Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 03:57PM |

Registered: 8 years ago Posts: 92 |

Quote

thebabymaker

Quote

iamquestar

Quote

UltiFix

Printing from sd card is fantastic!

I agree! It's great not to worry about messing up a print when using your computer. I do miss the feed back seen in Repitier, but I think the trade-off is worth it.

Have you looked into octoprint? It essentially makes the printer wireless. I have a raspberry pi set up with octoprint with the camera module. There is a web interface where you can view your print on the camera, see all the stats, and control your printer. If you set up port forwarding you can get to the octoprint interface from outside of your network as well (though unattended printing is a bit dangerous).

Yes!! It's on my wish/to-do list. I have to hold off on it for now. I've got parts coming for the v-slot X and Y axis and lead screw upgrade. Once that's complete, I'll probably move to a bowden extruder with an E3D hot end. Once that's done, I think I'll be done with upgrades, and will plan setting up a Pi with Octoprint. There have been many times when I'm working at the other end of the house, wishing I had a way to "look in" on the print.

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 04:05PM |

Registered: 8 years ago Posts: 314 |

Interesing, I will look into it... Im tech savvy so port forwarding and setting up a rasberyy pi is no problem.Quote

thebabymaker

Quote

iamquestar

Quote

UltiFix

Printing from sd card is fantastic!

I agree! It's great not to worry about messing up a print when using your computer. I do miss the feed back seen in Repitier, but I think the trade-off is worth it.

Have you looked into octoprint? It essentially makes the printer wireless. I have a raspberry pi set up with octoprint with the camera module. There is a web interface where you can view your print on the camera, see all the stats, and control your printer. If you set up port forwarding you can get to the octoprint interface from outside of your network as well (though unattended printing is a bit dangerous).

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 04:06PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 04:07PM |

Registered: 8 years ago Posts: 24 |

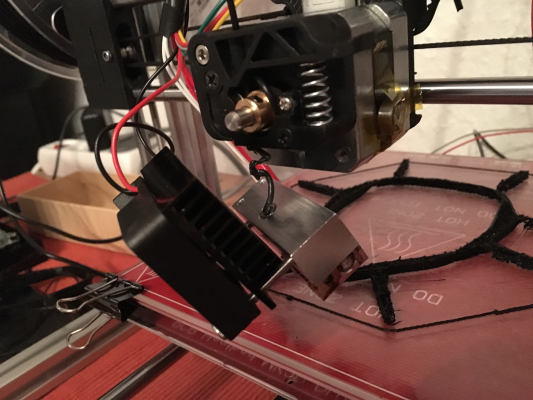

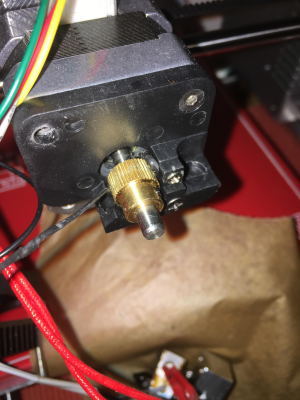

I have quite a big problem at the moment. Everytime I try to print something "bigger" (Say longer than 20 minutes) The filament keeps getting curled up around the feeder. (curled around the gold part)

Everytime I have to disassemble the whole extruder which is very annoying. Additionally I have to cut the filament at the barrel entry - so now it's kind of stuck. I already tried to heat the the nozzle up but I am unable to push the filament through.

Can anyone tell me what I am doing wrong?

I did not modify any hardware related things (stock i3 2020).

I am printing 1.75 mm PLA at 219° C and 70° C heatbed.

I already tried different extruder speeds but so far I have the problem at any settings.

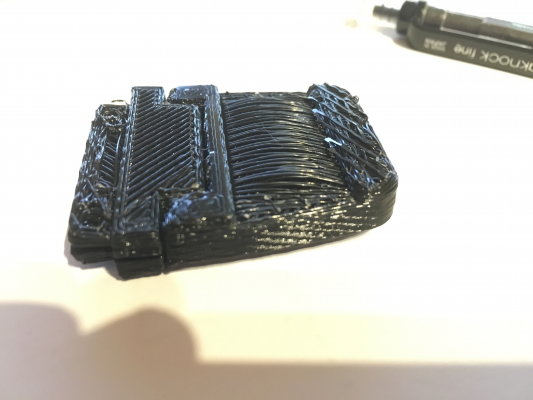

My other problem is the support material. The layers that are directly connected to the actual product are impossible to remove.

Are there any special settings for these?

Everytime I have to disassemble the whole extruder which is very annoying. Additionally I have to cut the filament at the barrel entry - so now it's kind of stuck. I already tried to heat the the nozzle up but I am unable to push the filament through.

Can anyone tell me what I am doing wrong?

I did not modify any hardware related things (stock i3 2020).

I am printing 1.75 mm PLA at 219° C and 70° C heatbed.

I already tried different extruder speeds but so far I have the problem at any settings.

My other problem is the support material. The layers that are directly connected to the actual product are impossible to remove.

Are there any special settings for these?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 05:01PM |

Registered: 8 years ago Posts: 92 |

Quote

MuckYu

I have quite a big problem at the moment. Everytime I try to print something "bigger" (Say longer than 20 minutes) The filament keeps getting curled up around the feeder. (curled around the gold part)

Everytime I have to disassemble the whole extruder which is very annoying. Additionally I have to cut the filament at the barrel entry - so now it's kind of stuck. I already tried to heat the the nozzle up but I am unable to push the filament through.

Can anyone tell me what I am doing wrong?

I did not modify any hardware related things (stock i3 2020).

I am printing 1.75 mm PLA at 219° C and 70° C heatbed.

I already tried different extruder speeds but so far I have the problem at any settings.

My other problem is the support material. The layers that are directly connected to the actual product are impossible to remove.

Are there any special settings for these?

I think it's your temperature. Try something like 190 or 195 (this is where I print). Some here are printing PLA as low as 185, but different machines will read temp. differently If you have a faulty thermistor or poor thermal connection between it and the block, it could read 219, but the hot end could be much higher!

If things are getting way too hot for PLA, it will soften the filiment all the way up into the extruder. That looks like what I would expect if the filament got soft...

You stating that this happens with longer prints seems to confirm it's a temp issue. It may take that long before the heat builds up in the extruder to cause the softening of the filament. (is the extruder fan working ok?)

Supports being hard to remove may also be a too-hot issue. The hotter the extrude, the more it's going to sag (and adhere) into the layer below. Supports are a hit or miss thing for me. Slic3r supports are always hard (impossible) for me to remove. Cura's have done better. The way a slicer does a support may make a difference. Perhaps if the top of the support is a little under extruded, then when the layer above is put down, it doesn't stick as much, so it removes easier. (not sure if this is the case, but it makes sense that it might be) If everything is too hot, then all that gets thrown out the window.

So... Try turning down the temp and see what happens. (if you have a touchless thermometer, and can shoot it at the hot end, while not perfect, can give you a little clue ff your thermistor's faulty too)

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 05:07PM |

Registered: 8 years ago Posts: 24 |

Quote

iamquestar

Quote

MuckYu

I have quite a big problem at the moment. Everytime I try to print something "bigger" (Say longer than 20 minutes) The filament keeps getting curled up around the feeder. (curled around the gold part)

Everytime I have to disassemble the whole extruder which is very annoying. Additionally I have to cut the filament at the barrel entry - so now it's kind of stuck. I already tried to heat the the nozzle up but I am unable to push the filament through.

Can anyone tell me what I am doing wrong?

I did not modify any hardware related things (stock i3 2020).

I am printing 1.75 mm PLA at 219° C and 70° C heatbed.

I already tried different extruder speeds but so far I have the problem at any settings.

My other problem is the support material. The layers that are directly connected to the actual product are impossible to remove.

Are there any special settings for these?

I think it's your temperature. Try something like 190 or 195 (this is where I print). Some here are printing PLA as low as 185, but different machines will read temp. differently If you have a faulty thermistor or poor thermal connection between it and the block, it could read 219, but the hot end could be much higher!

If things are getting way too hot for PLA, it will soften the filiment all the way up into the extruder. That looks like what I would expect if the filament got soft...

You stating that this happens with longer prints seems to confirm it's a temp issue. It may take that long before the heat builds up in the extruder to cause the softening of the filament. (is the extruder fan working ok?)

Supports being hard to remove may also be a too-hot issue. The hotter the extrude, the more it's going to sag (and adhere) into the layer below. Supports are a hit or miss thing for me. Slic3r supports are always hard (impossible) for me to remove. Cura's have done better. The way a slicer does a support may make a difference. Perhaps if the top of the support is a little under extruded, then when the layer above is put down, it doesn't stick as much, so it removes easier. (not sure if this is the case, but it makes sense that it might be) If everything is too hot, then all that gets thrown out the window.

So... Try turning down the temp and see what happens. (if you have a touchless thermometer, and can shoot it at the hot end, while not perfect, can give you a little clue ff your thermistor's faulty too)

--Andrew

Okay thanks for the info! I will try. However I now have a different problem. Part of the filament is still stuck in the barrel. I am not able to pull it out with pliers because it broke off flat on top. Pushing also doesn't work because the filament on top is still hard. Any idea what I can do here? I am not sure if I can put the temperature even higher because the PTFE tube might melt.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 05:48PM |

Registered: 8 years ago Posts: 430 |

Quote

MuckYu

Quote

iamquestar

Quote

MuckYu

I have quite a big problem at the moment. Everytime I try to print something "bigger" (Say longer than 20 minutes) The filament keeps getting curled up around the feeder. (curled around the gold part)

Everytime I have to disassemble the whole extruder which is very annoying. Additionally I have to cut the filament at the barrel entry - so now it's kind of stuck. I already tried to heat the the nozzle up but I am unable to push the filament through.

Can anyone tell me what I am doing wrong?

I did not modify any hardware related things (stock i3 2020).

I am printing 1.75 mm PLA at 219° C and 70° C heatbed.

I already tried different extruder speeds but so far I have the problem at any settings.

My other problem is the support material. The layers that are directly connected to the actual product are impossible to remove.

Are there any special settings for these?

I think it's your temperature. Try something like 190 or 195 (this is where I print). Some here are printing PLA as low as 185, but different machines will read temp. differently If you have a faulty thermistor or poor thermal connection between it and the block, it could read 219, but the hot end could be much higher!

If things are getting way too hot for PLA, it will soften the filiment all the way up into the extruder. That looks like what I would expect if the filament got soft...

You stating that this happens with longer prints seems to confirm it's a temp issue. It may take that long before the heat builds up in the extruder to cause the softening of the filament. (is the extruder fan working ok?)

Supports being hard to remove may also be a too-hot issue. The hotter the extrude, the more it's going to sag (and adhere) into the layer below. Supports are a hit or miss thing for me. Slic3r supports are always hard (impossible) for me to remove. Cura's have done better. The way a slicer does a support may make a difference. Perhaps if the top of the support is a little under extruded, then when the layer above is put down, it doesn't stick as much, so it removes easier. (not sure if this is the case, but it makes sense that it might be) If everything is too hot, then all that gets thrown out the window.

So... Try turning down the temp and see what happens. (if you have a touchless thermometer, and can shoot it at the hot end, while not perfect, can give you a little clue ff your thermistor's faulty too)

--Andrew

Okay thanks for the info! I will try. However I now have a different problem. Part of the filament is still stuck in the barrel. I am not able to pull it out with pliers because it broke off flat on top. Pushing also doesn't work because the filament on top is still hard. Any idea what I can do here? I am not sure if I can put the temperature even higher because the PTFE tube might melt.

Did you try taking off the nozzle? Maybe then you can push it out. Your fan is running on the cool block right?

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 06:48PM |

Registered: 8 years ago Posts: 24 |

Quote

msaeger

Quote

MuckYu

Quote

iamquestar

Quote

MuckYu

I have quite a big problem at the moment. Everytime I try to print something "bigger" (Say longer than 20 minutes) The filament keeps getting curled up around the feeder. (curled around the gold part)

[i.imgur.com]

[i.imgur.com]

[i.imgur.com]

[i.imgur.com]

Everytime I have to disassemble the whole extruder which is very annoying. Additionally I have to cut the filament at the barrel entry - so now it's kind of stuck. I already tried to heat the the nozzle up but I am unable to push the filament through.

Can anyone tell me what I am doing wrong?

I did not modify any hardware related things (stock i3 2020).

I am printing 1.75 mm PLA at 219° C and 70° C heatbed.

I already tried different extruder speeds but so far I have the problem at any settings.

My other problem is the support material. The layers that are directly connected to the actual product are impossible to remove.

[i.imgur.com]

Are there any special settings for these?

I think it's your temperature. Try something like 190 or 195 (this is where I print). Some here are printing PLA as low as 185, but different machines will read temp. differently If you have a faulty thermistor or poor thermal connection between it and the block, it could read 219, but the hot end could be much higher!

If things are getting way too hot for PLA, it will soften the filiment all the way up into the extruder. That looks like what I would expect if the filament got soft...

You stating that this happens with longer prints seems to confirm it's a temp issue. It may take that long before the heat builds up in the extruder to cause the softening of the filament. (is the extruder fan working ok?)

Supports being hard to remove may also be a too-hot issue. The hotter the extrude, the more it's going to sag (and adhere) into the layer below. Supports are a hit or miss thing for me. Slic3r supports are always hard (impossible) for me to remove. Cura's have done better. The way a slicer does a support may make a difference. Perhaps if the top of the support is a little under extruded, then when the layer above is put down, it doesn't stick as much, so it removes easier. (not sure if this is the case, but it makes sense that it might be) If everything is too hot, then all that gets thrown out the window.

So... Try turning down the temp and see what happens. (if you have a touchless thermometer, and can shoot it at the hot end, while not perfect, can give you a little clue ff your thermistor's faulty too)

--Andrew

Okay thanks for the info! I will try. However I now have a different problem. Part of the filament is still stuck in the barrel. I am not able to pull it out with pliers because it broke off flat on top. Pushing also doesn't work because the filament on top is still hard. Any idea what I can do here? I am not sure if I can put the temperature even higher because the PTFE tube might melt.

Did you try taking off the nozzle? Maybe then you can push it out. Your fan is running on the cool block right?

I took off the nozzle already. It is clear. The problem is inside the barrel/PTFE tube.

Here a picture: [imgur.com]

I was holding the cool block with some pliers while heating up the heating block. Then I tried to use a small screwdriver / allen key to push the filament through. Unfortunately the top as seen in the picture is still hard and it's impossible to push it through.

Edit: Okay nevermind. It seem the PTFE tube deformed and that is why I cannot push the filament through. What is the cause of this? Also the temperature?

Edited 2 time(s). Last edit at 02/11/2016 07:03PM by MuckYu.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 06:55PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 07:32PM |

Registered: 8 years ago Posts: 430 |

Quote

MuckYu

Quote

msaeger

Quote

MuckYu

Quote

iamquestar

Quote

MuckYu

I have quite a big problem at the moment. Everytime I try to print something "bigger" (Say longer than 20 minutes) The filament keeps getting curled up around the feeder. (curled around the gold part)

[i.imgur.com]

[i.imgur.com]

[i.imgur.com]

[i.imgur.com]

Everytime I have to disassemble the whole extruder which is very annoying. Additionally I have to cut the filament at the barrel entry - so now it's kind of stuck. I already tried to heat the the nozzle up but I am unable to push the filament through.

Can anyone tell me what I am doing wrong?

I did not modify any hardware related things (stock i3 2020).

I am printing 1.75 mm PLA at 219° C and 70° C heatbed.

I already tried different extruder speeds but so far I have the problem at any settings.

My other problem is the support material. The layers that are directly connected to the actual product are impossible to remove.

[i.imgur.com]

Are there any special settings for these?

I think it's your temperature. Try something like 190 or 195 (this is where I print). Some here are printing PLA as low as 185, but different machines will read temp. differently If you have a faulty thermistor or poor thermal connection between it and the block, it could read 219, but the hot end could be much higher!

If things are getting way too hot for PLA, it will soften the filiment all the way up into the extruder. That looks like what I would expect if the filament got soft...

You stating that this happens with longer prints seems to confirm it's a temp issue. It may take that long before the heat builds up in the extruder to cause the softening of the filament. (is the extruder fan working ok?)

Supports being hard to remove may also be a too-hot issue. The hotter the extrude, the more it's going to sag (and adhere) into the layer below. Supports are a hit or miss thing for me. Slic3r supports are always hard (impossible) for me to remove. Cura's have done better. The way a slicer does a support may make a difference. Perhaps if the top of the support is a little under extruded, then when the layer above is put down, it doesn't stick as much, so it removes easier. (not sure if this is the case, but it makes sense that it might be) If everything is too hot, then all that gets thrown out the window.

So... Try turning down the temp and see what happens. (if you have a touchless thermometer, and can shoot it at the hot end, while not perfect, can give you a little clue ff your thermistor's faulty too)

--Andrew

Okay thanks for the info! I will try. However I now have a different problem. Part of the filament is still stuck in the barrel. I am not able to pull it out with pliers because it broke off flat on top. Pushing also doesn't work because the filament on top is still hard. Any idea what I can do here? I am not sure if I can put the temperature even higher because the PTFE tube might melt.

Did you try taking off the nozzle? Maybe then you can push it out. Your fan is running on the cool block right?

I took off the nozzle already. It is clear. The problem is inside the barrel/PTFE tube.

Here a picture: [imgur.com]

I was holding the cool block with some pliers while heating up the heating block. Then I tried to use a small screwdriver / allen key to push the filament through. Unfortunately the top as seen in the picture is still hard and it's impossible to push it through.

Edit: Okay nevermind. It seem the PTFE tube deformed and that is why I cannot push the filament through. What is the cause of this? Also the temperature?

219 shouldn't be hot enough to mess up the line. Maybe the PLA melted in there and screwed it up that's why I was asking if the cooling fan is working. You could just get one of these [folgertech.com] or upgrade the hotend all together.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 09:08PM |

Registered: 8 years ago Posts: 5 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 11, 2016 10:46PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 12, 2016 04:13AM |

Registered: 8 years ago Posts: 38 |

Quote

elkayem

If you ever decide to upgrade to an E3D hotend, this fan works well: http://www.thingiverse.com/thing:510957

Thanks for all the fan recommendations! Adding that to the to do list...

On a different topic, I finally checked how much z movement I have. 138mm gives me a mm or two of pad. Dang. I guess I need to print the motor risers too.

Edited 1 time(s). Last edit at 02/12/2016 04:14AM by GrouchoDuke.

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 12, 2016 09:26AM |

Registered: 8 years ago Posts: 22 |

So this is a bit of a silly question - my ramps board does not have any pins on the 12v aux. How do i connect to these pins? Do i need to solder in some pins or should I just solder the wire to the pad?

Reason I am asking is because I am current using the D9 +12v to power my induction sensor, but I want to install a cooling fan to D9 for PLA so I need to move it. Would I fry my board if I connected both the fan and induction sensor to D9?

Reason I am asking is because I am current using the D9 +12v to power my induction sensor, but I want to install a cooling fan to D9 for PLA so I need to move it. Would I fry my board if I connected both the fan and induction sensor to D9?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 12, 2016 11:33AM |

Registered: 8 years ago Posts: 285 |

Quote

thebabymaker

So this is a bit of a silly question - my ramps board does not have any pins on the 12v aux. How do i connect to these pins? Do i need to solder in some pins or should I just solder the wire to the pad?

Reason I am asking is because I am current using the D9 +12v to power my induction sensor, but I want to install a cooling fan to D9 for PLA so I need to move it. Would I fry my board if I connected both the fan and induction sensor to D9?

Those terminals can supply way higher current for the bed and hotend heater than your fan and sensor combination would pull, so there should be no problem.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 12, 2016 02:09PM |

Registered: 8 years ago Posts: 92 |

Quote

Mach

Quote

thebabymaker

So this is a bit of a silly question - my ramps board does not have any pins on the 12v aux. How do i connect to these pins? Do i need to solder in some pins or should I just solder the wire to the pad?

Reason I am asking is because I am current using the D9 +12v to power my induction sensor, but I want to install a cooling fan to D9 for PLA so I need to move it. Would I fry my board if I connected both the fan and induction sensor to D9?

Those terminals can supply way higher current for the bed and hotend heater than your fan and sensor combination would pull, so there should be no problem.

But I'm under the impression you generally want to be able to turn your print cooling fan on and off during the print (usually off for the first few layers). You obviously couldn't do this if you set it up as described above.

I don't have a fan for cooling the print yet. I won't be doing this until my full rebuild next week (i'll be upgrading to the v-slot on x and y axis, adding lead screws, and adding the Z motor stand offs).

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 12, 2016 03:32PM |

Registered: 8 years ago Posts: 24 |

Quote

Boffster

Quote

GrouchoDuke

Quote

widespreaddeadhead

Get a print fan on that. It'll make all the difference for PLA.

I've been meaning to add a fan for similar issues. What's the best print fan for the stock FT setup?

I've printed this one as it provides cooling from both sides, although I haven't installed it yet due to using PETG.

How exactly do you reverse the Fan direction for this to work? I am not able to find the right option.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 12, 2016 07:32PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 12, 2016 08:32PM |

Registered: 8 years ago Posts: 430 |

Quote

MuckYu

Quote

Boffster

Quote

GrouchoDuke

Quote

widespreaddeadhead

Get a print fan on that. It'll make all the difference for PLA.

I've been meaning to add a fan for similar issues. What's the best print fan for the stock FT setup?

I've printed this one as it provides cooling from both sides, although I haven't installed it yet due to using PETG.

How exactly do you reverse the Fan direction for this to work? I am not able to find the right option.

Why would you need to reverse the fan?

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 12, 2016 08:35PM |

Registered: 8 years ago Posts: 430 |

Quote

GrouchoDuke

Quote

elkayem

If you ever decide to upgrade to an E3D hotend, this fan works well: http://www.thingiverse.com/thing:510957

Thanks for all the fan recommendations! Adding that to the to do list...

On a different topic, I finally checked how much z movement I have. 138mm gives me a mm or two of pad. Dang. I guess I need to print the motor risers too.

If you really want the height you could buy longer extrusions for 5 bucks.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 12, 2016 09:06PM |

Registered: 8 years ago Posts: 24 |

Quote

msaeger

Quote

MuckYu

Quote

Boffster

Quote

GrouchoDuke

Quote

widespreaddeadhead

Get a print fan on that. It'll make all the difference for PLA.

I've been meaning to add a fan for similar issues. What's the best print fan for the stock FT setup?

I've printed this one as it provides cooling from both sides, although I haven't installed it yet due to using PETG.

How exactly do you reverse the Fan direction for this to work? I am not able to find the right option.

Why would you need to reverse the fan?

In the comment section they say that the fan should blow "into" the extruder instead of blowing out. Someone mentioned that you have to reverse it in the firmware.

"so open up the marlin arduino firmware and there should be a fan motor reverse node and you should change it to true from false."

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 12, 2016 09:53PM |

Registered: 8 years ago Posts: 285 |

Quote

MuckYu

Quote

msaeger

Quote

MuckYu

Quote

Boffster

Quote

GrouchoDuke

Quote

widespreaddeadhead

Get a print fan on that. It'll make all the difference for PLA.

I've been meaning to add a fan for similar issues. What's the best print fan for the stock FT setup?

I've printed this one as it provides cooling from both sides, although I haven't installed it yet due to using PETG.

How exactly do you reverse the Fan direction for this to work? I am not able to find the right option.

Why would you need to reverse the fan?

In the comment section they say that the fan should blow "into" the extruder instead of blowing out. Someone mentioned that you have to reverse it in the firmware.

"so open up the marlin arduino firmware and there should be a fan motor reverse node and you should change it to true from false."

If you have the fan plugged directly into the power supply like FT's build manual has it, you either have to swap the wires, or turn the fan around.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 12, 2016 11:49PM |

Registered: 8 years ago Posts: 430 |

Quote

MuckYu

Quote

msaeger

Quote

MuckYu

Quote

Boffster

Quote

GrouchoDuke

Quote

widespreaddeadhead

Get a print fan on that. It'll make all the difference for PLA.

I've been meaning to add a fan for similar issues. What's the best print fan for the stock FT setup?

I've printed this one as it provides cooling from both sides, although I haven't installed it yet due to using PETG.

How exactly do you reverse the Fan direction for this to work? I am not able to find the right option.

Why would you need to reverse the fan?

In the comment section they say that the fan should blow "into" the extruder instead of blowing out. Someone mentioned that you have to reverse it in the firmware.

"so open up the marlin arduino firmware and there should be a fan motor reverse node and you should change it to true from false."

I guess what i'm saying is it should have been blowing into the extruder already so you wouldn't need to reverse it. If it's blowing the wrong way like Mach said just flip it around.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 13, 2016 12:18AM |

Registered: 8 years ago Posts: 93 |

Quote

MuckYu

Quote

msaeger

Quote

MuckYu

Quote

Boffster

Quote

GrouchoDuke

Quote

widespreaddeadhead

Get a print fan on that. It'll make all the difference for PLA.

I've been meaning to add a fan for similar issues. What's the best print fan for the stock FT setup?

I've printed this one as it provides cooling from both sides, although I haven't installed it yet due to using PETG.

How exactly do you reverse the Fan direction for this to work? I am not able to find the right option.

Why would you need to reverse the fan?

In the comment section they say that the fan should blow "into" the extruder instead of blowing out. Someone mentioned that you have to reverse it in the firmware.

"so open up the marlin arduino firmware and there should be a fan motor reverse node and you should change it to true from false."

The fan should be blowing into the extruder heatsink fins. If it is not, all you have to do is remove the screws that are through the bottom of the fan, take off the fan, and turn it around the other way. You don't need to muck with the wiring or settings. Don't try to make the fan blow backwards by reversing the wiring or anything. They are designed to blow one way only. The side of the fan with the label on it should be against the heatsink. The side that spins should face the front of the printer.

Also, I snap one of these into the front of the fan. Snap in Fan Guard. It keeps things out of the fan. Things like my fingers.

Edited 5 time(s). Last edit at 02/13/2016 12:35AM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 13, 2016 03:35PM |

Registered: 8 years ago Posts: 171 |

Quote

thebabymaker

Quote

iamquestar

Quote

UltiFix

Printing from sd card is fantastic!

I agree! It's great not to worry about messing up a print when using your computer. I do miss the feed back seen in Repitier, but I think the trade-off is worth it.

Have you looked into octoprint? It essentially makes the printer wireless. I have a raspberry pi set up with octoprint with the camera module. There is a web interface where you can view your print on the camera, see all the stats, and control your printer. If you set up port forwarding you can get to the octoprint interface from outside of your network as well (though unattended printing is a bit dangerous).

I just got Octoprint working with the camera, etc, and printing from the computer downstairs (and checking on the printer upstairs) is awesome. So much better than dedicating my laptop to the printer, or swapping the sd card around.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 13, 2016 06:07PM |

Registered: 8 years ago Posts: 314 |

Are you just using a rasberry pi?Quote

markts

Quote

thebabymaker

Quote

iamquestar

Quote

UltiFix

Printing from sd card is fantastic!

I agree! It's great not to worry about messing up a print when using your computer. I do miss the feed back seen in Repitier, but I think the trade-off is worth it.

Have you looked into octoprint? It essentially makes the printer wireless. I have a raspberry pi set up with octoprint with the camera module. There is a web interface where you can view your print on the camera, see all the stats, and control your printer. If you set up port forwarding you can get to the octoprint interface from outside of your network as well (though unattended printing is a bit dangerous).

I just got Octoprint working with the camera, etc, and printing from the computer downstairs (and checking on the printer upstairs) is awesome. So much better than dedicating my laptop to the printer, or swapping the sd card around.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 13, 2016 06:54PM |

Registered: 8 years ago Posts: 22 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 13, 2016 10:03PM |

Registered: 8 years ago Posts: 171 |

Quote

UltiFix

Are you just using a rasberry pi?Quote

markts

Quote

thebabymaker

Quote

iamquestar

Quote

UltiFix

Printing from sd card is fantastic!

I agree! It's great not to worry about messing up a print when using your computer. I do miss the feed back seen in Repitier, but I think the trade-off is worth it.

Have you looked into octoprint? It essentially makes the printer wireless. I have a raspberry pi set up with octoprint with the camera module. There is a web interface where you can view your print on the camera, see all the stats, and control your printer. If you set up port forwarding you can get to the octoprint interface from outside of your network as well (though unattended printing is a bit dangerous).

I just got Octoprint working with the camera, etc, and printing from the computer downstairs (and checking on the printer upstairs) is awesome. So much better than dedicating my laptop to the printer, or swapping the sd card around.

Yep, Pi 2 running Octoprint. Amazing little board. Full linux GUI with browser, peripherals,etc.

I printed a couple things today and am still having trouble with overhangs/bridges. I have a separate cooling fan with this shroud:

[www.thingiverse.com]

I put my hand up to the fan and I thought I had it blowing backwards. Pulled it off the shroud and sure enough, it was oriented correctly. I *think* the opening in the shroud is too small and the fan can't push it through. Has anyone had this problem?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 13, 2016 10:25PM |

Registered: 8 years ago Posts: 19 |

Quote

thebabymaker

So I replaced my pcb bed with a new one because it was very slow heating up. But the new bed is just the same. Resistance measured 1.6 on his new board and 1.8 on the old one. Could voltage be the issue? I'm seeing 11.25v when I measure the bed, shouldn't it be 12?

11.25v under load? I.e. when bed is heating? If so, thats fine. Are you placing the "lines" (copper traces) up or down? When using glass these can face up for better performance.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 13, 2016 10:32PM |

Registered: 8 years ago Posts: 22 |

Quote

bmays

Quote

thebabymaker

So I replaced my pcb bed with a new one because it was very slow heating up. But the new bed is just the same. Resistance measured 1.6 on his new board and 1.8 on the old one. Could voltage be the issue? I'm seeing 11.25v when I measure the bed, shouldn't it be 12?

11.25v under load? I.e. when bed is heating? If so, thats fine. Are you placing the "lines" (copper traces) up or down? When using glass these can face up for better performance.

Yup, 11.25 when bed is heating. Im using a 3mm aluminum plate with the traces facing up. I can get to 80c in about 20 minutes, which has been working fine for me for abs on kapton, but if I even needed to get to 110, I think it would take over an hour.

Sorry, only registered users may post in this forum.