Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 12, 2016 03:48AM |

Registered: 8 years ago Posts: 276 |

Quote

Toxic0n

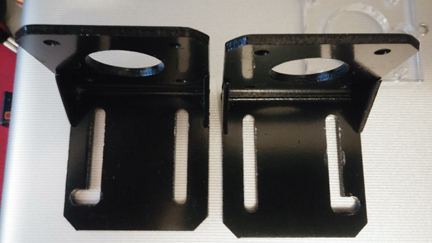

Any recommendations for an upgraded Y carriage bearing holders? I'm not sold on the zip tie approach. I found one for X carriage, but nothing for Y.

Also, the right side X axis mount (where the motor is attached)? The rod holes were slightly too small so I had to dremel them out so I'd rather print a new one now.

I remixed these to fit the Folgertech - [www.thingiverse.com]

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 12, 2016 07:27AM |

Registered: 8 years ago Posts: 130 |

Quote

Toxic0n

Any recommendations for an upgraded Y carriage bearing holders? I'm not sold on the zip tie approach. I found one for X carriage, but nothing for Y.

Also, the right side X axis mount (where the motor is attached)? The rod holes were slightly too small so I had to dremel them out so I'd rather print a new one now.

I used the following, and drilled holes in the aluminum plate:

[folgertech.com]

They really transmit noise. If that's a concern stick with the plastic mounts.

As to the motor mount on the x-axis, If I had printed a new part it would have been in PLA and the heat of that x-axis stepper would have warped the mount. Or did you take the ABS plunge right at the gun?

Edited 1 time(s). Last edit at 03/12/2016 07:46AM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 12, 2016 10:26AM |

Registered: 8 years ago Posts: 131 |

Hey Guys,

So looking for a little help for those that have done upgrades... I did a few upgrades at once.. I learned that's probably not a good idea because now I don't know what's causing my issues. I have ideas but no real answers.

Things upgraded:

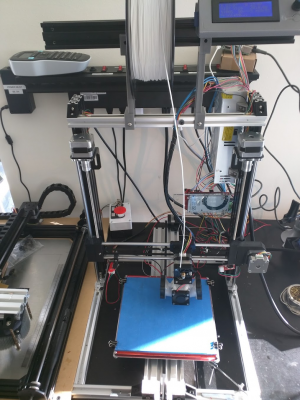

So here is my current new setup.. Print area is now 200x200x200.

Ignore the v slot on the left, that's my laser cutter....

Now here is my first print viewed from the side. Back is to the left.

As you can see I have a serious issue with the print leaning back and it only happens on the 1st 10mm... I checked my Z axis V-slot to make sure they were really at 90degree. They seem fine. I also checked the y axis gear on the stepper and my y axis belt. Everything is tight.

Edited 1 time(s). Last edit at 03/12/2016 10:26AM by marc2912.

So looking for a little help for those that have done upgrades... I did a few upgrades at once.. I learned that's probably not a good idea because now I don't know what's causing my issues. I have ideas but no real answers.

Things upgraded:

- Z axis V-slot - changed to longer pieces

- Z Axis Round bar - changed 5mm bars to the longer one I had from Y upgrade done previously.

- Extruder - Changed to E3D. Changed mount and cooling setup alongside it.

So here is my current new setup.. Print area is now 200x200x200.

Ignore the v slot on the left, that's my laser cutter....

Now here is my first print viewed from the side. Back is to the left.

As you can see I have a serious issue with the print leaning back and it only happens on the 1st 10mm... I checked my Z axis V-slot to make sure they were really at 90degree. They seem fine. I also checked the y axis gear on the stepper and my y axis belt. Everything is tight.

Edited 1 time(s). Last edit at 03/12/2016 10:26AM by marc2912.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 12, 2016 01:21PM |

Registered: 8 years ago Posts: 314 |

No matter what I do I can't get autolevel to work for me... changing z probe offset doesn't make a difference.. And I don't know why.

If I set the z offset to -0.6 after I run G29 it should be -0.6mm lower than before right?

But it isn't.

But it isn't.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

If I set the z offset to -0.6 after I run G29 it should be -0.6mm lower than before right?

But it isn't.

But it isn't.Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 12, 2016 02:06PM |

Registered: 8 years ago Posts: 10 |

Quote

therippa

Quote

Toxic0n

Any recommendations for an upgraded Y carriage bearing holders? I'm not sold on the zip tie approach. I found one for X carriage, but nothing for Y.

Also, the right side X axis mount (where the motor is attached)? The rod holes were slightly too small so I had to dremel them out so I'd rather print a new one now.

I remixed these to fit the Folgertech - [www.thingiverse.com]

Thanks, that's perfect!

Quote

flatlander

Quote

Toxic0n

Any recommendations for an upgraded Y carriage bearing holders? I'm not sold on the zip tie approach. I found one for X carriage, but nothing for Y.

Also, the right side X axis mount (where the motor is attached)? The rod holes were slightly too small so I had to dremel them out so I'd rather print a new one now.

I used the following, and drilled holes in the aluminum plate:

[folgertech.com]

They really transmit noise. If that's a concern stick with the plastic mounts.

As to the motor mount on the x-axis, If I had printed a new part it would have been in PLA and the heat of that x-axis stepper would have warped the mount. Or did you take the ABS plunge right at the gun?

I'm going with ABS, I understand it is better for printer parts.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 12, 2016 02:42PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Quote

UltiFix

Changing #define Z_PROBE_OFFSET_FROM_EXTRUDER -0.3 literally does nothing... Why?

Here is my configuration.h

ANY help is appreciated! Please?

I have been running g29, then g29z10 then m119 then I lower the extruder in .1mm untill the hotend just starts rubbing up against the paper. Lets say I had to click lower by .1mm 5 times, I set my z probe offset to -.5

is that right?

G29.2 Z10 is not supported by marlin firmware. Btw, have you tried just moving the probe up so that it is at the proper height. I know it is a pain to do, but you really only have to do it once and then it is set.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 12, 2016 03:58PM |

Registered: 8 years ago Posts: 314 |

I was thinking of doing that... But there is a reason why it isn't working and I would prefer to get it working right.Quote

Mach

Quote

UltiFix

Quote

UltiFix

Changing #define Z_PROBE_OFFSET_FROM_EXTRUDER -0.3 literally does nothing... Why?

Here is my configuration.h

ANY help is appreciated! Please?

I have been running g29, then g29z10 then m119 then I lower the extruder in .1mm untill the hotend just starts rubbing up against the paper. Lets say I had to click lower by .1mm 5 times, I set my z probe offset to -.5

is that right?

G29.2 Z10 is not supported by marlin firmware. Btw, have you tried just moving the probe up so that it is at the proper height. I know it is a pain to do, but you really only have to do it once and then it is set.

I mean G92Z10, I guess I was running the wrong command... Either way it doesn't matter. Somebody is helping on the github website

[github.com]

If I can't fix it though I guess I could just move the z probe.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 12, 2016 08:04PM |

Registered: 8 years ago Posts: 314 |

Problem solved!Quote

UltiFix

I was thinking of doing that... But there is a reason why it isn't working and I would prefer to get it working right.Quote

Mach

Quote

UltiFix

Quote

UltiFix

Changing #define Z_PROBE_OFFSET_FROM_EXTRUDER -0.3 literally does nothing... Why?

Here is my configuration.h

ANY help is appreciated! Please?

I have been running g29, then g29z10 then m119 then I lower the extruder in .1mm untill the hotend just starts rubbing up against the paper. Lets say I had to click lower by .1mm 5 times, I set my z probe offset to -.5

is that right?

G29.2 Z10 is not supported by marlin firmware. Btw, have you tried just moving the probe up so that it is at the proper height. I know it is a pain to do, but you really only have to do it once and then it is set.

I mean G92Z10, I guess I was running the wrong command... Either way it doesn't matter. Somebody is helping on the github website

[github.com]

If I can't fix it though I guess I could just move the z probe.

Between you guys letting me know I need to change my z min and z max and this guy on github.. Im golden!

[github.com]

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 12, 2016 09:55PM |

Registered: 8 years ago Posts: 7 |

When I put my linear rails in for the y carriage, in the lower frame, the longest rails I have seem short! Each end of the rails only goes into the SK8s about half way. Makes me think the kit should have had 405mm rods, not 395mm. In fact if this doesn't turn out to be something I did, I'm going to order longer rods! Any ideas? I'll get pictures up if needed.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 12, 2016 10:22PM |

Registered: 8 years ago Posts: 92 |

Quote

marc2912

Hey Guys,

So looking for a little help for those that have done upgrades... I did a few upgrades at once.. I learned that's probably not a good idea because now I don't know what's causing my issues. I have ideas but no real answers.

Things upgraded:

- Z axis V-slot - changed to longer pieces

- Z Axis Round bar - changed 5mm bars to the longer one I had from Y upgrade done previously.

- Extruder - Changed to E3D. Changed mount and cooling setup alongside it.

So here is my current new setup.. Print area is now 200x200x200.

Ignore the v slot on the left, that's my laser cutter....

Now here is my first print viewed from the side. Back is to the left.

As you can see I have a serious issue with the print leaning back and it only happens on the 1st 10mm... I checked my Z axis V-slot to make sure they were really at 90degree. They seem fine. I also checked the y axis gear on the stepper and my y axis belt. Everything is tight.

It looks like your Y stepper is missing steps, although it seems strange that would only happen on the first layers... Check your Y stepper driver current, you may want to turn it up. My Y axis v.ref is around .65v - almost 3x what the other motors are at - but with that larger motor, it still keeps its cool.

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 13, 2016 08:56AM |

Registered: 8 years ago Posts: 130 |

My Fume Extractor is finished. Or is it a turbocharged Ramps 1.4 bonfire chimney?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 13, 2016 09:12AM |

Registered: 8 years ago Posts: 130 |

Quote

UltiFix

Problem solved!

Between you guys letting me know I need to change my z min and z max and this guy on github.. Im golden!

[github.com]

Hurray!

Which fork to take? I think I have a version from the 1980's, ha, ha, ha.

[github.com]

vs.

[github.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 13, 2016 09:25AM |

Registered: 8 years ago Posts: 131 |

Quote

iamquestar

Quote

marc2912

Hey Guys,

So looking for a little help for those that have done upgrades... I did a few upgrades at once.. I learned that's probably not a good idea because now I don't know what's causing my issues. I have ideas but no real answers.

Things upgraded:

- Z axis V-slot - changed to longer pieces

- Z Axis Round bar - changed 5mm bars to the longer one I had from Y upgrade done previously.

- Extruder - Changed to E3D. Changed mount and cooling setup alongside it.

So here is my current new setup.. Print area is now 200x200x200.

Ignore the v slot on the left, that's my laser cutter....

Now here is my first print viewed from the side. Back is to the left.

As you can see I have a serious issue with the print leaning back and it only happens on the 1st 10mm... I checked my Z axis V-slot to make sure they were really at 90degree. They seem fine. I also checked the y axis gear on the stepper and my y axis belt. Everything is tight.

It looks like your Y stepper is missing steps, although it seems strange that would only happen on the first layers... Check your Y stepper driver current, you may want to turn it up. My Y axis v.ref is around .65v - almost 3x what the other motors are at - but with that larger motor, it still keeps its cool.

--Andrew

Thanks Andrew, already tried that, it's not skipping or if it is it's doing it still even though I increased the current twice.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 13, 2016 10:17AM |

Registered: 8 years ago Posts: 130 |

Quote

marc2912

Thanks Andrew, already tried that, it's not skipping or if it is it's doing it still even though I increased the current twice.

Is the extruder temperature or bed over-running because of odd thermistor behavior? If it's not alignment, the plastic is too hot causing slumping.

Did you lose some bearings on your y-axis rails?

Usb/serial communication errors? I think usb 2.0 is limited to a cable of 16 ft.

Have you accounted for the z-stepper motor mount slots not allowing the vertical rails to be parallel?

Have you tried a different slicer? I've seen some odd behavior if I get one of the Slic3r parameters out of bounds.

Added (edit):

Are the z lead screws mounted or aligned so that they are traveling in a wide arc, on the loose/bottom, end ? The vertical bearings, on the x carriage, can dampen in the x direction but somehow aren't able to dampen the y movement.

Edited 2 time(s). Last edit at 03/13/2016 10:52AM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 13, 2016 01:03PM |

Registered: 8 years ago Posts: 131 |

Quote

flatlander

Quote

marc2912

Thanks Andrew, already tried that, it's not skipping or if it is it's doing it still even though I increased the current twice.

Is the extruder temperature or bed over-running because of odd thermistor behavior? If it's not alignment, the plastic is too hot causing slumping.

Did you lose some bearings on your y-axis rails?

Usb/serial communication errors? I think usb 2.0 is limited to a cable of 16 ft.

Have you accounted for the z-stepper motor mount slots not allowing the vertical rails to be parallel?

Have you tried a different slicer? I've seen some odd behavior if I get one of the Slic3r parameters out of bounds.

Added (edit):

Are the z lead screws mounted or aligned so that they are traveling in a wide arc, on the loose/bottom, end ? The vertical bearings, on the x carriage, can dampen in the x direction but somehow aren't able to dampen the y movement.

I did test changing the temperature of my extruder since it's a new hot end. That didn't seem to do much for me...

I checked both of the z mount to make sure they are consistently at the same height from start to finish..

Printing of SD card changes nothing and as for slicer I stay away from slic3r and use Cura.

Not sure what you mean by your last question via Edit.

Thanks.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 13, 2016 01:34PM |

Registered: 8 years ago Posts: 130 |

Quote

marc2912

Quote

flatlander

Quote

marc2912

Thanks Andrew, already tried that, it's not skipping or if it is it's doing it still even though I increased the current twice.

Is the extruder temperature or bed over-running because of odd thermistor behavior? If it's not alignment, the plastic is too hot causing slumping.

Did you lose some bearings on your y-axis rails?

Usb/serial communication errors? I think usb 2.0 is limited to a cable of 16 ft.

Have you accounted for the z-stepper motor mount slots not allowing the vertical rails to be parallel?

Have you tried a different slicer? I've seen some odd behavior if I get one of the Slic3r parameters out of bounds.

Added (edit):

Are the z lead screws mounted or aligned so that they are traveling in a wide arc, on the loose/bottom, end ? The vertical bearings, on the x carriage, can dampen in the x direction but somehow aren't able to dampen the y movement.

I did test changing the temperature of my extruder since it's a new hot end. That didn't seem to do much for me...

I checked both of the z mount to make sure they are consistently at the same height from start to finish..

Printing of SD card changes nothing and as for slicer I stay away from slic3r and use Cura.

Not sure what you mean by your last question via Edit.

Thanks.

re last question via Edit:

The Lead Screws could be mounted in the couplers so that they scribe a cone with a wide circular base. This is unlikely the reason for so much slant in the y direction. It's happening at the bottom and then corrects itself.

I checked both of the z mount to make sure they are consistently at the same height from start to finish..

re: "I checked both of the z mount to make sure they are consistently at the same height from start to finish.."

It's not a height issue. If you place screws in the outside slots of the motor mounts your construction will be a trapezoid, wide at the top, not a rectangle.

from the folger tech wiki(http://folgertech.wikia.com/wiki/Main_Page):

Z axis motor mounting - The instructions call for using 3 screws and T nuts to mount each motor. This will result in a misaligned printer! The 3rd screw that goes into the vertical 20x20 extrusion should be left out and only the two that go into the top horizontal extrusion should be used. When fully assembled the two vertical chrome rods should be parallel to each other and the vertical frame.

You can splay/spread the smooth rod holders at the bottom to get close to parallel.

It is most likely in the y-bed movement. Is your glass sliding? hum?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 13, 2016 02:26PM |

Registered: 8 years ago Posts: 131 |

Quote

flatlander

Quote

marc2912

Quote

flatlander

Quote

marc2912

Thanks Andrew, already tried that, it's not skipping or if it is it's doing it still even though I increased the current twice.

Is the extruder temperature or bed over-running because of odd thermistor behavior? If it's not alignment, the plastic is too hot causing slumping.

Did you lose some bearings on your y-axis rails?

Usb/serial communication errors? I think usb 2.0 is limited to a cable of 16 ft.

Have you accounted for the z-stepper motor mount slots not allowing the vertical rails to be parallel?

Have you tried a different slicer? I've seen some odd behavior if I get one of the Slic3r parameters out of bounds.

Added (edit):

Are the z lead screws mounted or aligned so that they are traveling in a wide arc, on the loose/bottom, end ? The vertical bearings, on the x carriage, can dampen in the x direction but somehow aren't able to dampen the y movement.

I did test changing the temperature of my extruder since it's a new hot end. That didn't seem to do much for me...

I checked both of the z mount to make sure they are consistently at the same height from start to finish..

Printing of SD card changes nothing and as for slicer I stay away from slic3r and use Cura.

Not sure what you mean by your last question via Edit.

Thanks.

re last question via Edit:

The Lead Screws could be mounted in the couplers so that they scribe a cone with a wide circular base. This is unlikely the reason for so much slant in the y direction. It's happening at the bottom and then corrects itself.

I checked both of the z mount to make sure they are consistently at the same height from start to finish..

re: "I checked both of the z mount to make sure they are consistently at the same height from start to finish.."

It's not a height issue. If you place screws in the outside slots of the motor mounts your construction will be a trapezoid, wide at the top, not a rectangle.

from the folger tech wiki(http://folgertech.wikia.com/wiki/Main_Page):

Z axis motor mounting - The instructions call for using 3 screws and T nuts to mount each motor. This will result in a misaligned printer! The 3rd screw that goes into the vertical 20x20 extrusion should be left out and only the two that go into the top horizontal extrusion should be used. When fully assembled the two vertical chrome rods should be parallel to each other and the vertical frame.

You can splay/spread the smooth rod holders at the bottom to get close to parallel.

It is most likely in the y-bed movement. Is your glass sliding? hum?

I though y axis since that's what is showing the slant but I checked and that's actually the only thing I didn't change. I'll keep testing stuff.

Thx

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 13, 2016 09:09PM |

Registered: 8 years ago Posts: 1 |

Just purchased and built a Folger Tech Prusa i3 2020 kit. It seems to be doing well and I've dialed in most things but one problem.

My lines are a bit wavy. I can visibly see the flow pulsate from the nozzle. I'm printing with 1.75mm ABS. This happens in all layers. I've tried slowing down print speed, and changing the extrusion multiplier higher to 1.05 and 1.1. Nothing seems to change anything.

Here is a picture of a print in progress: [imgur.com]

Any help would be appreciated. Thanks.

My lines are a bit wavy. I can visibly see the flow pulsate from the nozzle. I'm printing with 1.75mm ABS. This happens in all layers. I've tried slowing down print speed, and changing the extrusion multiplier higher to 1.05 and 1.1. Nothing seems to change anything.

Here is a picture of a print in progress: [imgur.com]

Any help would be appreciated. Thanks.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 13, 2016 09:58PM |

Registered: 8 years ago Posts: 131 |

Quote

fallsgeek

Just purchased and built a Folger Tech Prusa i3 2020 kit. It seems to be doing well and I've dialed in most things but one problem.

My lines are a bit wavy. I can visibly see the flow pulsate from the nozzle. I'm printing with 1.75mm ABS. This happens in all layers. I've tried slowing down print speed, and changing the extrusion multiplier higher to 1.05 and 1.1. Nothing seems to change anything.

Here is a picture of a print in progress: [imgur.com]

Any help would be appreciated. Thanks.

Sounds like you're over extruding, you try dialing down the multiplier instead of up? did you try calibrating your extruder?

Edited 1 time(s). Last edit at 03/13/2016 09:59PM by marc2912.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 13, 2016 10:24PM |

Registered: 8 years ago Posts: 19 |

Z_PROBE_OFFSET_FROM_EXTRUDER Setting Issues

Sorry I'm late to the party. But for anyone else that may run into this issue. You need to run m500 (save command) in order for the new setting to take effect. I personally run M500 (save), M501 (check) and M502 (load) to make sure hte newest setting loads.

Was a huge struggle for me when setting up auto-bed leveling.

Sorry I'm late to the party. But for anyone else that may run into this issue. You need to run m500 (save command) in order for the new setting to take effect. I personally run M500 (save), M501 (check) and M502 (load) to make sure hte newest setting loads.

Was a huge struggle for me when setting up auto-bed leveling.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 13, 2016 11:47PM |

Registered: 8 years ago Posts: 314 |

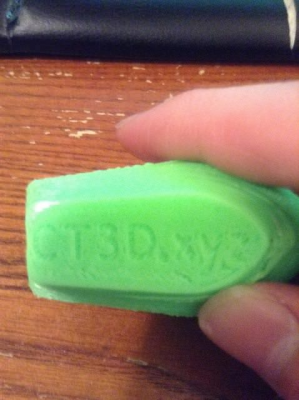

From these pic's what causes these problems? Extruder calibration? Anything else?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 14, 2016 12:23AM |

Registered: 8 years ago Posts: 2 |

Hello! I just built the Prusa i3 2020 following the guide provided by Folger Tech. I am now trying to configure everything and for some reason Repetier-Host V1.6.1 isn't connecting to the printer stating that "Access to the port 'COM5' is denied." I tried running Repetier-Host as an administrator, but that didn't make any difference. Any guidance is greatly appreciated.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 14, 2016 12:30AM |

Registered: 8 years ago Posts: 314 |

Welcome to the forums!!Quote

abstracity

Hello! I just built the Prusa i3 2020 following the guide provided by Folger Tech. I am now trying to configure everything and for some reason Repetier-Host V1.6.1 isn't connecting to the printer stating that "Access to the port 'COM5' is denied." I tried running Repetier-Host as an administrator, but that didn't make any difference. Any guidance is greatly appreciated.

Have you installed the arduino software? Does the board show up correctly in device manager?

-Sam

Edited 1 time(s). Last edit at 03/14/2016 12:30AM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 14, 2016 01:56AM |

Registered: 8 years ago Posts: 92 |

Quote

marc2912

Quote

fallsgeek

Just purchased and built a Folger Tech Prusa i3 2020 kit. It seems to be doing well and I've dialed in most things but one problem.

My lines are a bit wavy. I can visibly see the flow pulsate from the nozzle. I'm printing with 1.75mm ABS. This happens in all layers. I've tried slowing down print speed, and changing the extrusion multiplier higher to 1.05 and 1.1. Nothing seems to change anything.

Here is a picture of a print in progress: [imgur.com]

Any help would be appreciated. Thanks.

Sounds like you're over extruding, you try dialing down the multiplier instead of up? did you try calibrating your extruder?

I agree, it looks like you're WAY over extruding. If you haven't calibrated your extruder steps/mm start here: [www.youtube.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 14, 2016 08:24AM |

Registered: 8 years ago Posts: 130 |

Quote

UltiFix

From these pic's what causes these problems? Extruder calibration? Anything else?

I was having similar issues using slic3r. Cura wasn't presenting the same issue.

Increasing the Overlap "Infill/perimeters overlap" to 50% in slic3r was promising on the MorenaP Treefrog (http://www.thingiverse.com/thing:18479). I'm near the end of my roll and the Tugboat most likely won't complete. If I get a chance I'll try to get the hull to print...

Here are the steps if anyone needs them:

- File > Preferences > Mode: expert (Restart Slic3r)

- In the Advanced window > Overlap Infill/perimeters overlap 50% (save settings)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 14, 2016 08:48AM |

Registered: 8 years ago Posts: 268 |

Deleted...

Edited 1 time(s). Last edit at 03/14/2016 08:49AM by sonnylowe.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

Edited 1 time(s). Last edit at 03/14/2016 08:49AM by sonnylowe.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 14, 2016 10:24AM |

Registered: 8 years ago Posts: 2 |

Quote

UltiFix

Welcome to the forums!!Quote

abstracity

Hello! I just built the Prusa i3 2020 following the guide provided by Folger Tech. I am now trying to configure everything and for some reason Repetier-Host V1.6.1 isn't connecting to the printer stating that "Access to the port 'COM5' is denied." I tried running Repetier-Host as an administrator, but that didn't make any difference. Any guidance is greatly appreciated.

Have you installed the arduino software? Does the board show up correctly in device manager?

-Sam

Hello! Thank you for the welcome. Yes, I have the arduino software and I made sure that the ports matches.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 14, 2016 10:52AM |

Registered: 8 years ago Posts: 130 |

Quote

UltiFix

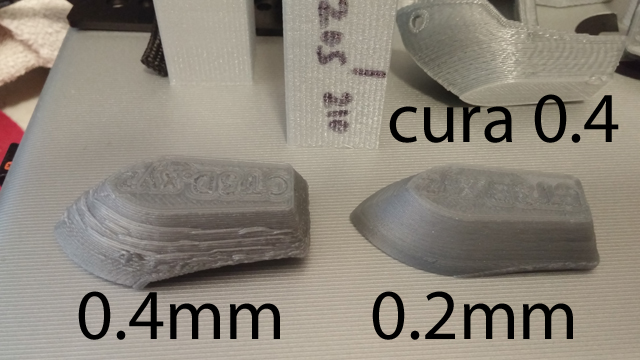

From these pic's what causes these problems? Extruder calibration? Anything else?

Quote

flatlander

I was having similar issues using slic3r. Cura wasn't presenting the same issue.

Increasing the Overlap "Infill/perimeters overlap" to 50% in slic3r was promising on the MorenaP Treefrog (http://www.thingiverse.com/thing:18479). I'm near the end of my roll and the Tugboat most likely won't complete. If I get a chance I'll try to get the hull to print...

Here are the steps if anyone needs them:

- File > Preferences > Mode: expert (Restart Slic3r)

- In the Advanced window > Overlap Infill/perimeters overlap 50% (save settings)

I gave it two attempts; one with a layer height of .4mm and the second at .2mm, both with 50% overlap. Layer height = .2mm is acceptable if you have the time for a longer print. There is some thought that layer height of .4 with a .4 mm nozzle is too big; height should be <.80 X nozzle diameter (http://reprap.org/wiki/Triffid_Hunter%27s_Calibration_Guide) I tried .32 mm and the results were strange. At some point I plan to revisit the "<.8 rule"...

Edited 1 time(s). Last edit at 03/14/2016 12:34PM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 14, 2016 05:16PM |

Registered: 8 years ago Posts: 314 |

Im actually using cura...Quote

flatlander

Quote

UltiFix

From these pic's what causes these problems? Extruder calibration? Anything else?

I was having similar issues using slic3r. Cura wasn't presenting the same issue.

Increasing the Overlap "Infill/perimeters overlap" to 50% in slic3r was promising on the MorenaP Treefrog (http://www.thingiverse.com/thing:18479). I'm near the end of my roll and the Tugboat most likely won't complete. If I get a chance I'll try to get the hull to print...

Here are the steps if anyone needs them:

- File > Preferences > Mode: expert (Restart Slic3r)

- In the Advanced window > Overlap Infill/perimeters overlap 50% (save settings)

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 14, 2016 05:18PM |

Registered: 8 years ago Posts: 314 |

So the arduino software succesfully communicated with the board and uploaded the software? But rep host wont? Strange... What is the baud rate set to for rep host?Quote

abstracity

Quote

UltiFix

Welcome to the forums!!Quote

abstracity

Hello! I just built the Prusa i3 2020 following the guide provided by Folger Tech. I am now trying to configure everything and for some reason Repetier-Host V1.6.1 isn't connecting to the printer stating that "Access to the port 'COM5' is denied." I tried running Repetier-Host as an administrator, but that didn't make any difference. Any guidance is greatly appreciated.

Have you installed the arduino software? Does the board show up correctly in device manager?

-Sam

Hello! Thank you for the welcome. Yes, I have the arduino software and I made sure that the ports matches.

Edited 1 time(s). Last edit at 03/14/2016 05:18PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

Sorry, only registered users may post in this forum.