Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 06:55PM |

Registered: 8 years ago Posts: 314 |

Well, by buying this printer I certianly didn't go for the asthetic route... LolQuote

tjnamtiw

Quote

UltiFix

I was reading about our folger tech printers and somebody said that if you replace the hotend it would be a much better printer, do you guys agree?

NO! The present FT extruder and hot end work just fine. If you read back through the posts, you'll see that it is more about 'tinkering' than improving. Some people swear other hot ends make better parts, probably to justify the investment, while others with the same hotend will admit that the new one just looks cooler!These printers ARE a tinkerer's dream so to each his own but there are a lot of people who are perfectly happy with the original hotend.

Talking about the asthetics, the guy that has his heatbed say makin sh$t, does he just print that out with paper or what? Wouldn't the heat mess it up?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 08:10PM |

Registered: 8 years ago Posts: 19 |

I agree and disagree at the same time with the hotend question. While I am able to print terrific prints at .05 where you cant see any lines at all with the factory MK9 extruder / hotend, I do know there is room for improvement and the more expensive extruders / hotends are an upgrade from the MK9. Matter of personal preference really. I'm personally satisfied with the the stock form ATM.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 08:46PM |

Registered: 8 years ago Posts: 24 |

Quote

tjnamtiw

Have you calibrated your extruder? It sounds like you are putting out too much material and it is oozing up around the nozzle. Each layer of over extrusion will compound the problem. Calibrate! Don't use extrusion multiplier as a crutch to hide the real problem of poor calibration.

I checked in the EEPROM settings. It was set to 90 mm (didn't have any problems with the settings before)

I then checked with the 100 mm extrusion measuring method to verify the correct extrusion length. Ended up changing it to 107 mm.

However - now the print looks kind of weird. The button I was printing before is now in an oval shape instead of circular

Maybe the settings before were better?

Maybe the settings before were better?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 09:26PM |

Registered: 8 years ago Posts: 285 |

Quote

MuckYu

Quote

tjnamtiw

Have you calibrated your extruder? It sounds like you are putting out too much material and it is oozing up around the nozzle. Each layer of over extrusion will compound the problem. Calibrate! Don't use extrusion multiplier as a crutch to hide the real problem of poor calibration.

I checked in the EEPROM settings. It was set to 90 mm (didn't have any problems with the settings before)

I then checked with the 100 mm extrusion measuring method to verify the correct extrusion length. Ended up changing it to 107 mm.

However - now the print looks kind of weird. The button I was printing before is now in an oval shape instead of circularMaybe the settings before were better?

If the extruder is properly calibrated and it gives worse prints, than I am pretty sure there is another underlying problem somewhere.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 10:39PM |

Registered: 8 years ago Posts: 131 |

Quote

MuckYu

Quote

tjnamtiw

Have you calibrated your extruder? It sounds like you are putting out too much material and it is oozing up around the nozzle. Each layer of over extrusion will compound the problem. Calibrate! Don't use extrusion multiplier as a crutch to hide the real problem of poor calibration.

I checked in the EEPROM settings. It was set to 90 mm (didn't have any problems with the settings before)

I then checked with the 100 mm extrusion measuring method to verify the correct extrusion length. Ended up changing it to 107 mm.

However - now the print looks kind of weird. The button I was printing before is now in an oval shape instead of circularMaybe the settings before were better?

Oval print sounds like either your x or y axis is out of calibration.

Edited 1 time(s). Last edit at 02/19/2016 10:39PM by marc2912.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 19, 2016 11:26PM |

Registered: 8 years ago Posts: 541 |

Quote

MuckYu

Quote

tjnamtiw

Have you calibrated your extruder? It sounds like you are putting out too much material and it is oozing up around the nozzle. Each layer of over extrusion will compound the problem. Calibrate! Don't use extrusion multiplier as a crutch to hide the real problem of poor calibration.

I checked in the EEPROM settings. It was set to 90 mm (didn't have any problems with the settings before)

I then checked with the 100 mm extrusion measuring method to verify the correct extrusion length. Ended up changing it to 107 mm.

However - now the print looks kind of weird. The button I was printing before is now in an oval shape instead of circularMaybe the settings before were better?

I'm assuming you mean you changed the estep from 90 to 107, not mm

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 20, 2016 12:06AM |

Registered: 8 years ago Posts: 3 |

Hi,

I'm in the process of using therippa's marlin code to enable auto-bed leveling on my 2020. Besides printer specific number changes, the code is as he uploaded it. I have gone through the auto-bed leveling section of the code and uncommented all of the define's, ifdef, etc. When I verify the code, i get an error of "exit status 1: 'define' does not name a type." for line 349: "define ENABLE_AUTO_BED_LEVELING." All of my files for this marlin code are in a single level folder located on my desktop. Does anyone have any suggestions of what to change to get this problem to go away?

Thanks in advance,

Caleb

I'm in the process of using therippa's marlin code to enable auto-bed leveling on my 2020. Besides printer specific number changes, the code is as he uploaded it. I have gone through the auto-bed leveling section of the code and uncommented all of the define's, ifdef, etc. When I verify the code, i get an error of "exit status 1: 'define' does not name a type." for line 349: "define ENABLE_AUTO_BED_LEVELING." All of my files for this marlin code are in a single level folder located on my desktop. Does anyone have any suggestions of what to change to get this problem to go away?

Thanks in advance,

Caleb

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 20, 2016 12:22AM |

Registered: 8 years ago Posts: 85 |

Quote

tjnamtiw

Quote

ihaveworms

What kind of extrusion multiplier are you all using? I am using 0.7 right now that seems really low, almost like I am doing something wrong.

Why would you use 0.7 extrusion multiplier?? It's there to make SMALL adjustments if your filament is not exactly 1.75 mm diameter. Using 0.7 is hiding a problem if your making good parts. That problem is that you need to calibrate your extruder, me thinks.

You need to broaden your horizons and print more than just PLA

I print PLA, ABS, and PETG (and hope to start printing nylon soon but want an all metal hot end to deal with the heat better before I dig in on that.)

My e steps are dialed in - when I extrude 100mm of filament I get 100mm of filament sucked through - even with the nozzle in and actually extruding.

But I run a 0.84 extrusion multiplier with PLA because otherwise my single wall test prints come out considerably thicker than they should. And yes, I've measured my filament and adjusted my filament size accordingly - but even with well sized PLA I get overextrusion with a multiplier of 1 even if my esteps are dead on.

With ABS I run a 0.918 multipler and with PETG I use a 1.

I think part of this is the nozzles from FT aren't horribly precise. I measured the free extrusion width (just raised my Z about 50mm above the bed and let it spit out some filament then measured the thickness of the string...and it was somewhat smaller than what some calculators I found suggested it should be for a 0.4mm nozzle. So I'm not convinced my 0.4mm nozzle really IS 0.4mm. It's only 2 months old so I doubt it's worn wider already but I could easily see the nozzle diameter being not super precise from FT.

If you're only running one material from one consistent vendor then I can see tweaking the e steps to get perfect extrusion. But it still seems like changing the steps on X/Y to get a perfect 20mm cube instead of addressing the problem correctly (as explained in Thomas' video.)

If you print a variety of materials then the extrusion multiplier is a godsend since e steps aren't the only factor.

Then again I freely admit I'm new at this (Got my printer just after Christmas) and mostly know how little I know. So I'm open to having my opinion on this changed. But if you're getting 100mm of filament fed through with your esteps and are still overextruding - then I would look at slicer settings rather than tweaking the e steps any further.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 20, 2016 08:22AM |

Registered: 8 years ago Posts: 13 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 20, 2016 08:22AM |

Registered: 8 years ago Posts: 541 |

Quote

jhitesma

Quote

tjnamtiw

Quote

ihaveworms

What kind of extrusion multiplier are you all using? I am using 0.7 right now that seems really low, almost like I am doing something wrong.

Why would you use 0.7 extrusion multiplier?? It's there to make SMALL adjustments if your filament is not exactly 1.75 mm diameter. Using 0.7 is hiding a problem if your making good parts. That problem is that you need to calibrate your extruder, me thinks.

You need to broaden your horizons and print more than just PLA

I print PLA, ABS, and PETG (and hope to start printing nylon soon but want an all metal hot end to deal with the heat better before I dig in on that.)

My e steps are dialed in - when I extrude 100mm of filament I get 100mm of filament sucked through - even with the nozzle in and actually extruding.

But I run a 0.84 extrusion multiplier with PLA because otherwise my single wall test prints come out considerably thicker than they should. And yes, I've measured my filament and adjusted my filament size accordingly - but even with well sized PLA I get overextrusion with a multiplier of 1 even if my esteps are dead on.

With ABS I run a 0.918 multipler and with PETG I use a 1.

I think part of this is the nozzles from FT aren't horribly precise. I measured the free extrusion width (just raised my Z about 50mm above the bed and let it spit out some filament then measured the thickness of the string...and it was somewhat smaller than what some calculators I found suggested it should be for a 0.4mm nozzle. So I'm not convinced my 0.4mm nozzle really IS 0.4mm. It's only 2 months old so I doubt it's worn wider already but I could easily see the nozzle diameter being not super precise from FT.

If you're only running one material from one consistent vendor then I can see tweaking the e steps to get perfect extrusion. But it still seems like changing the steps on X/Y to get a perfect 20mm cube instead of addressing the problem correctly (as explained in Thomas' video.)

If you print a variety of materials then the extrusion multiplier is a godsend since e steps aren't the only factor.

Then again I freely admit I'm new at this (Got my printer just after Christmas) and mostly know how little I know. So I'm open to having my opinion on this changed. But if you're getting 100mm of filament fed through with your esteps and are still overextruding - then I would look at slicer settings rather than tweaking the e steps any further.

I'm an engineer and take one step at a time, concerning your remark about 'broadening my horizons'. Rather than going helter skelter from one type of plastic to the next, I'd rather have fun and learn about one at a time and make one change at a time. When it's time, I'll probably jump right to PETG and avoid ABS and all its problems.

Also, having spent my entire working career, less military time, in plastics processing, I know about a phenomenon called 'die swell', which is different for each material. IF you want exactly 0.4 mm walls from a 0.4 mm die opening, then you WOULD use an extrusion multiplier to adjust for that for each material. But I'd have to ask 'Do you really want or need EXACTLY 0.4 mm width?'. You say "the wall test prints come out considerably thicker than they should". Just how thick do you think it should be? If the slicer moves over exactly 0.4 mm for the next row, then there will be little or no contact/adhesion to the previous row laid down. I'm talking on the same layer. It's all technical but the bottom line is DO WHAT WORKS FOR YOU. I just couldn't imagine a 0.7 extrusion multiplier NOT hiding an underlying problem elsewhere. But, hey, everyone can fabricate an answer for any problem. I just hate to see newcomers, me included, being led down the wrong path. There's MORE than enough confusion out there among all the people buying these printers without an inkling of knowledge as to mechanics or electronics.

NOTE: With you extruding a test 'string' up in the air, I would fully expect the thickness to be less than 0.4 mm since the weight of the plastic will stretch the extrudate as it exits the die and probably overcome any die swell that occurs. That's not a valid test method.

Edited 1 time(s). Last edit at 02/20/2016 08:51AM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 20, 2016 09:47AM |

Registered: 8 years ago Posts: 430 |

Quote

stanger2k

What do you guys recommend to do when you want to switch the type of filaments that you are using? Such as going from PLA to ABS and the other way around? I would think melting at the PLA temp would not melt the ABS but if you set the hot end to an ABS temp, then it would burn the PLA?

If you are worried about that heat the nozzle up to the temp of the filament that's in there and pull it out the top. Then set it to the temp of the new filament and load. There won't be enough left in there to matter. When I was using the direct drive extruder I would just cut it off, heat to the highest temp of the two filaments, start extruding then feed the new filament in the top. With the geared extruder I am using now I have to pull it out the top.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 20, 2016 12:02PM |

Registered: 8 years ago Posts: 314 |

How hard would it be to have 2 hotends both using differen't filaments? What whould I need to upgrade on a stock printer?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 20, 2016 01:26PM |

Registered: 8 years ago Posts: 85 |

Quote

tjnamtiw

I'm an engineer and take one step at a time, concerning your remark about 'broadening my horizons'. Rather than going helter skelter from one type of plastic to the next, I'd rather have fun and learn

about one at a time and make one change at a time. When it's time, I'll probably jump right to PETG and avoid ABS and all its problems.

I grew up in a house where my dad complained constantly about the engineers he had to work with...but later learned I would have loved to pursue engineering as a career path so try to play the part on the weekends now

My apologies for the antagonistic "broadening" comment, that was uncalled for, though in my defense the "Why would you use 0.7 extrusion multiplier??" comment put me on edge since for PLA I'm pretty close to 0.7.

My apologies for the antagonistic "broadening" comment, that was uncalled for, though in my defense the "Why would you use 0.7 extrusion multiplier??" comment put me on edge since for PLA I'm pretty close to 0.7.For me PLA isn't a great option, I live in the desert where 45c in the shade for weeks at a time is common. I've had PLA parts deform outside in the shade before the real heat hits. So While I did a bit of printing with PLA initially I'd always planned on tackling ABS - but then learned about PETG and found it much much more enjoyable to work with. Once I had PETG printing where I was happy with it I did go back and do some more work with ABS and have been VERY happy with what I can achieve with it, but without an enclosure (on my list but not there yet) it's about as good as it's going to get and not good enough for my goals. Right now I'm back to printing PLA and with the experience of working with PETG and ABS I've got my PLA doing better than I thought possible and am starting to soften towards it...but still worried about how brittle it is and the heat issues for my needs.

Quote

Also, having spent my entire working career, less military time, in plastics processing, I know about a phenomenon called 'die swell', which is different for each material. IF you want exactly 0.4 mm walls from a 0.4 mm die opening, then you WOULD use an extrusion multiplier to adjust for that for each material. But I'd have to ask 'Do you really want or need EXACTLY 0.4 mm width?'. You say "the wall test prints come out considerably thicker than they should". Just how thick do you think it should be? If the slicer moves over exactly 0.4 mm for the next row, then there will be little or no contact/adhesion to the previous row laid down. I'm talking on the same layer. It's all technical but the bottom line is DO WHAT WORKS FOR YOU. I just couldn't imagine a 0.7 extrusion multiplier NOT hiding an underlying problem elsewhere. But, hey, everyone can fabricate an answer for any problem. I just hate to see newcomers, me included, being led down the wrong path. There's MORE than enough confusion out there among all the people buying these printers without an inkling of knowledge as to mechanics or electronics.

I'm not expecting 0.4mm walls from a 0.4mm die. I fully understand that you don't get a 0.4mm extrusion out of a 0.4mm nozzle - and even if you did you wouldn't get 0.4mm wall thicknesses since the plastic has to "squish" for a number of reasons.

What I expect is a 0.48mm wall thickness because in slic3r that's waht I have set as my extrusion width. (Though I just yesterday learned that if you don't set it explicitly you can look in the gcode and find a comment at the top telling you what wall thickness slic3r calculated and is aiming for.)

I'm also not saying a 0.7mm multiplier isn't masking an underlying problem...but I don't believe it's a problem with the e steps if you're getting 100mm of filament sucked through when you ask for 100mm of extrusion. I suspect rather that it's an issue with the cheap hot end and extruder on our machines and the dynamics of what happens in the melt zone which I still barely have a grasp of.

I see it this way, steps (whether for extrusion or x/y/z) can and should be calculated. There seems to be little or no arguments about that for x/y/z but for some reason seems to really upset people when it's suggested for e steps. I suspect triffid hunters calibration guide is part of the reason...but that was written almost 5 years ago and while quite a bit about our machines and slicing software have changed since then very very little has changed about the guide.

I also admit that agreeing with the "extrude 100mm - measure - adjust steps" which I do agree contradicts my own opinion that steps should be calculated....I'm complex like that. (Taking a personality test in a psych class once I had to take it 5 times before it would accept my results because I gave "contradictory" answers too often...but to me the subtle changes in wording between questions were enough to change how I'd answer the question. I wasn't trying to cheat it...just as a programmer I tend to take things VERY literally sometimes!)

But it does make sense to me since accurate calculations of e steps are difficult for a number of reasons. So using an empirical method there makes sense to me.

It's the fine tuning in the TH guide that I have an issue with where it basically comes down to fine tuning by eye and using e steps for fine changes instead of the multiplier. I started loosing faith in the TH guide when I hit the line "Personally I go for layer height of 0.2mm, and extrusion width of 0.5mm regardless of which nozzle I'm using." immediately following a brief explanation of why those numbers change based on nozzle size. Why spend 4 paragraphs explaining how those are all interrelated and then say "but I ignore that and just go with these numbers on any size nozzle". That makes no sense to me.

When I first started dialing in my machine I was going crazy because I'd see things that looked like both under and over extrusion in the same print. It made no sense.

Then I changed from letting slic3r choose my extrusion width to setting it manually and suddenly EVERYTHING improved. I originally went with 0.45 based on the first calculator on this page: [nathan7.eu] Measuring my free extrusion width and doing a bit of math. I've since switched to 0.48 and things have gotten better - so perhaps (as you guessed) my methods of measuring my free extrusion were less than optimal thanks to our friend gravity.

I also still need to fine tune my layer heights...I'm printing at 0.2 out of laziness but with lead screws and a 0.4mm nozzle that's not exactly optimal I know.

Anyway I'm starting to drift off topic. My point is once TH gets into fine tuning e steps his methods come down to "how does it look" and I'm not a fan of "how does it look" as much as I am "how does it measure up". So to me printing single wall test objects and then measuring the wall thickness and comparing to what wall thickness slic3r was aiming for makes a LOT more sense for adjusting the extrusion multiplier and keeping my e steps consistent across filaments.

The method is also recommended by the original author of slic3r: [github.com] (who does agree with using TH's coarse e step cal method.)

I also admit that the "by eye" methods TH suggests were unusable for me partly due to my first rolls of filament. My first roll of PLA was orange from FT - and I didn't realize it was going to be a translucent orange. Trying to see individual infill layers even with a magnifier is all but impossible. Same with PETG, my first roll is translucent blue and hard to see exactly what's happening. So having a method that relies on measurement rather than visual observation really appeals to me.

Quote

NOTE: With you extruding a test 'string' up in the air, I would fully expect the thickness to be less than 0.4 mm since the weight of the plastic will stretch the extrudate as it exits the die and probably overcome any die swell that occurs. That's not a valid test method.

I was doing it very low to the bed and gently guiding (not pulling) the filament as it came out. Tried to find a better method but couldn't figure one out. Even so the measurements I got were fairly close to in line with what I expected. I've since switched from going by my measurement to going by the suggested calculation of 120% of the nozzle diameter and get even better results now.

Doing something like a 20x20 test cube I get 20 in all directions - or at least as accurate as my cheap calipers with their 0.03mm accuracy can measure. I see as much variation measuring the same face over and over as I do measuring different faces.

Doing the negative space test from Make I can now remove ALL of the pins including that nasty 0.2mm one. The dimensional accuracy test I'm dead on. Doing a test like this one: [www.thingiverse.com] I get the exact same readings in both diagonals (again within the accuracy of my calipers.)

So I'm pretty happy with how I have things dialed in using this method. I was able to print gzumwalt's demo spring: [www.thingiverse.com] off the original files and it all "just worked" when I assembled it with only a tiny tiny bit of sanding on the shafts and the dovetails. (the dovetails were actually the hardest part of that for me!)

Now I just need to get retraction and bridging dialed in as well and I'll be really happy. Getting close there but still convinced I can get better results without resorting to a new hot end

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 20, 2016 04:55PM |

Registered: 8 years ago Posts: 541 |

Quote

jhitesma

Quote

tjnamtiw

I'm an engineer and take one step at a time, concerning your remark about 'broadening my horizons'. Rather than going helter skelter from one type of plastic to the next, I'd rather have fun and learn

about one at a time and make one change at a time. When it's time, I'll probably jump right to PETG and avoid ABS and all its problems.

I grew up in a house where my dad complained constantly about the engineers he had to work with...but later learned I would have loved to pursue engineering as a career path so try to play the part on the weekends nowMy apologies for the antagonistic "broadening" comment, that was uncalled for, though in my defense the "Why would you use 0.7 extrusion multiplier??" comment put me on edge since for PLA I'm pretty close to 0.7.

For me PLA isn't a great option, I live in the desert where 45c in the shade for weeks at a time is common. I've had PLA parts deform outside in the shade before the real heat hits. So While I did a bit of printing with PLA initially I'd always planned on tackling ABS - but then learned about PETG and found it much much more enjoyable to work with. Once I had PETG printing where I was happy with it I did go back and do some more work with ABS and have been VERY happy with what I can achieve with it, but without an enclosure (on my list but not there yet) it's about as good as it's going to get and not good enough for my goals. Right now I'm back to printing PLA and with the experience of working with PETG and ABS I've got my PLA doing better than I thought possible and am starting to soften towards it...but still worried about how brittle it is and the heat issues for my needs.

Quote

Also, having spent my entire working career, less military time, in plastics processing, I know about a phenomenon called 'die swell', which is different for each material. IF you want exactly 0.4 mm walls from a 0.4 mm die opening, then you WOULD use an extrusion multiplier to adjust for that for each material. But I'd have to ask 'Do you really want or need EXACTLY 0.4 mm width?'. You say "the wall test prints come out considerably thicker than they should". Just how thick do you think it should be? If the slicer moves over exactly 0.4 mm for the next row, then there will be little or no contact/adhesion to the previous row laid down. I'm talking on the same layer. It's all technical but the bottom line is DO WHAT WORKS FOR YOU. I just couldn't imagine a 0.7 extrusion multiplier NOT hiding an underlying problem elsewhere. But, hey, everyone can fabricate an answer for any problem. I just hate to see newcomers, me included, being led down the wrong path. There's MORE than enough confusion out there among all the people buying these printers without an inkling of knowledge as to mechanics or electronics.

I'm not expecting 0.4mm walls from a 0.4mm die. I fully understand that you don't get a 0.4mm extrusion out of a 0.4mm nozzle - and even if you did you wouldn't get 0.4mm wall thicknesses since the plastic has to "squish" for a number of reasons.

What I expect is a 0.48mm wall thickness because in slic3r that's waht I have set as my extrusion width. (Though I just yesterday learned that if you don't set it explicitly you can look in the gcode and find a comment at the top telling you what wall thickness slic3r calculated and is aiming for.)

I'm also not saying a 0.7mm multiplier isn't masking an underlying problem...but I don't believe it's a problem with the e steps if you're getting 100mm of filament sucked through when you ask for 100mm of extrusion. I suspect rather that it's an issue with the cheap hot end and extruder on our machines and the dynamics of what happens in the melt zone which I still barely have a grasp of.

I see it this way, steps (whether for extrusion or x/y/z) can and should be calculated. There seems to be little or no arguments about that for x/y/z but for some reason seems to really upset people when it's suggested for e steps. I suspect triffid hunters calibration guide is part of the reason...but that was written almost 5 years ago and while quite a bit about our machines and slicing software have changed since then very very little has changed about the guide.

I also admit that agreeing with the "extrude 100mm - measure - adjust steps" which I do agree contradicts my own opinion that steps should be calculated....I'm complex like that. (Taking a personality test in a psych class once I had to take it 5 times before it would accept my results because I gave "contradictory" answers too often...but to me the subtle changes in wording between questions were enough to change how I'd answer the question. I wasn't trying to cheat it...just as a programmer I tend to take things VERY literally sometimes!)

But it does make sense to me since accurate calculations of e steps are difficult for a number of reasons. So using an empirical method there makes sense to me.

It's the fine tuning in the TH guide that I have an issue with where it basically comes down to fine tuning by eye and using e steps for fine changes instead of the multiplier. I started loosing faith in the TH guide when I hit the line "Personally I go for layer height of 0.2mm, and extrusion width of 0.5mm regardless of which nozzle I'm using." immediately following a brief explanation of why those numbers change based on nozzle size. Why spend 4 paragraphs explaining how those are all interrelated and then say "but I ignore that and just go with these numbers on any size nozzle". That makes no sense to me.

When I first started dialing in my machine I was going crazy because I'd see things that looked like both under and over extrusion in the same print. It made no sense.

Then I changed from letting slic3r choose my extrusion width to setting it manually and suddenly EVERYTHING improved. I originally went with 0.45 based on the first calculator on this page: [nathan7.eu] Measuring my free extrusion width and doing a bit of math. I've since switched to 0.48 and things have gotten better - so perhaps (as you guessed) my methods of measuring my free extrusion were less than optimal thanks to our friend gravity.

I also still need to fine tune my layer heights...I'm printing at 0.2 out of laziness but with lead screws and a 0.4mm nozzle that's not exactly optimal I know.

Anyway I'm starting to drift off topic. My point is once TH gets into fine tuning e steps his methods come down to "how does it look" and I'm not a fan of "how does it look" as much as I am "how does it measure up". So to me printing single wall test objects and then measuring the wall thickness and comparing to what wall thickness slic3r was aiming for makes a LOT more sense for adjusting the extrusion multiplier and keeping my e steps consistent across filaments.

The method is also recommended by the original author of slic3r: [github.com] (who does agree with using TH's coarse e step cal method.)

I also admit that the "by eye" methods TH suggests were unusable for me partly due to my first rolls of filament. My first roll of PLA was orange from FT - and I didn't realize it was going to be a translucent orange. Trying to see individual infill layers even with a magnifier is all but impossible. Same with PETG, my first roll is translucent blue and hard to see exactly what's happening. So having a method that relies on measurement rather than visual observation really appeals to me.

Quote

NOTE: With you extruding a test 'string' up in the air, I would fully expect the thickness to be less than 0.4 mm since the weight of the plastic will stretch the extrudate as it exits the die and probably overcome any die swell that occurs. That's not a valid test method.

I was doing it very low to the bed and gently guiding (not pulling) the filament as it came out. Tried to find a better method but couldn't figure one out. Even so the measurements I got were fairly close to in line with what I expected. I've since switched from going by my measurement to going by the suggested calculation of 120% of the nozzle diameter and get even better results now.

Doing something like a 20x20 test cube I get 20 in all directions - or at least as accurate as my cheap calipers with their 0.03mm accuracy can measure. I see as much variation measuring the same face over and over as I do measuring different faces.

Doing the negative space test from Make I can now remove ALL of the pins including that nasty 0.2mm one. The dimensional accuracy test I'm dead on. Doing a test like this one: [www.thingiverse.com] I get the exact same readings in both diagonals (again within the accuracy of my calipers.)

So I'm pretty happy with how I have things dialed in using this method. I was able to print gzumwalt's demo spring: [www.thingiverse.com] off the original files and it all "just worked" when I assembled it with only a tiny tiny bit of sanding on the shafts and the dovetails. (the dovetails were actually the hardest part of that for me!)

Now I just need to get retraction and bridging dialed in as well and I'll be really happy. Getting close there but still convinced I can get better results without resorting to a new hot end

Now That was some very interesting reading and you got ME to thinking and rethinking my methods! For measuring that extruded width, I'd slice something simple and put one line around it for starting. Then I'd raise my zero point up about 1 mm (I have BLTOUCH auto bed leveling) in the config.h file. Then I'd start the printing and stop it after it had laid down that outer line. Being up a mm would prevent any squishing.

Man, now you have me really curious as to how to attack this! hahaha.

I really enjoyed your post and I agree with you about the 'fine tuning' from TH. I read that whole thing and said "huh?".

I can also see why you shied away from PLA, being out there in the desert. I'm glad to hear you find PET easy to use. I may get a roll to play with. I have a dozen rolls of PLA of all colors!!! One word explanation > WIFE...............

Again, I enjoyed it and understand now. Thanks!!!

PS: That Make tolerance test looks like a great way to see if you are over extruding! I'll be playing with that tomorrow! Thanks for the inspiration!

Edited 1 time(s). Last edit at 02/20/2016 09:23PM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 20, 2016 11:11PM |

Registered: 8 years ago Posts: 85 |

Quote

tjnamtiw

Now That was some very interesting reading and you got ME to thinking and rethinking my methods! For measuring that extruded width, I'd slice something simple and put one line around it for starting. Then I'd raise my zero point up about 1 mm (I have BLTOUCH auto bed leveling) in the config.h file. Then I'd start the printing and stop it after it had laid down that outer line. Being up a mm would prevent any squishing.

Sorry about the novel...apparently my morning coffee kicked in and I didn't notice

Interesting idea on measuring the free extrusion. I toyed with just taking the extruder off and holding it right against the bed sideways so the bead could fall free...but doubt I could hold it steady enough to get a decent result. I'd love to try one of those bltouch's but am super happy with my inductive sensor. (Need to do a post on that, it got even better for me after a recent change - I now get no variation between probes doing a M48 - originally I was seeing a very small variance, much lower than what I've seen from servo setups. But I suspect the BL should do just as well and in some ways better since you don't have to account for the thickness of the glass.)

Interesting idea on measuring the free extrusion. I toyed with just taking the extruder off and holding it right against the bed sideways so the bead could fall free...but doubt I could hold it steady enough to get a decent result. I'd love to try one of those bltouch's but am super happy with my inductive sensor. (Need to do a post on that, it got even better for me after a recent change - I now get no variation between probes doing a M48 - originally I was seeing a very small variance, much lower than what I've seen from servo setups. But I suspect the BL should do just as well and in some ways better since you don't have to account for the thickness of the glass.)Quote

Man, now you have me really curious as to how to attack this! hahaha.

I really enjoyed your post and I agree with you about the 'fine tuning' from TH. I read that whole thing and said "huh?".

I can also see why you shied away from PLA, being out there in the desert. I'm glad to hear you find PET easy to use. I may get a roll to play with. I have a dozen rolls of PLA of all colors!!! One word explanation > WIFE...............

I love printing with PLA, it's so easy and I get such great results! But for a lot of my needs it's just not practical. I really wish it was because there are so many things I like about it. If I lived anywhere else it would be my first choice for sure.

That was a PLA RaspberryPi box a friend sent me last March. I had it outside out of the sun and under cover with good ventillation...but by mid June this happened to it.

I put the pieces under some bricks (not even in the sun) and in an hour they were flat as a board again

Now that I have my own printer though I look forward to doing some more tests on my own printed parts and how they handle our summers. Though given what our summer did to Henry Rollins I don't have much hope: [www.phoenixnewtimes.com] (And we hadn't even hit the hot part of summer yet when he visited.)

My wife barely tolerates my new obsession - even when I print her things

But my birthday is coming up in a few weeks and a package was delivered to her from OpenBuilds on Friday (though apparently she didn't fully understand my request because it's too small to have any rail in it

But my birthday is coming up in a few weeks and a package was delivered to her from OpenBuilds on Friday (though apparently she didn't fully understand my request because it's too small to have any rail in it  ) so it seems she at least doesn't mind occasionally encouraging me. She feels the 5 rolls of filament I have already should be enough. Even though 4 of them are getting really low and 1 is utter junk (not a fan of FT's ABS). And she still gets to pick the colors

) so it seems she at least doesn't mind occasionally encouraging me. She feels the 5 rolls of filament I have already should be enough. Even though 4 of them are getting really low and 1 is utter junk (not a fan of FT's ABS). And she still gets to pick the colors

Quote

Again, I enjoyed it and understand now. Thanks!!!

PS: That Make tolerance test looks like a great way to see if you are over extruding! I'll be playing with that tomorrow! Thanks for the inspiration!

Glad to hear we found common ground and made each other think! That's what I love about these kinds of projects - all kinds of new ideas to get exposed to and get the ideas flowing.

Now I just have to find a good test object for the retraction issue I'm having. I'm getting repeatable zits on the outside of my prints from retraction. Parts with low infill come out great. But parts with high infill where it does somewhat funky moves on the fill it leaves zits on the outside when it changes. May try printing some solid cubes instead of hollow cubes. I'm pretty sure I know what settings I need to tweak...just the only parts I've been printing where the problem shows up are really long prints and not great for testing!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 20, 2016 11:58PM |

Registered: 8 years ago Posts: 13 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 21, 2016 09:34AM |

Registered: 8 years ago Posts: 541 |

Quote

jhitesma

I love printing with PLA, it's so easy and I get such great results! But for a lot of my needs it's just not practical. I really wish it was because there are so many things I like about it. If I lived anywhere else it would be my first choice for sure.

[attachment 72981 11659960_10152870596651805_1606402430_o2.jpg]

That was a PLA RaspberryPi box a friend sent me last March. I had it outside out of the sun and under cover with good ventillation...but by mid June this happened to it.

My wife barely tolerates my new obsession - even when I print her thingsBut my birthday is coming up in a few weeks and a package was delivered to her from OpenBuilds on Friday (though apparently she didn't fully understand my request because it's too small to have any rail in it

) so it seems she at least doesn't mind occasionally encouraging me. She feels the 5 rolls of filament I have already should be enough. Even though 4 of them are getting really low and 1 is utter junk (not a fan of FT's ABS). And she still gets to pick the colors

Yes, the heat intolerance of the PLA is a real drawback, I know. I made a new holder for the guts of a garage door opener that got STEPPED ON for my son. He insists on putting it on his dash. It will never make it through the summer! KIDS!!

I want to do the single wall test today. I sliced it with Reptier and Cura and I examined the G Code, but it doesn't say what it expects the thickness to be. Is it always the 0.67 mm that the video shows? ((NOTE: of course it won't be since they are using 3.0 mm filament!)) I'll also try my idea of raising the head slightly and laying down the outer start-up loop to see if it's 120% of 0.4 or 0.48 mm.

Edited 1 time(s). Last edit at 02/21/2016 10:39AM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 21, 2016 02:34PM |

Registered: 8 years ago Posts: 85 |

Quote

tjnamtiw

I want to do the single wall test today. I sliced it with Reptier and Cura and I examined the G Code, but it doesn't say what it expects the thickness to be. Is it always the 0.67 mm that the video shows? ((NOTE: of course it won't be since they are using 3.0 mm filament!)) I'll also try my idea of raising the head slightly and laying down the outer start-up loop to see if it's 120% of 0.4 or 0.48 mm.

I've had no luck getting Cura to slice single wall objects so far

It's the main reason I haven't put more effort into getting better results from Cura.

It's the main reason I haven't put more effort into getting better results from Cura.I've been explicitly setting the extrusion width in slic3r Print Settings -> Advanced -> Default Extrusion Width and I see it showing up as the 3rd line in my generated gcode files as a comment. I haven't let slic3r figure it automatically in some time and don't have any gcode from when I did handy to see if it was including it then. I still have all my other extrusion widths set to 0 for automatic (except for first layer which I have at 200% for good adhesion)

I did mostly solve my zit problem last night by enabling external perimeters first, bumping my retraction 0.5mm, and disabling both retract on layer change and wipe while retracting (funny thing, I had enabled those two so solve a similar problem with PETG - but with PLA they seem to cause the same problem they mostly cured on the PET). In fact, I may have gone too far because now I see some tiny pinholes where some of the zits used to be

I did find that a 20mm solid cube was a good test object, but I only printed about the first 5-7mm - with 70% infill that was enough to get the zits repeatably. I tried doing some versions with some cutouts and curves to show the retraction more but they didn't make a big difference. Still at 7mm tall it only takes about 15 minutes to print so it's nice for testing.

I did find that a 20mm solid cube was a good test object, but I only printed about the first 5-7mm - with 70% infill that was enough to get the zits repeatably. I tried doing some versions with some cutouts and curves to show the retraction more but they didn't make a big difference. Still at 7mm tall it only takes about 15 minutes to print so it's nice for testing.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 21, 2016 02:47PM |

Registered: 8 years ago Posts: 541 |

Quote

jhitesma

Quote

tjnamtiw

I want to do the single wall test today. I sliced it with Reptier and Cura and I examined the G Code, but it doesn't say what it expects the thickness to be. Is it always the 0.67 mm that the video shows? ((NOTE: of course it won't be since they are using 3.0 mm filament!)) I'll also try my idea of raising the head slightly and laying down the outer start-up loop to see if it's 120% of 0.4 or 0.48 mm.

I've had no luck getting Cura to slice single wall objects so farIt's the main reason I haven't put more effort into getting better results from Cura.

I've been explicitly setting the extrusion width in slic3r Print Settings -> Advanced -> Default Extrusion Width and I see it showing up as the 3rd line in my generated gcode files as a comment. I haven't let slic3r figure it automatically in some time and don't have any gcode from when I did handy to see if it was including it then. I still have all my other extrusion widths set to 0 for automatic (except for first layer which I have at 200% for good adhesion)

I did mostly solve my zit problem last night by enabling external perimeters first, bumping my retraction 0.5mm, and disabling both retract on layer change and wipe while retracting (funny thing, I had enabled those two so solve a similar problem with PETG - but with PLA they seem to cause the same problem they mostly cured on the PET). In fact, I may have gone too far because now I see some tiny pinholes where some of the zits used to beI did find that a 20mm solid cube was a good test object, but I only printed about the first 5-7mm - with 70% infill that was enough to get the zits repeatably. I tried doing some versions with some cutouts and curves to show the retraction more but they didn't make a big difference. Still at 7mm tall it only takes about 15 minutes to print so it's nice for testing.

I printed two single wall _40x10 test pieces and saw that 0.9 extrusion multiplier brought it down to a wall of 0.48 mm. I'm printing the pin test piece right now.

I don't see any comments in my code but I just discovered that I have 'verbose gcode' turned off in slic3r. After this is done, I'll turn it on. It says that if you use SD cards, verbose mode could slow the processor down.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 21, 2016 03:12PM |

Registered: 8 years ago Posts: 19 |

I absolutely love PLA since it prints great for me. I agree, the FT ABS I got is a bit of a PITA to use. I bought some wood filament that I'm pretty stoked to try but I'm not certain this stock MK9 setup will do it justice.

@jhitesma, Why do you no longer have your marlin firmware listed in your signature? Your files are the only reason my auto level is working like a champ now

Edited 3 time(s). Last edit at 02/21/2016 08:29PM by bmays.

@jhitesma, Why do you no longer have your marlin firmware listed in your signature? Your files are the only reason my auto level is working like a champ now

Edited 3 time(s). Last edit at 02/21/2016 08:29PM by bmays.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 21, 2016 03:20PM |

Registered: 8 years ago Posts: 367 |

Quote

bmays

I absolutely love PLA since it prints great for me. I agree, the FT ABS I got is a but of a PITA to use. I bought some wood filament that I'm pretty stoked to try but I'm not certain this stock MK9 setup will do it justice.

@jhitesma, Why do you no longer have your marlin firmware listed in your signature? Your files are the only reason my auto level is working like a champ now

I have not had good experiences with the wood filaments. The ones with very fine particles don't give much of a wood appearance and the ones with larger particles can block a 0.4mm nozzle. [docs.google.com] tracks some of the filaments I've played with.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 21, 2016 08:03PM |

Registered: 8 years ago Posts: 430 |

Here's a stepper motor PSA.

Make sure you have all four screws holding the motor together. My extruder stopped working. After messing around a while I finally removed the motor and discovered I couldn't turn the shaft by hand. I only had two two of the screws in there holding the case together and the sideways pressure of the belt driven extruder caused the armature to get wedged. After taking the motor apart and putting in four screws it's working fine again.

Newbie with Folgertech 2020 i3.

Make sure you have all four screws holding the motor together. My extruder stopped working. After messing around a while I finally removed the motor and discovered I couldn't turn the shaft by hand. I only had two two of the screws in there holding the case together and the sideways pressure of the belt driven extruder caused the armature to get wedged. After taking the motor apart and putting in four screws it's working fine again.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 21, 2016 08:32PM |

Registered: 8 years ago Posts: 19 |

Quote

animoose

Quote

bmays

I absolutely love PLA since it prints great for me. I agree, the FT ABS I got is a but of a PITA to use. I bought some wood filament that I'm pretty stoked to try but I'm not certain this stock MK9 setup will do it justice.

@jhitesma, Why do you no longer have your marlin firmware listed in your signature? Your files are the only reason my auto level is working like a champ now

I have not had good experiences with the wood filaments. The ones with very fine particles don't give much of a wood appearance and the ones with larger particles can block a 0.4mm nozzle. [docs.google.com] tracks some of the filaments I've played with.

I picked up some from filabits on your recommendation, not sure if its a lot or a little wood. Just got a small sample. I'll have to pick up a .5 nozzle then.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 21, 2016 08:53PM |

Registered: 8 years ago Posts: 367 |

Quote

bmays

Quote

animoose

Quote

bmays

I absolutely love PLA since it prints great for me. I agree, the FT ABS I got is a but of a PITA to use. I bought some wood filament that I'm pretty stoked to try but I'm not certain this stock MK9 setup will do it justice.

@jhitesma, Why do you no longer have your marlin firmware listed in your signature? Your files are the only reason my auto level is working like a champ now

I have not had good experiences with the wood filaments. The ones with very fine particles don't give much of a wood appearance and the ones with larger particles can block a 0.4mm nozzle. [docs.google.com] tracks some of the filaments I've played with.

I picked up some from filabits on your recommendation, not sure if its a lot or a little wood. Just got a small sample. I'll have to pick up a .5 nozzle then.

Let me know how it goes - I will be interested to hear more experiences of it.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 21, 2016 10:36PM |

Registered: 8 years ago Posts: 85 |

Quote

bmays

I absolutely love PLA since it prints great for me. I agree, the FT ABS I got is a bit of a PITA to use. I bought some wood filament that I'm pretty stoked to try but I'm not certain this stock MK9 setup will do it justice.

@jhitesma, Why do you no longer have your marlin firmware listed in your signature? Your files are the only reason my auto level is working like a champ now

I've never had a signature, keep meaning to set one up and then forgetting

You may be thinking of TheRippa who has the latest stable Marlin in his signature. I do have my own branch of the latest RC3 here: [github.com] but have never bothered putting it in my sig.

I tried a bit of wood filament from cubicity using their samples, It did pretty good, didn't jam anything up and smelled great while printing. But I didn't have everything fully dialed in for it and the print wasn't quite as clean as I get from PLA. I kind of love/hate samples - like getting to experiment, just wish the samples were bigger so I could relax and get things dialed in before trying to actually print something with it

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 21, 2016 10:40PM |

Registered: 8 years ago Posts: 85 |

Quote

tjnamtiw

I printed two single wall _40x10 test pieces and saw that 0.9 extrusion multiplier brought it down to a wall of 0.48 mm. I'm printing the pin test piece right now.

Did you manually set the extrusion width to 0.48? I wouldn't worry about the comments if you're setting it manually.

Quote

I don't see any comments in my code but I just discovered that I have 'verbose gcode' turned off in slic3r. After this is done, I'll turn it on. It says that if you use SD cards, verbose mode could slow the processor down.

I just checked and I don't have verbose mode enabled.

Here's what the top my gcode output from slic3r looks like:

; generated by Slic3r 1.2.9 on 2016-02-21 at 09:58:32 ; external perimeters extrusion width = 0.48mm ; perimeters extrusion width = 0.48mm ; infill extrusion width = 0.48mm ; solid infill extrusion width = 0.48mm ; top infill extrusion width = 0.48mm M190 S70 ; set bed temperature G28 ; home all axes G29; Autolevel

Those last 2 lines are from my start g-code under printer settings.

Not sure what I may have enabled to get that there

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 21, 2016 10:49PM |

Registered: 8 years ago Posts: 85 |

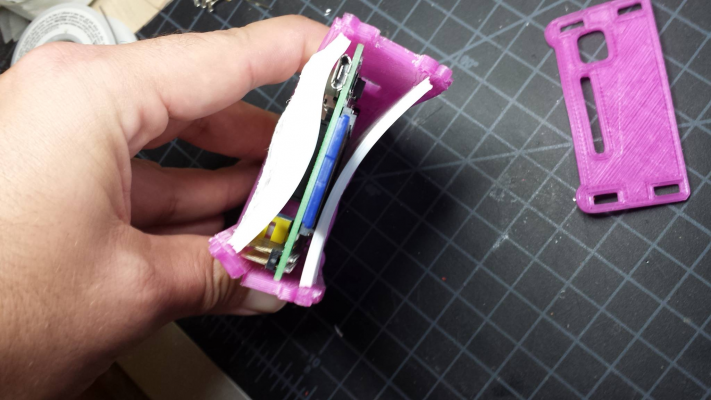

Pretty happy with this:

Didn't even have to chase the bolt holes for things to fit - snug but not too snug to get a bolt through with gentle pushing. My overhangs still need some fine tuning but the zits and pits are finally gone. All that's left is what I'm pretty sure is some ringing from the cheap bearings which I'm not going to worry about tuning out.

And the parts are printing almost twice as fast as the designer predicted now (instead of twice as slow as they were before.) Still taking longer than Repetier/Octoprint/slic3r predict but back to just 20-40% over the estimate instead of double the estimate!

Didn't even have to chase the bolt holes for things to fit - snug but not too snug to get a bolt through with gentle pushing. My overhangs still need some fine tuning but the zits and pits are finally gone. All that's left is what I'm pretty sure is some ringing from the cheap bearings which I'm not going to worry about tuning out.

And the parts are printing almost twice as fast as the designer predicted now (instead of twice as slow as they were before.) Still taking longer than Repetier/Octoprint/slic3r predict but back to just 20-40% over the estimate instead of double the estimate!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 22, 2016 12:01AM |

Registered: 8 years ago Posts: 367 |

Results of some experiments I did on the extrusion multiplier: [moosteria.blogspot.com]

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 22, 2016 01:25AM |

Registered: 8 years ago Posts: 85 |

Quote

animoose

Results of some experiments I did on the extrusion multiplier: [moosteria.blogspot.com]

Interesting to see your take on it, your blog and results played a large roll in me getting this printer and the upgrade paths I've chosen

This is some interesting reading I meant to link into my novel length post but forgot to include: [manual.slic3r.org] It addresses the question you raised in your blog post about why the wall thickness is so much bigger than the nozzle diameter far more thoroughly than I can

Though reading through it again now for the first time in a a few weeks I'm thinking about removing my manual 0.48mm setting and instead letting slic3er pick the sizes - but checking my gcode to see if the sizes it picks are there and then measuring to see how close I get to them.

Totally unrelated...but last week I got a C.H.I.P I had kickstarted because...hey $9 computer! Think RaspPi only $9, built in wifi and bluetooth, built in 4gb of storage, smaller, and on the downside considerably less I/O. I had no real plans for it when I backed it, but once I ordered my printer I started wondering how it would do running Octoprint.

Well, I set that up on Friday and have been using it most of the weekend and can confirm it works. Though I've also decided I'm not 100% huge on Octoprint, I could adapt to it, but it works best if I slice right in slic3r and send from there to OP without using rep-host. And I like the plating tools in rep-host far better than the ones in slic3r. I also like the quick slicing overrides in rep-host a lot and missed them. I was also disappointed in the mobile options with OP, the official android app is tablet only, but won't find my octoprint installation even though I have autodiscovery confirmed working, and I can't find any way to set it up manually

The two apps in the play store are also very lacking. One is out of date abandonware that looked nice but doesn't work with current versions of OP. And the other is really kind of crummy looking, spams me with constant notifications, and just doesn't seem to work in some ways

The two apps in the play store are also very lacking. One is out of date abandonware that looked nice but doesn't work with current versions of OP. And the other is really kind of crummy looking, spams me with constant notifications, and just doesn't seem to work in some ways

Still the allure of the stability I get from printing with SD but the ability to watch a visualization as it prints and not having to take the SD card in and out all appeal to me.

So I just tossed repetier-server on the C.H.I.P and have the first print running that way. So far I'm much more impressed by Rep-server than I was by OP. Seems much more polished and full featured. I may even spring the $4 for their android app to try.

The only drawback to using the C.H.I.P over a Pi so far is that the stock kernet the C.H.I.P comes with doesn't support webcams

There are people who've compiled custom kernels and confirmed it's got the power to keep up with a cam - but recompiling the kernel is rather complex and takes a full Linux machine or VM with more space than I have available on any of my current linux machines. But maybe over the next few weeks I can clear out some space and give that a try. Would be very nice to have webcam support!

There are people who've compiled custom kernels and confirmed it's got the power to keep up with a cam - but recompiling the kernel is rather complex and takes a full Linux machine or VM with more space than I have available on any of my current linux machines. But maybe over the next few weeks I can clear out some space and give that a try. Would be very nice to have webcam support!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 22, 2016 09:38AM |

Registered: 8 years ago Posts: 541 |

There's been a lot of discussion on this forum about alternate controllers from Arduino to Raspberry Pi to CHIP. I'm from a manufacturing/engineering/robotic/machine control background and I'm familiar with a type of programming called ladder logic, although I've used everything from Basic to C along the way. I am wondering if anyone knows about a really fully supported (many peripherals and free programming language) group of controllers called CUBLOC. [www.comfiletech.com]

While they may not have direct usage to control a printer, I wouldn't put it past some of the guru's here to find a way. This old fart is beyond that stage in life! I have two pellet stoves and found it easy to use ladder logic to mimic the control systems and safeties on them with CUBLOC controllers. You can program in both Basic and ladder logic and use subroutines to jump back and forth. Very intriguing. You can even link in touch screen displays (at an upcharge, of course!! $$$).

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

While they may not have direct usage to control a printer, I wouldn't put it past some of the guru's here to find a way. This old fart is beyond that stage in life! I have two pellet stoves and found it easy to use ladder logic to mimic the control systems and safeties on them with CUBLOC controllers. You can program in both Basic and ladder logic and use subroutines to jump back and forth. Very intriguing. You can even link in touch screen displays (at an upcharge, of course!! $$$).

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

Sorry, only registered users may post in this forum.