Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 09:24AM |

Registered: 8 years ago Posts: 131 |

Quote

GrouchoDuke

My BLTouch is finally working. Short story is that I had to power it with something other than the RAMPS board's Vcc pin.

I've been chasing my tail on this for a while. At first, I didn't know that the RAMPS board requires a jumper between the Vcc & 5V pins to provide power to the positive voltage servo pins (near the reset button by the servo connectors). After figuring that out I still couldn't get it to work. My BLTouch's pin would randomly not drop when doing Z homing. I later noticed that the BLTouch would redo its startup checks (the 3 cycles of the pin thing it does) sometimes when multiple axis motors were moving quickly.

So, I wired up a 5V/3A regulator and powered it from the main power supply. I used a servo connector to connect the 5V output of the regulator to the 5V pin on the RAMPS. After that, the BLTouch has been running perfectly. G28 & G29 commands now work and the results from G29 seems to be pretty consistent. I added G29 to my custom G code list in the slicer and also added a z axis move after the print's over to make sure the BLTouch pin clears (because it appears to drop the pin when a print is over for some reason). I adjusted the Z offset (which took a few test prints to get right) and now the printer seems to be working well.

It's time to print some stuff!

If you have time you should put detailed instructions on the wiki

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 10:28AM |

Registered: 8 years ago Posts: 131 |

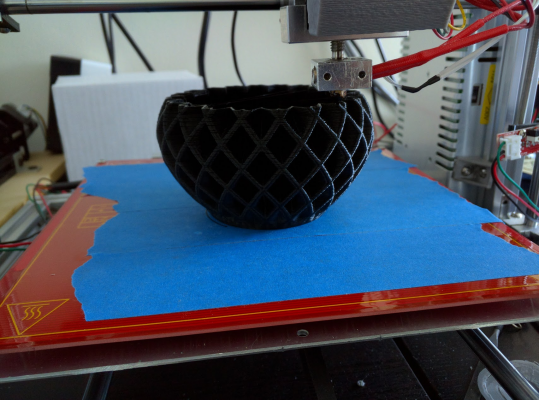

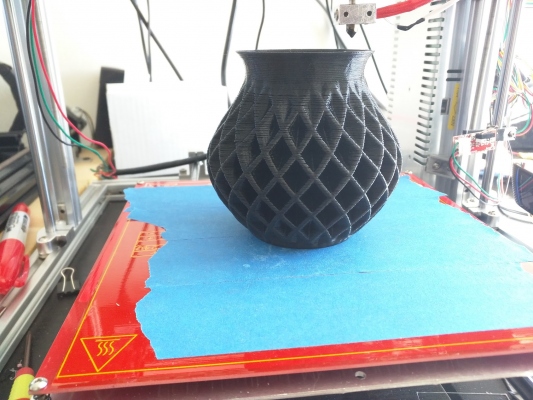

I thought I'd share my success in stopping a print for about 18 hours with the printer powered down and being to resume the print while having little to no impact on the print itself.

First I'm printing PLA on blue painters tap, this is a must for me since even with the bed cold the print doesn't move after it's started. I don't think I'd be able to do this with ABS. For me every time my bed cools down the abs pops right off. To even be able to attempt this with ABS I'd have to keep the bed powered which in turn really defeats the purpose of what I wanted to do.

So here was my situation, I had started a print that was due to complete in 4 hours, 5.5 hours into the print it's got 20% left. Unfortunately I have to leave the house at this point, I have an appointment. Luckily for me that morning I had switched from using the SD card reader or using a computer to send instructions to the printer. I had installed Repetier Server on a Raspberry Pi to act as my print server. I really like that it stores all my prints there, that I can queue prints via the web and that I can see and manage my printer remotely.

When I had to leave, I paused my print through the web interface, then used the same interface to power off the bed and the extruder. I then proceeded to turn off the main power to the printer. This leaves the Arduino and Ramps powered via usb from the Pi. This morning I came back to my print, turned the printer on, accessed the web interface, preheated the bed. Once it reached 80 I turned on my extruder, forced some PLA through it to make sure it was primed and hit play. The print resumed and finished cleanly.

I highly recommend Repetier Server Vs. using Host. The fact that I can set my prints via web interface is great. I also added an old webcam to it and now I can see what's going on with my printer anywhere in the house. Next step is adding software power on/off to it to be able to power on and off the printer remotely, after that I'll open the web interface to the web and password protect it so only I can reach it. This will allow me to leave a print on if I have to step out but monitor it with the ability to turn off the printer if I see an issue.

First picture is where I paused, 2nd is completed vase.

First I'm printing PLA on blue painters tap, this is a must for me since even with the bed cold the print doesn't move after it's started. I don't think I'd be able to do this with ABS. For me every time my bed cools down the abs pops right off. To even be able to attempt this with ABS I'd have to keep the bed powered which in turn really defeats the purpose of what I wanted to do.

So here was my situation, I had started a print that was due to complete in 4 hours, 5.5 hours into the print it's got 20% left. Unfortunately I have to leave the house at this point, I have an appointment. Luckily for me that morning I had switched from using the SD card reader or using a computer to send instructions to the printer. I had installed Repetier Server on a Raspberry Pi to act as my print server. I really like that it stores all my prints there, that I can queue prints via the web and that I can see and manage my printer remotely.

When I had to leave, I paused my print through the web interface, then used the same interface to power off the bed and the extruder. I then proceeded to turn off the main power to the printer. This leaves the Arduino and Ramps powered via usb from the Pi. This morning I came back to my print, turned the printer on, accessed the web interface, preheated the bed. Once it reached 80 I turned on my extruder, forced some PLA through it to make sure it was primed and hit play. The print resumed and finished cleanly.

I highly recommend Repetier Server Vs. using Host. The fact that I can set my prints via web interface is great. I also added an old webcam to it and now I can see what's going on with my printer anywhere in the house. Next step is adding software power on/off to it to be able to power on and off the printer remotely, after that I'll open the web interface to the web and password protect it so only I can reach it. This will allow me to leave a print on if I have to step out but monitor it with the ability to turn off the printer if I see an issue.

First picture is where I paused, 2nd is completed vase.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 10:56AM |

Registered: 8 years ago Posts: 38 |

Quote

marc2912

Quote

GrouchoDuke

My BLTouch is finally working.

If you have time you should put detailed instructions on the wiki

My prints are still mirrored in X. I'd rather not share config steps until I figure that out. I guess adding some info on porky entail BLTouch powering issues wouldn't hurt though.

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 11:01AM |

Registered: 8 years ago Posts: 131 |

Quote

GrouchoDuke

Quote

marc2912

Quote

GrouchoDuke

My BLTouch is finally working.

If you have time you should put detailed instructions on the wiki

My prints are still mirrored in X. I'd rather not share config steps until I figure that out. I guess adding some info on porky entail BLTouch powering issues wouldn't hurt though.

Definitely agree that fixing your x axis mirror should be priority but it shouldn't be related to the BLTouch config and setup.

Good luck with this last issue.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 12:29PM |

Registered: 8 years ago Posts: 541 |

Quote

GrouchoDuke

My BLTouch is finally working. Short story is that I had to power it with something other than the RAMPS board's Vcc pin.

I've been chasing my tail on this for a while. At first, I didn't know that the RAMPS board requires a jumper between the Vcc & 5V pins to provide power to the positive voltage servo pins (near the reset button by the servo connectors). After figuring that out I still couldn't get it to work. My BLTouch's pin would randomly not drop when doing Z homing. I later noticed that the BLTouch would redo its startup checks (the 3 cycles of the pin thing it does) sometimes when multiple axis motors were moving quickly.

So, I wired up a 5V/3A regulator and powered it from the main power supply. I used a servo connector to connect the 5V output of the regulator to the 5V pin on the RAMPS. After that, the BLTouch has been running perfectly. G28 & G29 commands now work and the results from G29 seems to be pretty consistent. I added G29 to my custom G code list in the slicer and also added a z axis move after the print's over to make sure the BLTouch pin clears (because it appears to drop the pin when a print is over for some reason). I adjusted the Z offset (which took a few test prints to get right) and now the printer seems to be working well.

It's time to print some stuff!

This comes straight from the arduino.cc website >> ''Supplying voltage via the 5V or 3.3V pins bypasses the regulator, and can damage your board. We don't advise it.'' so supplying an external source for the 5V may not be the safest thing to do in this case although I know several people who are. So you put the +5V on the 5V pin where the jumper used to be. Where did you put the negative lead?

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 01:28PM |

Registered: 8 years ago Posts: 171 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 01:41PM |

Registered: 8 years ago Posts: 367 |

Quote

markts

I finally stared the E3D-Lite6 assembly. It includes "ferrules" for "solder-free" assembly. That's a convenience thing, right? I'm comfortable soldering so there's downside soldering vs crimping with the ferrules, correct?

I soldered them and put some heatshrink over them, as I didn't fine the ferrules held on very well (though I don't own a crimping tool).

BTW, I later on bought one of these: [www.ebay.com]. It is much easier to attach than the original thermistor and comes with a connector. When I switched over from the E3D lite to a full E3D I used it instead.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 02:49PM |

Registered: 8 years ago Posts: 314 |

So in the rep host software how do I change my "default folgertech pla" temps? I see I can change default extruder temp but when I print using slic3r (Built into rep host) I have to choose a set parameters. So basically im asking how do I change that? Im print pla at 219 and i think it's to hot, I want to try 180.

Thanks!

Sam

Thanks!

Sam

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 02:58PM |

Registered: 8 years ago Posts: 367 |

Quote

UltiFix

So in the rep host software how do I change my "default folgertech pla" temps? I see I can change default extruder temp but when I print using slic3r (Built into rep host) I have to choose a set parameters. So basically im asking how do I change that? Im print pla at 219 and i think it's to hot, I want to try 180.

Thanks!

Sam

In Repetier's Slicer tab, click the Configuration button. After a while the configuration window for Slic3r should appear. Then you can click the Filament Settings tab and change or add profiles. Click the disc icon to save them.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 03:18PM |

Registered: 8 years ago Posts: 314 |

Thanks!Quote

animoose

Quote

UltiFix

So in the rep host software how do I change my "default folgertech pla" temps? I see I can change default extruder temp but when I print using slic3r (Built into rep host) I have to choose a set parameters. So basically im asking how do I change that? Im print pla at 219 and i think it's to hot, I want to try 180.

Thanks!

Sam

In Repetier's Slicer tab, click the Configuration button. After a while the configuration window for Slic3r should appear. Then you can click the Filament Settings tab and change or add profiles. Click the disc icon to save them.

Are there any free to download "better" printer settings? Better than the stock folgertech ones? Or should I just figure out what works best for me?

Changed first layer temp to 180 and the rest to 180 as well, let's see if I can still print!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 03:23PM |

Registered: 8 years ago Posts: 367 |

It's best to experiment, in my view. The ideal temperature varies with the filament (even amongst different suppliers of PLA) and the speed you print at. Based on my experience, I would say that 180 is a little low. These days I mostly use 190 or 195 with a bed temperature of 50.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 03:27PM |

Registered: 8 years ago Posts: 314 |

So far my print is going pretty good! Next print I can always bump it up and experiment! Im so glad plastic is DIRT cheapQuote

animoose

It's best to experiment, in my view. The ideal temperature varies with the filament (even amongst different suppliers of PLA) and the speed you print at. Based on my experience, I would say that 180 is a little low. These days I mostly use 190 or 195 with a bed temperature of 50.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 03:34PM |

Registered: 8 years ago Posts: 367 |

I thought you might like to see a moment of pure awesomeness. I am printing a large spiral spring. Cura tries to avoid travel moves which cross the perimeters of the object, unlike Slic3r which takes straight lines and so gives more spider's webs. And it does travel moves as fast as possible. Wait until about 1:10 in the video. [youtu.be]

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 03:52PM |

Registered: 8 years ago Posts: 171 |

Quote

animoose

I thought you might like to see a moment of pure awesomeness. I am printing a large spiral spring. Cura tries to avoid travel moves which cross the perimeters of the object, unlike Slic3r which takes straight lines and so gives more spider's webs. And it does travel moves as fast as possible. Wait until about 1:10 in the video. [youtu.be]

Wow! Hang on! lol

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 04:14PM |

Registered: 8 years ago Posts: 24 |

Hi, I just finished building the printer following the guide. I double and triple checked everything. I then started Repetier-Host to calibrate the X/Y/Z-axis. Then I got some problems

1) I realized that the heat bed is not working. How can I test if it is broken? Any ideas?

2) The PCB is sometimes blinking red. Any reason why?

3) Printing does not work at all. I import a model to Repetier-Host. I then slice it and press print. Nothing happens. When I want to "stop" the print nothing happens again. Trying to move the extruder or bed with the manual control is also not working then. I am also unable to close the program "extruder" still heating ..

The only reason to get back to the beginning is to kill the process in the task manager.

Long story short. So far I can only move the X/Y/Z axis with the manual control. Nothing else seems to work.

Can anyone help me with these problems? I was not able to find any good instructions for that

1) I realized that the heat bed is not working. How can I test if it is broken? Any ideas?

2) The PCB is sometimes blinking red. Any reason why?

3) Printing does not work at all. I import a model to Repetier-Host. I then slice it and press print. Nothing happens. When I want to "stop" the print nothing happens again. Trying to move the extruder or bed with the manual control is also not working then. I am also unable to close the program "extruder" still heating ..

The only reason to get back to the beginning is to kill the process in the task manager.

Long story short. So far I can only move the X/Y/Z axis with the manual control. Nothing else seems to work.

Can anyone help me with these problems? I was not able to find any good instructions for that

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 04:52PM |

Registered: 8 years ago Posts: 19 |

Quote

MuckYu

Hi, I just finished building the printer following the guide. I double and triple checked everything. I then started Repetier-Host to calibrate the X/Y/Z-axis. Then I got some problems

1) I realized that the heat bed is not working. How can I test if it is broken? Any ideas?

2) The PCB is sometimes blinking red. Any reason why?

3) Printing does not work at all. I import a model to Repetier-Host. I then slice it and press print. Nothing happens. When I want to "stop" the print nothing happens again. Trying to move the extruder or bed with the manual control is also not working then. I am also unable to close the program "extruder" still heating ..

The only reason to get back to the beginning is to kill the process in the task manager.

Long story short. So far I can only move the X/Y/Z axis with the manual control. Nothing else seems to work.

Can anyone help me with these problems? I was not able to find any good instructions for that

1- If your positive the heat bed is wired 100% with good solder connections and connected to the ramps board correctly then it may be defective. But I doubt it. Id go over everything yet again.

2- The PCB light blinking is telling you its "trying" to heat the bed / hotend.

3- Printing is not going to work until the bed and hot end heat up to operating temps. If your having issues with your bed this this will prevent that as the factory settings have the bed temps set to 70.

You dont really need a heated bed for PLA so I would turn off the heated bed and try printing again.

Edited 2 time(s). Last edit at 01/31/2016 06:28PM by bmays.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 05:05PM |

Registered: 8 years ago Posts: 19 |

Auto Level Issues

My printer was printing GREAT and I decided to go auto level with it. After some help from a few folks here the sensor is installed, Firmware is setup and working and auto level works. But...My questions are...

Ive tried per Toms video but apparently you cannot send some g-code commands threw Repetier which I am using?? I tried to download the "octoprint" but that didnt work. Whats recommended to send g-codes?

Setting the Z_PROBE_OFFSET_FROM_EXTRUDER seems to be a "FW" adjustment. Its been jamming the hotend into the bed ONLY when trying to print so I have adjusted this value many times until I can print without the hotend rubbing the bed but im not certain the setting is optimum. (Currently -0.02). Is there a generic basic way to do the paper test?

After moving my x axis endstop to the left it seems it needs to be moved over about 1.5" so everything works. I would like this to be set all the way to the left and other settings changed in firmware. (see attached pic)

Lastly, after running g28 is the hotend supposed to be center on the bed or the probe?

Thanks a ton!

Edited 1 time(s). Last edit at 01/31/2016 05:52PM by bmays.

My printer was printing GREAT and I decided to go auto level with it. After some help from a few folks here the sensor is installed, Firmware is setup and working and auto level works. But...My questions are...

Ive tried per Toms video but apparently you cannot send some g-code commands threw Repetier which I am using?? I tried to download the "octoprint" but that didnt work. Whats recommended to send g-codes?

Setting the Z_PROBE_OFFSET_FROM_EXTRUDER seems to be a "FW" adjustment. Its been jamming the hotend into the bed ONLY when trying to print so I have adjusted this value many times until I can print without the hotend rubbing the bed but im not certain the setting is optimum. (Currently -0.02). Is there a generic basic way to do the paper test?

After moving my x axis endstop to the left it seems it needs to be moved over about 1.5" so everything works. I would like this to be set all the way to the left and other settings changed in firmware. (see attached pic)

Lastly, after running g28 is the hotend supposed to be center on the bed or the probe?

Thanks a ton!

Edited 1 time(s). Last edit at 01/31/2016 05:52PM by bmays.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 05:14PM |

Registered: 8 years ago Posts: 2 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 05:23PM |

Registered: 8 years ago Posts: 314 |

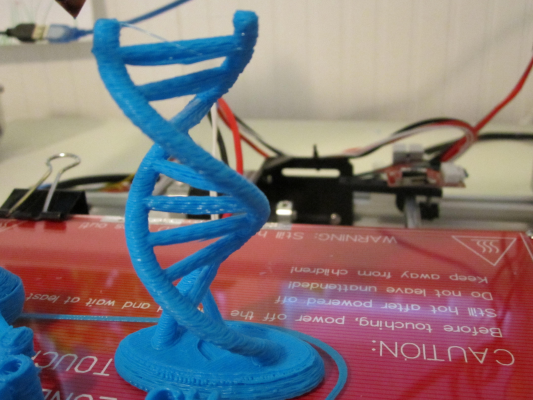

Not bad! No supports used, pla at 180, with bed at I think 70. Haven't even taken it off the bed yet, waiting for it to cool down.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 07:53PM |

Registered: 8 years ago Posts: 38 |

Quote

tjnamtiw

Quote

GrouchoDuke

My BLTouch is finally working. Short story is that I had to power it with something other than the RAMPS board's Vcc pin.

So, I wired up a 5V/3A regulator and powered it from the main power supply.

This comes straight from the arduino.cc website >> ''Supplying voltage via the 5V or 3.3V pins bypasses the regulator, and can damage your board. We don't advise it.'' so supplying an external source for the 5V may not be the safest thing to do in this case although I know several people who are. So you put the +5V on the 5V pin where the jumper used to be. Where did you put the negative lead?

Yeah, I put it on that 5v pin. Unless there's some other circuit-level reason, that Arduino verbiage sounds more like legalese than anything else. I used a common ground for the input for my regulator (the main power supply), so I didn't need to give it a ground. I only connected the +5v output from my regulator, not the ground. I could wire it directly to the BLTouch, but that doesn't look necessary. It gives a voltage to the BLTouch of 5.02V, so I should be good.

EXCEPT... My BLTouch started doing random reboots of itself again. It also calculated the bed at the wrong height after several G28/G29 attempts. So, I'm back to being frustrated. The regulator I used was very cheap. I may try wiring up my Anker USB charger instead. We'll see.

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 08:29PM |

Registered: 8 years ago Posts: 22 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 08:40PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 08:49PM |

Registered: 8 years ago Posts: 367 |

Quote

thebabymaker

Lookong for any recommendations on hardware (screws, bolts,etc) kits that I can buy to have a good stock of hardware for upgrades. Or, which sizes should I get to cover 90% of my needs? Nothing worse than realizing you are missing something in the middle of a project!

I didn't find any kits that I liked, but I did go to boltdepot.com and buy a selection of M3 and M4 bolts (from 8mm up to 50mm) plus washers and nuts. Maybe worth having a few LM8UU bearings lying around as well.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 09:59PM |

Registered: 8 years ago Posts: 13 |

I finished building my printer today and I set up Repitier to test manual control of it. So far the X-axis is working well but the other two axes will only go in one direction. For instance, the Z-axis will only go down, when I tell it to go up it says "endstops hit" but none of the end stops have been triggered. The Y-axis will only go towards the back of the printer and gives the same message if I tell it to go forward. I'm using the newest version of Marlin from Github (https://github.com/therippa/Marlin) and I've moved the X-endstop one to the right.

One other issue, I've installed the 2004 LCD display controller with adapter for RAMPS 1.4 but I'm not getting any display. Is there something else I need to do to enable the LCD screen?

One other issue, I've installed the 2004 LCD display controller with adapter for RAMPS 1.4 but I'm not getting any display. Is there something else I need to do to enable the LCD screen?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 10:13PM |

Registered: 8 years ago Posts: 19 |

Quote

chking

I finished building my printer today and I set up Repitier to test manual control of it. So far the X-axis is working well but the other two axes will only go in one direction. For instance, the Z-axis will only go down, when I tell it to go up it says "endstops hit" but none of the end stops have been triggered. The Y-axis will only go towards the back of the printer and gives the same message if I tell it to go forward. I'm using the newest version of Marlin from Github (https://github.com/therippa/Marlin) and I've moved the X-endstop one to the right.

One other issue, I've installed the 2004 LCD display controller with adapter for RAMPS 1.4 but I'm not getting any display. Is there something else I need to do to enable the LCD screen?

Swap the two plugs around on the display to get that working. Those better with firmware can assist with the endstop settings.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 10:58PM |

Registered: 8 years ago Posts: 46 |

Yet more bed leveling questions...

Anyone know how to interpret the output from the auto bed level command? I have 4 points being probed but when the G29 completes it prints a matrix of 9 values. Are these absolute values that show the deviation from the result of G28.or are they something else? When I'm printing with ABL enabled should I normally see some movement of the Z axis other than the normal step by layer? Maybe I need to put the bed in a very tilted position and try again.

Anyone know how to interpret the output from the auto bed level command? I have 4 points being probed but when the G29 completes it prints a matrix of 9 values. Are these absolute values that show the deviation from the result of G28.or are they something else? When I'm printing with ABL enabled should I normally see some movement of the Z axis other than the normal step by layer? Maybe I need to put the bed in a very tilted position and try again.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 11:41PM |

Registered: 8 years ago Posts: 314 |

What you change any of these? Especially if time isn't an issue? I just want a bit higher quality prints.

[prntscr.com]

[prntscr.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 11:51PM |

Registered: 8 years ago Posts: 430 |

Set perimeters, small perimeters, external perimeters, infill, solid infill, and top solid infill to 0 then set auto speed max print speed to 50 (or whatever you want to try) and see what that looks like. I have gotten the best results using the auto speed. I also set non print move speed to the same as the max print speed because it made the printer much quieter and didn't really add much to the overall time.

Edited 1 time(s). Last edit at 01/31/2016 11:58PM by msaeger.

Newbie with Folgertech 2020 i3.

Edited 1 time(s). Last edit at 01/31/2016 11:58PM by msaeger.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 31, 2016 11:59PM |

Registered: 8 years ago Posts: 314 |

I did that, and im doing a test print now. Hopefully it goes well! I don't have to do anything to enable auto do i?Quote

msaeger

Set perimeters, small perimeters, external perimeters, infill, solid infill, and top solid infill to 0 then set auto speed max print speed to 50 (or whatever you want to try) and see what that looks like. I have gotten the best results using the auto speed. I also set non print move speed to the same as the max print speed because it made the printer much quieter and didn't really add much to the overall time.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 01:39AM |

Registered: 8 years ago Posts: 92 |

Quote

iamquestar

Quote

UltiFix

I want to print multiple objects at once, some taller than others.. will the extruder "forget" one of the objects are there and hit it? Like at the end when it resets to default position?

Nevermind, the extruder will end up at the highest point of the print, duh

On a side note, would you guys let your printer run overnight?

I'm letting mine run right now. I'm about to go to bed, and it has another 7 hours to go on this print. The first time I did an all nighter, I woke up several times and each time went to check progress. I've had such great adhesion that I don't worry much any more. BUT I think it wise to have Thermal Runaway protection enabled. No sense tempting fate.

So I had to open my big mouth about "good adhesion..." I woke up this morning to this:

There were 4 other items on the build plate that, thankfully, stayed stuck AND didn't get killed by this wandering piece. Note to self, on things without a lot of contact area at the base... Use a brim!

Sorry, only registered users may post in this forum.