Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 02, 2016 09:03AM |

Registered: 8 years ago Posts: 541 |

Quote

stanger2k

I looked over that pdf and it answered a lot of my questions.. and no, I thought i could wire the power directly to the bltouch, not that I have to pass the power it into the board which sends it back to the sensor. If all goes well, I should have some time to hook it up this weekend.

Quote

tjnamtiw

Quote

stanger2k

So I've bought a bltouch and I already have therippa's code, my x stop is on the left and I'm planning to cut a usb cable and power it from a powered hub that I'll also will run octopi from. What I'm having problems understanding is what is the process of setting the correct needle height? With the manual control not normally working to set the extruder higher if I need to?

To be honest, I don't know what you are asking. You MOUNT the BLTOUCH so that when the pin is all the way up, it is HIGHER than the nozzle and when it is DOWN, it is lower than the nozzle. You can adjust the height somewhat with the set screw in the top but that is not the preferred way because if you go too far, then you lose magnetic force to pull the pin up. I have no idea what you mean by "with the manual control not normally working to set the extruder higher if I need to?"

You say you are going to power the BLTOUCH with the USB CABLE from a powered hub but you do realize that you have to send that power to a spare set of servo pins on the RAMPS board, right? AND you have to remove the jumper that normally sends power to the pins, right?

Maybe you need to read [www.antclabs.com]

It sounds like maybe you should take a step back and take the time to research how auto bed leveling, no matter what style, works and communicates with the board and Marlin. Use the custom search here and gain some more knowledge before throwing the power to it. That's just my suggestion.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 02, 2016 09:07AM |

Registered: 8 years ago Posts: 541 |

Quote

sonnylowe

BTW: I designed some magnetic mounts for my print glass...I love this upgrade, no more crappy binder clips in the way, well worth the effort!!!

What a great idea! Why didn't I think of that. I use the darn magnets for everything else!!!! Quick change glass!!! Thanks!!!

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 02, 2016 02:03PM |

Registered: 8 years ago Posts: 20 |

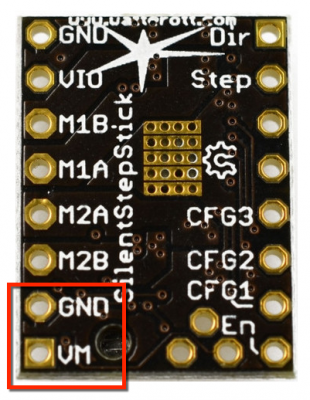

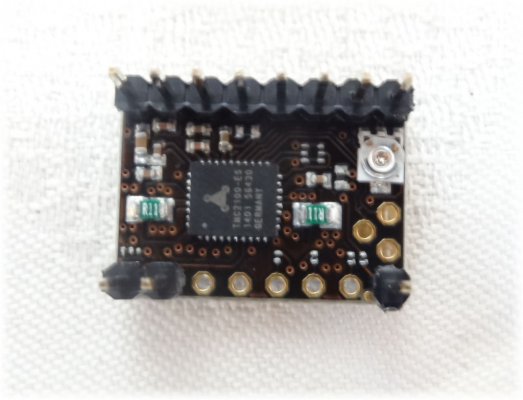

So I installed TMC2100's on the X&Y axis. If I lower the voltage below 1.15 I get a high pitch squeal from the Steppers... at this voltage the steppers run pretty hot... reading online I saw that running the TMV2100 off of 18 volts or higher could eliminate this.

So my question is can I just remove these two pins :

and the install pins on the top and run the motors off of a step-up board? then I can run 18v-24v on those two drivers and hopefully lower the output voltage...

next question is about the jumpers... reading more online I am confused. I have all the cfg pins (cfg1, cfg2 & cfg3) soldered to the tmc2100 and plugged into my ramps board, I removed all the jumpers. Is this the correct setup to get the 256 spreadCycle mode enabled?

Edited 1 time(s). Last edit at 03/02/2016 02:09PM by buffcleb.

So my question is can I just remove these two pins :

and the install pins on the top and run the motors off of a step-up board? then I can run 18v-24v on those two drivers and hopefully lower the output voltage...

next question is about the jumpers... reading more online I am confused. I have all the cfg pins (cfg1, cfg2 & cfg3) soldered to the tmc2100 and plugged into my ramps board, I removed all the jumpers. Is this the correct setup to get the 256 spreadCycle mode enabled?

Edited 1 time(s). Last edit at 03/02/2016 02:09PM by buffcleb.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 02, 2016 04:42PM |

Registered: 8 years ago Posts: 92 |

Would anyone who is running the E3D v6 with a Bowden care to share your retraction settings?

I am struggling to get it right. I've played with a number of different distances and speeds, but have been unhappy with the results at the start/stop point of each layer. I don't have stringing, but it seems that I either have blobs, or caves (or both!). What I mean by a cave is a divot at that point, where, obviously nothing was actually extruded at the very beginning of the layer. It results in a groove all the way up the print.

I know settings will vary based on filament type and tube length, but I'm wondering what settings others of you are using?

Right now I'm regretting going to the bowden, and may return to direct drive. (of course, to do that, I'd have to print a new hot-end/extruder/sendor mount for the v-slot gantry, and print quality is questionable right now...)

--Andrew

I am struggling to get it right. I've played with a number of different distances and speeds, but have been unhappy with the results at the start/stop point of each layer. I don't have stringing, but it seems that I either have blobs, or caves (or both!). What I mean by a cave is a divot at that point, where, obviously nothing was actually extruded at the very beginning of the layer. It results in a groove all the way up the print.

I know settings will vary based on filament type and tube length, but I'm wondering what settings others of you are using?

Right now I'm regretting going to the bowden, and may return to direct drive. (of course, to do that, I'd have to print a new hot-end/extruder/sendor mount for the v-slot gantry, and print quality is questionable right now...)

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 02, 2016 05:08PM |

Registered: 8 years ago Posts: 131 |

Quote

iamquestar

Would anyone who is running the E3D v6 with a Bowden care to share your retraction settings?

I am struggling to get it right. I've played with a number of different distances and speeds, but have been unhappy with the results at the start/stop point of each layer. I don't have stringing, but it seems that I either have blobs, or caves (or both!). What I mean by a cave is a divot at that point, where, obviously nothing was actually extruded at the very beginning of the layer. It results in a groove all the way up the print.

I know settings will vary based on filament type and tube length, but I'm wondering what settings others of you are using?

Right now I'm regretting going to the bowden, and may return to direct drive. (of course, to do that, I'd have to print a new hot-end/extruder/sendor mount for the v-slot gantry, and print quality is questionable right now...)

--Andrew

From everything I read retraction is close to impossible to get right on bowden, there's just too much play in the setup from stepper to hot-end.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 02, 2016 05:19PM |

Registered: 8 years ago Posts: 93 |

I've been wondering what the advantages of a Bowden are on a Prusa i3 printer. The direct extruder setup doesn't seem like too much weight for this type of printer design. I could understand needing it on a Kossel type printer.

Does the reduction in weight on the X axis really help enough to make it worth all the headaches that the Bowden introduces?

For those that have switched, what has been your experience? Did it really improve print quality over a direct extruder setup? Can you still print flex filaments?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

Does the reduction in weight on the X axis really help enough to make it worth all the headaches that the Bowden introduces?

For those that have switched, what has been your experience? Did it really improve print quality over a direct extruder setup? Can you still print flex filaments?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 02, 2016 05:41PM |

Registered: 8 years ago Posts: 268 |

Quote

iamquestar

Would anyone who is running the E3D v6 with a Bowden care to share your retraction settings?

I am struggling to get it right. I've played with a number of different distances and speeds, but have been unhappy with the results at the start/stop point of each layer. I don't have stringing, but it seems that I either have blobs, or caves (or both!). What I mean by a cave is a divot at that point, where, obviously nothing was actually extruded at the very beginning of the layer. It results in a groove all the way up the print.

I know settings will vary based on filament type and tube length, but I'm wondering what settings others of you are using?

Right now I'm regretting going to the bowden, and may return to direct drive. (of course, to do that, I'd have to print a new hot-end/extruder/sendor mount for the v-slot gantry, and print quality is questionable right now...)

--Andrew

Andrew,

I ran a bowden setup for a very long time with great success, even with dual extruders running a Cyclops (retract is even tougher on that hotend). I think my retract was 4mm on the filament and 1mm retract in Z. What exactly is going wrong with your quality that you think adjusting the retract will help...maybe you can post a photo or two!?!?

Sonny

Edit: I didn't fully read the post...my bad. It sounds like more of an issue with the Teflon tube than your retract. If it were the retract I think it would be a consistent problem of stringing, blobs or missing filament at the start. With it being either one or the other of the latter two I think the tube might be sliding in the fitting a bit. I ran these little beauties on mine Bowden Clips...they definitely keep the tube in place. If you aren't using them already give them a try...they might do the trick!?!?

Edited 1 time(s). Last edit at 03/02/2016 07:29PM by sonnylowe.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 02, 2016 11:03PM |

Registered: 8 years ago Posts: 430 |

Quote

sonnylowe

WOW...it's been longer than I thought since my last post...way back on page 132!!! I've been letting work get in my way ;-) I just wanted to stop by and catch up. Looks like a lot is going on, I'll have to read through the nine pages of post I've missed!!!

Even though I haven't been on thread much lately I have been answering PM's, so if you have any specific question for me or if I can help at all please feel free to PM me...I get an email notification which reminds me to check the thread...

I was requested to post my X-Axis Gen-2 files a while back which I did, so if anyone is interested in trying it out please check my Thingi Page I am very happy with the result of Gen-2, I am currently running both the X motor and extruder on the gantry with no issues at all. I did reduce the rapid travel speed a bit through S3D as it was chattering a bit while making those moves. now it nice and quiet again

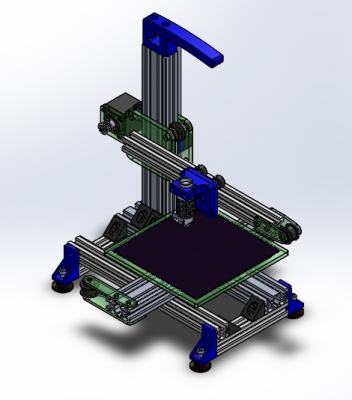

Therippa, have you seen or checked these out yet...might be another option for a control board upgrade!?!? I plan to use one on my latest printer build (see below).

ZeroPi

Raspberry Pi CNC Board

It's a bit off subject but here's my build SL Cantilevered 3D Printer I'm designing it to be as simple as possible and use as fewest (Quality) parts possible, currently it will be setup for PLA only as I've not included a heated bed...yet ;-)

Here's a quick peak...the link above has all the details.

BTW: I designed some magnetic mounts for my print glass...I love this upgrade, no more crappy binder clips in the way, well worth the effort!!!

The printer design looks neat similar to the printrbot metal simple and the same idea keep it as simple as possible. I like the extrusions over the smooth rods they use. It will be fun to see it get built.

I wonder if on the magnetic glass mount you could just place magnets on the top of the glass and get enough pull through the glass to hold it.

Edited 1 time(s). Last edit at 03/02/2016 11:08PM by msaeger.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 03:53AM |

Registered: 8 years ago Posts: 268 |

Quote

tjnamtiw

Quote

sonnylowe

BTW: I designed some magnetic mounts for my print glass...I love this upgrade, no more crappy binder clips in the way, well worth the effort!!!

What a great idea! Why didn't I think of that. I use the darn magnets for everything else!!!! Quick change glass!!! Thanks!!!

Thanks, I love magnets as well

This took several tries to get right, but again, I'm very happy with the results...

This took several tries to get right, but again, I'm very happy with the results...My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 03:59AM |

Registered: 8 years ago Posts: 268 |

Quote

msaeger

Quote

sonnylowe

WOW...it's been longer than I thought since my last post...way back on page 132!!! I've been letting work get in my way ;-) I just wanted to stop by and catch up. Looks like a lot is going on, I'll have to read through the nine pages of post I've missed!!!

Even though I haven't been on thread much lately I have been answering PM's, so if you have any specific question for me or if I can help at all please feel free to PM me...I get an email notification which reminds me to check the thread...

I was requested to post my X-Axis Gen-2 files a while back which I did, so if anyone is interested in trying it out please check my Thingi Page I am very happy with the result of Gen-2, I am currently running both the X motor and extruder on the gantry with no issues at all. I did reduce the rapid travel speed a bit through S3D as it was chattering a bit while making those moves. now it nice and quiet again

Therippa, have you seen or checked these out yet...might be another option for a control board upgrade!?!? I plan to use one on my latest printer build (see below).

ZeroPi

Raspberry Pi CNC Board

It's a bit off subject but here's my build SL Cantilevered 3D Printer I'm designing it to be as simple as possible and use as fewest (Quality) parts possible, currently it will be setup for PLA only as I've not included a heated bed...yet ;-)

Here's a quick peak...the link above has all the details.

BTW: I designed some magnetic mounts for my print glass...I love this upgrade, no more crappy binder clips in the way, well worth the effort!!!

The printer design looks neat similar to the printrbot metal simple and the same idea keep it as simple as possible. I like the extrusions over the smooth rods they use. It will be fun to see it get built.

I wonder if on the magnetic glass mount you could just place magnets on the top of the glass and get enough pull through the glass to hold it.

Yeah, not much you change when designing these canti printers, it really boils done to component choice. I wanted to use quality bearings and keep the parts count down...it's working so far ;-)

I tried putting the magnets top, the ones I had were not strong enough, I assume you could get larger ones that would do the trick though. I also wanted the glass clear on top just so there was nothing in the way of the hotend. I could technically used all of the glass now and print a bit wider

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 06:30AM |

Registered: 8 years ago Posts: 268 |

Quote

stanger2k

I looked over that pdf and it answered a lot of my questions.. and no, I thought i could wire the power directly to the bltouch, not that I have to pass the power it into the board which sends it back to the sensor. If all goes well, I should have some time to hook it up this weekend.

Quote

tjnamtiw

Quote

stanger2k

So I've bought a bltouch and I already have therippa's code, my x stop is on the left and I'm planning to cut a usb cable and power it from a powered hub that I'll also will run octopi from. What I'm having problems understanding is what is the process of setting the correct needle height? With the manual control not normally working to set the extruder higher if I need to?

To be honest, I don't know what you are asking. You MOUNT the BLTOUCH so that when the pin is all the way up, it is HIGHER than the nozzle and when it is DOWN, it is lower than the nozzle. You can adjust the height somewhat with the set screw in the top but that is not the preferred way because if you go too far, then you lose magnetic force to pull the pin up. I have no idea what you mean by "with the manual control not normally working to set the extruder higher if I need to?"

You say you are going to power the BLTOUCH with the USB CABLE from a powered hub but you do realize that you have to send that power to a spare set of servo pins on the RAMPS board, right? AND you have to remove the jumper that normally sends power to the pins, right?

Maybe you need to read [www.antclabs.com]

Update on the Zeropi: I contacted the guy who makes these through kickstarter, apparently that initial run is going to be the only run...

"Dear Daniel (not sure why he addressed me as Daniel LOL), as for the zeropi, we are not planning to sell it again, but we have developed a new board-Megapi which is better than zeropi and is going to be sold in the beginning of April. Pls kindly focus on our official web. www.makeblock.cc, thanks."

Looks like I'll have to check the new product out and there will be a bit of a wait for it...I might have to to drop back to something else for the new design!?!?

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 09:31AM |

Registered: 8 years ago Posts: 20 |

Quote

buffcleb

So I installed TMC2100's on the X&Y axis. If I lower the voltage below 1.15 I get a high pitch squeal from the Steppers... at this voltage the steppers run pretty hot... reading online I saw that running the TMV2100 off of 18 volts or higher could eliminate this.

So my question is can I just remove these two pins :

and the install pins on the top and run the motors off of a step-up board? then I can run 18v-24v on those two drivers and hopefully lower the output voltage...

next question is about the jumpers... reading more online I am confused. I have all the cfg pins (cfg1, cfg2 & cfg3) soldered to the tmc2100 and plugged into my ramps board, I removed all the jumpers. Is this the correct setup to get the 256 spreadCycle mode enabled?

So I did some testing last night... with the printer powered off I testing to see if cfg1, cfg2 & cfg3 went to ground. This is with all pins installed into the tmc2100 and all jumpers removed. None of them went to ground. I then tested on a spare ramps board and installed the jumper on cfg1 and again it did not go to ground. So that means that I was running the tmc2100 with cfg 1 & 2 open. My Y axis ran with this config without issue. I added a jumper to to surface of the tmc2100 taking cfg1 to ground and re-tested. It didn't seem to make a huge amount of difference but I was able to turn the voltage down to .58v which drastically reduced the temp of the stepper motor.

Now the X axis stepper (being the smaller of the two that ships with the 2020 i3) doesn't seem to like these drivers all that much. Its not very smooth... I figured if the larger stepper likes them I'll just order another of those and have one on the way. should be here this weekend and I'll test how it works...

still interested in running the drivers on 18v-24v by removing the pins from the image above and installing a header to the surface to power them with 18v-24v. I have a Step Up Converter coming and will test it this weekend.

Edited 1 time(s). Last edit at 03/03/2016 09:33AM by buffcleb.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 10:36AM |

Registered: 8 years ago Posts: 130 |

Quote

buffcleb

So I installed TMC2100's on the X&Y axis. If I lower the voltage below 1.15 I get a high pitch squeal from the Steppers... at this voltage the steppers run pretty hot... reading online I saw that running the TMV2100 off of 18 volts or higher could eliminate this.

So my question is can I just remove these two pins :

and the install pins on the top and run the motors off of a step-up board? then I can run 18v-24v on those two drivers and hopefully lower the output voltage...

next question is about the jumpers... reading more online I am confused. I have all the cfg pins (cfg1, cfg2 & cfg3) soldered to the tmc2100 and plugged into my ramps board, I removed all the jumpers. Is this the correct setup to get the 256 spreadCycle mode enabled?

The internet is a mess concerning these boards. One of the instructables (http://www.instructables.com/id/Install-and-configure-SilentStepStick-in-RAMPS-TMC/step5/All-done/) goes through elaborate instructions, then in the comments section, last paragraph, admits that the jumper pin instructions are wrong. The manufacturer suggests a protection standoff board (SilentStepStick Protector) with flyback protection for these boards. Good luck finding this part. They also have some elaborate recommendation for powering down the SilentStepStick to avoid damage to their tmc2100 board.

If I were going to give this a go, (unlikely) I would remove the cfgx pins from the SilentStepStick, and leave all jumpers on the ramps board in place.

from:

[www.instructables.com] (seems more correct than the instructable above.)

I guess if you get a 24V power supply you could run your heaterbed at 24V, and get your heater current off the ramps board....

I got my stepper noise pretty quiet by running my VREF for the Y-axis at 0.4V and VREF for all other steppers at 0.160V. These are the Folger Tech - stock steppers, the y-axis rated 3V - 1.512V and all others rated at 12V - 0.4 A. I suspect that hoops you will need to jump through, to keep the torque high, will introduce squeal somewhere. Good luck, you are blazing your own trail. Do you have links to the stuff recommending higher voltage?

You have me curious about the actual voltage the stock motor windings "see'. If the sound ever got to me I would look at low-tech solutions such as acoustic soundproofing wedge tile.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 11:18AM |

Registered: 8 years ago Posts: 20 |

Quote

flatlander

Quote

buffcleb

So I installed TMC2100's on the X&Y axis. If I lower the voltage below 1.15 I get a high pitch squeal from the Steppers... at this voltage the steppers run pretty hot... reading online I saw that running the TMV2100 off of 18 volts or higher could eliminate this.

So my question is can I just remove these two pins :

and the install pins on the top and run the motors off of a step-up board? then I can run 18v-24v on those two drivers and hopefully lower the output voltage...

next question is about the jumpers... reading more online I am confused. I have all the cfg pins (cfg1, cfg2 & cfg3) soldered to the tmc2100 and plugged into my ramps board, I removed all the jumpers. Is this the correct setup to get the 256 spreadCycle mode enabled?

The internet is a mess concerning these boards. One of the instructables (http://www.instructables.com/id/Install-and-configure-SilentStepStick-in-RAMPS-TMC/step5/All-done/) goes through elaborate instructions, then in the comments section, last paragraph, admits that the jumper pin instructions are wrong. The manufacturer suggests a protection standoff board (SilentStepStick Protector) with flyback protection for these boards. Good luck finding this part. They also have some elaborate recommendation for powering down the SilentStepStick to avoid damage to their tmc2100 board.

If I were going to give this a go, (unlikely) I would remove the cfgx pins from the SilentStepStick, and leave all jumpers on the ramps board in place.

from:

[www.instructables.com] (seems more correct than the instructable above.)

I guess if you get a 24V power supply you could run your heaterbed at 24V, and get your heater current off the ramps board....

I got my stepper noise pretty quiet by running my VREF for the Y-axis at 0.4V and VREF for all other steppers at 0.160V. These are the Folger Tech - stock steppers, the y-axis rated 3V - 1.512V and all others rated at 12V - 0.4 A. I suspect that hoops you will need to jump through, to keep the torque high, will introduce squeal somewhere. Good luck, you are blazing your own trail. Do you have links to the stuff recommending higher voltage?

You have me curious about the actual voltage the stock motor windings "see'. If the sound ever got to me I would look at low-tech solutions such as acoustic soundproofing wedge tile.

The step up power board I'm planning to use ( [amzn.to] ) only has 6a output so I'm not planning on running the heatbed as I assume even at 24v I would be over that... I'm dedicating this to the steppers...

I based the higher voltage off the silentStepStick FAQ I found : [github.com]

right now it runs and my Y axis is dead silent... my X is where I'm seeing issues... Like I said I think it might be the motor so I'm going to install on of the Y axis motors on my X axis when it gets here on Saturday...

the second link you provided (http://www.instructables.com/id/Vulcanus-V1-3D-Printer/?ALLSTEPS) leaves the motors in stealth chop mode... I was looking to get into spreadCycle mode which needs cfg1 being brought to ground... I added a wire jumper on the face of my X axis to do this... the Y axis seems fine with stealth chop mode... when I install the new stepper motors I may remove the jumper and see if there is enough torque

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 04:03PM |

Registered: 8 years ago Posts: 314 |

Im wondering why I need to move my X axis endstop to the left for auto level? I upgraded to therippas firmware and it works fine on the right. After I upgraded my extruder got reversed, so I switched the motor plug.

Edited 7 time(s). Last edit at 03/03/2016 05:06PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

Edited 7 time(s). Last edit at 03/03/2016 05:06PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 05:10PM |

Registered: 8 years ago Posts: 85 |

Quote

UltiFix

Im wondering why I need to move my X axis endstop to the left for auto level? I upgraded to therippas firmware and it works fine on the right. After I upgraded my extruder got reversed, so I switched the motor plug.

Because autolevel only knows how to calculate the plane of the bed when referencing from the front left as 0,0

If you're not using autolevel yet then therippas will work just fine with the endstop on the right (assuming you configure it for such)

But if you want to use autolevel you'll need it on the left or it won't be able to actually...autolevel.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 05:13PM |

Registered: 8 years ago Posts: 93 |

Quote

UltiFix

Im going to upgrade to the rippas firmware and setup autolevel, why do I need to move my x endstop to the left?

EDIT:

I upgraded and it's working fine on the right...

After the upgrade the extruder is no longer extruding, did my extruder get reversed?

EDIT:

I think it's reversed, how do I fix that?

You can reverse any of the stepper motors by taking the plug off the ramps board and turning over and plugging it back in.

Many, if not most, versions of the Marlin firmware have bugs that show up in autolevel with the endstop on the right. Putting it on the left eliminates the possibility of running into any problems related to this. This is because the code is developed and debugged on machines that all have an X-Min endstop (on the left) instead of the rather rare X-max endstop.

The normal Prusa i3 configuration is with the X-Min endstop, which means on the left. Folger is the only prusa type printer I know of that puts it on the right.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 05:58PM |

Registered: 8 years ago Posts: 314 |

Quote

jhitesma

Quote

UltiFix

Im wondering why I need to move my X axis endstop to the left for auto level? I upgraded to therippas firmware and it works fine on the right. After I upgraded my extruder got reversed, so I switched the motor plug.

Because autolevel only knows how to calculate the plane of the bed when referencing from the front left as 0,0

If you're not using autolevel yet then therippas will work just fine with the endstop on the right (assuming you configure it for such)

But if you want to use autolevel you'll need it on the left or it won't be able to actually...autolevel.

Thanks!

Quote

Bert3D

Quote

UltiFix

Im going to upgrade to the rippas firmware and setup autolevel, why do I need to move my x endstop to the left?

EDIT:

I upgraded and it's working fine on the right...

After the upgrade the extruder is no longer extruding, did my extruder get reversed?

EDIT:

I think it's reversed, how do I fix that?

You can reverse any of the stepper motors by taking the plug off the ramps board and turning over and plugging it back in.

Many, if not most, versions of the Marlin firmware have bugs that show up in autolevel with the endstop on the right. Putting it on the left eliminates the possibility of running into any problems related to this. This is because the code is developed and debugged on machines that all have an X-Min endstop (on the left) instead of the rather rare X-max endstop.

The normal Prusa i3 configuration is with the X-Min endstop, which means on the left. Folger is the only prusa type printer I know of that puts it on the right.

Edited 1 time(s). Last edit at 03/03/2016 05:58PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 10:47PM |

Registered: 8 years ago Posts: 13 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 10:48PM |

Registered: 8 years ago Posts: 276 |

Quote

jhitesma

Quote

UltiFix

Im wondering why I need to move my X axis endstop to the left for auto level? I upgraded to therippas firmware and it works fine on the right. After I upgraded my extruder got reversed, so I switched the motor plug.

Because autolevel only knows how to calculate the plane of the bed when referencing from the front left as 0,0

If you're not using autolevel yet then therippas will work just fine with the endstop on the right (assuming you configure it for such)

But if you want to use autolevel you'll need it on the left or it won't be able to actually...autolevel.

What jhitesma said. They didn't set up their math to work backwards from wherever X-max is.

Edited 1 time(s). Last edit at 03/03/2016 10:51PM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 03, 2016 11:18PM |

Registered: 8 years ago Posts: 285 |

Quote

Agedashi

I'm trying to upgrade to therippa's new version of marlin so I can get the full graphics LCD working. I'm porting my settings over but i noticed that the Z-Step value changed from 3840 to 4000. Which one should I be using with the original threaded rods?

Thanks!

4000

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 04, 2016 12:19AM |

Registered: 8 years ago Posts: 13 |

Quote

Mach

Quote

Agedashi

I'm trying to upgrade to therippa's new version of marlin so I can get the full graphics LCD working. I'm porting my settings over but i noticed that the Z-Step value changed from 3840 to 4000. Which one should I be using with the original threaded rods?

Thanks!

4000

Thanks for the quick reply. Any reason for the change? I assume the default was 3840 previously... I don't recall setting it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 04, 2016 02:58AM |

Registered: 8 years ago Posts: 92 |

Quote

Agedashi

Quote

Mach

Quote

Agedashi

I'm trying to upgrade to therippa's new version of marlin so I can get the full graphics LCD working. I'm porting my settings over but i noticed that the Z-Step value changed from 3840 to 4000. Which one should I be using with the original threaded rods?

Thanks!

4000

Thanks for the quick reply. Any reason for the change? I assume the default was 3840 previously... I don't recall setting it.

Yes, that was the default value FT set. It is wrong. You want to set your axis steps per mm via math. The threaded rod has a .8 mm pitch, meaning it travels .8mm per revolution. The stepper motors have 200 steps per revolution, times 16 micro steps per step (3200 per revolution), divide that by .8, and you get 4000 micro steps per mm of z travel.

-Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 04, 2016 03:06AM |

Registered: 8 years ago Posts: 92 |

Quote

sonnylowe

Quote

iamquestar

Would anyone who is running the E3D v6 with a Bowden care to share your retraction settings?

I am struggling to get it right. I've played with a number of different distances and speeds, but have been unhappy with the results at the start/stop point of each layer. I don't have stringing, but it seems that I either have blobs, or caves (or both!). What I mean by a cave is a divot at that point, where, obviously nothing was actually extruded at the very beginning of the layer. It results in a groove all the way up the print.

I know settings will vary based on filament type and tube length, but I'm wondering what settings others of you are using?

Right now I'm regretting going to the bowden, and may return to direct drive. (of course, to do that, I'd have to print a new hot-end/extruder/sendor mount for the v-slot gantry, and print quality is questionable right now...)

--Andrew

Andrew,

I ran a bowden setup for a very long time with great success, even with dual extruders running a Cyclops (retract is even tougher on that hotend). I think my retract was 4mm on the filament and 1mm retract in Z. What exactly is going wrong with your quality that you think adjusting the retract will help...maybe you can post a photo or two!?!?

Sonny

Edit: I didn't fully read the post...my bad. It sounds like more of an issue with the Teflon tube than your retract. If it were the retract I think it would be a consistent problem of stringing, blobs or missing filament at the start. With it being either one or the other of the latter two I think the tube might be sliding in the fitting a bit. I ran these little beauties on mine Bowden Clips...they definitely keep the tube in place. If you aren't using them already give them a try...they might do the trick!?!?

Thanks for the reply, I appreciate it. I don't think I was clear in my post . I'm not getting both issues at the same time, it just seems I can't find a happy medium. I'll try to post a pic in a couple days. I'm going out of town for the weekend and won't have a chance to do it before I leave. ( I sure wish I could figure out a way to take the printer vwith me...:-)

BTW, I'm going to print out and give those clips a try. Thanks!

-Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 04, 2016 09:34AM |

Registered: 8 years ago Posts: 130 |

Quote

iamquestar

Quote

sonnylowe

Quote

iamquestar

Would anyone who is running the E3D v6 with a Bowden care to share your retraction settings?

I am struggling to get it right. I've played with a number of different distances and speeds, but have been unhappy with the results at the start/stop point of each layer. I don't have stringing, but it seems that I either have blobs, or caves (or both!). What I mean by a cave is a divot at that point, where, obviously nothing was actually extruded at the very beginning of the layer. It results in a groove all the way up the print.

I know settings will vary based on filament type and tube length, but I'm wondering what settings others of you are using?

Right now I'm regretting going to the bowden, and may return to direct drive. (of course, to do that, I'd have to print a new hot-end/extruder/sendor mount for the v-slot gantry, and print quality is questionable right now...)

--Andrew

Andrew,

I ran a bowden setup for a very long time with great success, even with dual extruders running a Cyclops (retract is even tougher on that hotend). I think my retract was 4mm on the filament and 1mm retract in Z. What exactly is going wrong with your quality that you think adjusting the retract will help...maybe you can post a photo or two!?!?

Sonny

Edit: I didn't fully read the post...my bad. It sounds like more of an issue with the Teflon tube than your retract. If it were the retract I think it would be a consistent problem of stringing, blobs or missing filament at the start. With it being either one or the other of the latter two I think the tube might be sliding in the fitting a bit. I ran these little beauties on mine Bowden Clips...they definitely keep the tube in place. If you aren't using them already give them a try...they might do the trick!?!?

Thanks for the reply, I appreciate it. I don't think I was clear in my post . I'm not getting both issues at the same time, it just seems I can't find a happy medium. I'll try to post a pic in a couple days. I'm going out of town for the weekend and won't have a chance to do it before I leave. ( I sure wish I could figure out a way to take the printer vwith me...:-)

BTW, I'm going to print out and give those clips a try. Thanks!

-Andrew

I've felt 3d printer separation anxiety.

Are you keeping your PLA dry? I put my PLA in a jumbo freezer bag with a few containers of desiccant overnight. Blobs have mostly gone away for me after I started keeping my PLA dry. ( As long as I set my extrusion multiplier to 1.03 and not 103, ha, ha, ha. That poor little stepper was trying to to 103.)

I purchased some vacuum bags from Harbor Freight and will at some point employ them. That reminds me, I need to bake my silica gel at 220F for a few hours today.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 04, 2016 04:57PM |

Registered: 8 years ago Posts: 541 |

Quote

flatlander

I've felt 3d printer separation anxiety.

Are you keeping your PLA dry? I put my PLA in a jumbo freezer bag with a few containers of desiccant overnight. Blobs have mostly gone away for me after I started keeping my PLA dry. ( As long as I set my extrusion multiplier to 1.03 and not 103, ha, ha, ha. That poor little stepper was trying to to 103.)

I purchased some vacuum bags from Harbor Freight and will at some point employ them. That reminds me, I need to bake my silica gel at 220F for a few hours today.

I keep all my PLA in a large Tupperware container with a gasketed lid and 6 snaps. Inside I put this > [smile.amazon.com]

I have had no problems since this thing is meant for a small room! I even had one roll of red that was just about used up and it got brittle as Pringles. I put it in the box and after a week, it's just as pliable as the rest. The dehumidifier even plugs into the wall and rejuvenates itself!

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 04, 2016 10:43PM |

Registered: 8 years ago Posts: 9 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 04, 2016 11:43PM |

Registered: 8 years ago Posts: 314 |

How hard would it be to take a stock Folger tech 2020 other than say auto leveling and upgrade it to dual extruders?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 04, 2016 11:50PM |

Registered: 8 years ago Posts: 20 |

Quote

buffcleb

Quote

flatlander

Quote

buffcleb

So I installed TMC2100's on the X&Y axis. If I lower the voltage below 1.15 I get a high pitch squeal from the Steppers... at this voltage the steppers run pretty hot... reading online I saw that running the TMV2100 off of 18 volts or higher could eliminate this.

So my question is can I just remove these two pins :

and the install pins on the top and run the motors off of a step-up board? then I can run 18v-24v on those two drivers and hopefully lower the output voltage...

next question is about the jumpers... reading more online I am confused. I have all the cfg pins (cfg1, cfg2 & cfg3) soldered to the tmc2100 and plugged into my ramps board, I removed all the jumpers. Is this the correct setup to get the 256 spreadCycle mode enabled?

The internet is a mess concerning these boards. One of the instructables (http://www.instructables.com/id/Install-and-configure-SilentStepStick-in-RAMPS-TMC/step5/All-done/) goes through elaborate instructions, then in the comments section, last paragraph, admits that the jumper pin instructions are wrong. The manufacturer suggests a protection standoff board (SilentStepStick Protector) with flyback protection for these boards. Good luck finding this part. They also have some elaborate recommendation for powering down the SilentStepStick to avoid damage to their tmc2100 board.

If I were going to give this a go, (unlikely) I would remove the cfgx pins from the SilentStepStick, and leave all jumpers on the ramps board in place.

from:

[www.instructables.com] (seems more correct than the instructable above.)

I guess if you get a 24V power supply you could run your heaterbed at 24V, and get your heater current off the ramps board....

I got my stepper noise pretty quiet by running my VREF for the Y-axis at 0.4V and VREF for all other steppers at 0.160V. These are the Folger Tech - stock steppers, the y-axis rated 3V - 1.512V and all others rated at 12V - 0.4 A. I suspect that hoops you will need to jump through, to keep the torque high, will introduce squeal somewhere. Good luck, you are blazing your own trail. Do you have links to the stuff recommending higher voltage?

You have me curious about the actual voltage the stock motor windings "see'. If the sound ever got to me I would look at low-tech solutions such as acoustic soundproofing wedge tile.

The step up power board I'm planning to use ( [amzn.to] ) only has 6a output so I'm not planning on running the heatbed as I assume even at 24v I would be over that... I'm dedicating this to the steppers...

I based the higher voltage off the silentStepStick FAQ I found : [github.com]

right now it runs and my Y axis is dead silent... my X is where I'm seeing issues... Like I said I think it might be the motor so I'm going to install on of the Y axis motors on my X axis when it gets here on Saturday...

the second link you provided (http://www.instructables.com/id/Vulcanus-V1-3D-Printer/?ALLSTEPS) leaves the motors in stealth chop mode... I was looking to get into spreadCycle mode which needs cfg1 being brought to ground... I added a wire jumper on the face of my X axis to do this... the Y axis seems fine with stealth chop mode... when I install the new stepper motors I may remove the jumper and see if there is enough torque

so an update... I received another Y axis stepper from folgertech today and installed it on my X axis...I dialed the X axis tmc2100 to .5v and it works... very smooth and quite... I'm going to remove the jumper tomorrow that switches it from spreadCycle to stealthchop mode and see what it does... I received the 24v step up board but didn't use it... might not need to... in the middle of a several hour print with it right now : [3dp.hotpixl.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 05, 2016 10:38AM |

Registered: 8 years ago Posts: 541 |

I've been successfully running Marlin 1.1.0 RC3 with auto bed tuning now for, I guess, about a month or so. I hadn't, however, enabled #define EEPROM_SETTINGS so that I could save changes on my LCD screen. Today, I removed the // from in front of the #define and loaded the program with no other changes. Once loaded, when running a part, the nozzle didn't come down to the bed. I checked on the screen and it said my Z offset was 0.000 instead of the normal (for me) -3.3. Strange.... so I added the // back in front of the #define and reloaded the program. Voila, the Z offset was back to -3.3 magically.

Has any one else seen this or have an explanation why just adding CHITCHAT would make the Z offset be ignored?

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

Has any one else seen this or have an explanation why just adding CHITCHAT would make the Z offset be ignored?

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

Sorry, only registered users may post in this forum.