Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 05:36PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Thank you for your help and quick responses! Sorry if I sound like a idiotQuote

Mach

Quote

UltiFix

Im confused about how to calibrate my extruder, when I measure 150mm is that before I even insert any plastic into the extruder? Or do I have some inserted then measure from the top of the extruder.

Thanks!

Sam

EDIT:

Im assuming the second from looking at the video a second time.

Now I have a new question.. If I re upload the firmware do I need to add the folgertech setting's again?

As long as you are using the same file from before, everything will stay the same as the last time you saved it. Control + S is a helpful shortcut for saving things in filesOnce my dolphin is done printing im going to calibrate it.

Thanks!

Sam

No problem. everyone has to be new to something every once in a while.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 05:48PM |

Registered: 8 years ago Posts: 314 |

Well that was easy, i'm going to try printing another double helix, hopefully it will helpQuote

Mach

Quote

UltiFix

Thank you for your help and quick responses! Sorry if I sound like a idiotQuote

Mach

Quote

UltiFix

Im confused about how to calibrate my extruder, when I measure 150mm is that before I even insert any plastic into the extruder? Or do I have some inserted then measure from the top of the extruder.

Thanks!

Sam

EDIT:

Im assuming the second from looking at the video a second time.

Now I have a new question.. If I re upload the firmware do I need to add the folgertech setting's again?

As long as you are using the same file from before, everything will stay the same as the last time you saved it. Control + S is a helpful shortcut for saving things in filesOnce my dolphin is done printing im going to calibrate it.

Thanks!

Sam

No problem. everyone has to be new to something every once in a while.

If I like the results im gonna run a "huge" 5 hour print.

If I like the results im gonna run a "huge" 5 hour print.I was off by abuot 13mm, is that significant?

Edited 2 time(s). Last edit at 02/01/2016 05:52PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 06:01PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Well that was easy, i'm going to try printing another double helix, hopefully it will helpQuote

Mach

Quote

UltiFix

Thank you for your help and quick responses! Sorry if I sound like a idiotQuote

Mach

Quote

UltiFix

Im confused about how to calibrate my extruder, when I measure 150mm is that before I even insert any plastic into the extruder? Or do I have some inserted then measure from the top of the extruder.

Thanks!

Sam

EDIT:

Im assuming the second from looking at the video a second time.

Now I have a new question.. If I re upload the firmware do I need to add the folgertech setting's again?

As long as you are using the same file from before, everything will stay the same as the last time you saved it. Control + S is a helpful shortcut for saving things in filesOnce my dolphin is done printing im going to calibrate it.

Thanks!

Sam

No problem. everyone has to be new to something every once in a while.If I like the results im gonna run a "huge" 5 hour print.

I was off by abuot 13mm, is that significant?

Not sure I understand the question..

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 06:09PM |

Registered: 8 years ago Posts: 314 |

Sorry, it wasn't well typed out.Quote

Mach

Quote

UltiFix

Well that was easy, i'm going to try printing another double helix, hopefully it will helpQuote

Mach

Quote

UltiFix

Thank you for your help and quick responses! Sorry if I sound like a idiotQuote

Mach

Quote

UltiFix

Im confused about how to calibrate my extruder, when I measure 150mm is that before I even insert any plastic into the extruder? Or do I have some inserted then measure from the top of the extruder.

Thanks!

Sam

EDIT:

Im assuming the second from looking at the video a second time.

Now I have a new question.. If I re upload the firmware do I need to add the folgertech setting's again?

As long as you are using the same file from before, everything will stay the same as the last time you saved it. Control + S is a helpful shortcut for saving things in filesOnce my dolphin is done printing im going to calibrate it.

Thanks!

Sam

No problem. everyone has to be new to something every once in a while.If I like the results im gonna run a "huge" 5 hour print.

I was off by abuot 13mm, is that significant?

Not sure I understand the question..

I mean my extruder was off by 13mm, I changed the value from 90 to 103, is that a big change? So far my print still has some gaps in it, what else should i calibrate? The x y and z steps?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 06:20PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Sorry, it wasn't well typed out.Quote

Mach

Quote

UltiFix

Well that was easy, i'm going to try printing another double helix, hopefully it will helpQuote

Mach

Quote

UltiFix

Thank you for your help and quick responses! Sorry if I sound like a idiotQuote

Mach

Quote

UltiFix

Im confused about how to calibrate my extruder, when I measure 150mm is that before I even insert any plastic into the extruder? Or do I have some inserted then measure from the top of the extruder.

Thanks!

Sam

EDIT:

Im assuming the second from looking at the video a second time.

Now I have a new question.. If I re upload the firmware do I need to add the folgertech setting's again?

As long as you are using the same file from before, everything will stay the same as the last time you saved it. Control + S is a helpful shortcut for saving things in filesOnce my dolphin is done printing im going to calibrate it.

Thanks!

Sam

No problem. everyone has to be new to something every once in a while.If I like the results im gonna run a "huge" 5 hour print.

I was off by abuot 13mm, is that significant?

Not sure I understand the question..

I mean my extruder was off by 13mm, I changed the value from 90 to 103, is that a big change? So far my print still has some gaps in it, what else should i calibrate? The x y and z steps?

That is a huge difference. As for your X, Y and Z, the X and Y should be at 80, and the Z should be at 4000. Also make sure your belt are fairly taught, but not to much. It make have a dull "twung" sound when you shrum it. Make sure the set screws on the pulleys are tight too.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 06:29PM |

Registered: 8 years ago Posts: 314 |

My z is at 3840, not sure why? Will change it now.Quote

Mach

Quote

UltiFix

Sorry, it wasn't well typed out.Quote

Mach

Quote

UltiFix

Well that was easy, i'm going to try printing another double helix, hopefully it will helpQuote

Mach

Quote

UltiFix

Thank you for your help and quick responses! Sorry if I sound like a idiotQuote

Mach

Quote

UltiFix

Im confused about how to calibrate my extruder, when I measure 150mm is that before I even insert any plastic into the extruder? Or do I have some inserted then measure from the top of the extruder.

Thanks!

Sam

EDIT:

Im assuming the second from looking at the video a second time.

Now I have a new question.. If I re upload the firmware do I need to add the folgertech setting's again?

As long as you are using the same file from before, everything will stay the same as the last time you saved it. Control + S is a helpful shortcut for saving things in filesOnce my dolphin is done printing im going to calibrate it.

Thanks!

Sam

No problem. everyone has to be new to something every once in a while.If I like the results im gonna run a "huge" 5 hour print.

I was off by abuot 13mm, is that significant?

Not sure I understand the question..

I mean my extruder was off by 13mm, I changed the value from 90 to 103, is that a big change? So far my print still has some gaps in it, what else should i calibrate? The x y and z steps?

That is a huge difference. As for your X, Y and Z, the X and Y should be at 80, and the Z should be at 4000. Also make sure your belt are fairly taught, but not to much. It make have a dull "twung" sound when you shrum it. Make sure the set screws on the pulleys are tight too.

Also added a spring tensionor to my loose belt. And im trying this to.

EDIT: Pretty much everything i have done hasn't made a difference in my print quality. What else can I do? Tried letting the printer do the autospeed, tried calibrating exturder, and added spring's to the belt. Im printing pla at 190c with bed at 70c

Edited 2 time(s). Last edit at 02/01/2016 07:01PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 07:15PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

My z is at 3840, not sure why? Will change it now.Quote

Mach

Quote

UltiFix

Sorry, it wasn't well typed out.Quote

Mach

Quote

UltiFix

Well that was easy, i'm going to try printing another double helix, hopefully it will helpQuote

Mach

Quote

UltiFix

Thank you for your help and quick responses! Sorry if I sound like a idiotQuote

Mach

Quote

UltiFix

Im confused about how to calibrate my extruder, when I measure 150mm is that before I even insert any plastic into the extruder? Or do I have some inserted then measure from the top of the extruder.

Thanks!

Sam

EDIT:

Im assuming the second from looking at the video a second time.

Now I have a new question.. If I re upload the firmware do I need to add the folgertech setting's again?

As long as you are using the same file from before, everything will stay the same as the last time you saved it. Control + S is a helpful shortcut for saving things in filesOnce my dolphin is done printing im going to calibrate it.

Thanks!

Sam

No problem. everyone has to be new to something every once in a while.If I like the results im gonna run a "huge" 5 hour print.

I was off by abuot 13mm, is that significant?

Not sure I understand the question..

I mean my extruder was off by 13mm, I changed the value from 90 to 103, is that a big change? So far my print still has some gaps in it, what else should i calibrate? The x y and z steps?

That is a huge difference. As for your X, Y and Z, the X and Y should be at 80, and the Z should be at 4000. Also make sure your belt are fairly taught, but not to much. It make have a dull "twung" sound when you shrum it. Make sure the set screws on the pulleys are tight too.

Also added a spring tensionor to my loose belt. And im trying this to.

EDIT: Pretty much everything i have done hasn't made a difference in my print quality. What else can I do? Tried letting the printer do the autospeed, tried calibrating exturder, and added spring's to the belt. Im printing pla at 190c with bed at 70c

Did you level your bed? If you did, the only other thing I could think of could be your loose extruder. If the nozzle has to much play to it, that will mess up the precision of the generated tool path.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 07:26PM |

Registered: 8 years ago Posts: 314 |

I have leveled my bed multiple times, im printing that double helix as my test... Maybe that's a bad one because I was printing it at half of it's original size.. Probably causing to it print badly because it was designed to be twice as big.Quote

Mach

Quote

UltiFix

My z is at 3840, not sure why? Will change it now.Quote

Mach

Quote

UltiFix

Sorry, it wasn't well typed out.Quote

Mach

Quote

UltiFix

Well that was easy, i'm going to try printing another double helix, hopefully it will helpQuote

Mach

Quote

UltiFix

Thank you for your help and quick responses! Sorry if I sound like a idiotQuote

Mach

Quote

UltiFix

Im confused about how to calibrate my extruder, when I measure 150mm is that before I even insert any plastic into the extruder? Or do I have some inserted then measure from the top of the extruder.

Thanks!

Sam

EDIT:

Im assuming the second from looking at the video a second time.

Now I have a new question.. If I re upload the firmware do I need to add the folgertech setting's again?

As long as you are using the same file from before, everything will stay the same as the last time you saved it. Control + S is a helpful shortcut for saving things in filesOnce my dolphin is done printing im going to calibrate it.

Thanks!

Sam

No problem. everyone has to be new to something every once in a while.If I like the results im gonna run a "huge" 5 hour print.

I was off by abuot 13mm, is that significant?

Not sure I understand the question..

I mean my extruder was off by 13mm, I changed the value from 90 to 103, is that a big change? So far my print still has some gaps in it, what else should i calibrate? The x y and z steps?

That is a huge difference. As for your X, Y and Z, the X and Y should be at 80, and the Z should be at 4000. Also make sure your belt are fairly taught, but not to much. It make have a dull "twung" sound when you shrum it. Make sure the set screws on the pulleys are tight too.

Also added a spring tensionor to my loose belt. And im trying this to.

EDIT: Pretty much everything i have done hasn't made a difference in my print quality. What else can I do? Tried letting the printer do the autospeed, tried calibrating exturder, and added spring's to the belt. Im printing pla at 190c with bed at 70c

Did you level your bed? If you did, the only other thing I could think of could be your loose extruder. If the nozzle has to much play to it, that will mess up the precision of the generated tool path.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 07:40PM |

Registered: 8 years ago Posts: 285 |

The size of the print in relation to the original size should not affect the quality of the print other than any small details in the object. It would probably be better to do test prints with smaller object, so that less time would be spent on each test, and so that there are less possible variables to deal with. I would suggest a something simple like a small cube or cylinder.

Edited 1 time(s). Last edit at 02/01/2016 07:44PM by Mach.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

Edited 1 time(s). Last edit at 02/01/2016 07:44PM by Mach.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 08:05PM |

Registered: 8 years ago Posts: 14 |

So I have a weird question. How do I use the springs they provided as belt tensioners? I understand how the cylindrical "bedsprings" work for leveling the bed, I'm more wondering how to tighten the belt with the clip-like springs.

ETA: Do any of you have pictures of how you used them?

Edited 1 time(s). Last edit at 02/01/2016 08:08PM by bstern.

ETA: Do any of you have pictures of how you used them?

Edited 1 time(s). Last edit at 02/01/2016 08:08PM by bstern.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 08:16PM |

Registered: 8 years ago Posts: 285 |

Quote

bstern

So I have a weird question. How do I use the springs they provided as belt tensioners? I understand how the cylindrical "bedsprings" work for leveling the bed, I'm more wondering how to tighten the belt with the clip-like springs.

ETA: Do any of you have pictures of how you used them?

Here is a pic. They may be a royal pain in the butt to put on. I remember I spent about forth mins putting one on my Y belt.

was easier the second time I putting one on though

was easier the second time I putting one on thoughFolger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 08:32PM |

Registered: 8 years ago Posts: 13 |

For the LED screen issue I tried switching the two cables around but that had no effect.

For the end stop issue, I ran the M119 command and received the results below. Why would the endstops that don't have a switches connected to them show a TRIGGERED status?

19:28:36.536 : Reporting endstop status

19:28:36.536 : x_min: open

19:28:36.536 : x_max: open

19:28:36.536 : y_min: open

19:28:36.540 : y_max: TRIGGERED

19:28:36.540 : z_min: open

19:28:36.540 : z_max: TRIGGERED

19:28:36.540 : ok

For the end stop issue, I ran the M119 command and received the results below. Why would the endstops that don't have a switches connected to them show a TRIGGERED status?

19:28:36.536 : Reporting endstop status

19:28:36.536 : x_min: open

19:28:36.536 : x_max: open

19:28:36.536 : y_min: open

19:28:36.540 : y_max: TRIGGERED

19:28:36.540 : z_min: open

19:28:36.540 : z_max: TRIGGERED

19:28:36.540 : ok

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 08:40PM |

Registered: 8 years ago Posts: 285 |

Quote

chking

For the LED screen issue I tried switching the two cables around but that had no effect.

For the end stop issue, I ran the M119 command and received the results below. Why would the endstops that don't have a switches connected to them show a TRIGGERED status?

19:28:36.536 : Reporting endstop status

19:28:36.536 : x_min: open

19:28:36.536 : x_max: open

19:28:36.536 : y_min: open

19:28:36.540 : y_max: TRIGGERED

19:28:36.540 : z_min: open

19:28:36.540 : z_max: TRIGGERED

19:28:36.540 : ok

You have to enable the pullup resistors for the endstop positions in your firmware that you are not using, else the controller will think they are activated.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 09:21PM |

Registered: 8 years ago Posts: 541 |

Quote

bstern

So I have a weird question. How do I use the springs they provided as belt tensioners? I understand how the cylindrical "bedsprings" work for leveling the bed, I'm more wondering how to tighten the belt with the clip-like springs.

ETA: Do any of you have pictures of how you used them?

Roll the belt off of the motor and THEN put the spring on. Then roll the belt back on.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 10:03PM |

Registered: 8 years ago Posts: 314 |

I would reccomend using needle nosed pliers, go on not to badQuote

Mach

Quote

bstern

So I have a weird question. How do I use the springs they provided as belt tensioners? I understand how the cylindrical "bedsprings" work for leveling the bed, I'm more wondering how to tighten the belt with the clip-like springs.

ETA: Do any of you have pictures of how you used them?

Here is a pic. They may be a royal pain in the butt to put on. I remember I spent about forth mins putting one on my Y belt.was easier the second time I putting one on though

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 10:29PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 10:43PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Have any of you used cura over slicer? from some posts on the interwebs it looks like it does a finer job. I can obviously believe everything I read lol

I use it. I have never used slic3r so I cannot really say, but I believe it is better. Completely my personal opinion though. I have heard that a new slicer call craftware is better than cura, so I may have to try that out one day...

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 10:44PM |

Registered: 8 years ago Posts: 314 |

Iv been printing everything on %10 infill, is that to low? What about for the double helix thingy? Im assuming 10 is way to low

On slicer in the override section even if I move my infill really high the estimated print time isn't changed?

What?

Edited 1 time(s). Last edit at 02/01/2016 10:47PM by UltiFix.

On slicer in the override section even if I move my infill really high the estimated print time isn't changed?

What?

Edited 1 time(s). Last edit at 02/01/2016 10:47PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 10:48PM |

Registered: 8 years ago Posts: 314 |

Mind sharing your setup file for pla? I would like to try it out.Quote

Mach

Quote

UltiFix

Have any of you used cura over slicer? from some posts on the interwebs it looks like it does a finer job. I can obviously believe everything I read lol

I use it. I have never used slic3r so I cannot really say, but I believe it is better. Completely my personal opinion though. I have heard that a new slicer call craftware is better than cura, so I may have to try that out one day...

Edited 1 time(s). Last edit at 02/01/2016 10:48PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 10:51PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Mind sharing your setup file for pla? I would like to try it out.Quote

Mach

Quote

UltiFix

Have any of you used cura over slicer? from some posts on the interwebs it looks like it does a finer job. I can obviously believe everything I read lol

I use it. I have never used slic3r so I cannot really say, but I believe it is better. Completely my personal opinion though. I have heard that a new slicer call craftware is better than cura, so I may have to try that out one day...

For cura?

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 10:53PM |

Registered: 8 years ago Posts: 314 |

Yea, your using this folger tech printer right? Assuming you do hopefully the file will work decen't without a ton of tuningQuote

Mach

Quote

UltiFix

Mind sharing your setup file for pla? I would like to try it out.Quote

Mach

Quote

UltiFix

Have any of you used cura over slicer? from some posts on the interwebs it looks like it does a finer job. I can obviously believe everything I read lol

I use it. I have never used slic3r so I cannot really say, but I believe it is better. Completely my personal opinion though. I have heard that a new slicer call craftware is better than cura, so I may have to try that out one day...

For cura?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 10:57PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Yea, your using this folger tech printer right? Assuming you do hopefully the file will work decen't without a ton of tuningQuote

Mach

Quote

UltiFix

Mind sharing your setup file for pla? I would like to try it out.Quote

Mach

Quote

UltiFix

Have any of you used cura over slicer? from some posts on the interwebs it looks like it does a finer job. I can obviously believe everything I read lol

I use it. I have never used slic3r so I cannot really say, but I believe it is better. Completely my personal opinion though. I have heard that a new slicer call craftware is better than cura, so I may have to try that out one day...

For cura?

Yes I am using the FT. I am using bowden though, so some of the settings may be abit uh...interestting

. 10% infill is fine for that type of print btw.

. 10% infill is fine for that type of print btw.Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 11:01PM |

Registered: 8 years ago Posts: 314 |

Ah, ok. Did you find something wrong with the stock extruder?Quote

Mach

Quote

UltiFix

Yea, your using this folger tech printer right? Assuming you do hopefully the file will work decen't without a ton of tuningQuote

Mach

Quote

UltiFix

Mind sharing your setup file for pla? I would like to try it out.Quote

Mach

Quote

UltiFix

Have any of you used cura over slicer? from some posts on the interwebs it looks like it does a finer job. I can obviously believe everything I read lol

I use it. I have never used slic3r so I cannot really say, but I believe it is better. Completely my personal opinion though. I have heard that a new slicer call craftware is better than cura, so I may have to try that out one day...

For cura?

Yes I am using the FT. I am using bowden though, so some of the settings may be abit uh...interestting. 10% infill is fine for that type of print btw.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 11:06PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Ah, ok. Did you find something wrong with the stock extruder?Quote

Mach

Quote

UltiFix

Yea, your using this folger tech printer right? Assuming you do hopefully the file will work decen't without a ton of tuningQuote

Mach

Quote

UltiFix

Mind sharing your setup file for pla? I would like to try it out.Quote

Mach

Quote

UltiFix

Have any of you used cura over slicer? from some posts on the interwebs it looks like it does a finer job. I can obviously believe everything I read lol

I use it. I have never used slic3r so I cannot really say, but I believe it is better. Completely my personal opinion though. I have heard that a new slicer call craftware is better than cura, so I may have to try that out one day...

For cura?

Yes I am using the FT. I am using bowden though, so some of the settings may be abit uh...interestting. 10% infill is fine for that type of print btw.

The extruder hanging 4 inches off of the X carriage was driving my nuts, plus I wanted to be able to get faster speeds without sacrificing quality, or shaking apart the printer.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 11:12PM |

Registered: 8 years ago Posts: 285 |

Here is my cura config. You may have to change alot of the values and setting, special the speed setting.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 01, 2016 11:19PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 02, 2016 12:34AM |

Registered: 8 years ago Posts: 92 |

Quote

UltiFix

+1, all it takes is a loose wire by the extruder and boom, cable management is VERY important on these things!!Quote

marc2912

Quote

iamquestar

Quote

iamquestar

Quote

UltiFix

I want to print multiple objects at once, some taller than others.. will the extruder "forget" one of the objects are there and hit it? Like at the end when it resets to default position?

Nevermind, the extruder will end up at the highest point of the print, duh

On a side note, would you guys let your printer run overnight?

I'm letting mine run right now. I'm about to go to bed, and it has another 7 hours to go on this print. The first time I did an all nighter, I woke up several times and each time went to check progress. I've had such great adhesion that I don't worry much any more. BUT I think it wise to have Thermal Runaway protection enabled. No sense tempting fate.

So I had to open my big mouth about "good adhesion..." I woke up this morning to this:

[attachment 71376 goof.jpg]

There were 4 other items on the build plate that, thankfully, stayed stuck AND didn't get killed by this wandering piece. Note to self, on things without a lot of contact area at the base... Use a brim!

I'd recommend not running your printer overnight until you're sure it's stable and even then I'd recommend some safety features. 3d printers are a potential fire hazard and until you have them, for certain, dialed in properly I'd always run it supervised.

I completely agree! But that's not what happened here. I have good cable management, although when I rebuild my X axis I'm installing a couple cable chains. The issue with this one was just too little surface area contacting the bed. That cylinder was hollow, with no bottom, and was just 2 passes thick. On top of that, I am having an issue with sag on the extruder, so at times, it can bump the top of a piece. I think that's what dislodged this.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 02, 2016 12:46AM |

Registered: 8 years ago Posts: 92 |

Quote

iamquestar

Quote

therippa

Quote

iamquestar

Hello fellow FT2020ers! Let me start of by saying a huge THANK YOU to all of you who have contributed to the thread over the past several months. It has been an invaluable resource to me these past couple weeks since I received my FT 2020. (I'm reading through it, but am still back at page 92 - I'm getting caught up!)

I had a couple issues out of the gate (the same things as many of you). I also had a bad hot-end termistor which prevented me doing anything until I diagnosed that. I pulled the one off the bed to get things going, and have stuck with PLA for now.(The good folks at FT have taken good care of me, and sent out replacement parts immediately.)

So when I got things up and running, I ran my first print (without doing any other extruder calibration or anything) and it came out beautifully (I turned down the temp to 195c from the default 219). From that cube, I did some calibration to the XYZ steppers, and have calibrated the extruder to accurate 100mm runs.

Attached is a pic of my 6th or 7th print, and I think Benchy came out great.(.2mm, 30% Infill)

I'm having a couple issues that I can' figure out. First, the middle of my print bed is higher than the corners.It doesn't matter what I do, but I can get the corners all the same height, but I can't print anything in the middle unless my first layer is set to .4mm, as at .2, the nozzle touches hard, and can't extrude anything. I have checked the heat bed with a straight edge, and it looks good and flat. I've used multiple sheets of glass, and all have the same issue. Anyone else deal with something like this?

The second problem I'm having is with object scale. I printed out a set of the Z motor standoffs, to raise them up and reclaim my height, but they came out small. I couldn't insert the 608 bearings for the life of me, so I pulled out the calipers and sure enough, they measured small. I had to upscale them to 1.024 for them to print the right size. Now before you yell Calibrate! I have. When I print a 20mm cube, it comes right in at 20x20x20mm. I have a number things I want to print, but I need accurate dimensions, and I can't print each thing a second time (after seeing the results, then scaling up to compensate). So do any of you have any recommendations?

For your first problem, sounds like a rod may be bent, there's no reason it shouldn't be perfectly flat if you're printing on glass

For the second problem, a lot of people have problems with holes being too small (I'm in that camp, by like a fraction of a millimeter, I just design around it). Try googling for potential solutions (there's a bunch)

Thanks for the quick reply. You have provided many words of advice I have benefited from.

The first issue may be caused by the build plate. When I received it from FT, it was bent. I *thought* I had been able to bend it back to OK flatness (not perfect, but I figured if the heat bead was "floating" above it, it should be good enough.

The second issue us not just holes being too small. (although I realize my mention of the bearing made it sound like that.) I can deal with that. It's the whole part that is printing small. For example, on the z motor standoffs, they measure 39mm in the software. When I first printed them, the result was about 38.05 wide. Almost a full mm off for the screw hole alignment (at the base). Up-scaling by 2.4% got me to the proper size. If that was required for everything, I would expect the 20mm cube to print out at about 19.5mm but its printing right at 20. That's what has me so puzzled.

Just in case this helps any others out there that run into similar issues... I've resolved the sizing problem, and have discovered what is going on with the bed leveling challenges.

First, the scaling/size issue resolved itself after I updated to the latest Marlin firmware (thank you therippa!). After doing that and re-calibrating the extruder, things started printing accurately.

Now for the issue with the tip of the nozzle hitting the bed hard in the middle, I first upgraded my build glass to 3mm tempered. It was much stiffer than the cheap picture frame glass I was using (which could bend a little). My new glass looks very flat, when checked with a straight edge, and is strong to the point where I cannot deflect it with my hands, So once I started leveling the bed with this, I found that even across the surface from front to back, the middle of the bed appeared higher than the edges (even when rotating the glass). So I believe that the extruder is sagging just a bit (.1-.2mm in the middle of the rails, but closer to the sides, the shorter distance from the end pieces doesn't allow the weight of the extruder to make as big of a difference.

So that's what it looks like to me so I am planning on installing sonnylowe's v-slot x axis upgrade. I think it will solve that problem.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 02, 2016 01:13AM |

Registered: 8 years ago Posts: 92 |

Quote

UltiFix

Im printing at 15mm/s instead of 30mm/s, I want to see if it increases the print quality. Will report back!

How slow do you guys print?

I usually print between 50-60 mm./sec @ .2mm layers - If I'm going to .1, I slow that down to more like 30-40,

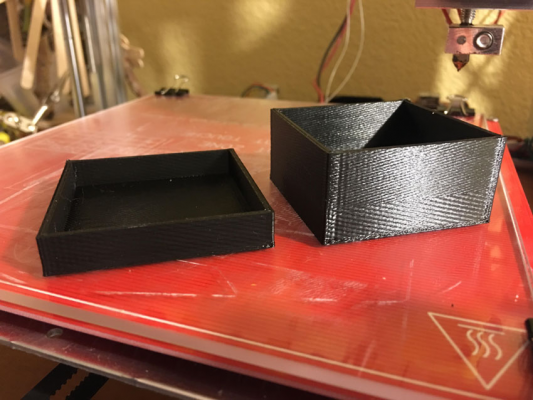

I just printed this small box (50mmx50mmx25mm) and lid for my son at .2mm layers, 50mm/sec. for inner perimeters, 40mm/sec outer perimeters, and, 75mm for infill (not that there was much)

I used Cura. I have found that it seems to be a cleaner job than Slic3r. Since Slic3r was the default, I used that a lot in the beginning, but have been very pleased with results from Cura, once I got used to the different settings.

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 02, 2016 01:25AM |

Registered: 8 years ago Posts: 314 |

Can you recommend me good cura setting's for a stock folgertech 2020 printing pla? Or a good 3D printer youtube channel?Quote

iamquestar

Quote

UltiFix

Im printing at 15mm/s instead of 30mm/s, I want to see if it increases the print quality. Will report back!

How slow do you guys print?

I usually print between 50-60 mm./sec @ .2mm layers - If I'm going to .1, I slow that down to more like 30-40,

I just printed this small box (50mmx50mmx25mm) and lid for my son at .2mm layers, 50mm/sec. for inner perimeters, 40mm/sec outer perimeters, and, 75mm for infill (not that there was much)

I used Cura. I have found that it seems to be a cleaner job than Slic3r. Since Slic3r was the default, I used that a lot in the beginning, but have been very pleased with results from Cura, once I got used to the different settings.

[attachment 71458 box.jpg]

--Andrew

Btw - Nice print!

Edited 1 time(s). Last edit at 02/02/2016 01:35AM by UltiFix.

Sorry, only registered users may post in this forum.