Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 28, 2016 10:53PM |

Registered: 8 years ago Posts: 92 |

Quote

UltiFix

Im planning on installing auto level with this proximity switch, below I have made a list of everything I need to do, anything else?

Also since im moving the x endstop to left do I need to change anything in the firmware?

- Upgrade to therippa's firmware

- Move X endstop to left and change the setting's from max to min in rep host

- Change the code in configuration.h that the wiki says to

- Wire it up to the ramps, no idea how to... Help?

Good luck! I'm in the midst of the struggle now.

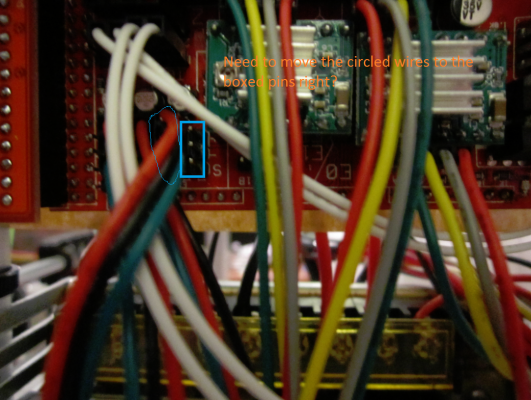

When moving the x end stop to the left, you need to move the plug over one, then in configuration.h you need to set the x home direction like the others:

#define X_HOME_DIR -1 #define Y_HOME_DIR -1 #define Z_HOME_DIR -1

I used this sensor: [www.amazon.com]

YMMV but it arrived in less than 2 weeks, Rather than the 4 Amazon estimated,

I will be typing up a detailed post about all the issues, but not until tomorrow. All at the same time, I decided to upgrade the x-axis to v-slot (Y axis coming soon), install lead screws, raise the z axis motors, go to a new j-head with bowden extruder, install the inductive sensor and get autoleveling going. I wouldn't recommend doing that much at once... I haven't printed since Wednesday and am going through withdrawal :-) !

I have been fighting with the software all afternoon, but finally got the printer to do a 9 point probe of the surface. The issue I have dealt with was the Y-max Endstop No matter what I did, it would display triggered along with the Y-Min, or Z-Min. It didn't matter if I had const bool Y_MAX_ENDSTOP_INVERTING = true; or false! I would do a m119 and get all as being open, the i'd home Y or Z and then do another m119, and find Y-max now triggered along with whatever else was triggered, This would prevent the Y axis from moving diring the autoleveling.

I thought maybe I had some solder bridges in the Ramps, but I pulled that and inspected it with magnifiers and tested with a multi-meter, and all was OK. I thought maybe I had something messed up in the firmware so I downloaded theRippas latest and started from scratch. Nope-it still didn't work.

I finally had to plug in a spare endstop (setting its inversion to true) and just have it hanging there for the reading to finally read "open" reliably. It was crazy, Anyone seen anything like that?

At anyrate, I should be ready to start calibrating the new extruder once I finish adjusting the Z off-set. I'll let you all know how it goes. I'll also detail how I hooked up the induction sensor and got it working. But that will come tomorrow (or later tonight if I feel ambitious)

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 11:12AM |

Registered: 8 years ago Posts: 16 |

Thanks. I changed the E steps per millimeter to be 101 after doing 2 calibration tests of extruding 100mm of filament. I now have my extrusion multiplier at 1.Quote

Mach

Quote

ihaveworms

Where in the configuration do you set steps per millimeter?Quote

Mach

Quote

ihaveworms

What kind of extrusion multiplier are you all using? I am using 0.7 right now that seems really low, almost like I am doing something wrong.

Did you calibrate your extruders steps/mm?

"#define DEFAULT_AXIS_STEPS_PER_UNIT". The parameters are X, Y, Z, E from left to right.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 03:34PM |

Registered: 8 years ago Posts: 92 |

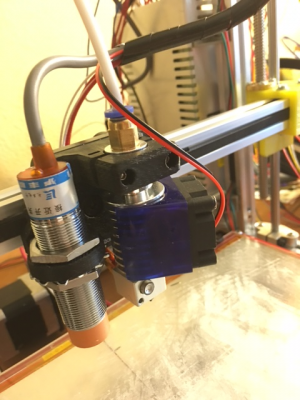

As I mentioned, I promised to detail how I hooked up the induction sensor. The one I got (LJ18A3-8-Z/BX) has an 8mm sense distance (lower with aluminum or thin galvanized). It runs on 6-36 volts (like most that are available) and has a diameter of 18mm. I used Sonnylowe's E3D V6 mini Gantry mount ( [www.thingiverse.com] ), and modified it to take an 18mm sensor.

I had heard about some running the sensors successfully on 5v (therefore making it possible to plug right in, in exchange for the z End-stop) but many others had sensors that would not work on 5v, so I decided not to try. The sensor has three wires, Brown, Black and Blue. Be sure to verify the wiring on your own sensor, but on Mine, Brown was for the +v DC supply, Blue was the ground (or -v DC), and black is the signal. I hooked up the brown to one of the +12v terminals on the power supply (I tied it in with the extruder fan), and the Blue one to one of the -12v terminals on the power supply (also the one I used for the extruder fan).

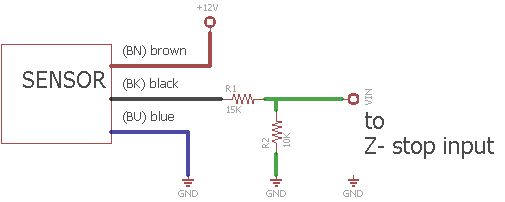

Since I'm supplying 12v to the sensor, the sensor will output 12v on the signal wire. That needs to be reduced to between 3-5 volts, or you could fry the Arduino. So I wired up a voltage divider. On the end of the Black wire, I soldered on a 15K ohm resistor, then on the other side of that I soldered a 10k ohm resistor, and the signal wire. The signal wire then went to a connector, and is plugged in to the bottom pin (where the green wire from the endstops attaches) on the Z-Min port (but don't plug it in until you've tested it!). Another wire is soldered to the end of the 10k resistor, and that is hooked up with the blue wire from the sensor, (to ground) on the -12v terminal of the PS.

Sorry - I meant to take a pic of this, but forgot to do so until I had already covered everything with heat-shrink tubing.

This is the schematic (image credit: mickeypop on Instructables):

To test, plug in the power supply. Use a multi-meter and check for voltage on the sensor wire. Depending on the sensor, you'll see either 0v or somewhere between 3.8-4.8 volts. (my divider is putting out 3.9v) Place a wrench, or the end of some pliers under the sensor. the light on it should light up. Check the sensor voltage again. If it was 0v, it should now be reading between 3-5 volts. If you had voltage before, it should be reading 0. If all looks good (especially the reading being below 5v) then you are good to plug it into the Ramps.

Again, depending on if the sensor is normally open (signal reads 0v when NOT triggered) or normally closed (signal reads 3-5v when NOT triggered) you'll need to adjust the line in the configuration.h file appropriately.

I hope this is helpful to some of you. If I wasn't clear about anything, please let me know. I'd be happy to answer any questions anyone has.

--Andrew

I had heard about some running the sensors successfully on 5v (therefore making it possible to plug right in, in exchange for the z End-stop) but many others had sensors that would not work on 5v, so I decided not to try. The sensor has three wires, Brown, Black and Blue. Be sure to verify the wiring on your own sensor, but on Mine, Brown was for the +v DC supply, Blue was the ground (or -v DC), and black is the signal. I hooked up the brown to one of the +12v terminals on the power supply (I tied it in with the extruder fan), and the Blue one to one of the -12v terminals on the power supply (also the one I used for the extruder fan).

Since I'm supplying 12v to the sensor, the sensor will output 12v on the signal wire. That needs to be reduced to between 3-5 volts, or you could fry the Arduino. So I wired up a voltage divider. On the end of the Black wire, I soldered on a 15K ohm resistor, then on the other side of that I soldered a 10k ohm resistor, and the signal wire. The signal wire then went to a connector, and is plugged in to the bottom pin (where the green wire from the endstops attaches) on the Z-Min port (but don't plug it in until you've tested it!). Another wire is soldered to the end of the 10k resistor, and that is hooked up with the blue wire from the sensor, (to ground) on the -12v terminal of the PS.

Sorry - I meant to take a pic of this, but forgot to do so until I had already covered everything with heat-shrink tubing.

This is the schematic (image credit: mickeypop on Instructables):

To test, plug in the power supply. Use a multi-meter and check for voltage on the sensor wire. Depending on the sensor, you'll see either 0v or somewhere between 3.8-4.8 volts. (my divider is putting out 3.9v) Place a wrench, or the end of some pliers under the sensor. the light on it should light up. Check the sensor voltage again. If it was 0v, it should now be reading between 3-5 volts. If you had voltage before, it should be reading 0. If all looks good (especially the reading being below 5v) then you are good to plug it into the Ramps.

Again, depending on if the sensor is normally open (signal reads 0v when NOT triggered) or normally closed (signal reads 3-5v when NOT triggered) you'll need to adjust the line in the configuration.h file appropriately.

const bool Y_MAX_ENDSTOP_INVERTING = true;For a normally open switch, this would be set to false. For a normally closed switch (like the ones shipped with the printer, and the sensor I have) this would be set to true.

I hope this is helpful to some of you. If I wasn't clear about anything, please let me know. I'd be happy to answer any questions anyone has.

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 03:46PM |

Registered: 8 years ago Posts: 22 |

I use this same sensor (LJ18A3-8-Z/BX DC 6-36V NPN 3-wire 8mm Inductive Proximity Sensor Switch Detector) and did not need to use a voltage divider. I have it plugged into my 12V power supply with my extruder fan and LEDs (as you have done), signal and ground into Z-stop input. From what I have been told, NPN sensors do not need a voltage divider - and it works as intended for me with this setup. I think the reason being that for NPN sensors do not have any voltage going back to the board on the signal wire.. i'm not an expert so don't hold me to this

Edited 1 time(s). Last edit at 02/29/2016 03:49PM by thebabymaker.

Edited 1 time(s). Last edit at 02/29/2016 03:49PM by thebabymaker.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 04:50PM |

Registered: 8 years ago Posts: 85 |

Quote

thebabymaker

I use this same sensor (LJ18A3-8-Z/BX DC 6-36V NPN 3-wire 8mm Inductive Proximity Sensor Switch Detector) and did not need to use a voltage divider. I have it plugged into my 12V power supply with my extruder fan and LEDs (as you have done), signal and ground into Z-stop input. From what I have been told, NPN sensors do not need a voltage divider - and it works as intended for me with this setup. I think the reason being that for NPN sensors do not have any voltage going back to the board on the signal wire.. i'm not an expert so don't hold me to this

You may want to check that. I'm using the same sensor (mine is blue but it's the same model number and specs) and was able to run it off 5v...but not reliably. It would work sometimes and not at all at others. So I switched to 12v. But before I did I checked it with a volt meter and confirmed that it IS 12v coming off it. So you may be on borrowed time and just lucky that your arduino hasn't fried yet.

Adding the two resistors to drop the voltage is quick and easy and a lot cheaper than replacing arduino's

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 04:59PM |

Registered: 8 years ago Posts: 22 |

Quote

jhitesma

Quote

thebabymaker

I use this same sensor (LJ18A3-8-Z/BX DC 6-36V NPN 3-wire 8mm Inductive Proximity Sensor Switch Detector) and did not need to use a voltage divider. I have it plugged into my 12V power supply with my extruder fan and LEDs (as you have done), signal and ground into Z-stop input. From what I have been told, NPN sensors do not need a voltage divider - and it works as intended for me with this setup. I think the reason being that for NPN sensors do not have any voltage going back to the board on the signal wire.. i'm not an expert so don't hold me to this

You may want to check that. I'm using the same sensor (mine is blue but it's the same model number and specs) and was able to run it off 5v...but not reliably. It would work sometimes and not at all at others. So I switched to 12v. But before I did I checked it with a volt meter and confirmed that it IS 12v coming off it. So you may be on borrowed time and just lucky that your arduino hasn't fried yet.

Adding the two resistors to drop the voltage is quick and easy and a lot cheaper than replacing arduino's

It's been running flawlessly for a month now - and i basically never turn off my printer.. so far so good! I have an orange sensor, did not work off 5v.. we may not have the same thing. I've seen it said in a few places that NPN NO sensors do not require a voltage divider. I had a PM with CDRU from here that advised me that it was not necessary which is what I went by.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 05:03PM |

Registered: 8 years ago Posts: 22 |

Do you have a link to the sensor you bought? LJ18A3-8-Z/BY is blue and is a pnp sensor that would need a voltage divider, the BX version is orange and is NPN which does not need a voltage divider.

EDIT: Actually i see a blue version of the BX too. lol i dont know anymore

Edited 1 time(s). Last edit at 02/29/2016 05:05PM by thebabymaker.

EDIT: Actually i see a blue version of the BX too. lol i dont know anymore

Edited 1 time(s). Last edit at 02/29/2016 05:05PM by thebabymaker.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 07:15PM |

Registered: 8 years ago Posts: 1 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 08:45PM |

Registered: 8 years ago Posts: 92 |

Quote

thebabymaker

Do you have a link to the sensor you bought? LJ18A3-8-Z/BY is blue and is a pnp sensor that would need a voltage divider, the BX version is orange and is NPN which does not need a voltage divider.

EDIT: Actually i see a blue version of the BX too. lol i dont know anymore

Here's the one I bought: (It's orange)

[www.amazon.com]

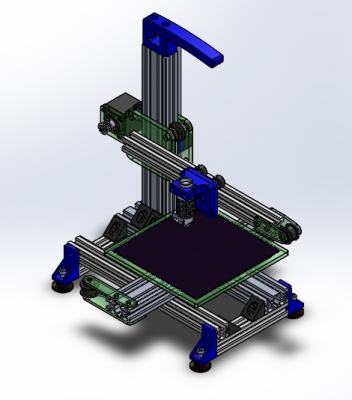

Here's a pic (notice the hot end/boden setup and v-slot x-axis w/ lead screws I installed this weekend):

PNP vs NPN largely only affects whether the switch is normally closed or normally open. See below for the info I got from a user on instructables regarding the issue. I believe he used this same sensor. This was in the comments of this: [www.instructables.com]

Quote

mickeypop Reply 4 months ago

I have seen several comments on a voltage divider and the hookup. (schematic below)

ABSOLUTELY, you do need the divider to protect the micro input pin.

Though 15K and 10K are most often noted, any pair where one is 1.5 times higher and both range between say 7K and 25K should work.

Some have noted their Z output from the divider was around 6V and still work.

The length of the wire and connection resistance may be the only things preventing the micro pin from damage.

This will likely shorten the life of the arduino. Atmel spec on the micro allow .3 volt higher max than the supply(5v).

If the output is around 6V a diode in series will steal .7 volt and greatly extend the arduino life. Alternatively, a 1.2K to 2K instead of the diode should also work.

Any voltage out between 3.3 and 5 volts will be best for the micro to detect it and safe from pin damage.

-------

Separately, several have mentioned capacitive sensors. I strongly suggest you stay away from them and only use inductive or the micro switch idea some have used.

Like standing close to a radio and the reception changes. The sensing distance is not constant if you are move around the printer the sensing distance will change too.

Electronics Engineer

I would HIGHLY encourage you to measure the output of the sensor, and if it's more than 5 volts, you may want to reconsider a voltage divider. Just because you havn't had an issue yet, doesn't mean you wont. All the same, you could make no change, and never have a problem. For me, I am confident that I don't have to worry about it because of the steps I took (and it really wasn't that hard).

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 08:51PM |

Registered: 8 years ago Posts: 130 |

Quote

marlonaraujo85

someone would have the assembly drawing to bed this printer?

Try the FolgerTech-2020-i3-Build-Manual-Rev-A.pdf, the document with the broken image link, at the following google drive (the soldering instructions are near page 9):

[drive.google.com]

Edited to remove cheekyness.

Edited 1 time(s). Last edit at 03/01/2016 08:51AM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 08:53PM |

Registered: 8 years ago Posts: 22 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 09:34PM |

Registered: 8 years ago Posts: 93 |

Speaking in general, and not specifically about proximity sensors, the reason some kinds of sensors don't absolutely require the drop down, is that they use a "pull down" approach to the output. They allow the pull-up resistors on the Arduino (or whatever else they are plugged into) to provide the voltage to bring the input to a "1" or "on" status, with the output from the sensor "floating" in a passive state, essentially providing no signal, then when they are active, they pull the output to 0 volts, grounding it, which turns it off or "0". This is called the sensor "sinking", or grounding out, the current.

Not all sensors work this way, and I cannot speak to these, since I don't have either part. I'm just pointing out that it is possible that some sensors can be ok.

However, if the sensor is a "pull up" type, it pulls the output up to voltage. In that case, if it is a 12 volt part, it will try to pull it up to 12v by supplying 12v on the output, which would definitely fry the Arduino. In this case the sensor is sourcing the current, which means providing the voltage.

Also, just because a sensor is PNP or NPN doesn't guarantee there are no internal pull-up resistors in it, so you can't always rely on that alone. You really need to read the datasheet for the specific part to know for certain. Most NPN sensors don't have internal pull up resistors, but a few do.

Ok, I pulled up the datasheet for these parts. The BX and BY are both NO (Normally Open). The BX is an NPN, and the BY is a PNP. The PNP will require the voltage divider. The NPN appears to have no internal pull up, so you should be ok without the voltage divider on that one.

And I apologize for the electronics lesson. I know nobody was asking for one, and I really didn't intend to turn this into one.

Edited 4 time(s). Last edit at 02/29/2016 10:25PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

Not all sensors work this way, and I cannot speak to these, since I don't have either part. I'm just pointing out that it is possible that some sensors can be ok.

However, if the sensor is a "pull up" type, it pulls the output up to voltage. In that case, if it is a 12 volt part, it will try to pull it up to 12v by supplying 12v on the output, which would definitely fry the Arduino. In this case the sensor is sourcing the current, which means providing the voltage.

Also, just because a sensor is PNP or NPN doesn't guarantee there are no internal pull-up resistors in it, so you can't always rely on that alone. You really need to read the datasheet for the specific part to know for certain. Most NPN sensors don't have internal pull up resistors, but a few do.

Ok, I pulled up the datasheet for these parts. The BX and BY are both NO (Normally Open). The BX is an NPN, and the BY is a PNP. The PNP will require the voltage divider. The NPN appears to have no internal pull up, so you should be ok without the voltage divider on that one.

And I apologize for the electronics lesson. I know nobody was asking for one, and I really didn't intend to turn this into one.

Edited 4 time(s). Last edit at 02/29/2016 10:25PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 10:57PM |

Registered: 8 years ago Posts: 85 |

It is the BX/NPN that I have, I don't have the link to it anymore but I made sure to get the NPN because I'd read the same threads and didn't want to bother with soldering up a resistor ladder to drop the voltage.

But, I also don't trust much of anything anyone if I can test it for myself. So before connecting it I hooked my volt meter between the signal wire and ground and triggered the sensor. And sure enough I saw 12v on there. So I wired up the voltage divider to play it safe.

I've had boards last when run overpowered - I ran a STM32 Discovery board with 5v fed to the 3.3v rails by mistake for over a year on one of my quadcopters and it flew great. But I'm amazed that processor didn't let out the magic smoke. I've also had boards fry going less than a volt over their limit on an input pin. So I tend to try and play it safe if I can.

But, I also don't trust much of anything anyone if I can test it for myself. So before connecting it I hooked my volt meter between the signal wire and ground and triggered the sensor. And sure enough I saw 12v on there. So I wired up the voltage divider to play it safe.

I've had boards last when run overpowered - I ran a STM32 Discovery board with 5v fed to the 3.3v rails by mistake for over a year on one of my quadcopters and it flew great. But I'm amazed that processor didn't let out the magic smoke. I've also had boards fry going less than a volt over their limit on an input pin. So I tend to try and play it safe if I can.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 11:30PM |

Registered: 8 years ago Posts: 314 |

This is the one I got, here is the datasheet for it..Quote

Bert3D

Speaking in general, and not specifically about proximity sensors, the reason some kinds of sensors don't absolutely require the drop down, is that they use a "pull down" approach to the output. They allow the pull-up resistors on the Arduino (or whatever else they are plugged into) to provide the voltage to bring the input to a "1" or "on" status, with the output from the sensor "floating" in a passive state, essentially providing no signal, then when they are active, they pull the output to 0 volts, grounding it, which turns it off or "0". This is called the sensor "sinking", or grounding out, the current.

Not all sensors work this way, and I cannot speak to these, since I don't have either part. I'm just pointing out that it is possible that some sensors can be ok.

However, if the sensor is a "pull up" type, it pulls the output up to voltage. In that case, if it is a 12 volt part, it will try to pull it up to 12v by supplying 12v on the output, which would definitely fry the Arduino. In this case the sensor is sourcing the current, which means providing the voltage.

Also, just because a sensor is PNP or NPN doesn't guarantee there are no internal pull-up resistors in it, so you can't always rely on that alone. You really need to read the datasheet for the specific part to know for certain. Most NPN sensors don't have internal pull up resistors, but a few do.

Ok, I pulled up the datasheet for these parts. The BX and BY are both NO (Normally Open). The BX is an NPN, and the BY is a PNP. The PNP will require the voltage divider. The NPN appears to have no internal pull up, so you should be ok without the voltage divider on that one.

And I apologize for the electronics lesson. I know nobody was asking for one, and I really didn't intend to turn this into one.

[industrial.omron.com.br]

The datasheet says its a npn-no so im correct in thinking I don't need a resister right? And it's always closed right? (Outputting no voltage)

Edited 2 time(s). Last edit at 02/29/2016 11:32PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 11:38PM |

Registered: 8 years ago Posts: 93 |

Quote

UltiFix

This is the one I got, here is the datasheet for it..Quote

Bert3D

Speaking in general, and not specifically about proximity sensors, the reason some kinds of sensors don't absolutely require the drop down, is that they use a "pull down" approach to the output. They allow the pull-up resistors on the Arduino (or whatever else they are plugged into) to provide the voltage to bring the input to a "1" or "on" status, with the output from the sensor "floating" in a passive state, essentially providing no signal, then when they are active, they pull the output to 0 volts, grounding it, which turns it off or "0". This is called the sensor "sinking", or grounding out, the current.

Not all sensors work this way, and I cannot speak to these, since I don't have either part. I'm just pointing out that it is possible that some sensors can be ok.

However, if the sensor is a "pull up" type, it pulls the output up to voltage. In that case, if it is a 12 volt part, it will try to pull it up to 12v by supplying 12v on the output, which would definitely fry the Arduino. In this case the sensor is sourcing the current, which means providing the voltage.

Also, just because a sensor is PNP or NPN doesn't guarantee there are no internal pull-up resistors in it, so you can't always rely on that alone. You really need to read the datasheet for the specific part to know for certain. Most NPN sensors don't have internal pull up resistors, but a few do.

Ok, I pulled up the datasheet for these parts. The BX and BY are both NO (Normally Open). The BX is an NPN, and the BY is a PNP. The PNP will require the voltage divider. The NPN appears to have no internal pull up, so you should be ok without the voltage divider on that one.

And I apologize for the electronics lesson. I know nobody was asking for one, and I really didn't intend to turn this into one.

[industrial.omron.com.br]

The datasheet says its a npn-no so im correct in thinking I don't need a resister right? And it's always closed right? (Outputting no voltage)

The datasheet says it includes a pull up resistor, so you will probably need the resistors to drop the voltage with that one.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) February 29, 2016 11:41PM |

Registered: 8 years ago Posts: 314 |

Your right, I missed that.Quote

Bert3D

Quote

UltiFix

This is the one I got, here is the datasheet for it..Quote

Bert3D

Speaking in general, and not specifically about proximity sensors, the reason some kinds of sensors don't absolutely require the drop down, is that they use a "pull down" approach to the output. They allow the pull-up resistors on the Arduino (or whatever else they are plugged into) to provide the voltage to bring the input to a "1" or "on" status, with the output from the sensor "floating" in a passive state, essentially providing no signal, then when they are active, they pull the output to 0 volts, grounding it, which turns it off or "0". This is called the sensor "sinking", or grounding out, the current.

Not all sensors work this way, and I cannot speak to these, since I don't have either part. I'm just pointing out that it is possible that some sensors can be ok.

However, if the sensor is a "pull up" type, it pulls the output up to voltage. In that case, if it is a 12 volt part, it will try to pull it up to 12v by supplying 12v on the output, which would definitely fry the Arduino. In this case the sensor is sourcing the current, which means providing the voltage.

Also, just because a sensor is PNP or NPN doesn't guarantee there are no internal pull-up resistors in it, so you can't always rely on that alone. You really need to read the datasheet for the specific part to know for certain. Most NPN sensors don't have internal pull up resistors, but a few do.

Ok, I pulled up the datasheet for these parts. The BX and BY are both NO (Normally Open). The BX is an NPN, and the BY is a PNP. The PNP will require the voltage divider. The NPN appears to have no internal pull up, so you should be ok without the voltage divider on that one.

And I apologize for the electronics lesson. I know nobody was asking for one, and I really didn't intend to turn this into one.

[industrial.omron.com.br]

The datasheet says its a npn-no so im correct in thinking I don't need a resister right? And it's always closed right? (Outputting no voltage)

The datasheet says it includes a pull up resistor, so you will probably need the resistors to drop the voltage with that one.

Thanks!

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 01, 2016 05:29AM |

Registered: 8 years ago Posts: 22 |

Quote

Bert3D

Speaking in general, and not specifically about proximity sensors, the reason some kinds of sensors don't absolutely require the drop down, is that they use a "pull down" approach to the output. They allow the pull-up resistors on the Arduino (or whatever else they are plugged into) to provide the voltage to bring the input to a "1" or "on" status, with the output from the sensor "floating" in a passive state, essentially providing no signal, then when they are active, they pull the output to 0 volts, grounding it, which turns it off or "0". This is called the sensor "sinking", or grounding out, the current.

Not all sensors work this way, and I cannot speak to these, since I don't have either part. I'm just pointing out that it is possible that some sensors can be ok.

However, if the sensor is a "pull up" type, it pulls the output up to voltage. In that case, if it is a 12 volt part, it will try to pull it up to 12v by supplying 12v on the output, which would definitely fry the Arduino. In this case the sensor is sourcing the current, which means providing the voltage.

Also, just because a sensor is PNP or NPN doesn't guarantee there are no internal pull-up resistors in it, so you can't always rely on that alone. You really need to read the datasheet for the specific part to know for certain. Most NPN sensors don't have internal pull up resistors, but a few do.

Ok, I pulled up the datasheet for these parts. The BX and BY are both NO (Normally Open). The BX is an NPN, and the BY is a PNP. The PNP will require the voltage divider. The NPN appears to have no internal pull up, so you should be ok without the voltage divider on that one.

And I apologize for the electronics lesson. I know nobody was asking for one, and I really didn't intend to turn this into one.

Thanks for the response. I was actually hoping for an electronics lesson! Thanks.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 01, 2016 10:04AM |

Registered: 8 years ago Posts: 130 |

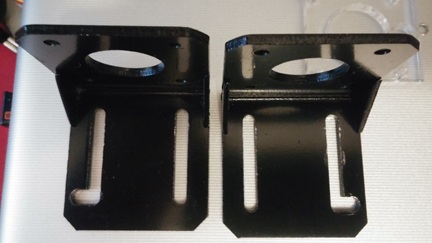

I had an itch caused by not attaching the lower bolts to the bottom of the motor mounts...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 01, 2016 11:04AM |

Registered: 8 years ago Posts: 4 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 01, 2016 11:07AM |

Registered: 8 years ago Posts: 32 |

Quote

flatlander

I had an itch caused by not attaching the lower bolts to the bottom of the motor mounts...

[attachment 73640 NEMA17motormountslotL.jpg]

Nice! I had the same itch, but I made some new Rod Holder Plates with a smaller hole for the threaded rod (I'm using Z-motor standoffs) and the hole for the straight rod centered to the screw holes.

I can share the STL if anyone wants it....

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 01, 2016 06:30PM |

Registered: 8 years ago Posts: 130 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 01, 2016 07:25PM |

Registered: 8 years ago Posts: 171 |

I have the E3d V6 Lite installed and it seems to be printing well. I still get some clicking/missing from the extruder. I remember I had to play with temperatures with the stock hotend, so I probably have to do that again (now that I'm printing at 195 instead of 175).

I didn't replace the gear that grabs the filament. They seemed to be the same size, and I thought, "Why take the chance of messing something up?" Is there a difference? I'm also planning to calibrate the extruder just in case anything's changed.

Is there a difference? I'm also planning to calibrate the extruder just in case anything's changed.

Last issue - the new fan from E3D is LOUD. It also must be blowing more air despite its smaller size. When I changed the firmware to switch thermistor values, I opted to enable "thermal runaway protection." Well, with the new 30mm fan along with the fan duct on the 40mm, it's blowing so much air that it's cooling the bed off, so the code thinks the thermistor is broken -> thermal runaway. I printed a small flat piece to serve as a wind deflector on the back side of the heat sink just to keep the breeze off the bed. Anyone else had this problem? I'm tempted to print another fan duct and ditch the loud fan!

I printed a small flat piece to serve as a wind deflector on the back side of the heat sink just to keep the breeze off the bed. Anyone else had this problem? I'm tempted to print another fan duct and ditch the loud fan!

I didn't replace the gear that grabs the filament. They seemed to be the same size, and I thought, "Why take the chance of messing something up?"

Is there a difference? I'm also planning to calibrate the extruder just in case anything's changed.

Is there a difference? I'm also planning to calibrate the extruder just in case anything's changed.Last issue - the new fan from E3D is LOUD. It also must be blowing more air despite its smaller size. When I changed the firmware to switch thermistor values, I opted to enable "thermal runaway protection." Well, with the new 30mm fan along with the fan duct on the 40mm, it's blowing so much air that it's cooling the bed off, so the code thinks the thermistor is broken -> thermal runaway.

I printed a small flat piece to serve as a wind deflector on the back side of the heat sink just to keep the breeze off the bed. Anyone else had this problem? I'm tempted to print another fan duct and ditch the loud fan!

I printed a small flat piece to serve as a wind deflector on the back side of the heat sink just to keep the breeze off the bed. Anyone else had this problem? I'm tempted to print another fan duct and ditch the loud fan!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 01, 2016 07:30PM |

Registered: 8 years ago Posts: 367 |

Quote

markts

I have the E3d V6 Lite installed and it seems to be printing well. I still get some clicking/missing from the extruder. I remember I had to play with temperatures with the stock hotend, so I probably have to do that again (now that I'm printing at 195 instead of 175).

I didn't replace the gear that grabs the filament. They seemed to be the same size, and I thought, "Why take the chance of messing something up?"Is there a difference? I'm also planning to calibrate the extruder just in case anything's changed.

Last issue - the new fan from E3D is LOUD. It also must be blowing more air despite its smaller size. When I changed the firmware to switch thermistor values, I opted to enable "thermal runaway protection." Well, with the new 30mm fan along with the fan duct on the 40mm, it's blowing so much air that it's cooling the bed off, so the code thinks the thermistor is broken -> thermal runaway.I printed a small flat piece to serve as a wind deflector on the back side of the heat sink just to keep the breeze off the bed. Anyone else had this problem? I'm tempted to print another fan duct and ditch the loud fan!

That E3d fan drove me mad, and I printed a duct for the 40mm fan which splits the air between the heatsink and the bed. It's a modified version of this: [www.thingiverse.com]. It seems to work well, with the only issue being that cheap fans don't always like to work except when they are vertical, and so after a while the fan bearings got noisy and I had to replace it. I didn't find any need to replace the gear either, and it has worked fine.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 01, 2016 07:34PM |

Registered: 8 years ago Posts: 13 |

So I've bought a bltouch and I already have therippa's code, my x stop is on the left and I'm planning to cut a usb cable and power it from a powered hub that I'll also will run octopi from. What I'm having problems understanding is what is the process of setting the correct needle height? With the manual control not normally working to set the extruder higher if I need to?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 01, 2016 09:56PM |

Registered: 8 years ago Posts: 171 |

Quote

animoose

Quote

markts

I have the E3d V6 Lite installed and it seems to be printing well. I still get some clicking/missing from the extruder. I remember I had to play with temperatures with the stock hotend, so I probably have to do that again (now that I'm printing at 195 instead of 175).

I didn't replace the gear that grabs the filament. They seemed to be the same size, and I thought, "Why take the chance of messing something up?"Is there a difference? I'm also planning to calibrate the extruder just in case anything's changed.

Last issue - the new fan from E3D is LOUD. It also must be blowing more air despite its smaller size. When I changed the firmware to switch thermistor values, I opted to enable "thermal runaway protection." Well, with the new 30mm fan along with the fan duct on the 40mm, it's blowing so much air that it's cooling the bed off, so the code thinks the thermistor is broken -> thermal runaway.I printed a small flat piece to serve as a wind deflector on the back side of the heat sink just to keep the breeze off the bed. Anyone else had this problem? I'm tempted to print another fan duct and ditch the loud fan!

That E3d fan drove me mad, and I printed a duct for the 40mm fan which splits the air between the heatsink and the bed. It's a modified version of this: [www.thingiverse.com]. It seems to work well, with the only issue being that cheap fans don't always like to work except when they are vertical, and so after a while the fan bearings got noisy and I had to replace it. I didn't find any need to replace the gear either, and it has worked fine.

Great, thanks for the info. I'd like to keep the possibility of printing ABS so I was hesitant to use that shroud. Hmm, maybe it needs a louver ....

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 01, 2016 10:25PM |

Registered: 8 years ago Posts: 430 |

Quote

markts

Quote

animoose

Quote

markts

I have the E3d V6 Lite installed and it seems to be printing well. I still get some clicking/missing from the extruder. I remember I had to play with temperatures with the stock hotend, so I probably have to do that again (now that I'm printing at 195 instead of 175).

I didn't replace the gear that grabs the filament. They seemed to be the same size, and I thought, "Why take the chance of messing something up?"Is there a difference? I'm also planning to calibrate the extruder just in case anything's changed.

Last issue - the new fan from E3D is LOUD. It also must be blowing more air despite its smaller size. When I changed the firmware to switch thermistor values, I opted to enable "thermal runaway protection." Well, with the new 30mm fan along with the fan duct on the 40mm, it's blowing so much air that it's cooling the bed off, so the code thinks the thermistor is broken -> thermal runaway.I printed a small flat piece to serve as a wind deflector on the back side of the heat sink just to keep the breeze off the bed. Anyone else had this problem? I'm tempted to print another fan duct and ditch the loud fan!

That E3d fan drove me mad, and I printed a duct for the 40mm fan which splits the air between the heatsink and the bed. It's a modified version of this: [www.thingiverse.com]. It seems to work well, with the only issue being that cheap fans don't always like to work except when they are vertical, and so after a while the fan bearings got noisy and I had to replace it. I didn't find any need to replace the gear either, and it has worked fine.

Great, thanks for the info. I'd like to keep the possibility of printing ABS so I was hesitant to use that shroud. Hmm, maybe it needs a louver ....

If you don't want to a duct that blows on the prints there are a ton of them on thingiverse that are the same as the stock e3d one that take a 40mm fan. That was one of the first things I made after installing the e3d. That 30mm fan is a joke they should just use a 40.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 01, 2016 10:44PM |

Registered: 8 years ago Posts: 541 |

Quote

stanger2k

So I've bought a bltouch and I already have therippa's code, my x stop is on the left and I'm planning to cut a usb cable and power it from a powered hub that I'll also will run octopi from. What I'm having problems understanding is what is the process of setting the correct needle height? With the manual control not normally working to set the extruder higher if I need to?

To be honest, I don't know what you are asking. You MOUNT the BLTOUCH so that when the pin is all the way up, it is HIGHER than the nozzle and when it is DOWN, it is lower than the nozzle. You can adjust the height somewhat with the set screw in the top but that is not the preferred way because if you go too far, then you lose magnetic force to pull the pin up. I have no idea what you mean by "with the manual control not normally working to set the extruder higher if I need to?"

You say you are going to power the BLTOUCH with the USB CABLE from a powered hub but you do realize that you have to send that power to a spare set of servo pins on the RAMPS board, right? AND you have to remove the jumper that normally sends power to the pins, right?

Maybe you need to read [www.antclabs.com]

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 02, 2016 01:19AM |

Registered: 8 years ago Posts: 314 |

I'm going to upgrade to therippas firmware; I just need to move the endstop plug over one to the right, correct? I also need to make sure my x endstop is set to max in my host software.

Did I miss anything?

Thanks!

-Sam

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

Did I miss anything?

Thanks!

-Sam

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 02, 2016 08:13AM |

Registered: 8 years ago Posts: 268 |

WOW...it's been longer than I thought since my last post...way back on page 132!!! I've been letting work get in my way ;-) I just wanted to stop by and catch up. Looks like a lot is going on, I'll have to read through the nine pages of post I've missed!!!

Even though I haven't been on thread much lately I have been answering PM's, so if you have any specific question for me or if I can help at all please feel free to PM me...I get an email notification which reminds me to check the thread...

I was requested to post my X-Axis Gen-2 files a while back which I did, so if anyone is interested in trying it out please check my Thingi Page I am very happy with the result of Gen-2, I am currently running both the X motor and extruder on the gantry with no issues at all. I did reduce the rapid travel speed a bit through S3D as it was chattering a bit while making those moves. now it nice and quiet again

Therippa, have you seen or checked these out yet...might be another option for a control board upgrade!?!? I plan to use one on my latest printer build (see below).

ZeroPi

Raspberry Pi CNC Board

It's a bit off subject but here's my build SL Cantilevered 3D Printer I'm designing it to be as simple as possible and use as fewest (Quality) parts possible, currently it will be setup for PLA only as I've not included a heated bed...yet ;-)

Here's a quick peak...the link above has all the details.

BTW: I designed some magnetic mounts for my print glass...I love this upgrade, no more crappy binder clips in the way, well worth the effort!!!

Edited 1 time(s). Last edit at 03/02/2016 08:19AM by sonnylowe.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

Even though I haven't been on thread much lately I have been answering PM's, so if you have any specific question for me or if I can help at all please feel free to PM me...I get an email notification which reminds me to check the thread...

I was requested to post my X-Axis Gen-2 files a while back which I did, so if anyone is interested in trying it out please check my Thingi Page I am very happy with the result of Gen-2, I am currently running both the X motor and extruder on the gantry with no issues at all. I did reduce the rapid travel speed a bit through S3D as it was chattering a bit while making those moves. now it nice and quiet again

Therippa, have you seen or checked these out yet...might be another option for a control board upgrade!?!? I plan to use one on my latest printer build (see below).

ZeroPi

Raspberry Pi CNC Board

It's a bit off subject but here's my build SL Cantilevered 3D Printer I'm designing it to be as simple as possible and use as fewest (Quality) parts possible, currently it will be setup for PLA only as I've not included a heated bed...yet ;-)

Here's a quick peak...the link above has all the details.

BTW: I designed some magnetic mounts for my print glass...I love this upgrade, no more crappy binder clips in the way, well worth the effort!!!

Edited 1 time(s). Last edit at 03/02/2016 08:19AM by sonnylowe.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 02, 2016 08:55AM |

Registered: 8 years ago Posts: 13 |

I looked over that pdf and it answered a lot of my questions.. and no, I thought i could wire the power directly to the bltouch, not that I have to pass the power it into the board which sends it back to the sensor. If all goes well, I should have some time to hook it up this weekend.

Quote

tjnamtiw

Quote

stanger2k

So I've bought a bltouch and I already have therippa's code, my x stop is on the left and I'm planning to cut a usb cable and power it from a powered hub that I'll also will run octopi from. What I'm having problems understanding is what is the process of setting the correct needle height? With the manual control not normally working to set the extruder higher if I need to?

To be honest, I don't know what you are asking. You MOUNT the BLTOUCH so that when the pin is all the way up, it is HIGHER than the nozzle and when it is DOWN, it is lower than the nozzle. You can adjust the height somewhat with the set screw in the top but that is not the preferred way because if you go too far, then you lose magnetic force to pull the pin up. I have no idea what you mean by "with the manual control not normally working to set the extruder higher if I need to?"

You say you are going to power the BLTOUCH with the USB CABLE from a powered hub but you do realize that you have to send that power to a spare set of servo pins on the RAMPS board, right? AND you have to remove the jumper that normally sends power to the pins, right?

Maybe you need to read [www.antclabs.com]

Sorry, only registered users may post in this forum.