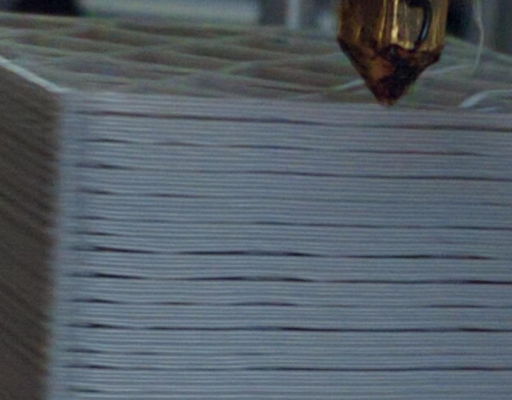

I'm having extrusion issues with both ABS and PLA. I've changed the extrusion from 100% all the way to 150% in 10% increment and see no real positive or negative changes. The infill looks better when around 120% but the pancaking layering I'm getting is persisting. What's really interesting is that it seems to only be affecting a layer every so often.

Edited 1 time(s). Last edit at 01/29/2016 06:54PM by marc2912.

Edited 1 time(s). Last edit at 01/29/2016 06:54PM by marc2912.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 06:56PM |

Registered: 8 years ago Posts: 314 |

Quote

tjnamtiw

Quote

UltiFix

In the guide it says to plug in the motor wires like this, [prntscr.com]

Thats backwards right? And It's so weird that the x carriage motor plug is backwards compared to the rest lol

According to the instruction manual, The plug for the X motor should have the red wire to the left. Put it just like the picture shows. The instructions call this the 'Z' motor again. Also these things need to be done that are different from the instructions.>>Got that

Change the following in configuration.h

#define INVERT_X_DIR true to #define INVERT_X_DIR false

#define X_HOME_DIR -1 to #define X_HOME_DIR 1

With the printer off PHYSICALLY move the x-axis stop plug to the left one set of pins (this makes it so it's the x max instead of x-min) Even if I keep the x endstop on the left?

Now if you are using rep host, you need to go to printer settings > printer shape and change home X: from min to Max. No idea what rep host is

One big glaring mistake in the build manual is putting the X stop plug in the wrong place on the board. It should be right next to the Y stop plug, not two over as the manual says. Also, for the X motor plug wires, keep them as you see. It's not a mistake to have them reversed from the others. I DID end up reversing the extruder motor plug because it was pushing the filament out the top! Even if I keep the x endstop on the left?

The new spring design extruder has a brass feed gear that, for me, was rubbing inside the motor housing and causing it to drag and skip steps Thanks

I marked up the quote

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 08:15PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 08:33PM |

Registered: 8 years ago Posts: 541 |

Quote

UltiFix

Quote

tjnamtiw

Quote

UltiFix

In the guide it says to plug in the motor wires like this, [prntscr.com]

Thats backwards right? And It's so weird that the x carriage motor plug is backwards compared to the rest lol

According to the instruction manual, The plug for the X motor should have the red wire to the left. Put it just like the picture shows. The instructions call this the 'Z' motor again. Also these things need to be done that are different from the instructions.>>Got that

Change the following in configuration.h

#define INVERT_X_DIR true to #define INVERT_X_DIR false

#define X_HOME_DIR -1 to #define X_HOME_DIR 1

With the printer off PHYSICALLY move the x-axis stop plug to the left one set of pins (this makes it so it's the x max instead of x-min) Even if I keep the x endstop on the left?

Now if you are using rep host, you need to go to printer settings > printer shape and change home X: from min to Max. No idea what rep host is

One big glaring mistake in the build manual is putting the X stop plug in the wrong place on the board. It should be right next to the Y stop plug, not two over as the manual says. Also, for the X motor plug wires, keep them as you see. It's not a mistake to have them reversed from the others. I DID end up reversing the extruder motor plug because it was pushing the filament out the top! Even if I keep the x endstop on the left?

The new spring design extruder has a brass feed gear that, for me, was rubbing inside the motor housing and causing it to drag and skip steps Thanks

I marked up the quote

You say "even if I keep the x endstop on the left' ...... That's not what the manual told you to do so all bets are off as to the instructions I gave you.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 08:45PM |

Registered: 8 years ago Posts: 541 |

Two steps forward and one back on the BLTOUCH saga here.

I found a 5.1 volt/ 2.1 amp wall wart for a DSL modem and checked that it actually puts out 5.2 volts. I wired a plug onto the end to match the servo pin setup. (thank heavens I'm an RC pilot with a lot of servo extensions and old servos). I removed the jumper that normally puts 5 volts on the servo bus and plugged the new powered plug into one of the spare servo spots being sure the ground went to ground and the 5 volt went to the 5 volt pin. Signal pin is blank on the new plug. This powered the BLTOUCH and it tested and dropped its pin. I turned on the printer and hit 'home' and it went through its routine of zeroing x and y and then went to the center while rising and then lowered until the BLT pin lit, it moved up and then more slowly back down until it touched again. Then moved up to a waiting position. At that point it started flashing rather than suck the pin into the up position. Not enough electromagnetics to raise it.

I did the routine again and at the end, I helped the pin rise to the up position and it stayed there with the light on. I then went to the LCD and selected Level Bed. It went through its routine and checked 9 spots (I selected 3 grid) but at the end, I got the flashing light again.

I spent a LOT of time trying to find the sweet spot where the pin would rise on its own but to no avail. I'll try again tomorrow. If I stray too far from the original spot, I get immediately a flashing red light when I turn on the printer. The initialization is done before I turn on the printer and if it's close, I get no red light flashing and the home routine works.

One question >> when I removed the jumper that was supplying 5 volts from the Arduino to the servo rail, should I have put it back in its original position between V1.4 and 5V?I was afraid that it might back feed into whatever v1.4 is. Dumb question - it is the board version so I assume that is a blank pin to park the jumper on.

I did check and found out the IC on the Arduino that supplies 5 volts is only rated for 1 amp max. That needs to be upgraded for sure.

Edited 2 time(s). Last edit at 01/29/2016 09:07PM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

I found a 5.1 volt/ 2.1 amp wall wart for a DSL modem and checked that it actually puts out 5.2 volts. I wired a plug onto the end to match the servo pin setup. (thank heavens I'm an RC pilot with a lot of servo extensions and old servos). I removed the jumper that normally puts 5 volts on the servo bus and plugged the new powered plug into one of the spare servo spots being sure the ground went to ground and the 5 volt went to the 5 volt pin. Signal pin is blank on the new plug. This powered the BLTOUCH and it tested and dropped its pin. I turned on the printer and hit 'home' and it went through its routine of zeroing x and y and then went to the center while rising and then lowered until the BLT pin lit, it moved up and then more slowly back down until it touched again. Then moved up to a waiting position. At that point it started flashing rather than suck the pin into the up position. Not enough electromagnetics to raise it.

I did the routine again and at the end, I helped the pin rise to the up position and it stayed there with the light on. I then went to the LCD and selected Level Bed. It went through its routine and checked 9 spots (I selected 3 grid) but at the end, I got the flashing light again.

I spent a LOT of time trying to find the sweet spot where the pin would rise on its own but to no avail. I'll try again tomorrow. If I stray too far from the original spot, I get immediately a flashing red light when I turn on the printer. The initialization is done before I turn on the printer and if it's close, I get no red light flashing and the home routine works.

One question >> when I removed the jumper that was supplying 5 volts from the Arduino to the servo rail, should I have put it back in its original position between V1.4 and 5V?

I did check and found out the IC on the Arduino that supplies 5 volts is only rated for 1 amp max. That needs to be upgraded for sure.

Edited 2 time(s). Last edit at 01/29/2016 09:07PM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 09:11PM |

Registered: 8 years ago Posts: 314 |

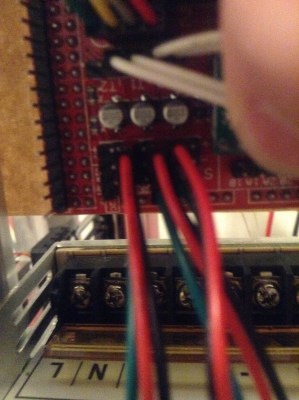

Oops, may bad. Sorry. My endstop is on the RIGHT, I will try and follow your instructions. Here is a pic of how I have my endstops wired, that is correct right?Quote

tjnamtiw

Quote

UltiFix

Quote

tjnamtiw

Quote

UltiFix

In the guide it says to plug in the motor wires like this, [prntscr.com]

Thats backwards right? And It's so weird that the x carriage motor plug is backwards compared to the rest lol

According to the instruction manual, The plug for the X motor should have the red wire to the left. Put it just like the picture shows. The instructions call this the 'Z' motor again. Also these things need to be done that are different from the instructions.>>Got that

Change the following in configuration.h

#define INVERT_X_DIR true to #define INVERT_X_DIR false

#define X_HOME_DIR -1 to #define X_HOME_DIR 1

With the printer off PHYSICALLY move the x-axis stop plug to the left one set of pins (this makes it so it's the x max instead of x-min) Even if I keep the x endstop on the left?

Now if you are using rep host, you need to go to printer settings > printer shape and change home X: from min to Max. No idea what rep host is

One big glaring mistake in the build manual is putting the X stop plug in the wrong place on the board. It should be right next to the Y stop plug, not two over as the manual says. Also, for the X motor plug wires, keep them as you see. It's not a mistake to have them reversed from the others. I DID end up reversing the extruder motor plug because it was pushing the filament out the top! Even if I keep the x endstop on the left?

The new spring design extruder has a brass feed gear that, for me, was rubbing inside the motor housing and causing it to drag and skip steps Thanks

I marked up the quote

You say "even if I keep the x endstop on the left' ...... That's not what the manual told you to do so all bets are off as to the instructions I gave you.

Thanks for the help!

Edited 1 time(s). Last edit at 01/29/2016 09:11PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 09:44PM |

Registered: 8 years ago Posts: 285 |

Quote

marc2912

I'm having extrusion issues with both ABS and PLA. I've changed the extrusion from 100% all the way to 150% in 10% increment and see no real positive or negative changes. The infill looks better when around 120% but the pancaking layering I'm getting is persisting. What's really interesting is that it seems to only be affecting a layer every so often.

Are your extruder temps staying relatively stable, and did you make sure you were not skipping steps.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 09:58PM |

Registered: 8 years ago Posts: 131 |

Quote

Mach

Quote

marc2912

I'm having extrusion issues with both ABS and PLA. I've changed the extrusion from 100% all the way to 150% in 10% increment and see no real positive or negative changes. The infill looks better when around 120% but the pancaking layering I'm getting is persisting. What's really interesting is that it seems to only be affecting a layer every so often.

Are your extruder temps staying relatively stable, and did you make sure you were not skipping steps.

Temp is stable on both filament types (+/- 3C) and I don't see how it would be skipping steps on the Z axis since it's threaded rods on both sides, I reprinted another, same thing and Z is moving properly.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 10:51PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 29, 2016 11:59PM |

Registered: 8 years ago Posts: 314 |

Awesome! X_HOME_DIR -1 did need to be changed to 1, while INVERT_X_DIR false was already falseQuote

tjnamtiw

Quote

UltiFix

In the guide it says to plug in the motor wires like this, [prntscr.com]

Thats backwards right? And It's so weird that the x carriage motor plug is backwards compared to the rest lol

According to the instruction manual, The plug for the X motor should have the red wire to the left. Put it just like the picture shows. The instructions call this the 'Z' motor again. Also these things need to be done that are different from the instructions.>>

Change the following in configuration.h

#define INVERT_X_DIR true to #define INVERT_X_DIR false

#define X_HOME_DIR -1 to #define X_HOME_DIR 1

With the printer off PHYSICALLY move the x-axis stop plug to the left one set of pins (this makes it so it's the x max instead of x-min)

Now if you are using rep host, you need to go to printer settings > printer shape and change home X: from min to Max.

One big glaring mistake in the build manual is putting the X stop plug in the wrong place on the board. It should be right next to the Y stop plug, not two over as the manual says. Also, for the X motor plug wires, keep them as you see. It's not a mistake to have them reversed from the others. I DID end up reversing the extruder motor plug because it was pushing the filament out the top!

The new spring design extruder has a brass feed gear that, for me, was rubbing inside the motor housing and causing it to drag and skip steps

Thanks for the heads up! And im going to be using rep host so I will need to change that to!

Why do I need to change X_HOME_DIR -1 to 1?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 12:33AM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 02:24AM |

Registered: 8 years ago Posts: 25 |

Quote

msaeger

Where are you guys ordering the BLtouch sensors? I can't figure out how to order off the indegogo page. I see them on ebay is that the only place to order from?

Here is the link to the instructions..

[www.indiegogo.com]

I sent them $33 and then sent them an email with my information as requested in update

14 days ago

Hello everyone who are interested in BLTouch!

Thank you for all of your support.

If you want to buy some BLTouch, you can order through PayPal.

Please send us an e-mail including quantity, shipping type, your name, address, zip code, and phone number.

BLTouch Price : $28 / ea

Shipping Price : Standard Int'l Shipping - $5 (5 - 20 days)

or Expedited Int'l Shipping - $28 (3-6 days)

PayPal Account & E-mail address : antclabs@gmail.com

Thank you again and happy new year

BLTouch Team (ANTCLABS)

PS. Please send us an e-mail who want to know the Bulk price list.

.. hope that helps

New Wikia page: [folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 02:27AM |

Registered: 8 years ago Posts: 25 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 02:28AM |

Registered: 8 years ago Posts: 25 |

Quote

marc2912

Quote

Mach

Quote

marc2912

I'm having extrusion issues with both ABS and PLA. I've changed the extrusion from 100% all the way to 150% in 10% increment and see no real positive or negative changes. The infill looks better when around 120% but the pancaking layering I'm getting is persisting. What's really interesting is that it seems to only be affecting a layer every so often.

Are your extruder temps staying relatively stable, and did you make sure you were not skipping steps.

Temp is stable on both filament types (+/- 3C) and I don't see how it would be skipping steps on the Z axis since it's threaded rods on both sides, I reprinted another, same thing and Z is moving properly.

I was having all kinds of problems like that in the beginning.. then I realized that my slicer settings were wrong even though I thought I imported FolgerTech's settings. So I suggest you go through your settings especially your extruder setting in Printer Settings.. hope that helps

New Wikia page: [folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 02:55AM |

Registered: 8 years ago Posts: 314 |

In the Slicer im just making my tabs look the the ones in the setup guide, is that correct?

Would your reccomend changing the temps to 175c and 65 c? Ill be printing pla. Any other must do tweaks right off the bat? Tomarrow im planning on calibrating it.

Edited 1 time(s). Last edit at 01/30/2016 03:05AM by UltiFix.

Would your reccomend changing the temps to 175c and 65 c? Ill be printing pla. Any other must do tweaks right off the bat? Tomarrow im planning on calibrating it.

Edited 1 time(s). Last edit at 01/30/2016 03:05AM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 03:07AM |

Registered: 8 years ago Posts: 276 |

Quote

UltiFix

In the Slicer im just making my tabs look the the ones in the setup guide, is that correct?

Would your reccomend changing the temps to 175c and 65 c? Ill be printing pla. Any other must do tweaks right off the bat? Tomarrow im planning on calibrating it.

175 is a good temp for PLA (from what I can remember). You don't need to heat the bed for PLA, but use blue painters tape. Maybe slow down your printing speed too. Also, you might be under-extruding, so try kicking it up 5-10%.

Edited 2 time(s). Last edit at 01/30/2016 03:09AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 03:16AM |

Registered: 8 years ago Posts: 38 |

It seems like this is the BLTouch channel lately.

I put the VCC/5V jumper on my RAMPS and the BLTouch is now working...mostly. For some reason, it doesn't always lower the pin when I start a G28. If I manually hit the individual axis home buttons in Repetier Host then move the probe toward the middle of the bed, the probe is sometimes up and sometimes down. When it's up, it doesn't seem to respond to manual commands to lower it.

I haven't been able to figure out why it's not always lowering the pin. Any ideas?

Thanks!

EDIT: Also, sometimes when the pin is down at the start of a z homing, the pin goes up by itself without actually touching anything. Hmm.

Edited 1 time(s). Last edit at 01/30/2016 03:22AM by GrouchoDuke.

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

I put the VCC/5V jumper on my RAMPS and the BLTouch is now working...mostly. For some reason, it doesn't always lower the pin when I start a G28. If I manually hit the individual axis home buttons in Repetier Host then move the probe toward the middle of the bed, the probe is sometimes up and sometimes down. When it's up, it doesn't seem to respond to manual commands to lower it.

I haven't been able to figure out why it's not always lowering the pin. Any ideas?

Thanks!

EDIT: Also, sometimes when the pin is down at the start of a z homing, the pin goes up by itself without actually touching anything. Hmm.

Edited 1 time(s). Last edit at 01/30/2016 03:22AM by GrouchoDuke.

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 03:31AM |

Registered: 8 years ago Posts: 22 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 08:13AM |

Registered: 8 years ago Posts: 268 |

Quote

thebabymaker

So, the nut that goes on the threaded rod keeps falling out of one the 3d printed pieces on the x carriage when z is homing.. anyone else have this issue before? If so, what did you find was the best solution? thinking about gluing it at this point.. or maybe a get slightly larger nut?

Wrap a layer of the 1/4" Kapton tape around the outside...

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 08:42AM |

Registered: 8 years ago Posts: 19 |

Quote

thebabymaker

So, the nut that goes on the threaded rod keeps falling out of one the 3d printed pieces on the x carriage when z is homing.. anyone else have this issue before? If so, what did you find was the best solution? thinking about gluing it at this point.. or maybe a get slightly larger nut?

Quote

sonnylowe

Quote

thebabymaker

So, the nut that goes on the threaded rod keeps falling out of one the 3d printed pieces on the x carriage when z is homing.. anyone else have this issue before? If so, what did you find was the best solution? thinking about gluing it at this point.. or maybe a get slightly larger nut?

Wrap a layer of the 1/4" Kapton tape around the outside...

Or, true up your printer and print my fix for this here...[www.thingiverse.com] works great!

Edited 1 time(s). Last edit at 01/30/2016 08:42AM by bmays.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 11:02AM |

Registered: 8 years ago Posts: 541 |

Quote

bmays

Quote

thebabymaker

So, the nut that goes on the threaded rod keeps falling out of one the 3d printed pieces on the x carriage when z is homing.. anyone else have this issue before? If so, what did you find was the best solution? thinking about gluing it at this point.. or maybe a get slightly larger nut?

Quote

sonnylowe

Quote

thebabymaker

So, the nut that goes on the threaded rod keeps falling out of one the 3d printed pieces on the x carriage when z is homing.. anyone else have this issue before? If so, what did you find was the best solution? thinking about gluing it at this point.. or maybe a get slightly larger nut?

Wrap a layer of the 1/4" Kapton tape around the outside...

Or, true up your printer and print my fix for this here...[www.thingiverse.com] works great!

Yes, if it's being driven out of its hole, that probably means that you don't have the X carriage level and your bearings are binding. Measure from the top of the upper rod to the table on each side. They must be identical. The fact that the nuts can come out is actually a safety feature (probably unintended) to protect the printer if it bottoms out.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 11:14AM |

Registered: 8 years ago Posts: 430 |

Quote

john-i

Quote

msaeger

Where are you guys ordering the BLtouch sensors? I can't figure out how to order off the indegogo page. I see them on ebay is that the only place to order from?

Here is the link to the instructions..

[www.indiegogo.com]

I sent them $33 and then sent them an email with my information as requested in update

14 days ago

Hello everyone who are interested in BLTouch!

Thank you for all of your support.

If you want to buy some BLTouch, you can order through PayPal.

Please send us an e-mail including quantity, shipping type, your name, address, zip code, and phone number.

BLTouch Price : $28 / ea

Shipping Price : Standard Int'l Shipping - $5 (5 - 20 days)

or Expedited Int'l Shipping - $28 (3-6 days)

PayPal Account & E-mail address : antclabs@gmail.com

Thank you again and happy new year

BLTouch Team (ANTCLABS)

PS. Please send us an e-mail who want to know the Bulk price list.

.. hope that helps

Thanks! Is it the same guy selling it on ebay?

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 12:21PM |

Registered: 8 years ago Posts: 38 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 12:24PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 01:46PM |

Registered: 8 years ago Posts: 314 |

So im going to be printing a pla test sphere on glass, so im going to set my default hotend temp to 175 c and my default bed temp to 65c, is that right?

Don't currently have the printer plugged in but this is where im supposed to change these settings for each print right?

[prntscr.com]

Don't currently have the printer plugged in but this is where im supposed to change these settings for each print right?

[prntscr.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 01:47PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Does everything look right? I have not calibrated yet so my endstops are not in the final position.

[imgur.com]

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 03:18PM |

Registered: 8 years ago Posts: 541 |

Quote

GrouchoDuke

It seems like this is the BLTouch channel lately.

I put the VCC/5V jumper on my RAMPS and the BLTouch is now working...mostly. For some reason, it doesn't always lower the pin when I start a G28. If I manually hit the individual axis home buttons in Repetier Host then move the probe toward the middle of the bed, the probe is sometimes up and sometimes down. When it's up, it doesn't seem to respond to manual commands to lower it.

I haven't been able to figure out why it's not always lowering the pin. Any ideas?

Thanks!

EDIT: Also, sometimes when the pin is down at the start of a z homing, the pin goes up by itself without actually touching anything. Hmm.

You mentioned G28, which means you are hooked up to a laptop. Have you tried it without a laptop? Turn it off and back on. What is the BLTOUCH doing?

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

Sorry, only registered users may post in this forum.