Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 09, 2016 08:53PM |

Registered: 8 years ago Posts: 46 |

Quote

tjnamtiw

Quote

DaveA

Quote

tjnamtiw

I've been running my BLTOUCH off of an external wall wart; however, I bought a 12V/5V regulator at Radio Shack and was going to install it on the back of the plexiglas where the Arduino is mounted. I think I remember reading that someone was using one of these 7805's and, for some reason, switched back to the external supply.

Whoever that was > why did you switch back? Like to know before installing mine.

That was me but I didn't switch back. I'm still using the 7805 regulator connected directly to the power supply and feeding +5v to one of the unused servo +5 pins. I removed the jumper at the ramps board. I noticed that without the extra 7805 regulator I would see some flickering of the LCD screen whenever the BLtouch pin cycled. Maybe I just have a wimpy 5 volt regulator on the Arduino but I had a 7805 in stock so it was a cheap fix. I did go back and forth a few times but I've decided to leave the regulator in place.

Thanks, Dave! I knew someone mentioned that they had stopped using it. That gives me something to do tomorrow! I'll have to dig through my electronics stash for a couple of caps.

tjnamtiw, I didn't even bother to add a couple of caps. It's been running with no problems but I should probably add two to conform to the 7805 datasheet.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 09, 2016 09:09PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

What is the printers actual height? I homed the z axis then set it to go to 150mm up and it was going to run into the piece of metal that attaches the threaded rod to the motor so I did an emergency stop. In my printer settings the height is set at 185mm.

Ideas?

Thanks!

-Sam

Mine only goes up to 146mm. Someone made some extensions to increase the height and put them on thingi.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 09, 2016 09:50PM |

Registered: 8 years ago Posts: 314 |

I will adjust mine accordingly, thanks! Just wanted to make sure it wasn't just my printer!Quote

Mach

Quote

UltiFix

What is the printers actual height? I homed the z axis then set it to go to 150mm up and it was going to run into the piece of metal that attaches the threaded rod to the motor so I did an emergency stop. In my printer settings the height is set at 185mm.

Ideas?

Thanks!

-Sam

Mine only goes up to 146mm. Someone made some extensions to increase the height and put them on thingi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 09, 2016 11:04PM |

Registered: 8 years ago Posts: 93 |

Quote

UltiFix

What is the printers actual height? I homed the z axis then set it to go to 150mm up and it was going to run into the piece of metal that attaches the threaded rod to the motor so I did an emergency stop. In my printer settings the height is set at 185mm.

Ideas?

Thanks!

-Sam

It really depends on exactly how you've assembled your throat and nozzle, and how high you have your print bed set. Home the printer, then run your head down until it is 0.3mm from the bed, then measure how much threaded rod you have exposed between the top of the x carriage mounts and the bottom of the metal cylinders that mount the rod to the motors (the z motor couplers). That's how high you can print.

You want to make sure you set your max height low enough it will never run the carriage into the cylinders, or you will damage motors and/or drivers.

Also, if you are using auto level, subtract another 2 or 3mm or so, just to leave some extra safety margin, because the zero Z position will vary depending on where the head is around the bed, and may not be the same as where you measure it.

Edited 2 time(s). Last edit at 02/09/2016 11:13PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 09, 2016 11:33PM |

Registered: 8 years ago Posts: 13 |

I moved the endstop plug over, changed the home's all to -1, and changed repetier host to be min on all directions. Then clicked on the home button and everything seems to be working now. I can even go up down, left and right from manual mode without any error messages. I also wasn't sure which pullup parameters you are talking about as there seems to be a few for each direction but like I said, it doesn't look like I'll need them after all.

I don't think I'll have time to make my test cube until this weekend but as of right now it looks very promising that I'll have some sort of cube. Thanks!

I don't think I'll have time to make my test cube until this weekend but as of right now it looks very promising that I'll have some sort of cube. Thanks!

Quote

elkayem

Quote

tjnamtiw

Quote

stanger2k

So i'm trying to calibrate my setup and I'm running into a boat load of problems. For some reason, when I'm in manual mode and I'd like to level the bed, the output in repetier tells me that it's hitting an end stop but it's not touching an end stop nor is the light on the end stop on. I'm using therippa's Marlin code and I believe I have all of the settings right, the settings in the configuration.h file is already setup for the x to be swapped, I have the end stop on the left hand side, opposite of where the power supply is, the end stop plug has been moved to be next to Y (min), and the end stop is set to max yet it's trying to go to the right side of the board.. I have all of the motors having the right cable to the left except the far one on the top right, then the red cable is on the right side. Am I missing something? I assume whenever I hear the high pitch hum, it means it's low on power? I haven't messed with the driver boards yet as I'm scared that I'm going to end up fry it but I think that's where I'm falling short on some of it from working.

If you moved the X endstop to the left, then make X MIN in Repetier. AND move your endstop plug back to where it was, all the way to the right. That's your problem. Also in config.h, you need to make

#define X_HOME_DIR -1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

Also, enable the pullup resistors for the offending endstops. This can be done in the config file. One of these days, I'm going to add this bit of advice to the wiki, because it seems to come up every few pages on this thread...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 10, 2016 02:27AM |

Registered: 8 years ago Posts: 92 |

Quote

UltiFix

What is the printers actual height? I homed the z axis then set it to go to 150mm up and it was going to run into the piece of metal that attaches the threaded rod to the motor so I did an emergency stop. In my printer settings the height is set at 185mm.

Ideas?

Thanks!

-Sam

I have my max Z set at 145mm. 185 is standard Prusa, I believe, but with our z motors up top, we lose some height. I have stand offs ready to raise my motors above the bar, but am waiting til I have all my rebuild parts in to do it all at once. I think I'll have close to 185 once that's done.

This is what I'm talking about: [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 10, 2016 07:46AM |

Registered: 8 years ago Posts: 32 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 10, 2016 10:17AM |

Registered: 8 years ago Posts: 85 |

Quote

Bert3D

What do you guys with proximity detection z-probes get when you do an M48? That's the Marlin Z-probe repeatability test. I'd be real in interested in seeing results for capacitive and inductive probe types. Anyone have one of the 8mm distance inductive probes? How much less accurate are they?

I use this:

M48 P5 V4

I've been meaning to try that...I'm running a 8mm sense distance inductive probe with a sheet of 28ga galvanized steel between my heater and glass.

Pretty happy with the results:

08:05:52.455 : 1 of 5 z: 3.840000 mean: 3.840000 sigma: 0.000000 08:05:57.182 : 2 of 5 z: 3.837500 mean: 3.838750 sigma: 0.001250 08:06:01.909 : 3 of 5 z: 3.837500 mean: 3.838333 sigma: 0.001178 08:06:06.637 : 4 of 5 z: 3.837500 mean: 3.838125 sigma: 0.001082 08:06:11.363 : 5 of 5 z: 3.837500 mean: 3.838000 sigma: 0.001000 08:06:13.133 : Mean: 3.838000 08:06:13.137 : Standard Deviation: 0.001000

Interesting that 4 out of 5 probes were identical. Wonder why the first one was .001250 off from the others.

Ran it again in the center of my bed and got similar but not quite as good results:

08:10:34.284 : 1 of 5 z: 3.200000 mean: 3.200000 sigma: 0.000000 08:10:39.006 : 2 of 5 z: 3.197500 mean: 3.198750 sigma: 0.001250 08:10:43.733 : 3 of 5 z: 3.197500 mean: 3.198333 sigma: 0.001179 08:10:48.461 : 4 of 5 z: 3.197500 mean: 3.198125 sigma: 0.001083 08:10:53.184 : 5 of 5 z: 3.200000 mean: 3.198500 sigma: 0.001225 08:10:54.958 : Mean: 3.198500 08:10:54.958 : Standard Deviation: 0.001225

Two readings different from the other 3 this time...but both equal to each other and only 0.001250 off from the 3 consistent ones.

Third test was really impressive:

08:13:32.695 : 1 of 5 z: 3.195000 mean: 3.195000 sigma: 0.000000 08:13:37.418 : 2 of 5 z: 3.195000 mean: 3.195000 sigma: 0.000000 08:13:42.141 : 3 of 5 z: 3.195000 mean: 3.195000 sigma: 0.000000 08:13:46.864 : 4 of 5 z: 3.195000 mean: 3.195000 sigma: 0.000000 08:13:51.587 : 5 of 5 z: 3.195000 mean: 3.195000 sigma: 0.000000 08:13:53.356 : Mean: 3.195000 08:13:53.361 : Standard Deviation: 0.000000

So I'd say there's no accuracy issues with the 8mm distance probe

Edited 1 time(s). Last edit at 02/10/2016 10:18AM by jhitesma.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 10, 2016 10:22AM |

Registered: 9 years ago Posts: 251 |

If you want some height back and you're using an e3d hotend try this mount/extruder.

[www.thingiverse.com]

[www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 10, 2016 01:38PM |

Registered: 8 years ago Posts: 314 |

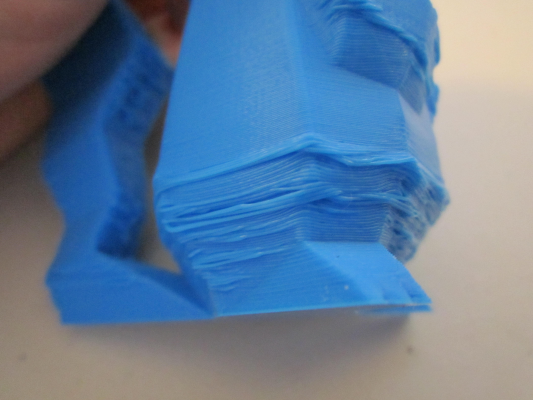

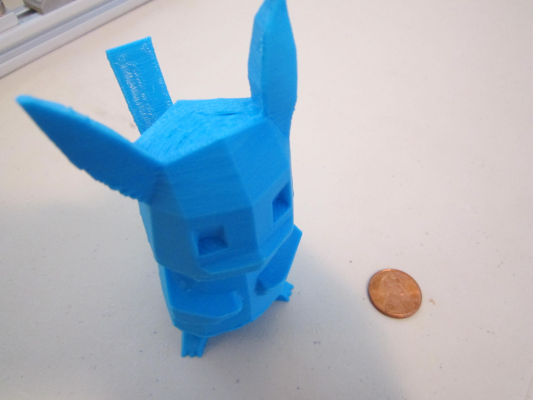

My Pikachu I printed turned out alright, but some of it isn't so great... Printing at 210C PLA and 75C bed & 10% infill, no cooling fan on plastic coming out, only the stock folgertech fan. Would lowering my PLA temp and getting a cooling fan help?

Shell Thickness ETC

Edited 1 time(s). Last edit at 02/10/2016 01:40PM by UltiFix.

Shell Thickness ETC

Edited 1 time(s). Last edit at 02/10/2016 01:40PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 10, 2016 01:45PM |

Registered: 8 years ago Posts: 541 |

Quote

UltiFix

My Pikachu I printed turned out alright, but some of it isn't so great... Printing at 210C PLA and 75C bed & 10% infill, no cooling fan on plastic coming out, only the stock folgertech fan. Would lowering my PLA temp and getting a cooling fan help?

Shell Thickness ETC

Get your temperature down around 185C at 40 mm/sec and you should be happy.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 10, 2016 01:46PM |

Registered: 8 years ago Posts: 93 |

Quote

UltiFix

My Pikachu I printed turned out alright, but some of it isn't so great... Printing at 210C PLA and 75C bed & 10% infill, no cooling fan on plastic coming out, only the stock folgertech fan. Would lowering my PLA temp and getting a cooling fan help?

Shell Thickness ETC

That seems awful hot for PLA. I print my PLA at 185 on a 60 degree bed.

At 210 it will take the PLA longer to cool, which will allow it to sag more. A cooling fan on the print would help too.

Edited 2 time(s). Last edit at 02/10/2016 01:50PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 10, 2016 01:47PM |

Registered: 9 years ago Posts: 251 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 10, 2016 04:50PM |

Registered: 8 years ago Posts: 541 |

Quote

iamquestar

Quote

UltiFix

What is the printers actual height? I homed the z axis then set it to go to 150mm up and it was going to run into the piece of metal that attaches the threaded rod to the motor so I did an emergency stop. In my printer settings the height is set at 185mm.

Ideas?

Thanks!

-Sam

I have my max Z set at 145mm. 185 is standard Prusa, I believe, but with our z motors up top, we lose some height. I have stand offs ready to raise my motors above the bar, but am waiting til I have all my rebuild parts in to do it all at once. I think I'll have close to 185 once that's done.

This is what I'm talking about: [www.thingiverse.com]

Even WITH the extensions, I'm lucky to get 160 mm.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 10, 2016 09:09PM |

Registered: 8 years ago Posts: 314 |

Im confused, im trying to enable the LCD settings in my Configuration.H file and my pins.h file but I don't think I did it right... Can somebody double check what I did compared to the guide and see if I did it right?

Am I supposed to remove the # symbol here?

[reprap.org]

Thank you!

-Sam

Am I supposed to remove the # symbol here?

[reprap.org]

Thank you!

-Sam

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 10, 2016 09:46PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Im confused, im trying to enable the LCD settings in my Configuration.H file and my pins.h file but I don't think I did it right... Can somebody double check what I did compared to the guide and see if I did it right?

Am I supposed to remove the # symbol here?

[reprap.org]

Thank you!

-Sam

No, just the ( // ), these comment out lines in the code.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 10, 2016 10:22PM |

Registered: 8 years ago Posts: 314 |

IQuote

Mach

Quote

UltiFix

Im confused, im trying to enable the LCD settings in my Configuration.H file and my pins.h file but I don't think I did it right... Can somebody double check what I did compared to the guide and see if I did it right?

Am I supposed to remove the # symbol here?

[reprap.org]

Thank you!

-Sam

No, just the ( // ), these comment out lines in the code.

My LCD is just blank with some squares on em.. I tried reversing the cables. Still blank

heres my config h and it looks right? Not sure what im doing wrong... I have coded arduinos and done html so im not a total moreon with code but im not sure why it isn't working?

*Duh, I didn't check to make sure the pins sat right in the ramps board! The female end on the board was bent so bad it didn't even go in! Now it's working fine...

Edited 5 time(s). Last edit at 02/10/2016 11:08PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 01:04AM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 02:52AM |

Registered: 8 years ago Posts: 38 |

Quote

widespreaddeadhead

Get a print fan on that. It'll make all the difference for PLA.

I've been meaning to add a fan for similar issues. What's the best print fan for the stock FT setup?

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 06:06AM |

Registered: 8 years ago Posts: 32 |

Quote

GrouchoDuke

Quote

widespreaddeadhead

Get a print fan on that. It'll make all the difference for PLA.

I've been meaning to add a fan for similar issues. What's the best print fan for the stock FT setup?

I've printed this one as it provides cooling from both sides, although I haven't installed it yet due to using PETG.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 06:07AM |

Registered: 8 years ago Posts: 32 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 10:23AM |

Registered: 8 years ago Posts: 85 |

Quote

GrouchoDuke

Quote

widespreaddeadhead

Get a print fan on that. It'll make all the difference for PLA.

I've been meaning to add a fan for similar issues. What's the best print fan for the stock FT setup?

Adding a print fan made a huge difference in my bridging/overhangs and PLA. Still not quite there with ABS (where the fan doesn't help) and still having horrible issues with PETG but getting better.

I'm not a fan of the shrouds that just scavenge air from the extruder fan. The thermal design of our extruder is pretty lousy to begin with and while the fan doesn't do much...it does make a difference as I learned printing without it the first few days of owning my printer since it shipped with a broken fan. Take away too much air from the extruder and you're looking as some serious jams at the drive gear/idler.

Plus I print in ABS which doesn't use a fan, PETG which doesn't use it as much, and even on PLA I like to keep my fan off the first few layers for better adhesion. So the passive shrouds don't really cut it for me since I can't easily turn them off.

I'm currently using this fan: [www.thingiverse.com]

It was the most flexible one I found that could be re-positioned easily. The funnel could be better, I've been toying with a different design in my head but haven't drawn it up yet. But it's better than nothing and has made a definite improvement in my PLA printing. I was also able to easily modify the mount so it doubles as my inductive sensor mount which was nice. Printing the funnel in PLA without a fan was tricky and I didn't get very good results. Without a fan I had better results on overhangs/bridges with ABS than PLA so I ended up printing it in ABS instead, now that the fan is installed PLA prints much better than ABS

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 10:34AM |

Registered: 9 years ago Posts: 251 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 10:52AM |

Registered: 8 years ago Posts: 22 |

Silicone Heating pads - does anyone use one for their folgertech 2020 and do you have any recommendations/links for the pad that you are using? I've been reading up a lot on these, and most are recommending an external solid state relay. I found one from 3D LEAP on ebay that is rated at ~17amps - i feel like this would melt my board. I've also see some rated at 11.5a. I'm trying to find something that I can connect to my existing setup. thanks.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 10:55AM |

Registered: 8 years ago Posts: 80 |

Quote

GrouchoDuke

Quote

widespreaddeadhead

Get a print fan on that. It'll make all the difference for PLA.

I've been meaning to add a fan for similar issues. What's the best print fan for the stock FT setup?

If you ever decide to upgrade to an E3D hotend, this fan works well: http://www.thingiverse.com/thing:510957 it also has a place on the other side to attach an inductive sensor or another fan.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 11:58AM |

Registered: 8 years ago Posts: 430 |

Quote

thebabymaker

Silicone Heating pads - does anyone use one for their folgertech 2020 and do you have any recommendations/links for the pad that you are using? I've been reading up a lot on these, and most are recommending an external solid state relay. I found one from 3D LEAP on ebay that is rated at ~17amps - i feel like this would melt my board. I've also see some rated at 11.5a. I'm trying to find something that I can connect to my existing setup. thanks.

Post a link to the one you are talking about. When they say you need a external relay it's because the heating pad runs off line voltage (120/240) and you are just turning it off and on though the relay. Watch Toms video about it. [www.youtube.com]

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 02:37PM |

Registered: 8 years ago Posts: 22 |

Quote

msaeger

Quote

thebabymaker

Silicone Heating pads - does anyone use one for their folgertech 2020 and do you have any recommendations/links for the pad that you are using? I've been reading up a lot on these, and most are recommending an external solid state relay. I found one from 3D LEAP on ebay that is rated at ~17amps - i feel like this would melt my board. I've also see some rated at 11.5a. I'm trying to find something that I can connect to my existing setup. thanks.

Post a link to the one you are talking about. When they say you need a external relay it's because the heating pad runs off line voltage (120/240) and you are just turning it off and on though the relay. Watch Toms video about it. [www.youtube.com]

This is the one i was checking out - [www.ebay.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 03:15PM |

Registered: 8 years ago Posts: 92 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 03:20PM |

Registered: 8 years ago Posts: 22 |

Quote

iamquestar

Quote

UltiFix

Printing from sd card is fantastic!

I agree! It's great not to worry about messing up a print when using your computer. I do miss the feed back seen in Repitier, but I think the trade-off is worth it.

Have you looked into octoprint? It essentially makes the printer wireless. I have a raspberry pi set up with octoprint with the camera module. There is a web interface where you can view your print on the camera, see all the stats, and control your printer. If you set up port forwarding you can get to the octoprint interface from outside of your network as well (though unattended printing is a bit dangerous).

Edited 1 time(s). Last edit at 02/11/2016 03:21PM by thebabymaker.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 03:52PM |

Registered: 8 years ago Posts: 92 |

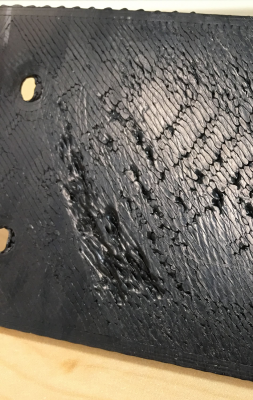

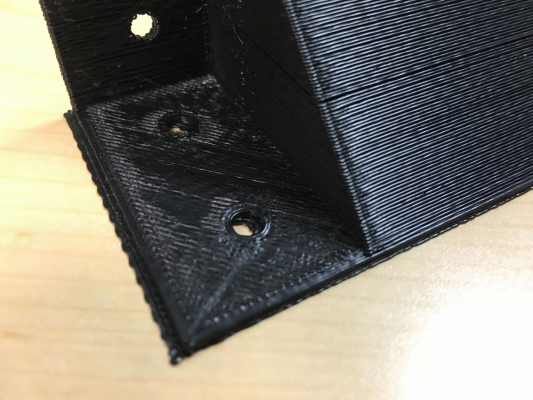

I hope one of you gurus out there can offer a little help. I put on a roll of ABS for the first time last night. I am having horrible quality on my 100% fill layers. Perimeters look fantastic.

In the video, you can see how the infill is being laid down in an uneven manner. This is ABS with 100 on the bed, and 240 on the nozzle (for the first layer). Printed on glass, with glue stick. I used this as a temp calibration piece where I lowered the temp every 10mm or so. Adhesion was great. I did have first layer set to 150% of normal layer width.

[youtu.be]

In this pic:

You are looking at the bottom of a different print. I had changed first layer extrusion width to 90% to see if that was the problem; getting too much material down. This was printed at 240 first layer, 225 additional layers, with 100 on the bed. .32 layer height stock .4 nozzle. Speed of 50mm/s Sliced with Slic3r. The whole piece stayed stuck on the bed, I had no issues with corner lift (piece is approx 50x110x50)

I've tried some different temps, with little change. What looks like big gaps there, are in fact, where the filament has bubbled up. Perhaps that is adhesion problems, but on the top side off all that, even where there is good first layer adhesion, the top surface is like the surface of the moon, it's so bad, that it caused skipping on the X axis during a move, dragging the nozzle across. You can hear it bumping along. In this second pic, you can see the top surface of the print, and it looks better than the first layer does, it's still terrible. Any ideas?

I had some similar issues with Hatchbox black PLA. The yellow PLA I got from FT hasn't given me any of these issues.

--Andrew

In the video, you can see how the infill is being laid down in an uneven manner. This is ABS with 100 on the bed, and 240 on the nozzle (for the first layer). Printed on glass, with glue stick. I used this as a temp calibration piece where I lowered the temp every 10mm or so. Adhesion was great. I did have first layer set to 150% of normal layer width.

[youtu.be]

In this pic:

You are looking at the bottom of a different print. I had changed first layer extrusion width to 90% to see if that was the problem; getting too much material down. This was printed at 240 first layer, 225 additional layers, with 100 on the bed. .32 layer height stock .4 nozzle. Speed of 50mm/s Sliced with Slic3r. The whole piece stayed stuck on the bed, I had no issues with corner lift (piece is approx 50x110x50)

I've tried some different temps, with little change. What looks like big gaps there, are in fact, where the filament has bubbled up. Perhaps that is adhesion problems, but on the top side off all that, even where there is good first layer adhesion, the top surface is like the surface of the moon, it's so bad, that it caused skipping on the X axis during a move, dragging the nozzle across. You can hear it bumping along. In this second pic, you can see the top surface of the print, and it looks better than the first layer does, it's still terrible. Any ideas?

I had some similar issues with Hatchbox black PLA. The yellow PLA I got from FT hasn't given me any of these issues.

--Andrew

Sorry, only registered users may post in this forum.