Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 05, 2016 10:58AM |

Registered: 8 years ago Posts: 541 |

On another topic, I was thinking more about die swell and the discussion I had with jhitesma about it as he successfully enlightened me about 'extrusion multiplier'. I raised my Z offset from the normal -3.3 mm to -2.7 mm so that my first pass would just lay down on the bed and not be squished as it normally would. At 40 mm/sec print speed, the extrudate after cooling measured 0.41 mm out of my 0.4 mm nozzle. I raised the print speed up to 120! and ran a pass. That string of plastic measured 0.57 mm!!! This is how much die swell we are talking about. This is with PLA.

Thanks to jhitesma, after making sure my feed rate is correct (100 mm called for equals 100 mm fed), I ran the single wall test again and again until my wall is 0.48 as the GCode says it should be. WHAT A DIFFERENCE in part quality! NOW, knowing that if we speed up the printer to higher print speeds, we get much more die swell, it stands to reason that we must also rerun the single wall test and adjust the extrusion multiplier to get what the GCode says it should be in width. Thinking about this as I type, I have not used Repetier to slice anything with the speed set higher to see if it calls for a wider width. I guess that is the next check.

In any event, be aware that, at higher speeds, your extrudate is going to be a LOT thicker. This could also explain some of the horrible parts that people are posting and asking what's wrong. Maybe they are unwittingly extruding at extremely fast rates for the stock dies.

PS: just checked on Repetier and slicing something running at 120 mm/sec print speed still calls for 0.48 mm width. Maybe running that fast stretches out the plastic down to 0.48?

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

Thanks to jhitesma, after making sure my feed rate is correct (100 mm called for equals 100 mm fed), I ran the single wall test again and again until my wall is 0.48 as the GCode says it should be. WHAT A DIFFERENCE in part quality! NOW, knowing that if we speed up the printer to higher print speeds, we get much more die swell, it stands to reason that we must also rerun the single wall test and adjust the extrusion multiplier to get what the GCode says it should be in width. Thinking about this as I type, I have not used Repetier to slice anything with the speed set higher to see if it calls for a wider width. I guess that is the next check.

In any event, be aware that, at higher speeds, your extrudate is going to be a LOT thicker. This could also explain some of the horrible parts that people are posting and asking what's wrong. Maybe they are unwittingly extruding at extremely fast rates for the stock dies.

PS: just checked on Repetier and slicing something running at 120 mm/sec print speed still calls for 0.48 mm width. Maybe running that fast stretches out the plastic down to 0.48?

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 05, 2016 03:33PM |

Registered: 8 years ago Posts: 14 |

As promised, here's my build document. I haven't put in any pictures yet, but I do have tons of them ready to be added as the week goes on. I have also included a Bill of Materials, broken out by step. (I know engineering BoM documents usually just lump everything together, but since this is a build guide, I broke it out anyway.)

Please do let me know if you see any errors.

Thanks!

https://docs.google.com/document/d/1eFqViNT0CsEdvpz9_bgYhEBXHmNKKkTfeloEk1y3swg/edit?usp=sharing

Please do let me know if you see any errors.

Thanks!

https://docs.google.com/document/d/1eFqViNT0CsEdvpz9_bgYhEBXHmNKKkTfeloEk1y3swg/edit?usp=sharing

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 05, 2016 06:43PM |

Registered: 8 years ago Posts: 314 |

I'm trying to setup autoleveling... I have my sensor wired, mounted and checked that when the sensor isn't detecting the bed z min is open when it is detecting the bed z min is closed.

X endstop on the left, running therippas firmware.

Configuration.H [pastebin.com]

Issue:

When I run the G29 command to do the autolevel procedure, it homes X then tries to home z but then the sensor is off of the bed, since the sensor isn't detecting the bed it proceeds to smash into the glass.

If I click the home z button and the sensor is outside of the bed, it tells me so and won't proceed in the homing of the z axis. Why then when I run G29 it tries to home the z axis when the sensor is off of the bed?

Also the Z axis safezone homing feature isn't working...

EDIT:

Finally! uncomment #define DISABLE_MAX_ENDSTOPS

I was googling around and stumbled accross this (https://github.com/MarlinFirmware/Marlin/issues/2897), He had the same issue I did...

Running the G29 command right now and it's working! YAY

EDIT:

See my post below, more issues...

Edited 11 time(s). Last edit at 03/05/2016 08:40PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

X endstop on the left, running therippas firmware.

Configuration.H [pastebin.com]

Issue:

When I run the G29 command to do the autolevel procedure, it homes X then tries to home z but then the sensor is off of the bed, since the sensor isn't detecting the bed it proceeds to smash into the glass.

If I click the home z button and the sensor is outside of the bed, it tells me so and won't proceed in the homing of the z axis. Why then when I run G29 it tries to home the z axis when the sensor is off of the bed?

Also the Z axis safezone homing feature isn't working...

EDIT:

Finally! uncomment #define DISABLE_MAX_ENDSTOPS

I was googling around and stumbled accross this (https://github.com/MarlinFirmware/Marlin/issues/2897), He had the same issue I did...

Running the G29 command right now and it's working! YAY

EDIT:

See my post below, more issues...

Edited 11 time(s). Last edit at 03/05/2016 08:40PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 05, 2016 08:34PM |

Registered: 8 years ago Posts: 314 |

How do I fix that?

Actually, this must be a REP host glitch. As the lcd display on my printer is showing the correct xyz coordinates.

Edited 1 time(s). Last edit at 03/05/2016 08:48PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 05, 2016 10:05PM |

Registered: 8 years ago Posts: 430 |

Anyone using the openbuilds v-slot stuff notice that the wheels are wearing? I am seeing some wear and some black particles on the rail. Everything still feels tight so it's not a lot yet. Just wonder if this is normal or if I have something adjusted wrong. I did recently loosen the eccentrics a little because I was feeling the build plate wasn't moving freely enough and I don't know if this is from before or after.

Newbie with Folgertech 2020 i3.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 06, 2016 12:44AM |

Registered: 8 years ago Posts: 314 |

Got autolevel working  Only took me a saterday

Only took me a saterday

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

Only took me a saterday

Only took me a saterday

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 06, 2016 02:24PM |

Registered: 8 years ago Posts: 2 |

We got the 2020 and walked into a rabbit warren to set up auto bed leveling... As far as I can tell the firmware that came with the printer dosen't include the ? code ? for it, and we are trying to get a newer version of marlin to send to the printer and have spent the last 3 days just trying to fix one compile error after another. Any suggestions?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 06, 2016 04:04PM |

Registered: 8 years ago Posts: 131 |

Quote

erik-in-mich

We got the 2020 and walked into a rabbit warren to set up auto bed leveling... As far as I can tell the firmware that came with the printer dosen't include the ? code ? for it, and we are trying to get a newer version of marlin to send to the printer and have spent the last 3 days just trying to fix one compile error after another. Any suggestions?

Look at theRippa's version somewhere on here...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 06, 2016 06:08PM |

Registered: 8 years ago Posts: 46 |

Look at the Wiki page: [folgertech.wikia.com]

The Folger firmware is pretty outdated and is not built to support auto leveling. Use the RC3 firmware that you can find by looking for one of theRippas posts here and follow the link. I've rebuilt this code with the current Arduino IDE with no problems.

The Folger firmware is pretty outdated and is not built to support auto leveling. Use the RC3 firmware that you can find by looking for one of theRippas posts here and follow the link. I've rebuilt this code with the current Arduino IDE with no problems.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 09:25AM |

Registered: 8 years ago Posts: 130 |

My hard to find compile errors are usually because I have the wrong board chosen in the >Tools >Boards. Sometimes it's that my Boards definitions need updating.

Is this the place to find theRippa's RC3:

[github.com]

If I have no desire to auto level is there any reason to get theRippa's firmware?

Which files are modified? Mostly Configuration.h, but what else?

Is this the place to find theRippa's RC3:

[github.com]

If I have no desire to auto level is there any reason to get theRippa's firmware?

Which files are modified? Mostly Configuration.h, but what else?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 10:45AM |

Registered: 8 years ago Posts: 130 |

Quote

msaeger

Anyone using the openbuilds v-slot stuff notice that the wheels are wearing? I am seeing some wear and some black particles on the rail. Everything still feels tight so it's not a lot yet. Just wonder if this is normal or if I have something adjusted wrong. I did recently loosen the eccentrics a little because I was feeling the build plate wasn't moving freely enough and I don't know if this is from before or after.

Rule of thumb is the gantry plate should roll on its own when the rail is tilted to a 45 degree angle. I would clean the rails & wheels with a q-tip often. Make sure any lubricant is compatible with Delrin. Delrin is "self lubricating." Something is going to wear, if not the rails the wheels. Aluminum oxide is hard stuff, my bet is the wheels lose the friction battle.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 12:03PM |

Registered: 8 years ago Posts: 276 |

The branch in my sig is 1.0.2-1 (latest marlin release). If you want to try RC3, you can use my personal branch, but it is pretty far from the stock folgertech setup at this point (leadscrews, sonnylowe y/x upgrades, extruder upgrades, full LCD,etc) - [github.com]

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 12:39PM |

Registered: 8 years ago Posts: 131 |

Quote

flatlander

Quote

msaeger

Anyone using the openbuilds v-slot stuff notice that the wheels are wearing? I am seeing some wear and some black particles on the rail. Everything still feels tight so it's not a lot yet. Just wonder if this is normal or if I have something adjusted wrong. I did recently loosen the eccentrics a little because I was feeling the build plate wasn't moving freely enough and I don't know if this is from before or after.

Rule of thumb is the gantry plate should roll on its own when the rail is tilted to a 45 degree angle. I would clean the rails & wheels with a q-tip often. Make sure any lubricant is compatible with Delrin. Delrin is "self lubricating." Something is going to wear, if not the rails the wheels. Aluminum oxide is hard stuff, my bet is the wheels lose the friction battle.

Are you talking about 45 degree even when hooked up to the stepper? Is that with the bed on it (if Y) or with extruder (if x), i find that if it's just an empty gantry then it wouldn't for me due to resistance from the stepper.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 01:54PM |

Registered: 8 years ago Posts: 85 |

Quote

tjnamtiw

On another topic, I was thinking more about die swell and the discussion I had with jhitesma about it as he successfully enlightened me about 'extrusion multiplier'. I raised my Z offset from the normal -3.3 mm to -2.7 mm so that my first pass would just lay down on the bed and not be squished as it normally would. At 40 mm/sec print speed, the extrudate after cooling measured 0.41 mm out of my 0.4 mm nozzle. I raised the print speed up to 120! and ran a pass. That string of plastic measured 0.57 mm!!! This is how much die swell we are talking about. This is with PLA.

Wow, I haven't messed with high speeds yet (but will be soon, got the gantry set for sonny's Y upgrade from my wife for my birthday Saturday...rest of the parts on order and should be here this week sometime.) so I haven't seen that much swell yet. I've actually been fighting the opposite problem - suddenly I started underextruding like crazy

It appears that the pivot for the tensioner on my extruder has wallowed out it's hole. Thankfully I had ordered an all metal one off ebay, I never installed it since it mounted the hot end differently and needed a 6mm nut I didn't have on hand. But I picked one up and swapped it in and it solved that problem. Which is ok for now, but the design of this one has the aluminum block the throat of the hot end screws into integrated in with the rest of it - so I won't be able to stick with it when I eventually upgrade to a better hot end. Still that's a ways off so for now problem solved.

Except then I burned out two stepper drivers on my Z axis in 3 days

We've been having hot weather (mid to upper 90f range) and despite that I refuse to give in and turn on my AC because it's just barely March! The first one burned out when the heat sink fell off the driver and wedged against the pins

We've been having hot weather (mid to upper 90f range) and despite that I refuse to give in and turn on my AC because it's just barely March! The first one burned out when the heat sink fell off the driver and wedged against the pins  I figured it fell off because the wires going to my extruder rubbed against it. So I added a bracket to keep the wires away and added a fan to the RAMPS to help deal with the warm weather - mostly over the extruder driver since I was also fighting with the under extrusion (which I've since determined is almost certainly mechanical as described above.)

I figured it fell off because the wires going to my extruder rubbed against it. So I added a bracket to keep the wires away and added a fan to the RAMPS to help deal with the warm weather - mostly over the extruder driver since I was also fighting with the under extrusion (which I've since determined is almost certainly mechanical as described above.) Then Saturday morning I was doing a string of prints and all was well...until the temp outside got to 82f or so (meaning it was even warmer in the room where my printer is due to the sun shining in the window.) and the heat sink fell off the replacement driver

This time I think it was just heat that did it in...except I've read the temps off those drivers many times and never seen them go over 37c. No more spares on hand so had to order new drivers. They'll be here today and I decided to try the DRV8825's with 32step micro stepping instead - so that will hopefully be interesting.

This time I think it was just heat that did it in...except I've read the temps off those drivers many times and never seen them go over 37c. No more spares on hand so had to order new drivers. They'll be here today and I decided to try the DRV8825's with 32step micro stepping instead - so that will hopefully be interesting.Quote

Thanks to jhitesma, after making sure my feed rate is correct (100 mm called for equals 100 mm fed), I ran the single wall test again and again until my wall is 0.48 as the GCode says it should be. WHAT A DIFFERENCE in part quality! NOW, knowing that if we speed up the printer to higher print speeds, we get much more die swell, it stands to reason that we must also rerun the single wall test and adjust the extrusion multiplier to get what the GCode says it should be in width. Thinking about this as I type, I have not used Repetier to slice anything with the speed set higher to see if it calls for a wider width. I guess that is the next check.

Amazing what a difference it makes isn't it! I was happy with my prints before figuring that out, but now I'm flat out amazed by the results. I look forward to seeing how you do with higher speeds and further refinement!

Quote

In any event, be aware that, at higher speeds, your extrudate is going to be a LOT thicker. This could also explain some of the horrible parts that people are posting and asking what's wrong. Maybe they are unwittingly extruding at extremely fast rates for the stock dies.

PS: just checked on Repetier and slicing something running at 120 mm/sec print speed still calls for 0.48 mm width. Maybe running that fast stretches out the plastic down to 0.48?

I wonder if slic3r is smart enough to account for higher die swell at higher speeds and cuts down the amount of extrusion as a result? Guess it will just take some further testing to figure out for sure!

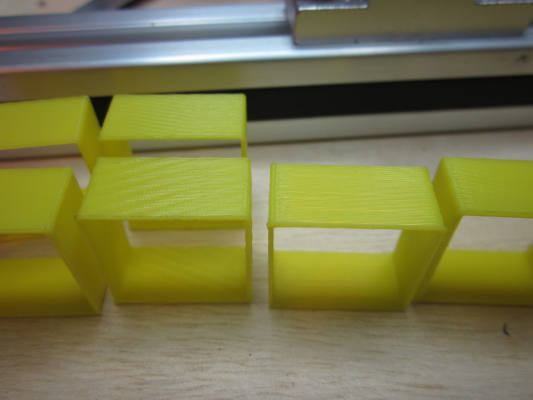

BTW - speaking of print quality. The change from the stock plastic extruder to the $13 metal one from ebay solved a minor print quality issue that I had assumed was due to the cheap linear bearings. I've always had a bit of a pattern on my prints - it's not measurable and I can't feel it, but it is visible as a pattern in the printed surface. Well, the metal extruder with it's adjustable tension has eliminated that:

On the left are single wall tests done with the original plastic extruder - you should be able to see the diagonal patterns I was getting. On the right is a test with the new metal extruder and higher idler tension - the pattern is gone, just the layer lines are left!

(excuse my fat first layers - my z probe offset was a bit off still as I was doing these tests.)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 02:49PM |

Registered: 8 years ago Posts: 25 |

Quote

jhitesma

Quote

tjnamtiw

On another topic, I was thinking more about die swell and the discussion I had with jhitesma about it as he successfully enlightened me about 'extrusion multiplier'. I raised my Z offset from the normal -3.3 mm to -2.7 mm so that my first pass would just lay down on the bed and not be squished as it normally would. At 40 mm/sec print speed, the extrudate after cooling measured 0.41 mm out of my 0.4 mm nozzle. I raised the print speed up to 120! and ran a pass. That string of plastic measured 0.57 mm!!! This is how much die swell we are talking about. This is with PLA.

Wow, I haven't messed with high speeds yet (but will be soon, got the gantry set for sonny's Y upgrade from my wife for my birthday Saturday...rest of the parts on order and should be here this week sometime.) so I haven't seen that much swell yet. I've actually been fighting the opposite problem - suddenly I started underextruding like crazy

It appears that the pivot for the tensioner on my extruder has wallowed out it's hole. Thankfully I had ordered an all metal one off ebay, I never installed it since it mounted the hot end differently and needed a 6mm nut I didn't have on hand. But I picked one up and swapped it in and it solved that problem. Which is ok for now, but the design of this one has the aluminum block the throat of the hot end screws into integrated in with the rest of it - so I won't be able to stick with it when I eventually upgrade to a better hot end. Still that's a ways off so for now problem solved.

Except then I burned out two stepper drivers on my Z axis in 3 daysWe've been having hot weather (mid to upper 90f range) and despite that I refuse to give in and turn on my AC because it's just barely March! The first one burned out when the heat sink fell off the driver and wedged against the pins

I figured it fell off because the wires going to my extruder rubbed against it. So I added a bracket to keep the wires away and added a fan to the RAMPS to help deal with the warm weather - mostly over the extruder driver since I was also fighting with the under extrusion (which I've since determined is almost certainly mechanical as described above.)

Then Saturday morning I was doing a string of prints and all was well...until the temp outside got to 82f or so (meaning it was even warmer in the room where my printer is due to the sun shining in the window.) and the heat sink fell off the replacement driverThis time I think it was just heat that did it in...except I've read the temps off those drivers many times and never seen them go over 37c. No more spares on hand so had to order new drivers. They'll be here today and I decided to try the DRV8825's with 32step micro stepping instead - so that will hopefully be interesting.

Quote

Thanks to jhitesma, after making sure my feed rate is correct (100 mm called for equals 100 mm fed), I ran the single wall test again and again until my wall is 0.48 as the GCode says it should be. WHAT A DIFFERENCE in part quality! NOW, knowing that if we speed up the printer to higher print speeds, we get much more die swell, it stands to reason that we must also rerun the single wall test and adjust the extrusion multiplier to get what the GCode says it should be in width. Thinking about this as I type, I have not used Repetier to slice anything with the speed set higher to see if it calls for a wider width. I guess that is the next check.

Amazing what a difference it makes isn't it! I was happy with my prints before figuring that out, but now I'm flat out amazed by the results. I look forward to seeing how you do with higher speeds and further refinement!

Quote

In any event, be aware that, at higher speeds, your extrudate is going to be a LOT thicker. This could also explain some of the horrible parts that people are posting and asking what's wrong. Maybe they are unwittingly extruding at extremely fast rates for the stock dies.

PS: just checked on Repetier and slicing something running at 120 mm/sec print speed still calls for 0.48 mm width. Maybe running that fast stretches out the plastic down to 0.48?

I wonder if slic3r is smart enough to account for higher die swell at higher speeds and cuts down the amount of extrusion as a result? Guess it will just take some further testing to figure out for sure!

BTW - speaking of print quality. The change from the stock plastic extruder to the $13 metal one from ebay solved a minor print quality issue that I had assumed was due to the cheap linear bearings. I've always had a bit of a pattern on my prints - it's not measurable and I can't feel it, but it is visible as a pattern in the printed surface. Well, the metal extruder with it's adjustable tension has eliminated that:

[attachment 74076 IMG_8255-X2.jpg]

On the left are single wall tests done with the original plastic extruder - you should be able to see the diagonal patterns I was getting. On the right is a test with the new metal extruder and higher idler tension - the pattern is gone, just the layer lines are left!

(excuse my fat first layers - my z probe offset was a bit off still as I was doing these tests.)

Interesting.. can you share what you ordered from ebay?

New Wikia page: [folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 03:13PM |

Registered: 8 years ago Posts: 130 |

Quote

marc2912

Quote

flatlander

Quote

msaeger

Anyone using the openbuilds v-slot stuff notice that the wheels are wearing? I am seeing some wear and some black particles on the rail. Everything still feels tight so it's not a lot yet. Just wonder if this is normal or if I have something adjusted wrong. I did recently loosen the eccentrics a little because I was feeling the build plate wasn't moving freely enough and I don't know if this is from before or after.

Rule of thumb is the gantry plate should roll on its own when the rail is tilted to a 45 degree angle. I would clean the rails & wheels with a q-tip often. Make sure any lubricant is compatible with Delrin. Delrin is "self lubricating." Something is going to wear, if not the rails the wheels. Aluminum oxide is hard stuff, my bet is the wheels lose the friction battle.

Are you talking about 45 degree even when hooked up to the stepper? Is that with the bed on it (if Y) or with extruder (if x), i find that if it's just an empty gantry then it wouldn't for me due to resistance from the stepper.

I did my setup with just the plate, no stepper attached, with one end of the 2020 v-rail in my hand the other braced on my desk. I don't think that 45 degrees is super specific. If the plate starts rolling at 40 degrees or as late as 55 degrees I'd bet you are in the ball park

The goal is to get both the eccentric spacers with about equal compression on the rail, and still let the plate roll the at 45 degree tilt. The eccentric nuts are turned, outward only about an 1/8 turn from top on my plate. It is just snug to the point of no play (no wobble).

The goal is to get both the eccentric spacers with about equal compression on the rail, and still let the plate roll the at 45 degree tilt. The eccentric nuts are turned, outward only about an 1/8 turn from top on my plate. It is just snug to the point of no play (no wobble).The official video, can explain it better than I: [www.youtube.com]

In my final setup I have the eccentric spacers to the bottom. They are easier to adjust when they are facing up, though.

[www.youtube.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 03:56PM |

Registered: 8 years ago Posts: 2 |

Hey guys!

I just finished building this printer about a week ago and I have to say I'm impressed! I have just been running into a pretty consistent issue. Every time I print it seems that about half way up the print, the entire print shifts to the left about a mm. Does anyone know what could be causing this? Also, seen clearly in the boat pictures, the layers that do not have a solid infill have very stringy perimeters. The quality of the perimeter is sufficiently better at the top of the boat than the bottom. Any help is great!! (first link frog, second and third are same boat)

[drive.google.com]

[drive.google.com]

[drive.google.com]

I just finished building this printer about a week ago and I have to say I'm impressed! I have just been running into a pretty consistent issue. Every time I print it seems that about half way up the print, the entire print shifts to the left about a mm. Does anyone know what could be causing this? Also, seen clearly in the boat pictures, the layers that do not have a solid infill have very stringy perimeters. The quality of the perimeter is sufficiently better at the top of the boat than the bottom. Any help is great!! (first link frog, second and third are same boat)

[drive.google.com]

[drive.google.com]

[drive.google.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 04:33PM |

Registered: 8 years ago Posts: 131 |

Quote

wefriend94

Hey guys!

I just finished building this printer about a week ago and I have to say I'm impressed! I have just been running into a pretty consistent issue. Every time I print it seems that about half way up the print, the entire print shifts to the left about a mm. Does anyone know what could be causing this? Also, seen clearly in the boat pictures, the layers that do not have a solid infill have very stringy perimeters. The quality of the perimeter is sufficiently better at the top of the boat than the bottom. Any help is great!! (first link frog, second and third are same boat)

[drive.google.com]

[drive.google.com]

[drive.google.com]

The shift could be caused if your x or y belt are not tight enough,

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 04:38PM |

Registered: 8 years ago Posts: 85 |

Quote

john-i

Interesting.. can you share what you ordered from ebay?

Sure, this is the one I used:

[www.ebay.com]

I picked that one because it was the cheapest available from the physically closest seller (I hate waiting on shipping!) but there are tons of sellers with the same thing at similar prices.

You'll also need a single M6 nut to go with it to to attach the stock hot end.

My DRV9925's arrived this morning so when I went home for lunch I had to get one installed for the Z

They go on with the adjustment pot facing the opposite direction, and as such the pot turns the opposite direction to adjust, which makes sense now but threw me when I discovered it. Quick adjustment to the pot to set the current, quick tweak of my z steps (I'm running leadscrews so I went from 400 to 800 since the old driverss did 16 microsteps and these do 32) then fired it up...and worked like a charm first try. It's actually a lot quieter than I expected, I'd seen videos of the difference between the stock drivers and these but in person it made a bigger difference than I expected. Can't wait to swap them in on X/Y and the extruder tonight!

They go on with the adjustment pot facing the opposite direction, and as such the pot turns the opposite direction to adjust, which makes sense now but threw me when I discovered it. Quick adjustment to the pot to set the current, quick tweak of my z steps (I'm running leadscrews so I went from 400 to 800 since the old driverss did 16 microsteps and these do 32) then fired it up...and worked like a charm first try. It's actually a lot quieter than I expected, I'd seen videos of the difference between the stock drivers and these but in person it made a bigger difference than I expected. Can't wait to swap them in on X/Y and the extruder tonight!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 04:41PM |

Registered: 8 years ago Posts: 85 |

Quote

marc2912

Quote

wefriend94

Hey guys!

I just finished building this printer about a week ago and I have to say I'm impressed! I have just been running into a pretty consistent issue. Every time I print it seems that about half way up the print, the entire print shifts to the left about a mm. Does anyone know what could be causing this? Also, seen clearly in the boat pictures, the layers that do not have a solid infill have very stringy perimeters. The quality of the perimeter is sufficiently better at the top of the boat than the bottom. Any help is great!! (first link frog, second and third are same boat)

[drive.google.com]

[drive.google.com]

[drive.google.com]

The shift could be caused if your x or y belt are not tight enough,

In addition to checking the tension on the belts you may need to adjust your stepper drivers current pot. I tried doing it "by the numbers" originally but after fighting skipped steps like that for a few days I gave in and just adjusted them "by feel" while it was printing looking for a sweet spot where it didn't jump - but ran quiet and the steppers didn't get too hot. Then I checked the values and confirmed I wasn't driving them too hard. I wound up with values around 0.45 on X/Y and the X and Z motos all run around 35c - 37c, the Y motor basically stays at room temp now and doesn't jump even though it's set a bit higher (closer to 0.6) but it's a bigger stepper so that's not very shocking.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 05:17PM |

Registered: 8 years ago Posts: 2 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 08:52PM |

Registered: 8 years ago Posts: 541 |

Quote

jhitesma

Wow, I haven't messed with high speeds yet (but will be soon, got the gantry set for sonny's Y upgrade from my wife for my birthday Saturday...rest of the parts on order and should be here this week sometime.) so I haven't seen that much swell yet. I've actually been fighting the opposite problem - suddenly I started underextruding like crazy

It appears that the pivot for the tensioner on my extruder has wallowed out it's hole. Thankfully I had ordered an all metal one off ebay, I never installed it since it mounted the hot end differently and needed a 6mm nut I didn't have on hand. But I picked one up and swapped it in and it solved that problem. Which is ok for now, but the design of this one has the aluminum block the throat of the hot end screws into integrated in with the rest of it - so I won't be able to stick with it when I eventually upgrade to a better hot end. Still that's a ways off so for now problem solved.

Except then I burned out two stepper drivers on my Z axis in 3 daysWe've been having hot weather (mid to upper 90f range) and despite that I refuse to give in and turn on my AC because it's just barely March! The first one burned out when the heat sink fell off the driver and wedged against the pins

I figured it fell off because the wires going to my extruder rubbed against it. So I added a bracket to keep the wires away and added a fan to the RAMPS to help deal with the warm weather - mostly over the extruder driver since I was also fighting with the under extrusion (which I've since determined is almost certainly mechanical as described above.)

Then Saturday morning I was doing a string of prints and all was well...until the temp outside got to 82f or so (meaning it was even warmer in the room where my printer is due to the sun shining in the window.) and the heat sink fell off the replacement driverThis time I think it was just heat that did it in...except I've read the temps off those drivers many times and never seen them go over 37c. No more spares on hand so had to order new drivers. They'll be here today and I decided to try the DRV8825's with 32step micro stepping instead - so that will hopefully be interesting.

I wonder if slic3r is smart enough to account for higher die swell at higher speeds and cuts down the amount of extrusion as a result? Guess it will just take some further testing to figure out for sure!

BTW - speaking of print quality. The change from the stock plastic extruder to the $13 metal one from ebay solved a minor print quality issue that I had assumed was due to the cheap linear bearings. I've always had a bit of a pattern on my prints - it's not measurable and I can't feel it, but it is visible as a pattern in the printed surface. Well, the metal extruder with it's adjustable tension has eliminated that:

[attachment 74076 IMG_8255-X2.jpg]

On the left are single wall tests done with the original plastic extruder - you should be able to see the diagonal patterns I was getting. On the right is a test with the new metal extruder and higher idler tension - the pattern is gone, just the layer lines are left!

(excuse my fat first layers - my z probe offset was a bit off still as I was doing these tests.)

First, Happy Birthday!

I'll have to keep an eye out for the wear pattern on the extruder. Maybe go ahead and order that metal replacement. Right hand drive, correct? I guess the left hand drive is for the Brits...... hahaha. Been there and done that! Scared a bunch of Brits too! Learned a few new words!

The pattern on the single wall is interesting.

Thanks again for your help. My prints are SO much better now.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 10:34PM |

Registered: 8 years ago Posts: 85 |

Quote

tjnamtiw

First, Happy Birthday!

I'll have to keep an eye out for the wear pattern on the extruder. Maybe go ahead and order that metal replacement. Right hand drive, correct? I guess the left hand drive is for the Brits...... hahaha. Been there and done that! Scared a bunch of Brits too! Learned a few new words!

Thanks, was actually a rather frustrating and annoying birthday...but it's getting better

The wear on the extruder is really hard to see, I really questioned if it was the problem or not. It was acting like a clogged nozzle, but not chewing up the filament so I figured it had to be the tension - or lack thereof. I went with the right but you could really go with either, I kind of wish I had gone with the left so I could have picked up another stepper and put my spare hot end on it to make a dual extruder. But now that my original plastic one isn't playing nice I may as well just get a whole second extruder if I do that. I was thinking about trying a geared extruder - may print up the parts to have on hand just in case before anything else goes wrong for me

The wear on the extruder is really hard to see, I really questioned if it was the problem or not. It was acting like a clogged nozzle, but not chewing up the filament so I figured it had to be the tension - or lack thereof. I went with the right but you could really go with either, I kind of wish I had gone with the left so I could have picked up another stepper and put my spare hot end on it to make a dual extruder. But now that my original plastic one isn't playing nice I may as well just get a whole second extruder if I do that. I was thinking about trying a geared extruder - may print up the parts to have on hand just in case before anything else goes wrong for me  Just had to pull some filament (I'm printing with some eSun black and it's driving me crazy because it gets brittle if I leave it in the extruder when I'm done with a print) and realized I don't even use the little handle - it's too small for my fingers. I just press on the top. So even the plain option I'd have been fine with.

Just had to pull some filament (I'm printing with some eSun black and it's driving me crazy because it gets brittle if I leave it in the extruder when I'm done with a print) and realized I don't even use the little handle - it's too small for my fingers. I just press on the top. So even the plain option I'd have been fine with.Quote

The pattern on the single wall is interesting.

Thanks again for your help. My prints are SO much better now.

I really thought the pattern was from resonant vibrations in the motion. Was pretty shocked at what a difference the change on extruder made. Extra tension against the drive gear really does make a bigger difference than I thought. Really glad to hear you're happy with the improvement in print quality. I want to go back and experiment with dialing it with automatic thickness now that I have a better grasp of how things work - but I'm not fiddling with anything until I finish the parts for this MPCNC. 3 more 2 hour prints and I should be done, then I can get back to experimenting

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 10:56PM |

Registered: 8 years ago Posts: 541 |

I have several rolls of ESun filament PLA and haven't had any problems. Most of my stuff is Hatchbox with a couple of Inland and Sainsmart. All are running well. After running, I snip off my roll and put it into my dry box. I didn't use to do that before my red turned into Pringles! Now nothing sits out.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 07, 2016 11:48PM |

Registered: 8 years ago Posts: 38 |

Quote

jhitesma

wear on the extruder is really hard to see, I really questioned if it was the problem or not. It was acting like a clogged nozzle, but not chewing up the filament so I figured it had to be the tension - or lack thereof.

I went through severe under extruding this weekend. My printer is about the same age as yours. Grrrr. Mine looked to be caused by a worn drive gear and bad alignment though. I didn't open mine up when I built it. The filament was riding right on the edge of the gear. The gear had worn some, so I pulled the gear out a bit and tightened it back down. Everything appears to be back to normal now, but I'm on the hunt for a new extruded design.

I remember someone had a sweet looking big geared setup. Sonnylowe maybe.

Hunting..,

(happy birthday!)

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 08, 2016 01:49AM |

Registered: 8 years ago Posts: 85 |

Quote

tjnamtiw

I have several rolls of ESun filament PLA and haven't had any problems. Most of my stuff is Hatchbox with a couple of Inland and Sainsmart. All are running well. After running, I snip off my roll and put it into my dry box. I didn't use to do that before my red turned into Pringles! Now nothing sits out.

This gets brittle before my heated bed cools. It doesn't even feel warm coming out of the top of the extruder - but it snaps right at the top of the extruder by the time the bed cools enough to remove a part if I don't pull it out of the extruder as soon as it's done printing. Haven't had that problem with Hatchbox, or Folger, or Atomic, or MakerGeeks.

Plus this roll of eSun stinks, almost as bad as ABS, when it prints. It also oozes more and strings more no matter what temps I print it at.

I actually ordered Hatchbox but Amazon sent me a roll of eSun with a sticker on it that said "HatchBox". I'm guessing one of their vendors had an old roll they were looking to offload. I didn't want to wait to ship it back and order a replacement so figured I'd try the eSun. Plus I didn't have time to take it to UPS to ship it back and wasn't going to be around to give it to a delivery guy to take so returning it was more hassle than it was worth. But after this I doubt I'll ever try eSun again, worst PLA I've tried yet. Maybe it's just this roll, but I'm not about to risk finding out again since there are so many other choices I like.

I keep my rolls in a vacuum bag with desiccant when I'm not using them. But this one roll has been miserable.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 08, 2016 01:59AM |

Registered: 8 years ago Posts: 85 |

Quote

GrouchoDuke

Quote

jhitesma

wear on the extruder is really hard to see, I really questioned if it was the problem or not. It was acting like a clogged nozzle, but not chewing up the filament so I figured it had to be the tension - or lack thereof.

I went through severe under extruding this weekend. My printer is about the same age as yours. Grrrr. Mine looked to be caused by a worn drive gear and bad alignment though. I didn't open mine up when I built it. The filament was riding right on the edge of the gear. The gear had worn some, so I pulled the gear out a bit and tightened it back down. Everything appears to be back to normal now, but I'm on the hunt for a new extruded design.

I remember someone had a sweet looking big geared setup. Sonnylowe maybe.

Hunting..,

(happy birthday!)

That was my first thought as I know a few other people who had the gear come loose. So that was one of the first things I did when assembling the kit - tighten it down. And sure enough it was still snug as could be.

I'm really liking the DRV8825 stepper drivers. Unfortunately I manged to kill one already

It went great for the first print, but then on the second one my inductive sensor cable somehow got over the bracket I had put in place to keep those wires off the RAMPS and knocked the heat sink off shorting it out again

It went great for the first print, but then on the second one my inductive sensor cable somehow got over the bracket I had put in place to keep those wires off the RAMPS and knocked the heat sink off shorting it out again  Arrrgh!

Arrrgh!Put on a replacement stepper, and dialed it in a bit more carefully this time. First I added a zip tie to the cables to hold them to that bracket so there's no way they can rub against the RAMPS for sure (I still want to print a cable chain but need to finish this current project first!) Then I read pololu's page about the DRV8825's....I had my vref on the current set at 0.4v which is about where I had my original stepper drivers...but apparently on these that's 0.8a current and according to folgers website our smaller steppers are only rated for 0.4a. So on the second driver I dialed it back to 0.2v and the Z is still moving smooth as silk...but even quieter and the motors are now barely above room temperature - nice! They also say that these drivers are capable of 1.5a per coil without heatsinks. So this time I left the heatsink off. I figure I've lost at least 2 and possibly 3 drivers because of the heat sinks coming loose so if these are supposedly rated to handle it without the heatsink why put one on.

First print after that went great. Except my hot end is oozing like crazy, guess I didn't get the nozzle quite tight enough after the extruder change. So gotta tear that all apart, clean it, and reassemble it. But too late for that tonight now.

Can't wait to put the DRV's on the X and Y to quiet things down a bit. Really can't wait for the extrusion I need to do Sonny's Y upgrade...though I do need to finish 3 more prints for the MPCNC before I can print the parts for that upgrade

Fingers crossed OpenBuilds ships quick...my order placed Saturday for the extrusion is still showing as awaiting fulfillment, but that and the printed parts are all I'm waiting on to do the upgrade and I'd love to have it quieter this upcoming weekend! (Though the parts for the MPCNC are also scheduled to arrive the next 2-3 days so I'll have that to assemble and start working with by this weekend as well!)

Fingers crossed OpenBuilds ships quick...my order placed Saturday for the extrusion is still showing as awaiting fulfillment, but that and the printed parts are all I'm waiting on to do the upgrade and I'd love to have it quieter this upcoming weekend! (Though the parts for the MPCNC are also scheduled to arrive the next 2-3 days so I'll have that to assemble and start working with by this weekend as well!)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 08, 2016 08:14AM |

Registered: 8 years ago Posts: 130 |

Quote

jhitesma

Quote

GrouchoDuke

Quote

jhitesma

wear on the extruder is really hard to see, I really questioned if it was the problem or not. It was acting like a clogged nozzle, but not chewing up the filament so I figured it had to be the tension - or lack thereof.

I went through severe under extruding this weekend. My printer is about the same age as yours. Grrrr. Mine looked to be caused by a worn drive gear and bad alignment though. I didn't open mine up when I built it. The filament was riding right on the edge of the gear. The gear had worn some, so I pulled the gear out a bit and tightened it back down. Everything appears to be back to normal now, but I'm on the hunt for a new extruded design.

I remember someone had a sweet looking big geared setup. Sonnylowe maybe.

Hunting..,

(happy birthday!)

That was my first thought as I know a few other people who had the gear come loose. So that was one of the first things I did when assembling the kit - tighten it down. And sure enough it was still snug as could be.

I'm really liking the DRV8825 stepper drivers. Unfortunately I manged to kill one alreadyIt went great for the first print, but then on the second one my inductive sensor cable somehow got over the bracket I had put in place to keep those wires off the RAMPS and knocked the heat sink off shorting it out again

Arrrgh!

Put on a replacement stepper, and dialed it in a bit more carefully this time. First I added a zip tie to the cables to hold them to that bracket so there's no way they can rub against the RAMPS for sure (I still want to print a cable chain but need to finish this current project first!) Then I read pololu's page about the DRV8825's....I had my vref on the current set at 0.4v which is about where I had my original stepper drivers...but apparently on these that's 0.8a current and according to folgers website our smaller steppers are only rated for 0.4a. So on the second driver I dialed it back to 0.2v and the Z is still moving smooth as silk...but even quieter and the motors are now barely above room temperature - nice! They also say that these drivers are capable of 1.5a per coil without heatsinks. So this time I left the heatsink off. I figure I've lost at least 2 and possibly 3 drivers because of the heat sinks coming loose so if these are supposedly rated to handle it without the heatsink why put one on.

First print after that went great. Except my hot end is oozing like crazy, guess I didn't get the nozzle quite tight enough after the extruder change. So gotta tear that all apart, clean it, and reassemble it. But too late for that tonight now.

Can't wait to put the DRV's on the X and Y to quiet things down a bit. Really can't wait for the extrusion I need to do Sonny's Y upgrade...though I do need to finish 3 more prints for the MPCNC before I can print the parts for that upgradeFingers crossed OpenBuilds ships quick...my order placed Saturday for the extrusion is still showing as awaiting fulfillment, but that and the printed parts are all I'm waiting on to do the upgrade and I'd love to have it quieter this upcoming weekend! (Though the parts for the MPCNC are also scheduled to arrive the next 2-3 days so I'll have that to assemble and start working with by this weekend as well!)

Did you catch this at: [www.pololu.com]?

"Warning: This carrier board uses low-ESR ceramic capacitors, which makes it susceptible to destructive LC voltage spikes, especially when using power leads longer than a few inches. Under the right conditions, these spikes can exceed the 45 V maximum voltage rating for the DRV8825 and permanently damage the board, even when the motor supply voltage is as low as 12 V. One way to protect the driver from such spikes is to put a large (at least 47 µF) electrolytic capacitor across motor power (VMOT) and ground somewhere close to the board."

I am still struggling with getting the x-axis VREF correct. I can't seem to get the VREF low enough to keep that one stepper cool. It's either too hot or skipping because of too low torque. That little Tugboat didn't stand a chance at low current. I went for the box-o-steppers, so that I can drive the x-axis stepper with a high enough current.

Edited 1 time(s). Last edit at 03/08/2016 10:21AM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 08, 2016 11:17AM |

Registered: 8 years ago Posts: 85 |

Quote

flatlander

Did you catch this at: [www.pololu.com]?

"Warning: This carrier board uses low-ESR ceramic capacitors, which makes it susceptible to destructive LC voltage spikes, especially when using power leads longer than a few inches. Under the right conditions, these spikes can exceed the 45 V maximum voltage rating for the DRV8825 and permanently damage the board, even when the motor supply voltage is as low as 12 V. One way to protect the driver from such spikes is to put a large (at least 47 µF) electrolytic capacitor across motor power (VMOT) and ground somewhere close to the

board."

They seem to be talking about the power supply to the steppers. With the way the RAMPS is laid out it would be fairly difficult to add any extra capacitance and the power leads are fairly short anyway since they're all on the PCB. So despite the warning I think the risk is low enough that the difficulty of adding such a large cap that close to the driver is more difficult than it's worth dealing with. A quick glance at the RAMPS schematic looks like there are some 100µF caps on there already (C3,C4,C7,C9,C10). The A4988 carries the same warning afterall: [www.pololu.com]

Not that the RAMPS is the greatest design. It's cheap and convenient...but I'm really not that happy or impressed with it. I've never been a fan of the power circuits on the arduino mega and the RAMPS just adds more issues on top of that. I'm kind of surprised there aren't more lower cost boards. Heck even the RAMPS 1.4.2 from 2013 seems like enough minor but important upgrades over the 1.4 that I'm shocked it hasn't become the variant of choice. It still has the under rated power connector, but adds blade fuses in place of the polyfuses, protection caps on the endstops, and some nicer labels on the board. Should be able to be cloned for about the same cost as a 1.4 and is still released under GPL...but there don't seem to be any available other than from the place that created it.

Even something like the printrboard shouldn't be as expensive as it is since it's basically just a RAMPS and Mega integrated (different processor but overall nothing radically different.) Yet even the clones sell for way more than RAMPS.

Something seems to be keeping the price of RAMPS setups artificially low...while better designed alternatives seem to be artificially high. I like the replicape - but the price is kind of high for what it is especially once you add in the cost of a beagle bone. An all in one solution based off that design with an integrated uC could likely be mass produced for close to the same price as just the current cape version if you could sell enough. The big problem is RAMPS is so entrenched with the super cheap clones it's tough to get the momentum on a new design - so we're stuck with dozens of overpriced designs or 1 poor design dirt cheap.

Quote

I am still struggling with getting the x-axis VREF correct. I can't seem to get the VREF low enough to keep that one stepper cool. It's either too hot or skipping because of too low torque. That little Tugboat didn't stand a chance at low current. I went for the box-o-steppers, so that I can drive the x-axis stepper with a high enough current.

My X runs kind of hot, but not too hot. Technically I'm probably over driving the stepper based on the actual numbers...but it's been working since December so I'm not going to complain. I found on X/Y just going by the numbers to be pretty much useless. Going by feel and just adjusting it to just above where it jumps steps worked best for me, even if according to the numbers I'm potentially driving it slightly above the 0.4a rating of our steppers. I'm probably running closer to 0.7a IIRC and my stepper runs around 37c. My extruder stepper runs hotter even though it's driven at lower current (I assume due to heat from the hot end soaking into it through the aluminum block the hot end mounts to.)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 08, 2016 11:25AM |

Registered: 8 years ago Posts: 541 |

Quote

jhitesma

Quote

tjnamtiw

I have several rolls of ESun filament PLA and haven't had any problems. Most of my stuff is Hatchbox with a couple of Inland and Sainsmart. All are running well. After running, I snip off my roll and put it into my dry box. I didn't use to do that before my red turned into Pringles! Now nothing sits out.

This gets brittle before my heated bed cools. It doesn't even feel warm coming out of the top of the extruder - but it snaps right at the top of the extruder by the time the bed cools enough to remove a part if I don't pull it out of the extruder as soon as it's done printing. Haven't had that problem with Hatchbox, or Folger, or Atomic, or MakerGeeks.

Plus this roll of eSun stinks, almost as bad as ABS, when it prints. It also oozes more and strings more no matter what temps I print it at.

I actually ordered Hatchbox but Amazon sent me a roll of eSun with a sticker on it that said "HatchBox". I'm guessing one of their vendors had an old roll they were looking to offload. I didn't want to wait to ship it back and order a replacement so figured I'd try the eSun. Plus I didn't have time to take it to UPS to ship it back and wasn't going to be around to give it to a delivery guy to take so returning it was more hassle than it was worth. But after this I doubt I'll ever try eSun again, worst PLA I've tried yet. Maybe it's just this roll, but I'm not about to risk finding out again since there are so many other choices I like.

I keep my rolls in a vacuum bag with desiccant when I'm not using them. But this one roll has been miserable.

Wow, you REALLY got an old roll!!! When I return stuff to Amazon, I just take off the old bar code and write on the box "Return to Amazon". I leave it on the porch or out front and UPS comes and gets it and leaves a receipt. I don't hang around for them to show up. It costs nothing. Now if you live in an apartment or somewhere where 'neighbors' would help themselves to your package, change of story.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

Sorry, only registered users may post in this forum.