Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 03, 2016 04:24PM |

Registered: 8 years ago Posts: 93 |

Quote

UltiFix

My build plate is glass and I don't really want to stick some aluminum inbetween... I plan on printing abs in the future, think I could get a capactiive to work alright?Quote

jhitesma

Quote

UltiFix

Have you thought about using a capacitive sensor so it will work with glass?

The same reasons I love capacitive sensors for touch screens...I'm not big on them for this. Too sensitive. I'm sure they're a lot better than the last time I messed with a capacitive sense circuit, but it would be affected by weather and humidity greatly.

I'm liking the inductive. Just was surprised that the new bigger one was sensitive enough for a bolt that far away to throw it off. But it's the only reason I can think of for the reading shifting in that one spot and adding more metal above it solved it.

Sonnylowe seems to like a capacitive sensor. I've not tried one on the printer, but had the same experience as jhitesma in the past. Detection distance varying with humidity, or nearby objects.

The nearby object thing can affect inductive sensors too, so make sure you probe it away from the mounting bolts, etc. If I go that route, I'll probably switch to one of the mk3 aluminum heaters.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 03, 2016 04:29PM |

Registered: 8 years ago Posts: 268 |

Quote

john-i

Quote

sonnylowe

Quote

Mopar99

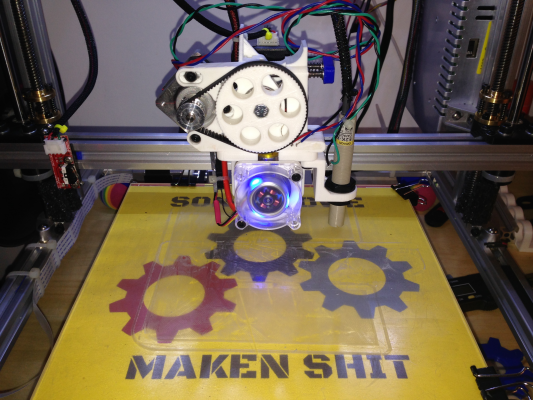

Just finish up installing sonny's gen1 upgrades:

full view:

E3D v6 direct drive:

Z- end stop, improvizedjust a m5 screw and t-nut.

Full veiw of the z axis, 400 mm lead screw (that why the 2x4 are under the printer, didn't want to cut them yet).

Still have some thing to clean up and fix. I will say it's a hole lot quieter than it was before with this setup. Used to be i could hear the printer printing downstairs when i was upstairs. This will help with when you have 2 little one running around. In the photos you can see the IKEA lack side table, i have another one to build an enclosure with. should all work when i move to the gen-2 setup. I think i only took off a 1.5 of material for the y rail. Took about 3 inches of the x rail and mounted that piece on the backside of the rail across the top to hole some wires up out of the way. Below is a list of part i used for my build.

- Change out the FT plate for the openbuild plate Build Plate

- Shorten both the x & y rails Rails

- mini v Gantry for X-Axis Mini V Gantry Set

- V-Slot Gantry Set for the Y-AxisV-Slot Gantry Set

- igus bearing instead of LM88UU

- misc hardware & bearings

- Ikea table Lack side table

Glad to see you have it up and running, the more I use my printer the happier I am with the upgrades

Nice job on the Z endstop improvise!!! Like I said in our PM exchanges...I never even thought about it LOL

Love the glow filament...I'm in the process of reprinting all my stuff in White

Sonnylowe, what about moving the extruder to the top of the rail instead of hanging it off the side? That way you don't have all that weight hanging so far out and I don't think you would loose too much height since the hot end would move up as well. If you didn't want to move the X-axis belt, you would need to have something to attach it to on each side of the gantry. Just a thought..

I just need to say, what an awesome job you guys did.. looks great, makes complete sense. FolgerTech should offer that as an upgrade

You could definitely move it in any direction at 90 degs intervals and leave the drive system (belt/stepper) as is....that's the beauty of the V-Slot Rail System. I have a mount designed to attached the extruder motor to the gantry plate running on the top of the rail, but you would have to run something like the E3D hotend so it would extend down far enough to print on the bed, the tip of the hotend has to be below the bottom of the rail. It doesn't seem that far, but add the bearings, spacers, gantry, and mount and it's pretty far from the bed, I am almost positive the stock extruder would not work!?!? If I can find the mount I'll post a picture...

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 03, 2016 05:21PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 03, 2016 05:42PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 03, 2016 07:33PM |

Registered: 8 years ago Posts: 268 |

Quote

UltiFix

Where would you guys reccomend buying abs plastic? I want decent quality not cheap crap.

-Sam

I've been using the Hatchbox from Amazon with very good success...

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 03, 2016 07:46PM |

Registered: 8 years ago Posts: 268 |

Quote

Bert3D

Quote

UltiFix

My build plate is glass and I don't really want to stick some aluminum inbetween... I plan on printing abs in the future, think I could get a capactiive to work alright?Quote

jhitesma

Quote

UltiFix

Have you thought about using a capacitive sensor so it will work with glass?

The same reasons I love capacitive sensors for touch screens...I'm not big on them for this. Too sensitive. I'm sure they're a lot better than the last time I messed with a capacitive sense circuit, but it would be affected by weather and humidity greatly.

I'm liking the inductive. Just was surprised that the new bigger one was sensitive enough for a bolt that far away to throw it off. But it's the only reason I can think of for the reading shifting in that one spot and adding more metal above it solved it.

Sonnylowe seems to like a capacitive sensor. I've not tried one on the printer, but had the same experience as jhitesma in the past. Detection distance varying with humidity, or nearby objects.

The nearby object thing can affect inductive sensors too, so make sure you probe it away from the mounting bolts, etc. If I go that route, I'll probably switch to one of the mk3 aluminum heaters.

I do like the Capacitive Sensor, but the one I have is an industrial version (~180.00 retail). I bought mine used on ebay so it was around $10.00. As far as humidity, it seems to stay spot on in my house with the heatpump. I imagine if you had gas heat the humidity could fluctuate a bit more!?!? I probe at 50 and 150 in X&Y so there is nothing close to cause interference.

I've tried them all except the Servo/Micro setup and to be honest, all of them work, and I think they all work well, it's really just a matter what setup you like and want to deal with...I do miss the clicky-clicky of the BLtouch...it let you know it was working

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 03, 2016 08:04PM |

Registered: 8 years ago Posts: 541 |

I have my 2020 running with the BLTOUCH now with or without the laptop hooked up. Just to be sure that the BLTOUCH would work even if it was in alarm mode, I put m280 P0 S160 as the first line in my Cura G code before printing. Then G28 and G29. I uploaded a video of it in action showing how the printer is actually adjusting the Z axis for the out of level print plate, which I created to test it. After the print, I measured the parts and they are all within 0.08 mm. Well, actually that was the range so they are + - 0.04 mm. I still have to lower my Z offset a couple more tenth though because I didn't get any squeeze out on the first layer, which I have set for 150%.

Pretty freaking amazing! Some math whiz needs a pat on the back!

[youtu.be]

Edited 1 time(s). Last edit at 02/03/2016 08:05PM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

Pretty freaking amazing! Some math whiz needs a pat on the back!

[youtu.be]

Edited 1 time(s). Last edit at 02/03/2016 08:05PM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 03, 2016 08:38PM |

Registered: 8 years ago Posts: 276 |

Quote

sonnylowe

Quote

therippa

Quote

sonnylowe

Quote

therippa

sonnylowe - you still thinking of upgrading the controller? I ran out of things to do on the printer and have been looking into the MiniRambo.

Haha...yup!!! I've checked out the Rambo, but not MiniRambo, I guess I know what I'll be doing at work today LOL

To be honest, I find myself looking at the Prinrbot board more and more, it seems like a good board at as reasonable price!?!? Check it out and let me know what you think...

I really like THIS as well...simply love machined aluminum!!! If my current Extruder design does work out it might end up and my short list ;-)

Here's my Belt Drive DDE mounted...just need to wire the NEMA 14, hope to run it tonight

I seems like it's a giant pain in the a** to flash that board since you can't just use Arduino Studio - [printrbot.dozuki.com]

Good catch, that's just crazy!!! I would really like to upgrade my board, but I just don't know enough about the firmware aspects of it all. I also like the smoothieboard, but damn, that's another firmware to learn. Would i be correct in assuming any board that runs Marlin would be easy to flash!?!?

Any board that has an Arduino at the heart of it (like Rambo and Mini Rambo) can be flashed like we do it now.

Also, be aware that smoothieboards currently have some problems working with Simplify3d.

Edited 1 time(s). Last edit at 02/03/2016 09:44PM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 12:13AM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 06:34AM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Quote

sonnylowe

Quote

therippa

Quote

sonnylowe

Quote

therippa

sonnylowe - you still thinking of upgrading the controller? I ran out of things to do on the printer and have been looking into the MiniRambo.

Haha...yup!!! I've checked out the Rambo, but not MiniRambo, I guess I know what I'll be doing at work today LOL

To be honest, I find myself looking at the Prinrbot board more and more, it seems like a good board at as reasonable price!?!? Check it out and let me know what you think...

I really like THIS as well...simply love machined aluminum!!! If my current Extruder design does work out it might end up and my short list ;-)

Here's my Belt Drive DDE mounted...just need to wire the NEMA 14, hope to run it tonight

I seems like it's a giant pain in the a** to flash that board since you can't just use Arduino Studio - [printrbot.dozuki.com]

Good catch, that's just crazy!!! I would really like to upgrade my board, but I just don't know enough about the firmware aspects of it all. I also like the smoothieboard, but damn, that's another firmware to learn. Would i be correct in assuming any board that runs Marlin would be easy to flash!?!?

Any board that has an Arduino at the heart of it (like Rambo and Mini Rambo) can be flashed like we do it now.

Also, be aware that smoothieboards currently have some problems working with Simplify3d.

Well I think you've talked me into it, the Rambo was on my list but the price was a bit high. However, if you want to play you have to pay

That's the direction I'll go once I'm ready for that upgrade.

Thanks for all the info and ongoing firmware support you've been providing, even though I can stumble through Marlin on my own now, it would have been much more difficult without your help...

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 06:36AM |

Registered: 8 years ago Posts: 268 |

Quote

tjnamtiw

I have my 2020 running with the BLTOUCH now with or without the laptop hooked up. Just to be sure that the BLTOUCH would work even if it was in alarm mode, I put m280 P0 S160 as the first line in my Cura G code before printing. Then G28 and G29. I uploaded a video of it in action showing how the printer is actually adjusting the Z axis for the out of level print plate, which I created to test it. After the print, I measured the parts and they are all within 0.08 mm. Well, actually that was the range so they are + - 0.04 mm. I still have to lower my Z offset a couple more tenth though because I didn't get any squeeze out on the first layer, which I have set for 150%.

Pretty freaking amazing! Some math whiz needs a pat on the back!

[youtu.be]

Damn it, the video is blocked at work, I'll take a look tonight...I miss the clicky-clicky and may have to go back

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 07:23AM |

Registered: 8 years ago Posts: 25 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 07:56AM |

Registered: 8 years ago Posts: 32 |

Quote

Boffster

Wow this thread's getting busy!

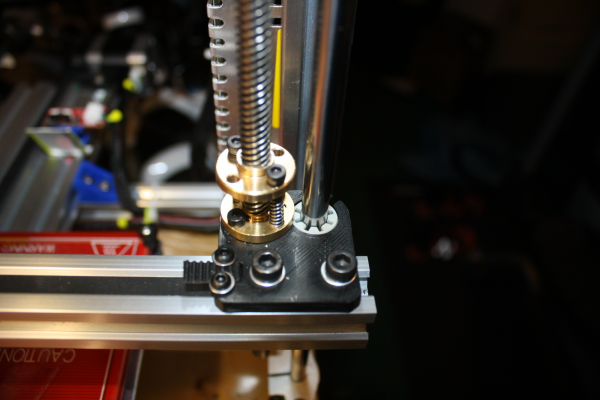

I'm hoping to change over to lead screws this weekend now all the bits have finally arrived but wanted to check with others regarding backlash. Wouldn't the weight of the X carriage eliminate any backlash as (thanks to gravity) it's always pulling down on the brass nut? When actually printing, the Z axis is only moving in one direction anyway...

Is my understanding correct that backlash is basically 'play' between the nut and bolt?

I printed out the Z anti backlash on Thingiverse (for the M5 rod) but didn't bother installing them for the same reason (also didn't really want to disassemble the printer twice due to lead screws on order).

Would really like to know what those with anti-backlash installed have noticed.

Just a bump to my previous message that got buried... Would really like to hear other people's opinions on this.....

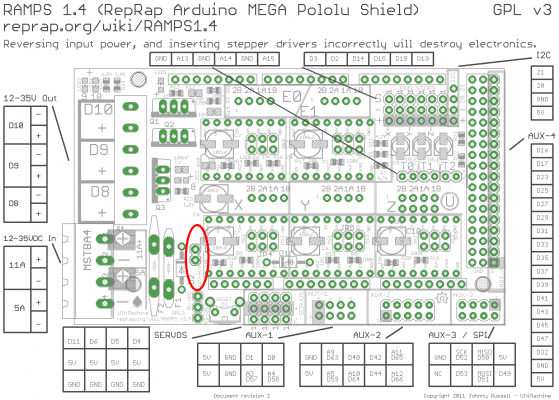

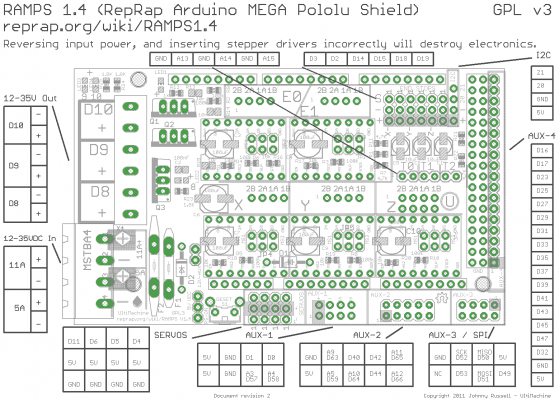

Also my other previous question about the 12v Aux connector on the RAMPS board - has anyone got the header pins on theirs?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 10:58AM |

Registered: 8 years ago Posts: 285 |

Quote

Boffster

Quote

Boffster

Wow this thread's getting busy!

I'm hoping to change over to lead screws this weekend now all the bits have finally arrived but wanted to check with others regarding backlash. Wouldn't the weight of the X carriage eliminate any backlash as (thanks to gravity) it's always pulling down on the brass nut? When actually printing, the Z axis is only moving in one direction anyway...

Is my understanding correct that backlash is basically 'play' between the nut and bolt?

I printed out the Z anti backlash on Thingiverse (for the M5 rod) but didn't bother installing them for the same reason (also didn't really want to disassemble the printer twice due to lead screws on order).

Would really like to know what those with anti-backlash installed have noticed.

Just a bump to my previous message that got buried... Would really like to hear other people's opinions on this.....

Also my other previous question about the 12v Aux connector on the RAMPS board - has anyone got the header pins on theirs?

Mine does not have header pins on it either.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 11:03AM |

Registered: 8 years ago Posts: 541 |

Quote

sonnylowe

Quote

tjnamtiw

I have my 2020 running with the BLTOUCH now with or without the laptop hooked up. Just to be sure that the BLTOUCH would work even if it was in alarm mode, I put m280 P0 S160 as the first line in my Cura G code before printing. Then G28 and G29. I uploaded a video of it in action showing how the printer is actually adjusting the Z axis for the out of level print plate, which I created to test it. After the print, I measured the parts and they are all within 0.08 mm. Well, actually that was the range so they are + - 0.04 mm. I still have to lower my Z offset a couple more tenth though because I didn't get any squeeze out on the first layer, which I have set for 150%.

Pretty freaking amazing! Some math whiz needs a pat on the back!

[youtu.be]

Damn it, the video is blocked at work, I'll take a look tonight...I miss the clicky-clicky and may have to go back

Hahaha. Whatever device you use to auto-level, it is just amazing that it actually works! Now that I see all the movements in the Z axis, I may have to rethink the Z backlash possibility eventhough my X carriage 'floats' on the vertical rods. I see some roughness in the top finish of the part that wasn't there before.

At least, I solved the problem of the BLTOUCH alarming in the stand alone (without PC) condition. So simple that I hesitate to say what it was. You can see the problem in this video. [www.youtube.com]

For some reason, even though the BLTOUCH pulls almost no current, it was resetting my firmware. I ended up with an external supply. The MAIN problem for it going into alarm condition though was that you have to have the pin in the down position when you energize it to prevent the alarm. In the stand alone configuration, you have no way to send the reset code except if you put it at the beginning of a slicer file, which I now do just in case. It would be nice to have a menu item that would do that for me. I just can't find where that coding is located yet.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 11:18AM |

Registered: 8 years ago Posts: 268 |

Quote

Boffster

Quote

Boffster

Wow this thread's getting busy!

I'm hoping to change over to lead screws this weekend now all the bits have finally arrived but wanted to check with others regarding backlash. Wouldn't the weight of the X carriage eliminate any backlash as (thanks to gravity) it's always pulling down on the brass nut? When actually printing, the Z axis is only moving in one direction anyway...

Is my understanding correct that backlash is basically 'play' between the nut and bolt?

I printed out the Z anti backlash on Thingiverse (for the M5 rod) but didn't bother installing them for the same reason (also didn't really want to disassemble the printer twice due to lead screws on order).

Would really like to know what those with anti-backlash installed have noticed.

Just a bump to my previous message that got buried... Would really like to hear other people's opinions on this.....

Also my other previous question about the 12v Aux connector on the RAMPS board - has anyone got the header pins on theirs?

Z backlash: The weight of the X Carriage is not always enough, resistances caused by poor rod alignment and poor bearing movement. If the X Carriage sticks at all coming down it will lag on the way back up. Once it's catches up and the slack is gone I would agree, it is along for the ride and should stay on point. I believe it becomes much more critical when you are running auto leveling as the Z Axis is constantly changing direction so you'll see the results in your prints.

The other issue with a sloppy fit between the LS and LS nuts is renaissance...mine made a horrible chattering noise before I installed the anti-backlash.

I came up with this anti-backlash solution, other than simply not liking the brass LS Nuts (they are cheap, poorly machined and wear out way too quickly) it works great!!!

Second question, try D2 it's a 12V AUX pin set, it is on my ramps board.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 11:28AM |

Registered: 8 years ago Posts: 268 |

Quote

tjnamtiw

Quote

sonnylowe

Quote

tjnamtiw

I have my 2020 running with the BLTOUCH now with or without the laptop hooked up. Just to be sure that the BLTOUCH would work even if it was in alarm mode, I put m280 P0 S160 as the first line in my Cura G code before printing. Then G28 and G29. I uploaded a video of it in action showing how the printer is actually adjusting the Z axis for the out of level print plate, which I created to test it. After the print, I measured the parts and they are all within 0.08 mm. Well, actually that was the range so they are + - 0.04 mm. I still have to lower my Z offset a couple more tenth though because I didn't get any squeeze out on the first layer, which I have set for 150%.

Pretty freaking amazing! Some math whiz needs a pat on the back!

[youtu.be]

Damn it, the video is blocked at work, I'll take a look tonight...I miss the clicky-clicky and may have to go back

Hahaha. Whatever device you use to auto-level, it is just amazing that it actually works! Now that I see all the movements in the Z axis, I may have to rethink the Z backlash possibility eventhough my X carriage 'floats' on the vertical rods. I see some roughness in the top finish of the part that wasn't there before.

At least, I solved the problem of the BLTOUCH alarming in the stand alone (without PC) condition. So simple that I hesitate to say what it was. You can see the problem in this video. [www.youtube.com]

For some reason, even though the BLTOUCH pulls almost no current, it was resetting my firmware. I ended up with an external supply. The MAIN problem for it going into alarm condition though was that you have to have the pin in the down position when you energize it to prevent the alarm. In the stand alone configuration, you have no way to send the reset code except if you put it at the beginning of a slicer file, which I now do just in case. It would be nice to have a menu item that would do that for me. I just can't find where that coding is located yet.

Good advice, adding that bit of Start G-Code is great no matter how you start your prints. I had an alarm and didn't notice it when I started a print...I drove my Yellow BLt so far into the bed that it cracked the case. This would have prevented that!!!!

"slicker than owl crap" I love it LOL

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 12:02PM |

Registered: 8 years ago Posts: 13 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 03:36PM |

Registered: 8 years ago Posts: 15 |

Okay guy's i thought i was free and clear had everything moving correctly,homing,etc.

then i was adjusting my v on my steppers(first time with a multimeter) and i killed the board.

since then i have ordered 1 new board ramps and adruino. they all worked,but eventually started getting errors.

now i can't do any type of movements. I have tried lowering the steppers and hiring them and still errors out.

I was wondering if there's a way to test if a board is bad ramps/mega. I do have to order a new thermistor and heater i think that failed on me too.

could be my wiring maybe? it was all working perfect(besides I couldn't print,couldn't get the extruder to feed by it's self) not worried about this right now just want it to get moving then I can worry about that.

ill post the error in repetier. I would just order another....new set,but i cant really afford to keep doing this. i checked all my wiring and it was all correct...however not to confuse you anymore,I did have the heatbed wiring on the ramps backwards, I asked and they said that wouldn't do anything to it.

thanks guys.

then i was adjusting my v on my steppers(first time with a multimeter) and i killed the board.

since then i have ordered 1 new board ramps and adruino. they all worked,but eventually started getting errors.

now i can't do any type of movements. I have tried lowering the steppers and hiring them and still errors out.

I was wondering if there's a way to test if a board is bad ramps/mega. I do have to order a new thermistor and heater i think that failed on me too.

could be my wiring maybe? it was all working perfect(besides I couldn't print,couldn't get the extruder to feed by it's self) not worried about this right now just want it to get moving then I can worry about that.

ill post the error in repetier. I would just order another....new set,but i cant really afford to keep doing this. i checked all my wiring and it was all correct...however not to confuse you anymore,I did have the heatbed wiring on the ramps backwards, I asked and they said that wouldn't do anything to it.

thanks guys.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 04:01PM |

Registered: 8 years ago Posts: 285 |

Quote

Zeegzeigler

Okay guy's i thought i was free and clear had everything moving correctly,homing,etc.

then i was adjusting my v on my steppers(first time with a multimeter) and i killed the board.

since then i have ordered 1 new board ramps and adruino. they all worked,but eventually started getting errors.

now i can't do any type of movements. I have tried lowering the steppers and hiring them and still errors out.

I was wondering if there's a way to test if a board is bad ramps/mega. I do have to order a new thermistor and heater i think that failed on me too.

could be my wiring maybe? it was all working perfect(besides I couldn't print,couldn't get the extruder to feed by it's self) not worried about this right now just want it to get moving then I can worry about that.

ill post the error in repetier. I would just order another....new set,but i cant really afford to keep doing this. i checked all my wiring and it was all correct...however not to confuse you anymore,I did have the heatbed wiring on the ramps backwards, I asked and they said that wouldn't do anything to it.

thanks guys.

After looking through marlin for that error, I think I have found that the error message is related to temperature errors, so I would guess that it is either due to your thermistor, or somethings in your config causing false errors.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 04:04PM |

Registered: 8 years ago Posts: 15 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 04:19PM |

Registered: 8 years ago Posts: 285 |

Quote

Zeegzeigler

thanks for the reply. it recently worked thought is why im confused nothing has changed besides the boards. the thermistor shouldn't make it not move right? oir would it?

the mega is a chinned knock off if that matters. im guna try to go back to my original mega

Temp errors may cause the printer to ignore movement commands, I have not tested it or searched through marlin enough to be sure.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 04:25PM |

Registered: 8 years ago Posts: 15 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 04:30PM |

Registered: 8 years ago Posts: 285 |

Quote

Zeegzeigler

alright ill order the thermistor and heater. just sucks I have had it for a month and haven't got a single print. ill ask someone to unplug their thermistors and see what it does for.

them. do you think it's a good chance it's the board again or no?

thanks.

If it worked without problem before, I would doubt it.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 05:22PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 06:38PM |

Registered: 8 years ago Posts: 32 |

Quote

sonnylowe

Z backlash: The weight of the X Carriage is not always enough, resistances caused by poor rod alignment and poor bearing movement. If the X Carriage sticks at all coming down it will lag on the way back up. Once it's catches up and the slack is gone I would agree, it is along for the ride and should stay on point. I believe it becomes much more critical when you are running auto leveling as the Z Axis is constantly changing direction so you'll see the results in your prints.

The other issue with a sloppy fit between the LS and LS nuts is renaissance...mine made a horrible chattering noise before I installed the anti-backlash.

I came up with this anti-backlash solution, other than simply not liking the brass LS Nuts (they are cheap, poorly machined and wear out way too quickly) it works great!!!

Second question, try D2 it's a 12V AUX pin set, it is on my ramps board.

Thanks for the replies sonnylowe & mach!

sonnylowe - I'd forgotten all about those using auto-level and yes it makes a lot more sense as there's constant adjustments being made. I'd originally planned to do some kind of antibacklash solution along with the lead screw upgrade so ordered an extra set of the brass nuts (although I'm using manual level) after seeing one of your earlier photos. But I might as well do it now so if I do go down the auto-level road in future I won't need to take apart the printer again!

As for the aux power on the RAMPS, I think we're talking about the same thing - except on mine (and mach's) there are no header pins...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 07:41PM |

Registered: 8 years ago Posts: 541 |

Quote

sonnylowe

Quote

tjnamtiw

Quote

sonnylowe

Quote

tjnamtiw

I have my 2020 running with the BLTOUCH now with or without the laptop hooked up. Just to be sure that the BLTOUCH would work even if it was in alarm mode, I put m280 P0 S160 as the first line in my Cura G code before printing. Then G28 and G29. I uploaded a video of it in action showing how the printer is actually adjusting the Z axis for the out of level print plate, which I created to test it. After the print, I measured the parts and they are all within 0.08 mm. Well, actually that was the range so they are + - 0.04 mm. I still have to lower my Z offset a couple more tenth though because I didn't get any squeeze out on the first layer, which I have set for 150%.

Pretty freaking amazing! Some math whiz needs a pat on the back!

[youtu.be]

Damn it, the video is blocked at work, I'll take a look tonight...I miss the clicky-clicky and may have to go back

Hahaha. Whatever device you use to auto-level, it is just amazing that it actually works! Now that I see all the movements in the Z axis, I may have to rethink the Z backlash possibility eventhough my X carriage 'floats' on the vertical rods. I see some roughness in the top finish of the part that wasn't there before.

At least, I solved the problem of the BLTOUCH alarming in the stand alone (without PC) condition. So simple that I hesitate to say what it was. You can see the problem in this video. [www.youtube.com]

For some reason, even though the BLTOUCH pulls almost no current, it was resetting my firmware. I ended up with an external supply. The MAIN problem for it going into alarm condition though was that you have to have the pin in the down position when you energize it to prevent the alarm. In the stand alone configuration, you have no way to send the reset code except if you put it at the beginning of a slicer file, which I now do just in case. It would be nice to have a menu item that would do that for me. I just can't find where that coding is located yet.

Good advice, adding that bit of Start G-Code is great no matter how you start your prints. I had an alarm and didn't notice it when I started a print...I drove my Yellow BLt so far into the bed that it cracked the case. This would have prevented that!!!!

"slicker than owl crap" I love it LOL

I 'modified' the owl crap statement slightly.

I was videoing the self leveling routine for Charles at ANTCLABS today and I had the alarm because I plugged in the BLTOUCH after I started up and, sure enough, it cleared when I started the print. I copied and pasted that into every one of my different slicer routines.

I was videoing the self leveling routine for Charles at ANTCLABS today and I had the alarm because I plugged in the BLTOUCH after I started up and, sure enough, it cleared when I started the print. I copied and pasted that into every one of my different slicer routines.Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 10:45PM |

Registered: 8 years ago Posts: 541 |

Quote

jhitesma

This was another biggie that helped me get things really aligned: [www.thingiverse.com] I had to use the customizer to print it about 25mm longer than stock to work with our setup but it makes getting the X and Y aligned so much easier. Originally I was just using my calipers to measure from the lower X smooth rod to the table...but then realized it was the Y rails that really mattered so started measuring between them and the X instead of the table. That got me really close but it was fiddly to do with the calipers. With these it's much easier, just lower Z until the lower side touches, then twist the screw on the other to get it to the same point.

Before using the alignment tool to align my X I was able to get about a 0.1mm difference on this test: [www.thingiverse.com]

After using the alignment tool I can no longer detect any difference between the diagonals with my cheap harbor freight calipers.

I thought that was a great idea and a good observation. I too had been measuring from the X carriage bars to the table. I printed one out today and WOW are my bars way off! No wonder my auto-level is correcting like crazy as it moves! Thanks!

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 11:47PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 04, 2016 11:49PM |

Registered: 8 years ago Posts: 5 |

Quote

UltiFix

Im liking cura, if you haven't tried it give it a go!

I've been going back and forth between Slic3r and Cura. Here's what I really like about Cura: it has a Support Type of "Touching build plate", so you can do supports just on the bottom. Slic3r has "Enforce support for the first layers" but it doesn't work.

Sorry, only registered users may post in this forum.

I'm having tons of fun printing and working on it! I'm amazed at how good my print quality is without much time spent tuning!

I'm having tons of fun printing and working on it! I'm amazed at how good my print quality is without much time spent tuning!