Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 12:27AM |

Registered: 8 years ago Posts: 430 |

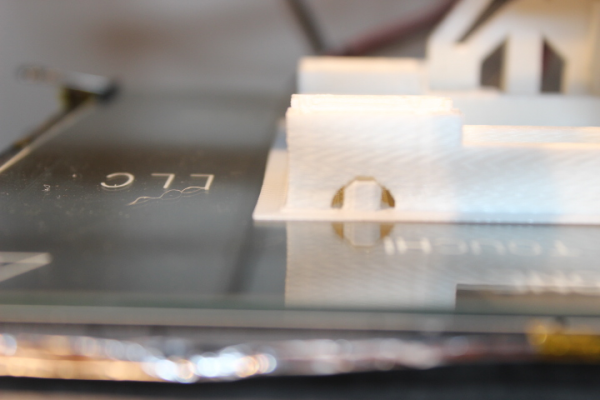

I finally got around to installing Sonny's v-slot Y axis. I would defiantly recommend doing this as your first upgrade. It is only slightly quieter than what I had but I spent a lot of time and went through many iterations to get it as quiet as it was. Installing this was so much easier than the rods and bearings you don't really need to worry about getting anything lined up like with the stock setup. I want to switch to the v-slot X axis too but first I think I will do something about the power supply. I am thinking about modding an ATX one because I can't find and LED strip type with enough power that doesn't have a fan so I doubt they would be quieter than what I have now.

Here's a pic and video of my Sonnytech printer [goo.gl]

Thanks Sonny!

Newbie with Folgertech 2020 i3.

Here's a pic and video of my Sonnytech printer [goo.gl]

Thanks Sonny!

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 08:10AM |

Registered: 8 years ago Posts: 59 |

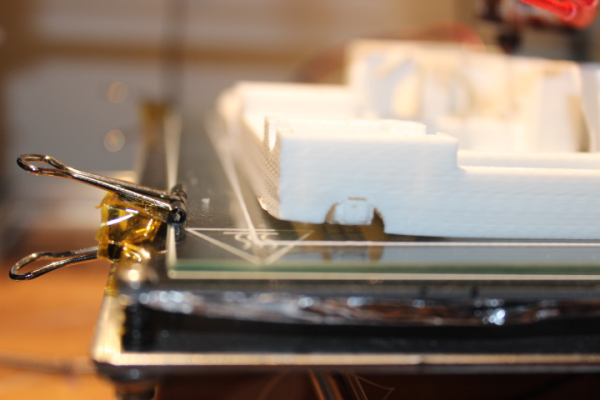

Need help diagnosing the problem shown in the photo. Seems that anytime I print a relatively large rectangular object 1/2" thick or more, the corners peel up. I'm printing ABS, extruder at 220 and bed at 100 with 25% infiill. Printing directly to the glass with good adhesion on the first layer. I have run autotune on the bed and was hoping that would fix it but it didn't. Maybe I need to try increasing the bed to 110?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 08:15AM |

Registered: 8 years ago Posts: 25 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 08:18AM |

Registered: 8 years ago Posts: 59 |

Hey Ultifix! I have had great success with Hatchbox glow-in-the-dark. I printed the MakerBot T-Rex skull with it. It's one of the most fun filaments to play with. Keep in mind that it has to be "charged" first under a light to glow, the more intense the better, but the effect is very cool.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 08:20AM |

Registered: 8 years ago Posts: 59 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 08:23AM |

Registered: 8 years ago Posts: 268 |

Quote

msaeger

I finally got around to installing Sonny's v-slot Y axis. I would defiantly recommend doing this as your first upgrade. It is only slightly quieter than what I had but I spent a lot of time and went through many iterations to get it as quiet as it was. Installing this was so much easier than the rods and bearings you don't really need to worry about getting anything lined up like with the stock setup. I want to switch to the v-slot X axis too but first I think I will do something about the power supply. I am thinking about modding an ATX one because I can't find and LED strip type with enough power that doesn't have a fan so I doubt they would be quieter than what I have now.

Here's a pic and video of my Sonnytech printer [goo.gl]

Thanks Sonny!

"Sonnytech"...I love it. Printer looks great, glad you like the upgrade

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 10:55AM |

Registered: 8 years ago Posts: 430 |

Quote

LancelotL

[attachment 71927 IMG_1870.JPG]Need help diagnosing the problem shown in the photo. Seems that anytime I print a relatively large rectangular object 1/2" thick or more, the corners peel up. I'm printing ABS, extruder at 220 and bed at 100 with 25% infiill. Printing directly to the glass with good adhesion on the first layer. I have run autotune on the bed and was hoping that would fix it but it didn't. Maybe I need to try increasing the bed to 110?

What are you putting on the glass to make it stick? I have found just coating the glass with white elmers glue and letting the heated bed dry it to be the best. It's hard to get stuff off sometimes but it's not warping.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 11:05AM |

Registered: 8 years ago Posts: 268 |

Quote

jabu32

Anyone mess with the swap filament command? M600

I've not used the M600 command...I use this code to swap filament:

G0 Y150 Z10 F600 (Z height changes dependent on swap height)

M0

G92 E0

Octprint pauses, I swap filament, purge filament using manual controls and hit resume...

Edit:

Here's and example at layer 20, the added G-Code is red...

G1 X102.725 Y90.940 E7.2535

G1 X105.082 Y90.940 E7.3319

G1 X109.060 Y94.918 E7.5190

G1 X109.060 Y92.561 E7.5974

G1 X107.439 Y90.940 E7.6736

G92 E0

G1 E-1.0000 F1800

G1 Z3.830 F1002

G0 Y150 Z10 F600

M0

G92 E0

; layer 20, Z = 3.98

; inner perimeter

G1 X109.400 Y90.600 F4800

G1 Z3.630 F1002

G1 E0.0000 F1800

G92 E0

G1 X109.400 Y109.400 E0.6253 F1463

G1 X90.600 Y109.400 E1.2506

G1 X90.600 Y90.600 E1.8759

Edited 1 time(s). Last edit at 02/06/2016 11:11AM by sonnylowe.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 11:38AM |

Registered: 8 years ago Posts: 59 |

I don't put anything on the bed as I like the mirror polish I get from direct contact as well as the constant gap. I may have to try that though if the higher temp doesn't work. I am also going to use a skirt net time to see if that helps. Thanks!Quote

msaeger

Quote

LancelotL

[attachment 71927 IMG_1870.JPG]Need help diagnosing the problem shown in the photo. Seems that anytime I print a relatively large rectangular object 1/2" thick or more, the corners peel up. I'm printing ABS, extruder at 220 and bed at 100 with 25% infiill. Printing directly to the glass with good adhesion on the first layer. I have run autotune on the bed and was hoping that would fix it but it didn't. Maybe I need to try increasing the bed to 110?

What are you putting on the glass to make it stick? I have found just coating the glass with white elmers glue and letting the heated bed dry it to be the best. It's hard to get stuff off sometimes but it's not warping.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 11:40AM |

Registered: 8 years ago Posts: 430 |

Quote

LancelotL

I don't put anything on the bed as I like the mirror polish I get from direct contact as well as the constant gap. I may have to try that though if the higher temp doesn't work. I am also going to use a skirt net time to see if that helps. Thanks!Quote

msaeger

Quote

LancelotL

[attachment 71927 IMG_1870.JPG]Need help diagnosing the problem shown in the photo. Seems that anytime I print a relatively large rectangular object 1/2" thick or more, the corners peel up. I'm printing ABS, extruder at 220 and bed at 100 with 25% infiill. Printing directly to the glass with good adhesion on the first layer. I have run autotune on the bed and was hoping that would fix it but it didn't. Maybe I need to try increasing the bed to 110?

What are you putting on the glass to make it stick? I have found just coating the glass with white elmers glue and letting the heated bed dry it to be the best. It's hard to get stuff off sometimes but it's not warping.

You can try a brim but from what I have seen with something that large it will still warp. If I mix some glue with a few drops of water and painting it on with a brush I still get a smooth bottom. I was sick of messing with the brush so I have started just smearing on the straight glue which ends up not being as smooth.

Edited 1 time(s). Last edit at 02/06/2016 11:46AM by msaeger.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 11:49AM |

Registered: 8 years ago Posts: 70 |

Quote

LancelotL

I don't put anything on the bed as I like the mirror polish I get from direct contact as well as the constant gap. I may have to try that though if the higher temp doesn't work. I am also going to use a skirt net time to see if that helps. Thanks!Quote

msaeger

Quote

LancelotL

[attachment 71927 IMG_1870.JPG]Need help diagnosing the problem shown in the photo. Seems that anytime I print a relatively large rectangular object 1/2" thick or more, the corners peel up. I'm printing ABS, extruder at 220 and bed at 100 with 25% infiill. Printing directly to the glass with good adhesion on the first layer. I have run autotune on the bed and was hoping that would fix it but it didn't. Maybe I need to try increasing the bed to 110?

What are you putting on the glass to make it stick? I have found just coating the glass with white elmers glue and letting the heated bed dry it to be the best. It's hard to get stuff off sometimes but it's not warping.

You can use hair spray, mega hold or extreme hold(pink can #10 for hold factor). Still get the glass finish. Just coat the glass with it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 12:14PM |

Registered: 8 years ago Posts: 285 |

So I just got done trying out craftware, and....I am disappointed. It is missing so many features that using it right this point would be too inconvenient. One thing that I really was surprised to find is that you cannot even connect to and manually control the printer other than the temperature. I do not know if it is because it is still in development, or if it was made more for their printer but it definitely has a ways to go.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 02:44PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 02:50PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 02:54PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

So when I print 2 objects like one has a piece that fit's into another piece, male and female the female piece is to small, maybe the male end is to big to. How do I get my printer to print the scale right?

The two options are to scale it, or to modify it in a cad program. The downside of simply scaling it is that features that you do not want to scale will scale in addition to the improperly sized features.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 02:54PM |

Registered: 8 years ago Posts: 131 |

Quote

UltiFix

So when I print 2 objects like one has a piece that fit's into another piece, male and female the female piece is to small, maybe the male end is to big to. How do I get my printer to print the scale right?

At this time what have you tried? Tuning your printer is a time consuming process which leaves a slightly different printer for everyone. Did you tune your x, y and z axis, and if yes how so? How precise was your tuning? Did you tune your extruder? Have you tried different slicer settings? Different extruder and bed temperatures? Just posting questions like above really make it difficult to help you without knowing if you've done anything to help yourself.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 03:02PM |

Registered: 8 years ago Posts: 314 |

Good point, I have calibrated the extruder and that's it... Should I start off by printing a cube and seeing where im at?Quote

marc2912

Quote

UltiFix

So when I print 2 objects like one has a piece that fit's into another piece, male and female the female piece is to small, maybe the male end is to big to. How do I get my printer to print the scale right?

At this time what have you tried? Tuning your printer is a time consuming process which leaves a slightly different printer for everyone. Did you tune your x, y and z axis, and if yes how so? How precise was your tuning? Did you tune your extruder? Have you tried different slicer settings? Different extruder and bed temperatures? Just posting questions like above really make it difficult to help you without knowing if you've done anything to help yourself.

Im printing PLA at 210 and bed at 75

I calibrated the extruder by marking the PLA at 150mm and then extruded 100mm and checked the mark to see how far off my printer was.

Thanks!

-Sam

Edited 3 time(s). Last edit at 02/06/2016 03:17PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 03:17PM |

Registered: 8 years ago Posts: 314 |

Alright thanks!Quote

Mach

Quote

UltiFix

So when I print 2 objects like one has a piece that fit's into another piece, male and female the female piece is to small, maybe the male end is to big to. How do I get my printer to print the scale right?

The two options are to scale it, or to modify it in a cad program. The downside of simply scaling it is that features that you do not want to scale will scale in addition to the improperly sized features.

For all I know the person that made the .stl file has there printer off, so maybe ill just learn how to modify it in the cad program, thanks!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 03:25PM |

Registered: 8 years ago Posts: 367 |

Quote

UltiFix

So when I print 2 objects like one has a piece that fit's into another piece, male and female the female piece is to small, maybe the male end is to big to. How do I get my printer to print the scale right?

One option which sometimes works is to print either of both parts with reduced extrusion. In Slic3r, you do this by changing extrusion multiplier in the filament settings. 0.9 or 0.85 are typically good values. Cura uses the flow value in the filament settings for the same thing, though I've not always found it to work well. I reported on some experiments I did at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 04:09PM |

Registered: 8 years ago Posts: 85 |

Quote

UltiFix

I have a 12mm proximity sensor coming, how do you reccomend I mount it to the stock folgertech 2020 extruder? I looked on thingiverse and didn't find anything for the folger tech...

[www.thingiverse.com]

I'm partial to this one I designed: [www.thingiverse.com]

It's based off another I found for the folger combined with a print cooling fan mount I use. I have both a 12mm and a 18mm version uploaded now. The 18mm version is a bit more fine tuned than the 12mm since I'm now using the 18mm sensor as it's improved sensing really makes a big difference for me.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 04:24PM |

Registered: 8 years ago Posts: 131 |

Quote

UltiFix

Good point, I have calibrated the extruder and that's it... Should I start off by printing a cube and seeing where im at?Quote

marc2912

Quote

UltiFix

So when I print 2 objects like one has a piece that fit's into another piece, male and female the female piece is to small, maybe the male end is to big to. How do I get my printer to print the scale right?

At this time what have you tried? Tuning your printer is a time consuming process which leaves a slightly different printer for everyone. Did you tune your x, y and z axis, and if yes how so? How precise was your tuning? Did you tune your extruder? Have you tried different slicer settings? Different extruder and bed temperatures? Just posting questions like above really make it difficult to help you without knowing if you've done anything to help yourself.

Im printing PLA at 210 and bed at 75

I calibrated the extruder by marking the PLA at 150mm and then extruded 100mm and checked the mark to see how far off my printer was.

Thanks!

-Sam

That seems really hot for pla but if you're sure you've calibrated it right then yes, I'd move on to calibrating your axis. If you start changing extrusion multiplier or changing the size in the FTL you might be masking issues with your setup that will creep up and mess you up later.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 04:56PM |

Registered: 8 years ago Posts: 314 |

Well I am currently using some PLA I got off of ebay, I ordered some plastic from hatchbox so maybe that will be higher quality.Quote

marc2912

Quote

UltiFix

Good point, I have calibrated the extruder and that's it... Should I start off by printing a cube and seeing where im at?Quote

marc2912

Quote

UltiFix

So when I print 2 objects like one has a piece that fit's into another piece, male and female the female piece is to small, maybe the male end is to big to. How do I get my printer to print the scale right?

At this time what have you tried? Tuning your printer is a time consuming process which leaves a slightly different printer for everyone. Did you tune your x, y and z axis, and if yes how so? How precise was your tuning? Did you tune your extruder? Have you tried different slicer settings? Different extruder and bed temperatures? Just posting questions like above really make it difficult to help you without knowing if you've done anything to help yourself.

Im printing PLA at 210 and bed at 75

I calibrated the extruder by marking the PLA at 150mm and then extruded 100mm and checked the mark to see how far off my printer was.

Thanks!

-Sam

That seems really hot for pla but if you're sure you've calibrated it right then yes, I'd move on to calibrating your axis. If you start changing extrusion multiplier or changing the size in the FTL you might be masking issues with your setup that will creep up and mess you up later.

Edited 1 time(s). Last edit at 02/06/2016 05:01PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 06, 2016 10:48PM |

Registered: 8 years ago Posts: 314 |

I may just print that one and use it even though I don't have a fan mount, this is the sensor i ordered, im assuming im going to need to give it a 12v PSU? If so not a big deal...Quote

jhitesma

Quote

UltiFix

I have a 12mm proximity sensor coming, how do you reccomend I mount it to the stock folgertech 2020 extruder? I looked on thingiverse and didn't find anything for the folger tech...

[www.thingiverse.com]

I'm partial to this one I designed: [www.thingiverse.com]

It's based off another I found for the folger combined with a print cooling fan mount I use. I have both a 12mm and a 18mm version uploaded now. The 18mm version is a bit more fine tuned than the 12mm since I'm now using the 18mm sensor as it's improved sensing really makes a big difference for me.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 07, 2016 01:15AM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 07, 2016 01:23AM |

Registered: 8 years ago Posts: 367 |

Might be the normals pointing the wrong way. That is, the faces of the inset portion might be pointing inwards rather than outwards. The fact that the faces are colored differently and you can see the grid showing through suggests something like this is wrong. I don't know sketchup, so I don't know if you can check and fix this (you can in Blender, which is what I usually use). Also try putting it through netfabb.azurewebsites.net to see if that fixes it.

Edited 1 time(s). Last edit at 02/07/2016 01:24AM by animoose.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 07, 2016 01:32AM |

Registered: 8 years ago Posts: 285 |

Quote

animoose

Might be the normals pointing the wrong way. That is, the faces of the inset portion might be pointing inwards rather than outwards. The fact that the faces are colored differently and you can see the grid showing through suggests something like this is wrong. I don't know sketchup, so I don't know if you can check and fix this (you can in Blender, which is what I usually use). Also try putting it through netfabb.azurewebsites.net to see if that fixes it.

Animoose is correct. In sketchup, faces will appear gray when they are backward and white when they are the correct way. You can reverse the face by right clicking on it and selecting "reverse face". Also, all of the faces need to have depth to them, or else they will just be 2D, which cannot actually exist. The face on the bottom and sides of your model is perpetually flat.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 07, 2016 01:55AM |

Registered: 8 years ago Posts: 314 |

I reversed the face so it's white now, but im not sure how to add depth to my faces? Using the push pull tool it just expends my entire modelQuote

Mach

Quote

animoose

Might be the normals pointing the wrong way. That is, the faces of the inset portion might be pointing inwards rather than outwards. The fact that the faces are colored differently and you can see the grid showing through suggests something like this is wrong. I don't know sketchup, so I don't know if you can check and fix this (you can in Blender, which is what I usually use). Also try putting it through netfabb.azurewebsites.net to see if that fixes it.

Animoose is correct. In sketchup, faces will appear gray when they are backward and white when they are the correct way. You can reverse the face by right clicking on it and selecting "reverse face". Also, all of the faces need to have depth to them, or else they will just be 2D, which cannot actually exist. The face on the bottom and sides of your model is perpetually flat.

[prntscr.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 07, 2016 01:58AM |

Registered: 8 years ago Posts: 314 |

I did try going through netfabbQuote

animoose

Might be the normals pointing the wrong way. That is, the faces of the inset portion might be pointing inwards rather than outwards. The fact that the faces are colored differently and you can see the grid showing through suggests something like this is wrong. I don't know sketchup, so I don't know if you can check and fix this (you can in Blender, which is what I usually use). Also try putting it through netfabb.azurewebsites.net to see if that fixes it.

How did you learn to use blender? Can you reccomend a good youtube series on learning it?

How did you learn to use blender? Can you reccomend a good youtube series on learning it?It seems to have a huge learning curve..

Edited 1 time(s). Last edit at 02/07/2016 01:58AM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 07, 2016 08:26AM |

Registered: 8 years ago Posts: 59 |

Quote

msaeger

Quote

LancelotL

I don't put anything on the bed as I like the mirror polish I get from direct contact as well as the constant gap. I may have to try that though if the higher temp doesn't work. I am also going to use a skirt net time to see if that helps. Thanks!Quote

msaeger

Quote

LancelotL

[attachment 71927 IMG_1870.JPG]Need help diagnosing the problem shown in the photo. Seems that anytime I print a relatively large rectangular object 1/2" thick or more, the corners peel up. I'm printing ABS, extruder at 220 and bed at 100 with 25% infiill. Printing directly to the glass with good adhesion on the first layer. I have run autotune on the bed and was hoping that would fix it but it didn't. Maybe I need to try increasing the bed to 110?

What are you putting on the glass to make it stick? I have found just coating the glass with white elmers glue and letting the heated bed dry it to be the best. It's hard to get stuff off sometimes but it's not warping.

You can try a brim but from what I have seen with something that large it will still warp. If I mix some glue with a few drops of water and painting it on with a brush I still get a smooth bottom. I was sick of messing with the brush so I have started just smearing on the straight glue which ends up not being as smooth.

Thanks msaeger, and Mopar99! I solved the problem, but changed three variables in the process so I'm not really sure which one fixed it. I upped the bed temp to 110, moved to the center, and added a 5 mm brim. I have tried adhesives like hairspray before but found that they make the build surface irregular very quickly and the glass needs to be cleaned constantly. I have had much better luck with consistency printing straight to glass and spend a lot less time cleaning and resetting the end stop.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 07, 2016 11:36AM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

I reversed the face so it's white now, but im not sure how to add depth to my faces? Using the push pull tool it just expends my entire modelQuote

Mach

Quote

animoose

Might be the normals pointing the wrong way. That is, the faces of the inset portion might be pointing inwards rather than outwards. The fact that the faces are colored differently and you can see the grid showing through suggests something like this is wrong. I don't know sketchup, so I don't know if you can check and fix this (you can in Blender, which is what I usually use). Also try putting it through netfabb.azurewebsites.net to see if that fixes it.

Animoose is correct. In sketchup, faces will appear gray when they are backward and white when they are the correct way. You can reverse the face by right clicking on it and selecting "reverse face". Also, all of the faces need to have depth to them, or else they will just be 2D, which cannot actually exist. The face on the bottom and sides of your model is perpetually flat.

[prntscr.com]

Sent you a PM

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

Sorry, only registered users may post in this forum.