Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

First Print! March 14, 2016 09:19PM |

Registered: 8 years ago Posts: 12 |

[www.flickr.com]

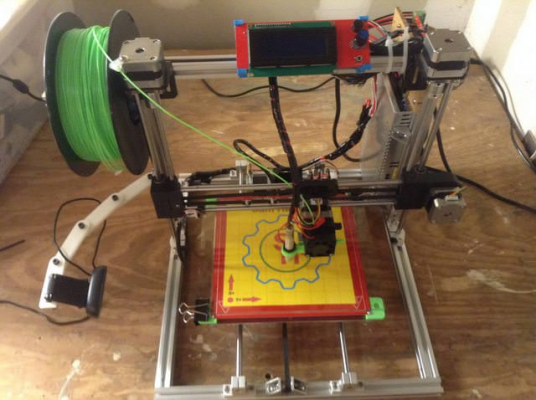

This forum has been extraordinarily good to me, although I haven't contributed a lot to it. Therippa's Marlin firmware configured for the Folgertech Prusa I3 was really good -- it saved me much annoying software wrangling in getting Things Running. Her name is now Cora.

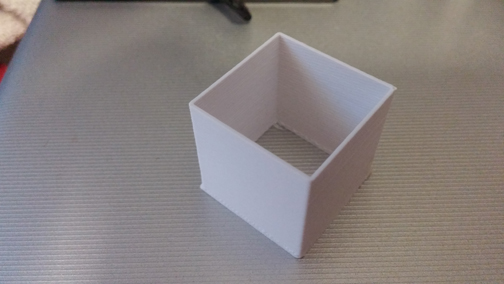

This was printed in natural-color ABS on window glass, with a generous helping of Printer Juice (ABS dissolved in acetone) swabbed on with a cotton ball wrapped around a bamboo skewer. On advice of a local expert, I moved the X limit switch to the left side of the bracket seen from the front, rather than the right side as the directions specify. I'm told this will make auto bed level much easier, although I'll have to print the parts out first. Changing the Configuration.h file to account for this was pretty simple after reading the comments.

Cora still needs a little dialing-in. The heart-shaped box has some filaments misplaced around the curves, and it looks like the extruder temperature is a bit hot at 230. I'll be fixin' that as I go I reckon.

This forum has been extraordinarily good to me, although I haven't contributed a lot to it. Therippa's Marlin firmware configured for the Folgertech Prusa I3 was really good -- it saved me much annoying software wrangling in getting Things Running. Her name is now Cora.

This was printed in natural-color ABS on window glass, with a generous helping of Printer Juice (ABS dissolved in acetone) swabbed on with a cotton ball wrapped around a bamboo skewer. On advice of a local expert, I moved the X limit switch to the left side of the bracket seen from the front, rather than the right side as the directions specify. I'm told this will make auto bed level much easier, although I'll have to print the parts out first. Changing the Configuration.h file to account for this was pretty simple after reading the comments.

Cora still needs a little dialing-in. The heart-shaped box has some filaments misplaced around the curves, and it looks like the extruder temperature is a bit hot at 230. I'll be fixin' that as I go I reckon.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 14, 2016 09:19PM |

Registered: 8 years ago Posts: 130 |

First ABS, wahoo! Beginners luck...

The second and third were "lacy" things. They were gorgeous filter like objects when held up to the light. If I wanted lacy-frilly I wouldn't be able to duplicate the effect. Repeat after me, "ABS is for sturdy machine parts not doilies."

I think I like ABS better than PLA. It extrudes like dough. Too bad it requires a bed temperature the could boil water...and it doesn't decompose.

The second and third were "lacy" things. They were gorgeous filter like objects when held up to the light. If I wanted lacy-frilly I wouldn't be able to duplicate the effect. Repeat after me, "ABS is for sturdy machine parts not doilies."

I think I like ABS better than PLA. It extrudes like dough. Too bad it requires a bed temperature the could boil water...and it doesn't decompose.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 15, 2016 12:14AM |

Registered: 8 years ago Posts: 16 |

Hey guys, I appreciate all the good info in this enormous thread. I've got my printer built and am going through calibration now. I used therippa's firmware, but had the following error messages when it was compiling the sketch:

--------------------------------------------------------------------------------------------------------------------------------------------

Arduino: 1.6.8 (Windows XP), Board: "Arduino/Genuino Mega or Mega 2560, ATmega2560 (Mega 2560)"

sketch\Marlin_main.cpp:2667:36: warning: invalid suffix on literal; C++11 requires a space between literal and identifier [-Wliteral-suffix]

LCD_MESSAGEPGM(MACHINE_NAME" "MSG_OFF".");

^

sketch\temperature.cpp:565:50: warning: extra tokens at end of #ifdef directive [enabled by default]

#ifdef THERMAL_RUNAWAY_PROTECTION_BED_PERIOD && THERMAL_RUNAWAY_PROTECTION_BED_PERIOD > 0

^

Sketch uses 102,872 bytes (40%) of program storage space. Maximum is 253,952 bytes.

Global variables use 4,223 bytes (51%) of dynamic memory, leaving 3,969 bytes for local variables. Maximum is 8,192 bytes.

--------------------------------------------------------------------------------------------------------------------------------------------

I am also getting a lot of checksum errors as well, but this probably has to do with the old XP machine I'm using, so it won't upload the firmware at all. I carried the printer upstairs to use a newer mac to upload the firmware and it connected fine, but still had the errors I copied above. Is this a problem that I need to address? I downloaded therippa's the other day so it should be current.

I'm also having some funny X-axis behavior. When moving the printer around manually, the X-direction loses its place. When I press X-home, it moves slightly to the left (instead of all the way to the right like normal). After I hit X-home, the printer thinks the carriage is at X-max and I can move it to the left, but it could be anywhere on the bed and I can move it farther than it should go. I've got the X endstop in the 6th position on the controller and the setting changed to MAX in Repetier, and sometimes it works fine. But if I start a print with the extruder in the middle of the bed, it goes to Y and Z homes, but not X, and the print is offset and can run off the edge of the bed. I can fix the problem by manually pushing the carriage to the X-home, hitting the X-home button, and then it moves around fine manually and will print fine.

Any ideas?

--------------------------------------------------------------------------------------------------------------------------------------------

Arduino: 1.6.8 (Windows XP), Board: "Arduino/Genuino Mega or Mega 2560, ATmega2560 (Mega 2560)"

sketch\Marlin_main.cpp:2667:36: warning: invalid suffix on literal; C++11 requires a space between literal and identifier [-Wliteral-suffix]

LCD_MESSAGEPGM(MACHINE_NAME" "MSG_OFF".");

^

sketch\temperature.cpp:565:50: warning: extra tokens at end of #ifdef directive [enabled by default]

#ifdef THERMAL_RUNAWAY_PROTECTION_BED_PERIOD && THERMAL_RUNAWAY_PROTECTION_BED_PERIOD > 0

^

Sketch uses 102,872 bytes (40%) of program storage space. Maximum is 253,952 bytes.

Global variables use 4,223 bytes (51%) of dynamic memory, leaving 3,969 bytes for local variables. Maximum is 8,192 bytes.

--------------------------------------------------------------------------------------------------------------------------------------------

I am also getting a lot of checksum errors as well, but this probably has to do with the old XP machine I'm using, so it won't upload the firmware at all. I carried the printer upstairs to use a newer mac to upload the firmware and it connected fine, but still had the errors I copied above. Is this a problem that I need to address? I downloaded therippa's the other day so it should be current.

I'm also having some funny X-axis behavior. When moving the printer around manually, the X-direction loses its place. When I press X-home, it moves slightly to the left (instead of all the way to the right like normal). After I hit X-home, the printer thinks the carriage is at X-max and I can move it to the left, but it could be anywhere on the bed and I can move it farther than it should go. I've got the X endstop in the 6th position on the controller and the setting changed to MAX in Repetier, and sometimes it works fine. But if I start a print with the extruder in the middle of the bed, it goes to Y and Z homes, but not X, and the print is offset and can run off the edge of the bed. I can fix the problem by manually pushing the carriage to the X-home, hitting the X-home button, and then it moves around fine manually and will print fine.

Any ideas?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 15, 2016 09:01AM |

Registered: 8 years ago Posts: 130 |

Quote

pizzachef

Hey guys, I appreciate all the good info in this enormous thread. I've got my printer built and am going through calibration now. I used therippa's firmware, but had the following error messages when it was compiling the sketch:

--------------------------------------------------------------------------------------------------------------------------------------------

Arduino: 1.6.8 (Windows XP), Board: "Arduino/Genuino Mega or Mega 2560, ATmega2560 (Mega 2560)"

sketch\Marlin_main.cpp:2667:36: warning: invalid suffix on literal; C++11 requires a space between literal and identifier [-Wliteral-suffix]

LCD_MESSAGEPGM(MACHINE_NAME" "MSG_OFF".");

^

sketch\temperature.cpp:565:50: warning: extra tokens at end of #ifdef directive [enabled by default]

#ifdef THERMAL_RUNAWAY_PROTECTION_BED_PERIOD && THERMAL_RUNAWAY_PROTECTION_BED_PERIOD > 0

^

Sketch uses 102,872 bytes (40%) of program storage space. Maximum is 253,952 bytes.

Global variables use 4,223 bytes (51%) of dynamic memory, leaving 3,969 bytes for local variables. Maximum is 8,192 bytes.

--------------------------------------------------------------------------------------------------------------------------------------------

I am also getting a lot of checksum errors as well, but this probably has to do with the old XP machine I'm using, so it won't upload the firmware at all. I carried the printer upstairs to use a newer mac to upload the firmware and it connected fine, but still had the errors I copied above. Is this a problem that I need to address? I downloaded therippa's the other day so it should be current.

I'm also having some funny X-axis behavior. When moving the printer around manually, the X-direction loses its place. When I press X-home, it moves slightly to the left (instead of all the way to the right like normal). After I hit X-home, the printer thinks the carriage is at X-max and I can move it to the left, but it could be anywhere on the bed and I can move it farther than it should go. I've got the X endstop in the 6th position on the controller and the setting changed to MAX in Repetier, and sometimes it works fine. But if I start a print with the extruder in the middle of the bed, it goes to Y and Z homes, but not X, and the print is offset and can run off the edge of the bed. I can fix the problem by manually pushing the carriage to the X-home, hitting the X-home button, and then it moves around fine manually and will print fine.

Any ideas?

Windows XP, yikes! Get a modern OS, like any flavor of free linux, on that machine

Maybe not, there is some overhead with admin permissions and usb dialout groups on linux...

Maybe not, there is some overhead with admin permissions and usb dialout groups on linux...Which Processor have you chosen in Arduino >Tools >Processor? I think "AVRISP" or "AVRISP mkII" will work. I have "AVRISP mkII" chosen.

You are getting errors similar to what I get when I have cut and pasted from a webpage, outside of the "protected" code block. This introduces "hidden" characters. These characters maybe already be in the code hidden, behind comments (//). When you uncomment you may be introducing hidden bugs. I always use the RAW version on github when I need code fragments. There is a utility to strip unwanted characters but it escapes my memory...saving text as utf-8??? Hopefully someone can help us. ha ha ha.

Disregard the past statements as complete rubbish. Sometimes I'm so full of it. ha, ha, ha.

It's has to do with method naming in the temperature.cpp and temperature.h files being incorrect.

EDIT: here ya go, Hotbed issue #2253: [github.com]

Edited 2 time(s). Last edit at 03/15/2016 02:27PM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 15, 2016 09:30AM |

Registered: 8 years ago Posts: 12 |

Quote

pizzachef

Hey guys, I appreciate all the good info in this enormous thread. I've got my printer built and am going through calibration now. I used therippa's firmware, but had the following error messages when it was compiling the sketch:

--------------------------------------------------------------------------------------------------------------------------------------------

Arduino: 1.6.8 (Windows XP), Board: "Arduino/Genuino Mega or Mega 2560, ATmega2560 (Mega 2560)"

sketch\Marlin_main.cpp:2667:36: warning: invalid suffix on literal; C++11 requires a space between literal and identifier [-Wliteral-suffix]

LCD_MESSAGEPGM(MACHINE_NAME" "MSG_OFF".");

^

sketch\temperature.cpp:565:50: warning: extra tokens at end of #ifdef directive [enabled by default]

#ifdef THERMAL_RUNAWAY_PROTECTION_BED_PERIOD && THERMAL_RUNAWAY_PROTECTION_BED_PERIOD > 0

^

Sketch uses 102,872 bytes (40%) of program storage space. Maximum is 253,952 bytes.

Global variables use 4,223 bytes (51%) of dynamic memory, leaving 3,969 bytes for local variables. Maximum is 8,192 bytes.

I got exactly those warning (not error) messages building therippa's firmware on the very latest & greatest Arduino IDE. Older compilers did not generate them. Since they were just compiler warnings and did not stop the build, I went ahead and loaded it into Cora (my printer) from my IBM R50e running Debian Jessie. Everything so far is working as designed. I'll see about cleaning up the warning messages RSN.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 15, 2016 03:06PM |

Registered: 8 years ago Posts: 10 |

So I've calibrated the extruder, adjusted the stepper voltages, printed out some new bearing holders, leveled the bed. I'm getting decent prints for boxy parts (mounts, end stops etc) but seeing some separation? on more complex objects.

Here's a Yoda I printed.

Folger ABS, 240/105c, 0.3mm layer height, 80mm/s printing speed, no support and 3 perimiter walls. About 20c ambient with some drafts.

[imgur.com]

Any suggestions?

Here's a Yoda I printed.

Folger ABS, 240/105c, 0.3mm layer height, 80mm/s printing speed, no support and 3 perimiter walls. About 20c ambient with some drafts.

[imgur.com]

Any suggestions?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 15, 2016 10:05PM |

Registered: 8 years ago Posts: 92 |

Quote

Toxic0n

So I've calibrated the extruder, adjusted the stepper voltages, printed out some new bearing holders, leveled the bed. I'm getting decent prints for boxy parts (mounts, end stops etc) but seeing some separation? on more complex objects.

Here's a Yoda I printed.

Folger ABS, 240/105c, 0.3mm layer height, 80mm/s printing speed, no support and 3 perimiter walls. About 20c ambient with some drafts.

[imgur.com]

Any suggestions?

Try slowing your speed or upping your temp. Generally the faster you print, the hotter your nozzle needs to be, because the plastic doesn't spend as much time in the hot end, so it's not getting heated as much.

I print at something like 50mm/s with FT ABS at 240/100c

Also, it could be caused by drafts. Try eliminating them.

I was reading something recently that said that it's hard to large ABS prints without some layer separation on an open printer due to layer cooling and shrinkage. Ideally you want your build changer to be quite warm, then cooled slowly when an ABS print is done. I plan on building an enclosure in the near future for mine, for this very reason. (full disclosure: I have printed little with ABS (15-20 prints) because of this issue. The small things I have done have turned out well. If I get 40+mm high on a part, I start seeing cracks due to layer delamination. - sometimes not happening until a day or 2 later). The problem with enclosing the entire printer are heat concerns with the power supply, ramps board, and motors. Electronics can be "easily" mounted outside the enclosure, the motors, not so much.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 15, 2016 10:46PM |

Registered: 8 years ago Posts: 314 |

Here is an enclousure idea... I use this. Total cost probably around $20 (Can't remember the price of the box maybe $12?... And the plexiglass stuff I think costed around $7 Maybe? Then the bolts and nut's aren't much.) Only problem, it doesn't fit if the big clunky usb cable is sticking out the back of the arduino so I ordered a 90 degree angle usb cable so hopefully that will solve it. Also it's easy to remove, just take the bin offQuote

iamquestar

Quote

Toxic0n

So I've calibrated the extruder, adjusted the stepper voltages, printed out some new bearing holders, leveled the bed. I'm getting decent prints for boxy parts (mounts, end stops etc) but seeing some separation? on more complex objects.

Here's a Yoda I printed.

Folger ABS, 240/105c, 0.3mm layer height, 80mm/s printing speed, no support and 3 perimiter walls. About 20c ambient with some drafts.

[imgur.com]

Any suggestions?

Try slowing your speed or upping your temp. Generally the faster you print, the hotter your nozzle needs to be, because the plastic doesn't spend as much time in the hot end, so it's not getting heated as much.

I print at something like 50mm/s with FT ABS at 240/100c

Also, it could be caused by drafts. Try eliminating them.

I was reading something recently that said that it's hard to large ABS prints without some layer separation on an open printer due to layer cooling and shrinkage. Ideally you want your build changer to be quite warm, then cooled slowly when an ABS print is done. I plan on building an enclosure in the near future for mine, for this very reason. (full disclosure: I have printed little with ABS (15-20 prints) because of this issue. The small things I have done have turned out well. If I get 40+mm high on a part, I start seeing cracks due to layer delamination. - sometimes not happening until a day or 2 later). The problem with enclosing the entire printer are heat concerns with the power supply, ramps board, and motors. Electronics can be "easily" mounted outside the enclosure, the motors, not so much.

[www.ebay.com]

I just printed the lower jaw of the t rex today... Will do the top tomarrow!

What's the fastest you can print while still having good print quality? Maybe 80mm? Lately I have been printing at 47mm... Just cause that's what I set it to awhile ago and kinda forgot about it

Edited 3 time(s). Last edit at 03/15/2016 10:48PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 15, 2016 11:50PM |

Registered: 8 years ago Posts: 16 |

Quote

lemgandi

Quote

pizzachef

Hey guys, I appreciate all the good info in this enormous thread. I've got my printer built and am going through calibration now. I used therippa's firmware, but had the following error messages when it was compiling the sketch:

--------------------------------------------------------------------------------------------------------------------------------------------

Arduino: 1.6.8 (Windows XP), Board: "Arduino/Genuino Mega or Mega 2560, ATmega2560 (Mega 2560)"

sketch\Marlin_main.cpp:2667:36: warning: invalid suffix on literal; C++11 requires a space between literal and identifier [-Wliteral-suffix]

LCD_MESSAGEPGM(MACHINE_NAME" "MSG_OFF".");

^

sketch\temperature.cpp:565:50: warning: extra tokens at end of #ifdef directive [enabled by default]

#ifdef THERMAL_RUNAWAY_PROTECTION_BED_PERIOD && THERMAL_RUNAWAY_PROTECTION_BED_PERIOD > 0

^

Sketch uses 102,872 bytes (40%) of program storage space. Maximum is 253,952 bytes.

Global variables use 4,223 bytes (51%) of dynamic memory, leaving 3,969 bytes for local variables. Maximum is 8,192 bytes.

I got exactly those warning (not error) messages building therippa's firmware on the very latest & greatest Arduino IDE. Older compilers did not generate them. Since they were just compiler warnings and did not stop the build, I went ahead and loaded it into Cora (my printer) from my IBM R50e running Debian Jessie. Everything so far is working as designed. I'll see about cleaning up the warning messages RSN.

Thanks for the tip. I found the previous version of Arduino IDE, 1.6.7 and installed it. The warning messages still showed up, but it uploaded the firmware!! Then it told me there was an update

If the warning messages don't mean there are any significant issues, I'll run with it.

If the warning messages don't mean there are any significant issues, I'll run with it. Yea, I figured I'd get some flack for mentioning XP, but its the only extra computer I had laying around that I could leave in the basement with the printer. If I could do what I needed with a chromebook, I'd be golden! I'll get Linux on it sooner or later, but the project of building the printer outweighed the project of getting Linux running reliably on this thing. And I have a display for the printer, so once its calibrated and running, the computer won't be used for much.Quote

flatlander

Windows XP, yikes! Get a modern OS, like any flavor of free linux, on that machineMaybe not, there is some overhead with admin permissions and usb dialout groups on linux...

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 02:05AM |

Registered: 8 years ago Posts: 314 |

I did some googling around and it looks like

Sounds good to you guys?

Edited 4 time(s). Last edit at 03/16/2016 02:11AM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 09:49AM |

Registered: 8 years ago Posts: 130 |

I use sewing machine oil or 3-In-One, just a drop or two at each friction point and a good wipe down with a lint-free rag on some weekly cleaning schedule.Quote

UltiFix

I have been succesfully printing on my folger for awhile and now the z axis makes annoying screeching noises... Can I use WD-40 on the threaded rod? I have autolevel if that makes any difference.

I did some googling around and it looks likelithium grease(I guess that collects dirt fast, so people are using motor oil instead) for the threaded rods, and silicon grease for the rods...

Sounds good to you guys?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 10:14AM |

Registered: 8 years ago Posts: 130 |

Gentle ribbing not flack. You do what ya got a do. I just last night got a "stable" version of theRippa's firmware and I'm still using the back right corner for (0, 0, 0). My display is still sitting in its anti static bag...I'm not sure I want to add any more current to RAMPS until I beef-up the 12V-dc-in or until I get the Heat Bed Current off the RAMPS board.Quote

pizzachef

Yea, I figured I'd get some flack for mentioning XP, but its the only extra computer I had laying around that I could leave in the basement with the printer. If I could do what I needed with a chromebook, I'd be golden! I'll get Linux on it sooner or later, but the project of building the printer outweighed the project of getting Linux running reliably on this thing. And I have a display for the printer, so once its calibrated and running, the computer won't be used for much.

On a side note, is there a good way to see 'graphically' the Folger Tech Marlin branches/version lineage?

Edited 2 time(s). Last edit at 03/16/2016 10:19AM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 10:24AM |

Registered: 8 years ago Posts: 130 |

Is there any reason not to do temperature profile of ABS with steps similar to the following:

D. Run a temperature profile test using a tall cuboid.

1. Load a 100mm cuboid, 25mmX25mmX100mm should do.

2. Slice the cuboid to print just the outer layer, one layer thick, no infill.

3. Modify the g-code to start at the highest temperature parameter of your filament. This should be a manufacturer specification printed on the filament spool. Then every 5mm lower the temperature 5 degrees. The g-code for modifying the temperature is M104. So, M104 S210 will change the temp to 210 C.

4. The result should be a tall tower. At some point the plastic looks “better/shiny” and still resists tearing apart between layers. This is the temperature range at which you want to print. You can do the same test, changing every degree at this newly found range.

D. Run a temperature profile test using a tall cuboid.

1. Load a 100mm cuboid, 25mmX25mmX100mm should do.

2. Slice the cuboid to print just the outer layer, one layer thick, no infill.

3. Modify the g-code to start at the highest temperature parameter of your filament. This should be a manufacturer specification printed on the filament spool. Then every 5mm lower the temperature 5 degrees. The g-code for modifying the temperature is M104. So, M104 S210 will change the temp to 210 C.

4. The result should be a tall tower. At some point the plastic looks “better/shiny” and still resists tearing apart between layers. This is the temperature range at which you want to print. You can do the same test, changing every degree at this newly found range.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 11:41AM |

Registered: 8 years ago Posts: 130 |

One my gotchas has to do with "sane defaults." It's where the extrusion volume is reduced on the perimeter so the object looks 'pretty.' I think all of our slicers are using this to some degree. Re: last paragraph at the following:

[manual.slic3r.org]

I'll probably use the maths from here to get overlap and width correct:

[hydraraptor.blogspot.co.uk]

Specifying my own width should help overhangs. Maybe printing 'perimeters first' might help too.

Edited 1 time(s). Last edit at 03/16/2016 11:42AM by flatlander.

[manual.slic3r.org]

I'll probably use the maths from here to get overlap and width correct:

[hydraraptor.blogspot.co.uk]

Specifying my own width should help overhangs. Maybe printing 'perimeters first' might help too.

Edited 1 time(s). Last edit at 03/16/2016 11:42AM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 02:15PM |

Registered: 8 years ago Posts: 85 |

Quote

flatlander

One my gotchas has to do with "sane defaults." It's where the extrusion volume is reduced on the perimeter so the object looks 'pretty.' I think all of our slicers are using this to some degree. Re: last paragraph at the following:

[manual.slic3r.org]

I'll probably use the maths from here to get overlap and width correct:

[hydraraptor.blogspot.co.uk]

Specifying my own width should help overhangs. Maybe printing 'perimeters first' might help too.

I've found that explicitly setting a default extrusion width in slic3r gives far better results than it's defaults.

The default is nozzle_width * 1.05 which with our stock 0.4mm nozzle comes out to 0.42 But my testing and tjnamtiw's seems to really back up that that's too low as the free air extrusion from our nozzles comes out larger due to die swell (http://forums.reprap.org/read.php?406,512329,635611#msg-635611)

The value I've heard is best is 120% which on a 0.40mm nozzle comes out to 0.48 I also tried 0.45 and that gave me better results than slic3r's default 0.42 but 0.48 has given me by far the best results - once I adjust my filament diameter and extrusion multiplier so single wall test prints come out with the actual default extrusion with I've set.

This blog describes the process quite well: [northwoods3d.weebly.com]

Once I switched to a 0.48mm default extrusion width and dialed in my extrusion multiplier for each filament I use my accuracy improved greatly. I can now do just about any print in place design with no issues and can do the make negative space tolerance test and the first 3 pegs fall out by themselves and even the 0.2mm clearance peg can be removed by hand.

This is the single wall test piece I use for a 0.4mm nozzle: [drive.google.com]

Note: this method won't work in cura since cura won't slice a single wall part

At least I've yet to find a way to get it to do so.

At least I've yet to find a way to get it to do so.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 02:18PM |

Registered: 8 years ago Posts: 85 |

Quote

flatlander

On a side note, is there a good way to see 'graphically' the Folger Tech Marlin branches/version lineage?

Usually you can click on the count next to forks in github and view the network graph for a project to see a visual representation of the forks and how they relate.

But Marlin has almost 3k forks and github won't render the network graph when there are that many forks

[github.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 02:27PM |

Registered: 8 years ago Posts: 314 |

Lately I have been printing everything at 0.2mm, im using the stock extruder and hotend... Should I change it? Im using curaQuote

jhitesma

Quote

flatlander

One my gotchas has to do with "sane defaults." It's where the extrusion volume is reduced on the perimeter so the object looks 'pretty.' I think all of our slicers are using this to some degree. Re: last paragraph at the following:

[manual.slic3r.org]

I'll probably use the maths from here to get overlap and width correct:

[hydraraptor.blogspot.co.uk]

Specifying my own width should help overhangs. Maybe printing 'perimeters first' might help too.

I've found that explicitly setting a default extrusion width in slic3r gives far better results than it's defaults.

The default is nozzle_width * 1.05 which with our stock 0.4mm nozzle comes out to 0.42 But my testing and tjnamtiw's seems to really back up that that's too low as the free air extrusion from our nozzles comes out larger due to die swell (http://forums.reprap.org/read.php?406,512329,635611#msg-635611)

The value I've heard is best is 120% which on a 0.40mm nozzle comes out to 0.48 I also tried 0.45 and that gave me better results than slic3r's default 0.42 but 0.48 has given me by far the best results - once I adjust my filament diameter and extrusion multiplier so single wall test prints come out with the actual default extrusion with I've set.

This blog describes the process quite well: [northwoods3d.weebly.com]

Once I switched to a 0.48mm default extrusion width and dialed in my extrusion multiplier for each filament I use my accuracy improved greatly. I can now do just about any print in place design with no issues and can do the make negative space tolerance test and the first 3 pegs fall out by themselves and even the 0.2mm clearance peg can be removed by hand.

This is the single wall test piece I use for a 0.4mm nozzle: [drive.google.com]

Note: this method won't work in cura since cura won't slice a single wall partAt least I've yet to find a way to get it to do so.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 02:41PM |

Registered: 8 years ago Posts: 131 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 03:00PM |

Registered: 8 years ago Posts: 130 |

Quote

jhitesma

Quote

flatlander

One my gotchas has to do with "sane defaults." It's where the extrusion volume is reduced on the perimeter so the object looks 'pretty.' I think all of our slicers are using this to some degree. Re: last paragraph at the following:

[manual.slic3r.org]

I'll probably use the maths from here to get overlap and width correct:

[hydraraptor.blogspot.co.uk]

Specifying my own width should help overhangs. Maybe printing 'perimeters first' might help too.

I've found that explicitly setting a default extrusion width in slic3r gives far better results than it's defaults.

The default is nozzle_width * 1.05 which with our stock 0.4mm nozzle comes out to 0.42 But my testing and tjnamtiw's seems to really back up that that's too low as the free air extrusion from our nozzles comes out larger due to die swell (http://forums.reprap.org/read.php?406,512329,635611#msg-635611)

The value I've heard is best is 120% which on a 0.40mm nozzle comes out to 0.48 I also tried 0.45 and that gave me better results than slic3r's default 0.42 but 0.48 has given me by far the best results - once I adjust my filament diameter and extrusion multiplier so single wall test prints come out with the actual default extrusion with I've set.

This blog describes the process quite well: [northwoods3d.weebly.com]

Once I switched to a 0.48mm default extrusion width and dialed in my extrusion multiplier for each filament I use my accuracy improved greatly. I can now do just about any print in place design with no issues and can do the make negative space tolerance test and the first 3 pegs fall out by themselves and even the 0.2mm clearance peg can be removed by hand.

This is the single wall test piece I use for a 0.4mm nozzle: [drive.google.com]

Note: this method won't work in cura since cura won't slice a single wall partAt least I've yet to find a way to get it to do so.

Good stuff thanks a lot! One question to clarify one missing parameter. Are you specifying a height of 0.32mm? That would fit with all the maths I've been looking at. TIA

p.s. Looks like too many github branches to suss out our Marlin lineage.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 03:53PM |

Registered: 8 years ago Posts: 85 |

Quote

UltiFix

Lately I have been printing everything at 0.2mm, im using the stock extruder and hotend... Should I change it? Im using cura

Layer height? 0.2 should be good Prusa has a calculator that helps you figure out optimal layer heights based on your z screws: [prusaprinters.org]

For extrusion width 0.2 would be WAY too narrow. But like I said I don't use cura because I can't get it to do single wall prints so I can't test the extrusion multiplier accurately.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 04:10PM |

Registered: 8 years ago Posts: 85 |

Quote

flatlander

Good stuff thanks a lot! One question to clarify one missing parameter. Are you specifying a height of 0.32mm? That would fit with all the maths I've been looking at. TIA

p.s. Looks like too many github branches to suss out our Marlin lineage.

I use a first layer height around 0.30...I'm not at home so I can't confirm exactly what I'm currently using. I measure my skirts after each print at various points to confirm how good my first layer is and how level my bed is. When I was manually leveling I always saw SOME variation in thickness across different parts of the skirt no matter how close I thought I had the bed. When I switched to the inductive auto level with galvanized steel under the glass I always saw one corner slightly thicker where the steel didn't sit perfectly flat due to the edge curling slightly when I cut it. Now that I'm using aluminum foil under the glass my skirts are consistently the same thickness at all points within the tolerance limit my calipers are capable of.

For other layers I use 0.2 or 0.24 or 0.26 depending on whether I want faster speed or smoother surface. I've been known to print at 0.3 if I really want something fast but I love the smoothness of lower layers. I've done some tests at lower levels but it's so agonizingly slow I haven't done that since I really got things dialed in...I should try some again, just been too busy printing parts for projects to stop and mess with tests like that lately

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 04:51PM |

Registered: 8 years ago Posts: 276 |

If anyone is curious about the marlin lineage, the only two files changed on my fork from the official Marlin fork is configuration.h and pins.h. If you want to see the differences, compare the two files using BeyondCompare.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 05:24PM |

Registered: 8 years ago Posts: 85 |

Quote

therippa

If anyone is curious about the marlin lineage, the only two files changed on my fork from the official Marlin fork is configuration.h and pins.h. If you want to see the differences, compare the two files using BeyondCompare.

Can also use github to see the differences:

[github.com]

Though it shows 4 files changed - configuration.h, pins.h - as well as configuration_adv.h and README. Though the changes in README are basically just cosmetic and the change in configuration_adv.h are minor enough they could be ignored.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 05:35PM |

Registered: 8 years ago Posts: 314 |

Is layer height and quality the same? On cura it says quality..Quote

jhitesma

Quote

UltiFix

Lately I have been printing everything at 0.2mm, im using the stock extruder and hotend... Should I change it? Im using cura

Layer height? 0.2 should be good Prusa has a calculator that helps you figure out optimal layer heights based on your z screws: [prusaprinters.org]

For extrusion width 0.2 would be WAY too narrow. But like I said I don't use cura because I can't get it to do single wall prints so I can't test the extrusion multiplier accurately.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 05:40PM |

Registered: 8 years ago Posts: 314 |

What would it take for me to be able to print at 100mm with decent quality on my folger? Or is that totally out of the ballpark?

Or is it just a matter of cranking up my print speed to 100mm, do i need to change the feed rate?

Edited 1 time(s). Last edit at 03/16/2016 05:41PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

Or is it just a matter of cranking up my print speed to 100mm, do i need to change the feed rate?

Edited 1 time(s). Last edit at 03/16/2016 05:41PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 06:18PM |

Registered: 8 years ago Posts: 314 |

Has anybody here upgraded to bowden? And is it worth it?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 07:45PM |

Registered: 8 years ago Posts: 131 |

I noticed someone else mention it on here. I have an E3D with the stock extruder. I had to remove the aluminum block that sits under the extruder that the heat block screws into. I was going to upgrade my extruder to this from ebay but the block isn't removable and I won't be able to attach the hotend. What are people running with an E3D that is NOT a bowden extruder.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 08:15PM |

Registered: 8 years ago Posts: 430 |

Quote

marc2912

I noticed someone else mention it on here. I have an E3D with the stock extruder. I had to remove the aluminum block that sits under the extruder that the heat block screws into. I was going to upgrade my extruder to this from ebay but the block isn't removable and I won't be able to attach the hotend. What are people running with an E3D that is NOT a bowden extruder.

[www.thingiverse.com] with a belt instead of the gears.

If you don't want to try and build it from scratch this guy is selling it ready to go. I bought a different design from him and it was good. [www.ebay.com]

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 08:31PM |

Registered: 8 years ago Posts: 130 |

Quote

marc2912

I noticed someone else mention it on here. I have an E3D with the stock extruder. I had to remove the aluminum block that sits under the extruder that the heat block screws into. I was going to upgrade my extruder to this from ebay but the block isn't removable and I won't be able to attach the hotend. What are people running with an E3D that is NOT a bowden extruder.

I purchased this on a recommendation from our Folger Tech thread here. I ran into the same problem, the hotend tube does screw into the bottom of this device and it probably would feed filament into the hotend. There were threads on the in-feed; I would drill out and the countersink that hole. It looked like it could transfer heat to the extruder stepper. It's for another day when I feel more adventurous. It's buyers remorse with a lowercase b. I did print out the instructions and folded them into the box.

It does say this, "Reduce the wiredrawing problem when working for remote feeding." Now that would make sense if it was a welder, but I'm not feeding any wire into my 3d printer.

Edited 1 time(s). Last edit at 03/16/2016 08:32PM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 09:36PM |

Registered: 8 years ago Posts: 131 |

Quote

flatlander

Quote

marc2912

I noticed someone else mention it on here. I have an E3D with the stock extruder. I had to remove the aluminum block that sits under the extruder that the heat block screws into. I was going to upgrade my extruder to this from ebay but the block isn't removable and I won't be able to attach the hotend. What are people running with an E3D that is NOT a bowden extruder.

I purchased this on a recommendation from our Folger Tech thread here. I ran into the same problem, the hotend tube does screw into the bottom of this device and it probably would feed filament into the hotend. There were threads on the in-feed; I would drill out and the countersink that hole. It looked like it could transfer heat to the extruder stepper. It's for another day when I feel more adventurous. It's buyers remorse with a lowercase b. I did print out the instructions and folded them into the box.

It does say this, "Reduce the wiredrawing problem when working for remote feeding." Now that would make sense if it was a welder, but I'm not feeding any wire into my 3d printer.

Thanks with a stock hot end with an e3d it's even more pain as I'd have to mill part of the lower section away and find a way to fasten the hot end. Obviously not happening hence why I'm looking for people direct feeding e3d.

Sorry, only registered users may post in this forum.