Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 03:20PM |

Registered: 8 years ago Posts: 541 |

I just posted this comment over on the new BLTOUCH PAGE.

"I also am having problems with BLTOUCH using FolgerTech 2020 with Ramps 1.4 and Marlin 1.1.0 RC3. WITH a laptop hooked up to the Ramps, I am successful in modifying firmware so that BLTOUCH triggers, goes to center and homes correctly first fast and then slowly. It also performs the bed level function correctly. HOWEVER, if I disconnect the USB/laptop, the BLTOUCH starts flashing and the Arduino resets if I try to home again. If I shut off the printer and turn it back on, the BLTOUCH just flashes trying to self test but can't and then flashes the error signal.

I thought it was a power problem on the Ramps so I removed the jumper from VCC to +5V that supplies the servos and attached an external 5.2 volt 2.1 amp power supply from an internet modem. That should be plenty of power since the Arduino only supplies 1 amp to the Ramps. When I attach the external supply, BLTOUCH lights red and flashes as it tries to self test but the pin does not move and then it goes into alarm mode. I measure 4.94 volts on the servo pins. As this point, I am about ready to give up! "

[plus.google.com]

This thing and Ramps boards are like oil and water IMHO. Going back to manual leveling for now. I've had enough!

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

"I also am having problems with BLTOUCH using FolgerTech 2020 with Ramps 1.4 and Marlin 1.1.0 RC3. WITH a laptop hooked up to the Ramps, I am successful in modifying firmware so that BLTOUCH triggers, goes to center and homes correctly first fast and then slowly. It also performs the bed level function correctly. HOWEVER, if I disconnect the USB/laptop, the BLTOUCH starts flashing and the Arduino resets if I try to home again. If I shut off the printer and turn it back on, the BLTOUCH just flashes trying to self test but can't and then flashes the error signal.

I thought it was a power problem on the Ramps so I removed the jumper from VCC to +5V that supplies the servos and attached an external 5.2 volt 2.1 amp power supply from an internet modem. That should be plenty of power since the Arduino only supplies 1 amp to the Ramps. When I attach the external supply, BLTOUCH lights red and flashes as it tries to self test but the pin does not move and then it goes into alarm mode. I measure 4.94 volts on the servo pins. As this point, I am about ready to give up! "

[plus.google.com]

This thing and Ramps boards are like oil and water IMHO. Going back to manual leveling for now. I've had enough!

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 03:33PM |

Registered: 8 years ago Posts: 541 |

Quote

marc2912

Quote

Mach

Quote

marc2912

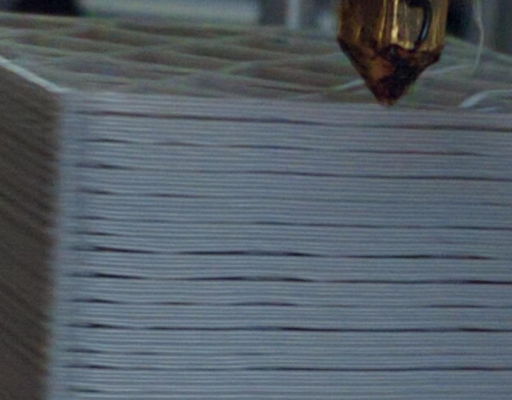

I'm having extrusion issues with both ABS and PLA. I've changed the extrusion from 100% all the way to 150% in 10% increment and see no real positive or negative changes. The infill looks better when around 120% but the pancaking layering I'm getting is persisting. What's really interesting is that it seems to only be affecting a layer every so often.

Are your extruder temps staying relatively stable, and did you make sure you were not skipping steps.

Temp is stable on both filament types (+/- 3C) and I don't see how it would be skipping steps on the Z axis since it's threaded rods on both sides, I reprinted another, same thing and Z is moving properly.

Have you calibrated your extruder and made sure it uses 100mm of filament when you tell it to?

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 03:34PM |

Registered: 8 years ago Posts: 131 |

Quote

tjnamtiw

Quote

marc2912

Quote

Mach

Quote

marc2912

I'm having extrusion issues with both ABS and PLA. I've changed the extrusion from 100% all the way to 150% in 10% increment and see no real positive or negative changes. The infill looks better when around 120% but the pancaking layering I'm getting is persisting. What's really interesting is that it seems to only be affecting a layer every so often.

Are your extruder temps staying relatively stable, and did you make sure you were not skipping steps.

Temp is stable on both filament types (+/- 3C) and I don't see how it would be skipping steps on the Z axis since it's threaded rods on both sides, I reprinted another, same thing and Z is moving properly.

Have you calibrated your extruder and made sure it uses 100mm of filament when you tell it to?

yes....

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 03:35PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 04:04PM |

Registered: 8 years ago Posts: 314 |

[prntscr.com]

I have a handheld Ir temp reader and the hotend isn't even 100c

I didn't know I need to push the spring down. Maybe somebody else will learn from my mistake LOL

Edited 2 time(s). Last edit at 01/30/2016 04:17PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 04:19PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

I have my hotend at 235c and I can't get the pla to melt and feed it in manually. Ideas?

[prntscr.com]

I have a handheld Ir temp reader and the hotend isn't even 100c

Do you have the proper thermistor selected in marlin? The fact that the printer thinks that it is at a higher temp than it actually is makes me think that either the proper thermistor is not selected, or your thermistor is faulty.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 04:20PM |

Registered: 8 years ago Posts: 38 |

Quote

tjnamtiw

You mentioned G28, which means you are hooked up to a laptop. Have you tried it without a laptop? Turn it off and back on. What is the BLTOUCH doing?

It looks like it does a normal startup cycle. It does three up/down cycles on the pin. I think the startup has always been normal (after I added the Vcc/5v jumper to my RAMPS, that is).

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 04:37PM |

Registered: 8 years ago Posts: 541 |

Quote

GrouchoDuke

Quote

tjnamtiw

You mentioned G28, which means you are hooked up to a laptop. Have you tried it without a laptop? Turn it off and back on. What is the BLTOUCH doing?

It looks like it does a normal startup cycle. It does three up/down cycles on the pin. I think the startup has always been normal (after I added the Vcc/5v jumper to my RAMPS, that is).

That's interesting. I think I got a dud! If I unplug it and plug it back in while the printers turned on, it actually reboots the Marlin. It must be drawing down the voltage that much. Maybe it's time to pull the boards off and look at solder joints, which I never did.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 04:39PM |

Registered: 8 years ago Posts: 541 |

Quote

UltiFix

I have my hotend at 235c and I can't get the pla to melt and feed it in manually. Ideas?

[prntscr.com]

I have a handheld Ir temp reader and the hotend isn't even 100c

I didn't know I need to push the spring down. Maybe somebody else will learn from my mistake LOL

IR thermometers are notoriously crap, especially reading shiny, silver surfaces. Hold a piece of filament against the hotend and see if it melts.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 05:22PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 05:24PM |

Registered: 8 years ago Posts: 13 |

I'm at step 24 of the instructions where you cut the end of the AC power cord and wire it into the power supply. The colors of the three wires are brown, blue, and greenish blue (teal?) and I'm not sure which wire is the ground. I have a multimeter (see image Multimeter_Wire) but I'm not sure how to test to see which wire is which. Any advice? Does anyone else have the same color wires? Thanks.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 06:09PM |

Registered: 8 years ago Posts: 314 |

I had somebody help me check my ac cord with a multimeter and this is what mine came out as. I would reccomend checking yours not just copying mine as it might be differentQuote

chking

I'm at step 24 of the instructions where you cut the end of the AC power cord and wire it into the power supply. The colors of the three wires are brown, blue, and greenish blue (teal?) and I'm not sure which wire is the ground. I have a multimeter (see image Multimeter_Wire) but I'm not sure how to test to see which wire is which. Any advice? Does anyone else have the same color wires? Thanks.

Take a look at both of these pics.

[prntscr.com]

[prntscr.com]

Curentlly on my second print and it hasn't exploded

Sadly I had to scrap my first print, one of my belt's was loose and it might have skipped a few bits and it got it messed up. I added a belt tensioner and the second print is looking way way better!

Edited 1 time(s). Last edit at 01/30/2016 06:10PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 06:27PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 06:35PM |

Registered: 8 years ago Posts: 367 |

Quote

UltiFix

Im amazed at how hard my PLA sticks to the glass heated bed, it's not wanting to come off

If it's stuck really hard, try warming up the bed with the manual controls in Repetier to around 50C.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 06:36PM |

Registered: 8 years ago Posts: 314 |

I let it cool down and ripped it off, I thought letting it be cool would help but I guess not.Quote

animoose

Quote

UltiFix

Im amazed at how hard my PLA sticks to the glass heated bed, it's not wanting to come off

If it's stuck really hard, try warming up the bed with the manual controls in Repetier to around 50C.

Thanks for letting me now!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 06:38PM |

Registered: 8 years ago Posts: 314 |

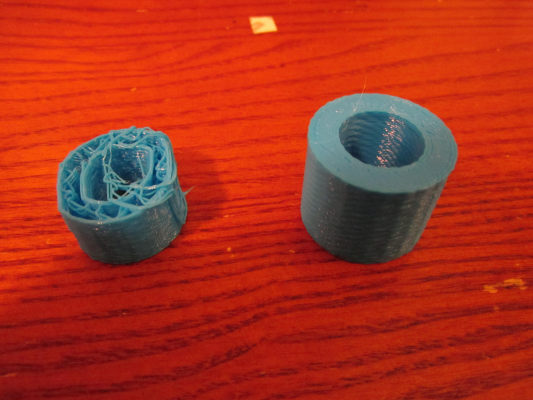

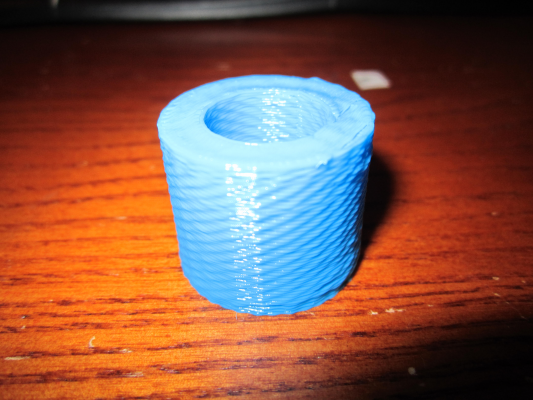

First print, on the left, x belt was loose and it got goofed up so I cancelled then ripped it off with pliers... Added a belt/sping tensioner to the belt and redid the print (On the right)

I couldn't be happier, for my second print that cylinder is amazing!

Would you guys consider that cylinder acceptable?

Edited 1 time(s). Last edit at 01/30/2016 06:39PM by UltiFix.

I couldn't be happier, for my second print that cylinder is amazing!

Would you guys consider that cylinder acceptable?

Edited 1 time(s). Last edit at 01/30/2016 06:39PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 06:38PM |

Registered: 8 years ago Posts: 367 |

Quote

UltiFix

I let it cool down and ripped it off, I thought letting it be cool would help but I guess not.Quote

animoose

Quote

UltiFix

Im amazed at how hard my PLA sticks to the glass heated bed, it's not wanting to come off

If it's stuck really hard, try warming up the bed with the manual controls in Repetier to around 50C.

Thanks for letting me now!

One thing to be aware of when doing this is that the PLA will be slightly soft, so if you have fine details (like a small gear tooth) you can distort the piece. So use this technique with caution.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 06:46PM |

Registered: 8 years ago Posts: 314 |

Thanks!Quote

animoose

Quote

UltiFix

I let it cool down and ripped it off, I thought letting it be cool would help but I guess not.Quote

animoose

Quote

UltiFix

Im amazed at how hard my PLA sticks to the glass heated bed, it's not wanting to come off

If it's stuck really hard, try warming up the bed with the manual controls in Repetier to around 50C.

Thanks for letting me now!

One thing to be aware of when doing this is that the PLA will be slightly soft, so if you have fine details (like a small gear tooth) you can distort the piece. So use this technique with caution.

What do you think of my cylinder? (2 posts up)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 07:23PM |

Registered: 8 years ago Posts: 285 |

Quote

chking

I'm at step 24 of the instructions where you cut the end of the AC power cord and wire it into the power supply. The colors of the three wires are brown, blue, and greenish blue (teal?) and I'm not sure which wire is the ground. I have a multimeter (see image Multimeter_Wire) but I'm not sure how to test to see which wire is which. Any advice? Does anyone else have the same color wires? Thanks.

Turn the selector switch on the multimeter to the setting that reads resistance. You may have to look at your instruction manual to find where that is on your's, but it usually is indicated by a horseshoe shaped symbol. Touch one lead, any one, from the dmm to one of the three wires from the cord. Then touch the other lead from the multimeter to each of the three prongs on the plug. Once you touch the prong that is linked to the wire that your other lead is connected to, the meter will go from showing a -1 to some other number; this signifies that you have continuity. Place some kind of marker like a piece of tape or something on that prong and its linked wire. Do this same procedure for the other two wires and their prong, and remember to mark each pair with different indicators. The left prong is neutral, the right prong is hot, and the bottom prong is ground.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 09:54PM |

Registered: 8 years ago Posts: 22 |

Do you all use octoprint for this printer? I plugged in my printer to my raspberry pi and the LCD on the printer went white, then smoke started coming out of the MEGA and now its dead. I took the mega off and noticed a bent pin on the board, do you think thats what caused the short?

Thanks everyone for all the help BTW - this forum has been so helpful in setting up my printer.

Another question, how long does the bed take to heat normally? I had it going for an hour and it was just at 100C - i'm in a cold room with a glass bed.

Thanks everyone for all the help BTW - this forum has been so helpful in setting up my printer.

Another question, how long does the bed take to heat normally? I had it going for an hour and it was just at 100C - i'm in a cold room with a glass bed.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 10:08PM |

Registered: 8 years ago Posts: 367 |

Quote

thebabymaker

Do you all use octoprint for this printer? I plugged in my printer to my raspberry pi and the LCD on the printer went white, then smoke started coming out of the MEGA and now its dead. I took the mega off and noticed a bent pin on the board, do you think thats what caused the short?

Thanks everyone for all the help BTW - this forum has been so helpful in setting up my printer.

Another question, how long does the bed take to heat normally? I had it going for an hour and it was just at 100C - i'm in a cold room with a glass bed.

That seems like a long time. Some options: find a way of enclosing your printer; run PID autotune (do a search for info); put a paperback book on the bed while it is heating (note: remove the book before printing starts).

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 10:50PM |

Registered: 8 years ago Posts: 4 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 10:55PM |

Registered: 8 years ago Posts: 131 |

Quote

mrw0609

Hi everyone. So I am in the process of assembling printer at the moment. After I put on the belt for the x axis, I ran the bearings along the rods to test the belt. When I did this the stepper motor locked up and I can not the shaft to rotate anymore. Can anyone help with this?

Is your stepper powered? A stepper motor uses power to keep its position which in turn creates a strong lock. If it's not powered if should rotate smoothly. To note is that when you move the carriage back and forth your creating a positive voltage that goes backwards through the circuit, it's always best to do so slowly or unplug the stepper as it could damage your electronics.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 10:57PM |

Registered: 8 years ago Posts: 4 |

Quote

marc2912

Quote

mrw0609

Hi everyone. So I am in the process of assembling printer at the moment. After I put on the belt for the x axis, I ran the bearings along the rods to test the belt. When I did this the stepper motor locked up and I can not the shaft to rotate anymore. Can anyone help with this?

Is your stepper powered? A stepper motor uses power to keep its position which in turn creates a strong lock. If it's not powered if should rotate smoothly. To note is that when you move the carriage back and forth your creating a positive voltage that goes backwards through the circuit, it's always best to do so slowly or unplug the stepper as it could damage your electronics.

The stepper is not powered.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 30, 2016 11:15PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 01:21AM |

Registered: 10 years ago Posts: 477 |

Quote

UltiFix

Im wondering how much you guys like autolevel? And whats the easiest way to do it?

With my Prusa i3's I've never needed it. Honestly I think it shouldn't be needed if you have a properly built chassis and a flat heated bed.

Why would you want the z-axis motors moving while printing a layer? Only to compensate for an uneven build.

With a delta style printer I can see the use, but for an i3 style it shouldn't be needed.

I only check the tramming of my printer bed if I have physically moved the printer and I rarely need check the z-height after I change filament.

Steve

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 02:01AM |

Registered: 8 years ago Posts: 314 |

Nevermind, the extruder will end up at the highest point of the print, duh

On a side note, would you guys let your printer run overnight?

Edited 2 time(s). Last edit at 01/31/2016 02:14AM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 02:28AM |

Registered: 8 years ago Posts: 314 |

Yea, if your not moving your printer and you have a good level frame it should in theory be fine... Wouldn't using auto bed leveling, AKA the z axis moving up and down while printing lower the overall print quality?Quote

SteveRoy

Quote

UltiFix

Im wondering how much you guys like autolevel? And whats the easiest way to do it?

With my Prusa i3's I've never needed it. Honestly I think it shouldn't be needed if you have a properly built chassis and a flat heated bed.

Why would you want the z-axis motors moving while printing a layer? Only to compensate for an uneven build.

With a delta style printer I can see the use, but for an i3 style it shouldn't be needed.

I only check the tramming of my printer bed if I have physically moved the printer and I rarely need check the z-height after I change filament.

Steve

So what we call bed leveling isn't really. It's just a trick that may help or make it worse? True bed leveling would be if you had a bunch of stepper motors actually controlling the bed height... Which does not sound worth it at all

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 03:29AM |

Registered: 8 years ago Posts: 92 |

Quote

UltiFix

I want to print multiple objects at once, some taller than others.. will the extruder "forget" one of the objects are there and hit it? Like at the end when it resets to default position?

Nevermind, the extruder will end up at the highest point of the print, duh

On a side note, would you guys let your printer run overnight?

I'm letting mine run right now. I'm about to go to bed, and it has another 7 hours to go on this print. The first time I did an all nighter, I woke up several times and each time went to check progress. I've had such great adhesion that I don't worry much any more. BUT I think it wise to have Thermal Runaway protection enabled. No sense tempting fate.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 04:49AM |

Registered: 8 years ago Posts: 38 |

My BLTouch is finally working. Short story is that I had to power it with something other than the RAMPS board's Vcc pin.

I've been chasing my tail on this for a while. At first, I didn't know that the RAMPS board requires a jumper between the Vcc & 5V pins to provide power to the positive voltage servo pins (near the reset button by the servo connectors). After figuring that out I still couldn't get it to work. My BLTouch's pin would randomly not drop when doing Z homing. I later noticed that the BLTouch would redo its startup checks (the 3 cycles of the pin thing it does) sometimes when multiple axis motors were moving quickly.

So, I wired up a 5V/3A regulator and powered it from the main power supply. I used a servo connector to connect the 5V output of the regulator to the 5V pin on the RAMPS. After that, the BLTouch has been running perfectly. G28 & G29 commands now work and the results from G29 seems to be pretty consistent. I added G29 to my custom G code list in the slicer and also added a z axis move after the print's over to make sure the BLTouch pin clears (because it appears to drop the pin when a print is over for some reason). I adjusted the Z offset (which took a few test prints to get right) and now the printer seems to be working well.

It's time to print some stuff!

Edited 1 time(s). Last edit at 01/31/2016 04:52AM by GrouchoDuke.

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

I've been chasing my tail on this for a while. At first, I didn't know that the RAMPS board requires a jumper between the Vcc & 5V pins to provide power to the positive voltage servo pins (near the reset button by the servo connectors). After figuring that out I still couldn't get it to work. My BLTouch's pin would randomly not drop when doing Z homing. I later noticed that the BLTouch would redo its startup checks (the 3 cycles of the pin thing it does) sometimes when multiple axis motors were moving quickly.

So, I wired up a 5V/3A regulator and powered it from the main power supply. I used a servo connector to connect the 5V output of the regulator to the 5V pin on the RAMPS. After that, the BLTouch has been running perfectly. G28 & G29 commands now work and the results from G29 seems to be pretty consistent. I added G29 to my custom G code list in the slicer and also added a z axis move after the print's over to make sure the BLTouch pin clears (because it appears to drop the pin when a print is over for some reason). I adjusted the Z offset (which took a few test prints to get right) and now the printer seems to be working well.

It's time to print some stuff!

Edited 1 time(s). Last edit at 01/31/2016 04:52AM by GrouchoDuke.

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

Sorry, only registered users may post in this forum.