Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 18, 2016 05:57PM |

Registered: 8 years ago Posts: 20 |

Quote

Bert3D

Quote

buffcleb

Did anyone have to cut the length of there BLTouch probe? If I use the adjuster to bring the probe high enough to clear the bottom of the nozzle in the raise position it is not able to lift itself... I am running off a 5v adjustable power supply for the BLTouch. I adjusted it for 5.4 volts to see if that helps... it did not...

I used this mount to mount the BLTouch : [www.thingiverse.com]

I order to get it to clear I removed some plastic from the extruder as I was not able to get it to mount... I'm thinking about making a new mount the raises it up as this one just does not work well... unless people cut the tip of the probe...

I raised the mount by scaling it at 300% along the Z axis in Slic3r before printing it. Was a lot quicker than making a new one.

you didn't run into clearance issues where it mounts to the hotend?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 18, 2016 06:05PM |

Registered: 8 years ago Posts: 93 |

BLTouch Tip

If you are using a the default mk9 extruder and nozzle that folger is now shipping, the mount thingiverse BLTouch Mount may put it too low. To correct the problem, scale the mount 300% along the z axis in your slicer to make it taller. If you try to adjust the BLTouch to high, it will not be able to extend and retract properly, because the magnet will be too far above the coil. I'd recommend not adjusting the BLTouch if you can avoid it. The original position seems to give the best range of motion and sensitivity.

Also be very careful with the metal probe tip. it is a pretty soft and delicate metal, and if you scratch it with pliers, bed clips, etc., it will start sticking in the probe. You can polish it smooth again, but it isn't easy, and it is definitely easier to just avoid scratching it in the first place. Just a warning.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

If you are using a the default mk9 extruder and nozzle that folger is now shipping, the mount thingiverse BLTouch Mount may put it too low. To correct the problem, scale the mount 300% along the z axis in your slicer to make it taller. If you try to adjust the BLTouch to high, it will not be able to extend and retract properly, because the magnet will be too far above the coil. I'd recommend not adjusting the BLTouch if you can avoid it. The original position seems to give the best range of motion and sensitivity.

Also be very careful with the metal probe tip. it is a pretty soft and delicate metal, and if you scratch it with pliers, bed clips, etc., it will start sticking in the probe. You can polish it smooth again, but it isn't easy, and it is definitely easier to just avoid scratching it in the first place. Just a warning.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 18, 2016 06:12PM |

Registered: 8 years ago Posts: 93 |

Quote

buffcleb

Quote

Bert3D

Quote

buffcleb

Did anyone have to cut the length of there BLTouch probe? If I use the adjuster to bring the probe high enough to clear the bottom of the nozzle in the raise position it is not able to lift itself... I am running off a 5v adjustable power supply for the BLTouch. I adjusted it for 5.4 volts to see if that helps... it did not...

I used this mount to mount the BLTouch : [www.thingiverse.com]

I order to get it to clear I removed some plastic from the extruder as I was not able to get it to mount... I'm thinking about making a new mount the raises it up as this one just does not work well... unless people cut the tip of the probe...

I raised the mount by scaling it at 300% along the Z axis in Slic3r before printing it. Was a lot quicker than making a new one.

you didn't run into clearance issues where it mounts to the hotend?

Nope. It fit fine on my printer scaled taller. I just used longer screws on the extruder side. The ones that come with the BLTouch are very long, so no issues on that side.

You might want to check and make sure your heat break block is turned the right way.

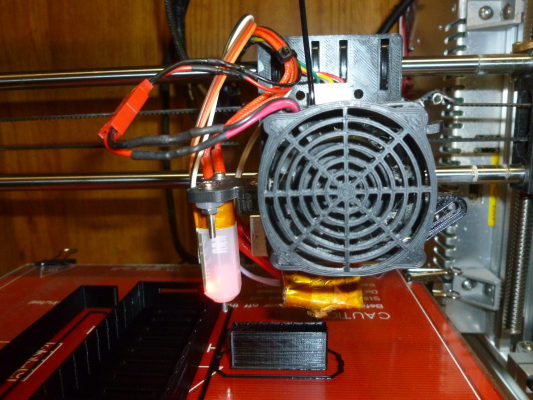

Not a good shot, but you can see it here:

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 18, 2016 07:24PM |

Registered: 8 years ago Posts: 541 |

Just uploaded my modification to the mount. I've been using it for a while now with no problems. I didn't have to adjust the height of the probe.

[www.thingiverse.com]

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

[www.thingiverse.com]

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 18, 2016 07:33PM |

Registered: 8 years ago Posts: 314 |

100% stock other than a lcd display... And I do have bearing's for the plastic spool... Not sure if I did that before or after I printed the boat?Quote

markts

Quote

UltiFix

First abs print! Wahoo!

The abs is green, and the clearish is glow in the dark pla.

Those do look great! Stock setup?

I'm jealous of you guys with the great overhangs.I printed and have been using a fan duct (separate fan) and even still, overhangs still come out "janky" (as my son puts it). At the moment I'm using a stock printer/hot end (though the E3DV6-lite is ready to go!), PLA at 175. With the fan running, is there anything else I should be looking to adjust? I've read you want the extrusion multiplier to be less than 100%, and the speed greater than 100% (I think I'm using 80%/150% ?) in order to "stretch" the plastic across the bridge. Is that the right approach? Any suggestions for S3D settings?

Im using cura, i like it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 18, 2016 07:34PM |

Registered: 8 years ago Posts: 314 |

yea, the spool is working great now! No unrollingQuote

flatlander

Quote

UltiFix

I took the extra bearing's and upgraded the spool holder, it's so smooth the spool is unrolling itself! Maybe that because I had to unwind some of it to get it off... Not sure.

I made some bearing-spool rings too. That glow-in-the-dark boat is really cool!

I took apart the hotend block and applied PTFE tape to all threads; the oozing of PLA from the top of the heat block is gone. FYI: I took it apart while applying heat (200 C) in the manual settings of Repetier-Host and got all the threads cleaned up while hot. I left the the heat-brake bloc attached so had a place to grab while placing the heat block into my wrenches.

|

Printing defect February 18, 2016 08:42PM |

Registered: 8 years ago Posts: 12 |

Was wondering if you guys could take a look at this and give me an idea where to start to fix it.

Print is a 20mm square X 100mm tall, single shell print in PLA. This one is at 200 degrees and a known good extrusion rate.

filament is Matterhackers.

Printer is a folger 2020 i3

That roughness is found on all 4 sides but is worse on the side nearest the x axis drive motor.

Any Ideas?

[imgur.com]

Print is a 20mm square X 100mm tall, single shell print in PLA. This one is at 200 degrees and a known good extrusion rate.

filament is Matterhackers.

Printer is a folger 2020 i3

That roughness is found on all 4 sides but is worse on the side nearest the x axis drive motor.

Any Ideas?

[imgur.com]

|

Re: Printing defect February 18, 2016 08:54PM |

Registered: 8 years ago Posts: 22 |

I had something like this happen that i fixed by disabling the wipe nozzle feature that i had checked off in S3D.. this was on thin walls and small details so it may not be your issue, worth a shot i guess. Also, check your retraction settings, when i had those set too high i was getting breaks in the extrusion.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 18, 2016 09:27PM |

Registered: 8 years ago Posts: 171 |

Quote

UltiFix

100% stock other than a lcd display... And I do have bearing's for the plastic spool... Not sure if I did that before or after I printed the boat?Quote

markts

Quote

UltiFix

First abs print! Wahoo!

The abs is green, and the clearish is glow in the dark pla.

Those do look great! Stock setup?

I'm jealous of you guys with the great overhangs.I printed and have been using a fan duct (separate fan) and even still, overhangs still come out "janky" (as my son puts it). At the moment I'm using a stock printer/hot end (though the E3DV6-lite is ready to go!), PLA at 175. With the fan running, is there anything else I should be looking to adjust? I've read you want the extrusion multiplier to be less than 100%, and the speed greater than 100% (I think I'm using 80%/150% ?) in order to "stretch" the plastic across the bridge. Is that the right approach? Any suggestions for S3D settings?

Im using cura, i like it.

Would you mind sharing your settings?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 18, 2016 10:08PM |

Registered: 8 years ago Posts: 85 |

Quote

UltiFix

Well, I have been printing like crazy and been having a ton of fun! Here are some pics... Planning to attach a 40mm fan to the extruder once it arrives.

Oh yeah, how are you guys attaching the glass to the bed? I have ran my hotend into those stupid black clamps.

[imgur.com]

Hey neat, that's the first one of my inductive sensor mounts I've seen printed other than the ones I made

Thanks so much for sharing that!

Thanks so much for sharing that!I really should update the 12mm version with the revisions I made to the 18mm one.....

What material did you print those in? Your funnel came out better than my first try at one, but your sensor mount is a lot rougher on the overhangs than any of mine came out. I've only printed them in ABS and PETG. Since it's right next to the hot end I don't trust PLA for it. But I tend to get better bridging/overhangs with PLA than PETG. ABS is sometimes better sometimes worse...still trying to figure out what's going on with bridging

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 18, 2016 10:56PM |

Registered: 8 years ago Posts: 314 |

Actually these setting's are from another kind person hereQuote

markts

Quote

UltiFix

100% stock other than a lcd display... And I do have bearing's for the plastic spool... Not sure if I did that before or after I printed the boat?Quote

markts

Quote

UltiFix

First abs print! Wahoo!

The abs is green, and the clearish is glow in the dark pla.

Those do look great! Stock setup?

I'm jealous of you guys with the great overhangs.I printed and have been using a fan duct (separate fan) and even still, overhangs still come out "janky" (as my son puts it). At the moment I'm using a stock printer/hot end (though the E3DV6-lite is ready to go!), PLA at 175. With the fan running, is there anything else I should be looking to adjust? I've read you want the extrusion multiplier to be less than 100%, and the speed greater than 100% (I think I'm using 80%/150% ?) in order to "stretch" the plastic across the bridge. Is that the right approach? Any suggestions for S3D settings?

Im using cura, i like it.

Would you mind sharing your settings?

So I can't take the credit

So I can't take the credit

Here ya go!

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 18, 2016 10:58PM |

Registered: 8 years ago Posts: 314 |

Some ebay pla plastic... I have since moved on and am using hatchbox, although I still have a bit left. I even used supports with the 12mm sensor mount D: Maybe I should try printing it agian with some higher quality plastic.Quote

jhitesma

Quote

UltiFix

Well, I have been printing like crazy and been having a ton of fun! Here are some pics... Planning to attach a 40mm fan to the extruder once it arrives.

Oh yeah, how are you guys attaching the glass to the bed? I have ran my hotend into those stupid black clamps.

[imgur.com]

Hey neat, that's the first one of my inductive sensor mounts I've seen printed other than the ones I madeThanks so much for sharing that!

I really should update the 12mm version with the revisions I made to the 18mm one.....

What material did you print those in? Your funnel came out better than my first try at one, but your sensor mount is a lot rougher on the overhangs than any of mine came out. I've only printed them in ABS and PETG. Since it's right next to the hot end I don't trust PLA for it. But I tend to get better bridging/overhangs with PLA than PETG. ABS is sometimes better sometimes worse...still trying to figure out what's going on with bridging

Please let me know if you upgrade the 12mm version

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Printing defect February 18, 2016 11:13PM |

Registered: 8 years ago Posts: 19 |

Looks like the x axis belt may have slop in it? Try tightening up the belt or adding belt tension spring.

Quote

JustAGuy

Was wanderings if you guys could take a look at this and give me an idea where to start to fix it.

Print is a 20mm square X 100mm tall, single shell print in PLA. This one is at 200 degrees and a known good extrusion rate.

filament is Matterhackers.

Printer is a folger 2020 i3

That roughness is found on all 4 sides but is worse on the side nearest the x axis drive motor.

Any Ideas?

[imgur.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 18, 2016 11:21PM |

Registered: 8 years ago Posts: 430 |

I finally cleaned up the wires and replaced the jet engine like power supply with a silent one.

[goo.gl]

I used this power supply from microcenter they had refurb ones for 22 dollars. This think makes no noise even with the printer running. Now it makes me want to find a more quiet one for the cool block.

Newbie with Folgertech 2020 i3.

[goo.gl]

I used this power supply from microcenter they had refurb ones for 22 dollars. This think makes no noise even with the printer running. Now it makes me want to find a more quiet one for the cool block.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 09:06AM |

Registered: 8 years ago Posts: 20 |

Quote

Bert3D

Quote

buffcleb

Quote

Bert3D

Quote

buffcleb

Did anyone have to cut the length of there BLTouch probe? If I use the adjuster to bring the probe high enough to clear the bottom of the nozzle in the raise position it is not able to lift itself... I am running off a 5v adjustable power supply for the BLTouch. I adjusted it for 5.4 volts to see if that helps... it did not...

I used this mount to mount the BLTouch : [www.thingiverse.com]

I order to get it to clear I removed some plastic from the extruder as I was not able to get it to mount... I'm thinking about making a new mount the raises it up as this one just does not work well... unless people cut the tip of the probe...

I raised the mount by scaling it at 300% along the Z axis in Slic3r before printing it. Was a lot quicker than making a new one.

you didn't run into clearance issues where it mounts to the hotend?

Nope. It fit fine on my printer scaled taller. I just used longer screws on the extruder side. The ones that come with the BLTouch are very long, so no issues on that side.

You might want to check and make sure your heat break block is turned the right way.

Not a good shot, but you can see it here:

I went a different route

With this setup I top mounted the BLTouch and flipped the mount over as there must be some variation in the extruders... there is no way your setup would not hit with my extruder... with this setup I was able to get it to work and successfully do an auto-level...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 09:34AM |

Registered: 8 years ago Posts: 171 |

Quote

UltiFix

Actually these setting's are from another kind person hereQuote

markts

Quote

UltiFix

100% stock other than a lcd display... And I do have bearing's for the plastic spool... Not sure if I did that before or after I printed the boat?Quote

markts

Quote

UltiFix

First abs print! Wahoo!

The abs is green, and the clearish is glow in the dark pla.

Those do look great! Stock setup?

I'm jealous of you guys with the great overhangs.I printed and have been using a fan duct (separate fan) and even still, overhangs still come out "janky" (as my son puts it). At the moment I'm using a stock printer/hot end (though the E3DV6-lite is ready to go!), PLA at 175. With the fan running, is there anything else I should be looking to adjust? I've read you want the extrusion multiplier to be less than 100%, and the speed greater than 100% (I think I'm using 80%/150% ?) in order to "stretch" the plastic across the bridge. Is that the right approach? Any suggestions for S3D settings?

Im using cura, i like it.

Would you mind sharing your settings?So I can't take the credit

Here ya go!

Awesome! Thanks - I'll give 'em a try!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 12:57PM |

Registered: 8 years ago Posts: 24 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 01:58PM |

Registered: 8 years ago Posts: 92 |

Quote

MuckYu

I have another small problem. I was trying to print a small button. After about 10 minutes the part is sticking to the extruder and the extruder is moving it around. Any reason for this to happen? I am printing with brim by the way

There are two things that I'm aware of that could cause this. First, it could be an adhesion issue. What material are you printing, and what are you printing on? Bare/glued glass? Heated or not? What temps on the bed and nozzle?

Second, if you are over-extruding, then the nozzle can knock into the top of the part. Adding a little z-hop (< .5mm), and the printer will lift the nozzle on travel moves, and may prevent this. For small parts, a little z-hop will not add much time, or wear on the threaded rods. Also, turning down your extrusion multiplier may help too.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 02:01PM |

Registered: 8 years ago Posts: 541 |

Have you calibrated your extruder? It sounds like you are putting out too much material and it is oozing up around the nozzle. Each layer of over extrusion will compound the problem. Calibrate! Don't use extrusion multiplier as a crutch to hide the real problem of poor calibration.

Edited 1 time(s). Last edit at 02/19/2016 02:03PM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

Edited 1 time(s). Last edit at 02/19/2016 02:03PM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 02:56PM |

Registered: 8 years ago Posts: 24 |

Quote

iamquestar

Quote

MuckYu

I have another small problem. I was trying to print a small button. After about 10 minutes the part is sticking to the extruder and the extruder is moving it around. Any reason for this to happen? I am printing with brim by the way

There are two things that I'm aware of that could cause this. First, it could be an adhesion issue. What material are you printing, and what are you printing on? Bare/glued glass? Heated or not? What temps on the bed and nozzle?

Second, if you are over-extruding, then the nozzle can knock into the top of the part. Adding a little z-hop (< .5mm), and the printer will lift the nozzle on travel moves, and may prevent this. For small parts, a little z-hop will not add much time, or wear on the threaded rods. Also, turning down your extrusion multiplier may help too.

Material: PLA

Surface: Bare glass + heated bed (cleaned with alcohol)

Extruder temp = 185° and heated bed = 60°

I only have this exact problem with small parts ("button size").

Bigger parts didn't have big problems so far. Only sometimes the corners warp. (I can print the same part 5 times and 2 of them would have the warping).

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 04:08PM |

Registered: 8 years ago Posts: 16 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 04:51PM |

Registered: 8 years ago Posts: 314 |

Im having an issue like this ever since I changed filament, may be over extruding...Quote

MuckYu

I have another small problem. I was trying to print a small button. After about 10 minutes the part is sticking to the extruder and the extruder is moving it around. Any reason for this to happen? I am printing with brim by the way

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 04:52PM |

Registered: 8 years ago Posts: 285 |

Quote

ihaveworms

What kind of extrusion multiplier are you all using? I am using 0.7 right now that seems really low, almost like I am doing something wrong.

Did you calibrate your extruders steps/mm?

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 05:25PM |

Registered: 8 years ago Posts: 92 |

Quote

tjnamtiw

Have you calibrated your extruder? It sounds like you are putting out too much material and it is oozing up around the nozzle. Each layer of over extrusion will compound the problem. Calibrate! Don't use extrusion multiplier as a crutch to hide the real problem of poor calibration.

Steps per mm is only part of the extruder calibration equation. Because different filaments can have some variance in diameter (or even shape), you generally will modify the extrusion multiplier for different filaments. I recently read this post and watched the videos linked there (this from way back on page 24!). There is some good info there:

Quote

mel0n

Quote

markts

Quote

mel0n

This had been exactly my experience up until I took the time to work through all the possible settings in slic3r, and print a lot of calibration/test shapes, and single extrusion width cubes to super fine tune my extrusion multiplier. (not measuring a 20mmx20mm cube as Tom points out is wrong)

I think Slic3r may be more susceptible to mechanical issues than Cura which is why I couldn't get slic3r to work well after I finished my build, but now that the vast majority of my mechanical issues are ironed out, I am getting better prints with slic3r than Cura. Especially since I understand a lot more about the entire process, and all the settings in the slicer/ how they affect the print.

Good to know! I'm up for learning about the process, just gotta make time for it.

When you say, "not measuring a 20mmx20mm cube as Tom points out is wrong", are you saying that you're making a mistake NOT measuring the 20x20 cube? Or Tom is wrong by suggesting that? (I think I can find the video you're referring to, but do you have a link handy? Is it just his extrusion calibration video?)

Sure! I am fine tuning my extrusion using methods such as these :

[www.youtube.com]

[www.youtube.com]

Here is Tom's video explaining why measuring a 20x20 cube is wrong:

[www.youtube.com]

So I am fine tuning the width of a single extrusion, not the width of a cube. And once you have been printing/playing enough you should have a pretty good grasp on how your slicer settings affect your print, and if not, EXPERIMENT!

Another thing to try with small parts: Blue tape. I know, I know, the glass bed is often preferable with its smooth finish, but if the parts small, there's little time wasted of you don't like it, but it may work.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 06:00PM |

Registered: 8 years ago Posts: 314 |

About 5 years ago a library near me would have 3d printing class, we designed stuff in sketchup and then the teacher converted it in some other program... The printer had a crapload of blue tape on the bed and they always had adhesion issues, if my memory serves me correctly the printer cost about 2k.Quote

iamquestar

Quote

tjnamtiw

Have you calibrated your extruder? It sounds like you are putting out too much material and it is oozing up around the nozzle. Each layer of over extrusion will compound the problem. Calibrate! Don't use extrusion multiplier as a crutch to hide the real problem of poor calibration.

Steps per mm is only part of the extruder calibration equation. Because different filaments can have some variance in diameter (or even shape), you generally will modify the extrusion multiplier for different filaments. I recently read this post and watched the videos linked there (this from way back on page 24!). There is some good info there:

Quote

mel0n

Quote

markts

Quote

mel0n

This had been exactly my experience up until I took the time to work through all the possible settings in slic3r, and print a lot of calibration/test shapes, and single extrusion width cubes to super fine tune my extrusion multiplier. (not measuring a 20mmx20mm cube as Tom points out is wrong)

I think Slic3r may be more susceptible to mechanical issues than Cura which is why I couldn't get slic3r to work well after I finished my build, but now that the vast majority of my mechanical issues are ironed out, I am getting better prints with slic3r than Cura. Especially since I understand a lot more about the entire process, and all the settings in the slicer/ how they affect the print.

Good to know! I'm up for learning about the process, just gotta make time for it.

When you say, "not measuring a 20mmx20mm cube as Tom points out is wrong", are you saying that you're making a mistake NOT measuring the 20x20 cube? Or Tom is wrong by suggesting that? (I think I can find the video you're referring to, but do you have a link handy? Is it just his extrusion calibration video?)

Sure! I am fine tuning my extrusion using methods such as these :

[www.youtube.com]

[www.youtube.com]

Here is Tom's video explaining why measuring a 20x20 cube is wrong:

[www.youtube.com]

So I am fine tuning the width of a single extrusion, not the width of a cube. And once you have been printing/playing enough you should have a pretty good grasp on how your slicer settings affect your print, and if not, EXPERIMENT!

Another thing to try with small parts: Blue tape. I know, I know, the glass bed is often preferable with its smooth finish, but if the parts small, there's little time wasted of you don't like it, but it may work.

Amazing, our cheap little printers print great without that blue tape everywhere

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 06:02PM |

Registered: 8 years ago Posts: 93 |

Oozing around nozzle? Did you hot-tighten your nozzle and the heat break tube/barrel into the heater block?

Don't assume the hot end comes assembled correctly. Mine wasn't, and I had similar problems. Before using the printer, you should heat up the hot end to around 240 and tighten the nozzle into the block, then tighten the heat break tube down firmly against it. This is easier to do if you hold the hot end block in pliers or even locking pliers, but you can also do it without taking the tube out of the printer. If you tighten it while it is cold, it will not be tight when it is hot, and will leak.

When I got my printer, the whole extruder and hot end came already put together, so I didn't even check it. But the throat was screwed way too far into the heater block, and the nozzle was just barely in the block at all, and eventually fell out while printing. It looked like they had stripped the threads trying to force the nozzle in further. Folger did send me a new hot end at no cost, but I wish I'd taken it apart and checked everything before I ever put filament through it.

To get it perfect, take the block, and screw the nozzle in until it stops, then back it off 1/4 to 1/2 turn. Then screw the heat break tube in to the block until it is tight against the nozzle. Then put in the thermistor and heater, and heat it up to 240 and tighten then both down until they are firm. The block is aluminum, so don't gorilla tighten it, or you will strip it out, but get it as solid as you can without over torqueing it. 5 newton/meters is about right if you want to use a small torque wrench, but generally as tight as you can get it with a wrench or pliers, without stripping anything. When it cools back down, it will all lock into place, and should never leak again. The indentation on the heat break tube should be just above the hot end block, and below the heat break block. The longer side of the tube goes in the heat break block, which is the big aluminum block that touches the motor and heat sink.

Edited 2 time(s). Last edit at 02/19/2016 06:07PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

Don't assume the hot end comes assembled correctly. Mine wasn't, and I had similar problems. Before using the printer, you should heat up the hot end to around 240 and tighten the nozzle into the block, then tighten the heat break tube down firmly against it. This is easier to do if you hold the hot end block in pliers or even locking pliers, but you can also do it without taking the tube out of the printer. If you tighten it while it is cold, it will not be tight when it is hot, and will leak.

When I got my printer, the whole extruder and hot end came already put together, so I didn't even check it. But the throat was screwed way too far into the heater block, and the nozzle was just barely in the block at all, and eventually fell out while printing. It looked like they had stripped the threads trying to force the nozzle in further. Folger did send me a new hot end at no cost, but I wish I'd taken it apart and checked everything before I ever put filament through it.

To get it perfect, take the block, and screw the nozzle in until it stops, then back it off 1/4 to 1/2 turn. Then screw the heat break tube in to the block until it is tight against the nozzle. Then put in the thermistor and heater, and heat it up to 240 and tighten then both down until they are firm. The block is aluminum, so don't gorilla tighten it, or you will strip it out, but get it as solid as you can without over torqueing it. 5 newton/meters is about right if you want to use a small torque wrench, but generally as tight as you can get it with a wrench or pliers, without stripping anything. When it cools back down, it will all lock into place, and should never leak again. The indentation on the heat break tube should be just above the hot end block, and below the heat break block. The longer side of the tube goes in the heat break block, which is the big aluminum block that touches the motor and heat sink.

Edited 2 time(s). Last edit at 02/19/2016 06:07PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 06:21PM |

Registered: 8 years ago Posts: 314 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 06:42PM |

Registered: 8 years ago Posts: 541 |

Quote

ihaveworms

What kind of extrusion multiplier are you all using? I am using 0.7 right now that seems really low, almost like I am doing something wrong.

Why would you use 0.7 extrusion multiplier?? It's there to make SMALL adjustments if your filament is not exactly 1.75 mm diameter. Using 0.7 is hiding a problem if your making good parts. That problem is that you need to calibrate your extruder, me thinks.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 06:45PM |

Registered: 8 years ago Posts: 541 |

Quote

UltiFix

I was reading about our folger tech printers and somebody said that if you replace the hotend it would be a much better printer, do you guys agree?

NO! The present FT extruder and hot end work just fine. If you read back through the posts, you'll see that it is more about 'tinkering' than improving. Some people swear other hot ends make better parts, probably to justify the investment, while others with the same hotend will admit that the new one just looks cooler!

These printers ARE a tinkerer's dream so to each his own but there are a lot of people who are perfectly happy with the original hotend.

These printers ARE a tinkerer's dream so to each his own but there are a lot of people who are perfectly happy with the original hotend.Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 06:50PM |

Registered: 8 years ago Posts: 541 |

Quote

MuckYu

Quote

iamquestar

Quote

MuckYu

I have another small problem. I was trying to print a small button. After about 10 minutes the part is sticking to the extruder and the extruder is moving it around. Any reason for this to happen? I am printing with brim by the way

There are two things that I'm aware of that could cause this. First, it could be an adhesion issue. What material are you printing, and what are you printing on? Bare/glued glass? Heated or not? What temps on the bed and nozzle?

Second, if you are over-extruding, then the nozzle can knock into the top of the part. Adding a little z-hop (< .5mm), and the printer will lift the nozzle on travel moves, and may prevent this. For small parts, a little z-hop will not add much time, or wear on the threaded rods. Also, turning down your extrusion multiplier may help too.

Material: PLA

Surface: Bare glass + heated bed (cleaned with alcohol)

Extruder temp = 185° and heated bed = 60°

I only have this exact problem with small parts ("button size").

Bigger parts didn't have big problems so far. Only sometimes the corners warp. (I can print the same part 5 times and 2 of them would have the warping).

You could also be printing too fast and the previous layer doesn't have time to cool and the nozzle keeps accumulating for plastic. Slow down dramatically to see if that helps.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

Sorry, only registered users may post in this forum.