Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 16, 2016 10:58PM |

Registered: 8 years ago Posts: 93 |

Quote

msaeger

[www.thingiverse.com] with a belt instead of the gears.

If you don't want to try and build it from scratch this guy is selling it ready to go. I bought a different design from him and it was good. [www.ebay.com]

Doesn't that extruder design cut off some of the vertical print height?

It would seem better to have the motor off to one side or to the front.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 02:28AM |

Registered: 8 years ago Posts: 85 |

Yeah I have one of those metal ones on my machine right now. I do like the higher tension it gives on the idler, that cleaned up a pattern I was seeing in my prints. But my stepper has been running about 10-15 degrees hotter since the change and started skipping. I initially thought it was due to the aluminum extruder letting more hot end heat get into the stepper...but now I think it's the extra tension making the stepper work harder - I turned up the current on my stepper driver a bit (doing the math I'm now over the 0.4a the stepper is rated for...but still under 0.5a so not much over) and even though I'm apparently over the current limit the stepper is running cooler and not skipping steps anymore so I'm going with it...close to 30 hours of printing at that setting so far and still working great.)

I also had some issues with the idler not lining up with the entrance to the heat break and with the tensioner not moving well if I tightened the screw it mounts with enough that I didn't worry about the screw falling out. I solved both problems by putting a 3mm washer between the tensioner and the body of the extruder with a dab of super lube grease on it:

To try and stop heat from the hot end getting into the stepper I added a gasket cut from some high temp gasket material I picked up for a few bucks at tractor supply for another project and had plenty of extra on hand:

The gasket didn't really help much, but the washer got the idler lined up with the heat break much better so it's much easier to load filament now and it has a straight path through the extruder - you can see the gasket and the washer here if you look closely:

But my e3d v6 (full all metal version since I want to try nylon) should be here tomorrow so I've got this printing right now: [www.thingiverse.com] It should be done in about half an hour. Not sure how I'll mount my inductive sensor though...may have to rig something up. I'm a little worried about the stepper hitting the top bar and costing me some Z...but we'll just have to see how that goes. I do like that the stepper is exposed so I can put the stock heat sink on the back of it to help cool it some. I want to do the compact geared extruder: [www.thingiverse.com] but that will take a bit more work to collect the vitamins for since I'll have to make a hobbed bolt so won't tackle that until this weekend at the earliest.

I may just go with animoose's mount and the stock extruder - I'm starting to think the issues I had with the stock extruder may be more related to stepper current than they were tension. I printed his mount and this remix: [www.thingiverse.com] to fit my inductive sensor. So I should have two options to try tomorrow. Doubt I'll get the e3d on and printing tomorrow but at least I'll have a few extruders to experiment with.

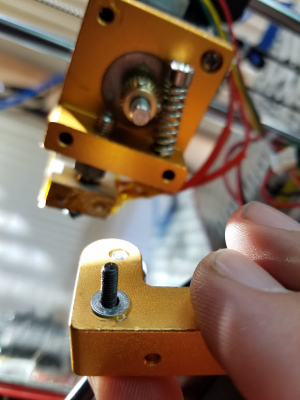

I also had some issues with the idler not lining up with the entrance to the heat break and with the tensioner not moving well if I tightened the screw it mounts with enough that I didn't worry about the screw falling out. I solved both problems by putting a 3mm washer between the tensioner and the body of the extruder with a dab of super lube grease on it:

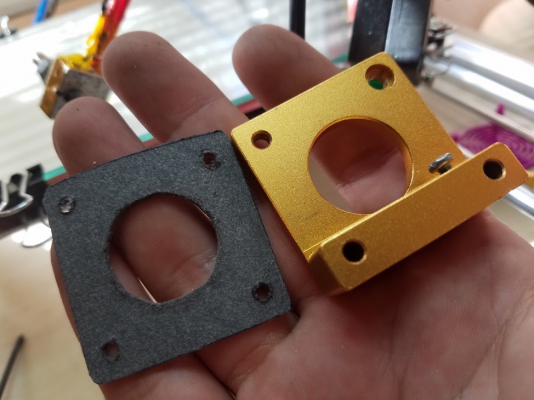

To try and stop heat from the hot end getting into the stepper I added a gasket cut from some high temp gasket material I picked up for a few bucks at tractor supply for another project and had plenty of extra on hand:

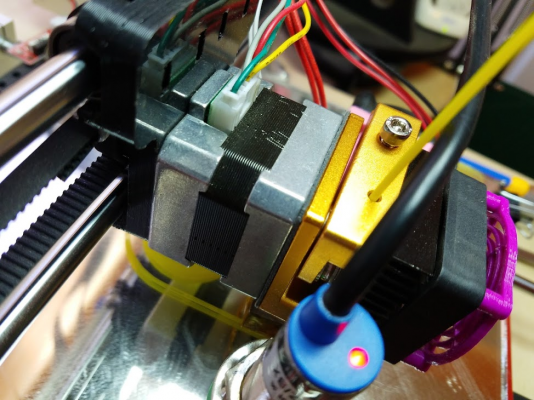

The gasket didn't really help much, but the washer got the idler lined up with the heat break much better so it's much easier to load filament now and it has a straight path through the extruder - you can see the gasket and the washer here if you look closely:

But my e3d v6 (full all metal version since I want to try nylon) should be here tomorrow so I've got this printing right now: [www.thingiverse.com] It should be done in about half an hour. Not sure how I'll mount my inductive sensor though...may have to rig something up. I'm a little worried about the stepper hitting the top bar and costing me some Z...but we'll just have to see how that goes. I do like that the stepper is exposed so I can put the stock heat sink on the back of it to help cool it some. I want to do the compact geared extruder: [www.thingiverse.com] but that will take a bit more work to collect the vitamins for since I'll have to make a hobbed bolt so won't tackle that until this weekend at the earliest.

I may just go with animoose's mount and the stock extruder - I'm starting to think the issues I had with the stock extruder may be more related to stepper current than they were tension. I printed his mount and this remix: [www.thingiverse.com] to fit my inductive sensor. So I should have two options to try tomorrow. Doubt I'll get the e3d on and printing tomorrow but at least I'll have a few extruders to experiment with.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 06:07AM |

Registered: 8 years ago Posts: 131 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 08:13AM |

Registered: 8 years ago Posts: 130 |

Quote

marc2912

Quote

flatlander

Quote

marc2912

I noticed someone else mention it on here. I have an E3D with the stock extruder. I had to remove the aluminum block that sits under the extruder that the heat block screws into. I was going to upgrade my extruder to this from ebay but the block isn't removable and I won't be able to attach the hotend. What are people running with an E3D that is NOT a bowden extruder.

I purchased this on a recommendation from our Folger Tech thread here. I ran into the same problem, the hotend tube does screw into the bottom of this device and it probably would feed filament into the hotend. There were threads on the in-feed;I would drill out and the countersink that hole.It looked like it could transfer heat to the extruder stepper. It's for another day when I feel more adventurous. It's buyers remorse with a lowercase b. I did print out the instructions and folded them into the box.

It does say this, "Reduce the wiredrawing problem when working for remote feeding." Now that would make sense if it was a welder, but I'm not feeding any wire into my 3d printer.

Thanks with a stock hot end with an e3d it's even more pain as I'd have to mill part of the lower section away and find a way to fasten the hot end. Obviously not happening hence why I'm looking for people direct feeding e3d.

Sleeping on this I have a better solution. You need something to get the filament into the roller and drive-gear. I think a push-to-connect-fitting would center the filament and eliminate the need to drill:

[folgertech.com]

Is the problem that the top of the E3D doesn't have M6 threads? I'll bet that there is a female/female M6 to xxM fitting. I'm working on getting a direct feed on top of a v-rail,I think your E3D is the solution.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 08:27AM |

Registered: 8 years ago Posts: 130 |

Mine came with threads on top not the fine little hole you have...hence the need for a fitting up top.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 08:51AM |

Registered: 8 years ago Posts: 130 |

Would a 24V to 12V Golf Cart Buck provide clean enough current to run the Ramps 1.4 board?

Poor symbolic representation follows:

24V DC 15A 360W Regulated Switching Power Supply -----> golf cart buck(http://www.amazon.com/HOSSEN%C2%AE-Converter-Regulator-Step-Down/dp/B00BWKXTUU) -----> Ramps 1.4

Poor symbolic representation follows:

24V DC 15A 360W Regulated Switching Power Supply -----> golf cart buck(http://www.amazon.com/HOSSEN%C2%AE-Converter-Regulator-Step-Down/dp/B00BWKXTUU) -----> Ramps 1.4

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 10:48AM |

Registered: 8 years ago Posts: 430 |

Quote

Bert3D

Quote

msaeger

[www.thingiverse.com] with a belt instead of the gears.

If you don't want to try and build it from scratch this guy is selling it ready to go. I bought a different design from him and it was good. [www.ebay.com]

Doesn't that extruder design cut off some of the vertical print height?

It would seem better to have the motor off to one side or to the front.

I get 150MM with no Z motor extensions or anything. The tip of the nozzle ends up being just slightly lower than the X axix mount and the motor is far enough forward that it clears the horizontal extrusion at the top.

I think you need something with gearing to drive these things. It seems like the motor is too weak to push the filament though with the direct drive setups. I know I when I had the direct drive I was getting clicking and I keep reading other people with the same issue. I prefer the simplicity of the direct drive though so I am thinking about getting a geared stepper and trying it on the direct drive one like how the bulldog xl is, or I will just keep using what I have because it works. It's hard to not keep changing stuff on these things.

Edited 1 time(s). Last edit at 03/17/2016 10:56AM by msaeger.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 11:56AM |

Registered: 8 years ago Posts: 85 |

Quote

flatlander

Mine came with threads on top not the fine little hole you have...hence the need for a fitting up top.

[attachment 74765 AllMetalFeed72dpi.jpg]

Yeah, that's a little different. Could probably print a little adapter to screw into that. Or use a bowden fitting, I'm guessing that's why it was designed like that so you could run a tube off either end.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 11:59AM |

Registered: 8 years ago Posts: 131 |

Quote

jhitesma

Quote

flatlander

Mine came with threads on top not the fine little hole you have...hence the need for a fitting up top.

[attachment 74765 AllMetalFeed72dpi.jpg]

Yeah, that's a little different. Could probably print a little adapter to screw into that. Or use a bowden fitting, I'm guessing that's why it was designed like that so you could run a tube off either end.

correct that's if you're using it as a bowden extruder.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 12:04PM |

Registered: 8 years ago Posts: 10 |

How accurate are the printing estimations in Repetier/Slic3r?

When I was printing at 0.4 and 0.3mm layer height, I thought they were pretty close.

Printed these Z mounts at 0.2mm for the first time last night and the ETA said 2:44 and it took over 5 hours? 60mm/s printing speed. On the flip side, they look good!

[imgur.com]

When I was printing at 0.4 and 0.3mm layer height, I thought they were pretty close.

Printed these Z mounts at 0.2mm for the first time last night and the ETA said 2:44 and it took over 5 hours? 60mm/s printing speed. On the flip side, they look good!

[imgur.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 01:48PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Has anybody here upgraded to bowden? And is it worth it?

I upgraded to bowden and it work pretty well for me. Some people have mentioned that they do not like bowden because the retraction settings are difficult to perfect.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 01:53PM |

Registered: 8 years ago Posts: 85 |

Quote

Toxic0n

How accurate are the printing estimations in Repetier/Slic3r?

When I was printing at 0.4 and 0.3mm layer height, I thought they were pretty close.

Printed these Z mounts at 0.2mm for the first time last night and the ETA said 2:44 and it took over 5 hours? 60mm/s printing speed. On the flip side, they look good!

[imgur.com]

I've found slic3r's estimates to be pretty far off sometimes. I've had things it said would be 4 hours take over 8.

rep-server seems to do a much better job of estimating printing times, once I updated it's settings to match my actual acceleration/travel/print speeds. I'm guessing slic3r is expecting different acceleration speeds (since it obviously knows about the travel/print speeds) but I've yet to get that figured out. I generally send my gcode to rep-server then check there to get a more realistic time estimate now.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 02:17PM |

Registered: 8 years ago Posts: 92 |

Quote

UltiFix

Has anybody here upgraded to bowden? And is it worth it?

I did. It was not worth it IMHO.

My goal was to lighten the hotend, to increase speed. I haven't been happy with some of the high speed tests I've done, so I'm still printing at the same rate. In addition, I had to mess with feed rate and retraction settings A LOT to get back to where I am reasonably happy with the results, however I had to drastically shorten the bowden tube before I was happy with how it was doing.

Initially I had the extruder mounted on the back of the frame, behind the left-hand upright. The tube ran out the back, then up and over the top bar to the hot end. Total length was probably around 60 cm or so. I could not get retraction settings dialed in with this. I think where was just too much slop introduced in that long of a tube.

I moved the extruder to the top bar, thereby cutting the length of tub to less than half of the original. This works MUCH BETTER. (I'll post a pic later when I get home) I am reasonably happy with the results, HOWEVER changing filament is a PITA.

All that being said, I am seriously considering going back to mounting the extruder to the X carriage. I did the v-slot upgrade, but got a bad gantry plate. The wheels don't tighten up all the way against the rail (just a little play, maybe .1mm). I contacted Open Builds and they admitted they had a bad batch of plates, with errors in the hole spacing. They are sending me a new one, so since I'll have to tear it all apart anyway, I think I'll be switching back at that time. I am thinking about going with one of the belted extruders, with a NEMA 14 motor to keep the weight down... But we'll see. I'm getting to the point where I want to stop messing with the printer, and just to be printing with it.

It's about time to move on to my next project: Either a CNC mini mill, or a laser engraver/cutter.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 02:37PM |

Registered: 8 years ago Posts: 10 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 03:02PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 03:06PM |

Registered: 10 years ago Posts: 477 |

Quote

Toxic0n

How accurate are the printing estimations in Repetier/Slic3r?

When I was printing at 0.4 and 0.3mm layer height, I thought they were pretty close.

Printed these Z mounts at 0.2mm for the first time last night and the ETA said 2:44 and it took over 5 hours? 60mm/s printing speed. On the flip side, they look good!

[imgur.com]

From what I understand the slicers don't take acceleration/deceleration into account when estimating the times.

I usually use [gcode.ws] for a better estimate

My updated Instructable on our Prusa i3 Build

[www.instructables.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 05:07PM |

Registered: 8 years ago Posts: 314 |

Quote

iamquestar

Quote

UltiFix

Has anybody here upgraded to bowden? And is it worth it?

I did. It was not worth it IMHO.

My goal was to lighten the hotend, to increase speed. I haven't been happy with some of the high speed tests I've done, so I'm still printing at the same rate. In addition, I had to mess with feed rate and retraction settings A LOT to get back to where I am reasonably happy with the results, however I had to drastically shorten the bowden tube before I was happy with how it was doing.

Initially I had the extruder mounted on the back of the frame, behind the left-hand upright. The tube ran out the back, then up and over the top bar to the hot end. Total length was probably around 60 cm or so. I could not get retraction settings dialed in with this. I think where was just too much slop introduced in that long of a tube.

I moved the extruder to the top bar, thereby cutting the length of tub to less than half of the original. This works MUCH BETTER. (I'll post a pic later when I get home) I am reasonably happy with the results, HOWEVER changing filament is a PITA.

All that being said, I am seriously considering going back to mounting the extruder to the X carriage. I did the v-slot upgrade, but got a bad gantry plate. The wheels don't tighten up all the way against the rail (just a little play, maybe .1mm). I contacted Open Builds and they admitted they had a bad batch of plates, with errors in the hole spacing. They are sending me a new one, so since I'll have to tear it all apart anyway, I think I'll be switching back at that time. I am thinking about going with one of the belted extruders, with a NEMA 14 motor to keep the weight down... But we'll see. I'm getting to the point where I want to stop messing with the printer, and just to be printing with it.

It's about time to move on to my next project: Either a CNC mini mill, or a laser engraver/cutter.

Honestly I guess I will just stick to direct for now... Im thinking of doing dual extruders, which I think would be a LOT of weight on the x axis... So maybe 1 bowden, and 1 direct drive.Quote

Mach

Quote

UltiFix

Has anybody here upgraded to bowden? And is it worth it?

I upgraded to bowden and it work pretty well for me. Some people have mentioned that they do not like bowden because the retraction settings are difficult to perfect.

What do you guys think of this dual extruder setup? (I did not make this design)

[www.thingiverse.com]

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 17, 2016 05:34PM |

Registered: 8 years ago Posts: 85 |

Quote

SteveRoy

From what I understand the slicers don't take acceleration/deceleration into account when estimating the times.

I usually use [gcode.ws] for a better estimate

That would explain why rep-server does a better job at estimating than slic3r then.

Mailman showed up with not only my e3d today but also the spare stepper I ordered in case I burn my extruder out - so tonight I get to build up a new print head without having to take parts off my printer

Should be a fun evening...assuming I find all the bits I need at the hardware store after work!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 18, 2016 12:37AM |

Registered: 8 years ago Posts: 276 |

Quote

SteveRoy

Quote

Toxic0n

How accurate are the printing estimations in Repetier/Slic3r?

When I was printing at 0.4 and 0.3mm layer height, I thought they were pretty close.

Printed these Z mounts at 0.2mm for the first time last night and the ETA said 2:44 and it took over 5 hours? 60mm/s printing speed. On the flip side, they look good!

[imgur.com]

From what I understand the slicers don't take acceleration/deceleration into account when estimating the times.

I usually use [gcode.ws] for a better estimate

That's a really cool web app!

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 18, 2016 08:33AM |

Registered: 8 years ago Posts: 32 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 18, 2016 09:32AM |

Registered: 8 years ago Posts: 131 |

Quote

Boffster

Bookmarked! Thanks for the link!

Just tried it on a print I ran Wednesday.

Actual Print time 12 hours and 28 minutes.

gcode.ws "Estimated print time: 9:0:52", that's over a 30% discrepancy

Repetier Server "9h 30m 36s" closer but still around 30% off.

Overall still can't find something to be even close to accurate print time...

M.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 18, 2016 12:22PM |

Registered: 8 years ago Posts: 2 |

My FolgerTech 2020 i3 printer was working great except for 2 issues. Prints were 4% short on the Z-axis, and on some prints it was clear that filament volume was too low. I fixed both my changing DEFAULT_AXIS_STEPS_PER_UNIT in configuration.h

Here's my question: Why does the firmware on the FolgerTech Google drive have these settings: {80,80,3840,90} ? My printer works much better with what seems to be 'normal' settings {80,80,4000,100} for this printer design.

I have this resolved, just curious about the settings published on the Google Drive

Here's my question: Why does the firmware on the FolgerTech Google drive have these settings: {80,80,3840,90} ? My printer works much better with what seems to be 'normal' settings {80,80,4000,100} for this printer design.

I have this resolved, just curious about the settings published on the Google Drive

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 18, 2016 12:24PM |

Registered: 8 years ago Posts: 131 |

Quote

jag

My FolgerTech 2020 i3 printer was working great except for 2 issues. Prints were 4% short on the Z-axis, and on some prints it was clear that filament volume was too low. I fixed both my changing DEFAULT_AXIS_STEPS_PER_UNIT in configuration.h

Here's my question: Why does the firmware on the FolgerTech Google drive have these settings: {80,80,3840,90} ? My printer works much better with what seems to be 'normal' settings {80,80,4000,100} for this printer design.

I have this resolved, just curious about the settings published on the Google Drive

It seems that FT had a bad value for the threaded rods hence the issue there, it's been a reoccurring topic on this thread. 4K is correct.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 18, 2016 12:34PM |

Registered: 8 years ago Posts: 314 |

What about 90 vs 100Quote

marc2912

Quote

jag

My FolgerTech 2020 i3 printer was working great except for 2 issues. Prints were 4% short on the Z-axis, and on some prints it was clear that filament volume was too low. I fixed both my changing DEFAULT_AXIS_STEPS_PER_UNIT in configuration.h

Here's my question: Why does the firmware on the FolgerTech Google drive have these settings: {80,80,3840,90} ? My printer works much better with what seems to be 'normal' settings {80,80,4000,100} for this printer design.

I have this resolved, just curious about the settings published on the Google Drive

It seems that FT had a bad value for the threaded rods hence the issue there, it's been a reoccurring topic on this thread. 4K is correct.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 18, 2016 12:50PM |

Registered: 8 years ago Posts: 131 |

Quote

UltiFix

What about 90 vs 100Quote

marc2912

Quote

jag

My FolgerTech 2020 i3 printer was working great except for 2 issues. Prints were 4% short on the Z-axis, and on some prints it was clear that filament volume was too low. I fixed both my changing DEFAULT_AXIS_STEPS_PER_UNIT in configuration.h

Here's my question: Why does the firmware on the FolgerTech Google drive have these settings: {80,80,3840,90} ? My printer works much better with what seems to be 'normal' settings {80,80,4000,100} for this printer design.

I have this resolved, just curious about the settings published on the Google Drive

It seems that FT had a bad value for the threaded rods hence the issue there, it's been a reoccurring topic on this thread. 4K is correct.

If you really tune everything the numbers won't be 80, 80 4000, 90 anyways, it could be he actually tuned his printer accordingly.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 18, 2016 03:02PM |

Registered: 8 years ago Posts: 130 |

Quote

jag

My FolgerTech 2020 i3 printer was working great except for 2 issues. Prints were 4% short on the Z-axis, and on some prints it was clear that filament volume was too low. I fixed both my changing DEFAULT_AXIS_STEPS_PER_UNIT in configuration.h

Here's my question: Why does the firmware on the FolgerTech Google drive have these settings: {80,80,3840,90} ? My printer works much better with what seems to be 'normal' settings {80,80,4000,100} for this printer design.

I have this resolved, just curious about the settings published on the Google Drive

Yea, I wish someone would do a little house keeping. I had the printer a week before I saw the wiki. This is the first I have seen the link you have. My link is [drive.google.com] It looks similar to yours, but not quite right. Hum?

My thought is you want the firmware settings to allow the machine to mechanically move by the amount the you tell it to move in g-code. Print size may be the result of shrinkage and should be accounted for by slightly scaling the objects. Am I wrong about the basic method for tuning our printers? Not that I haven't fiddled with the extrusion multiplier, when I probably should look at the firmware figures

On a slight tangent, do you draw your objects to scale and then account for shrinkage at time of printing, by scaling? I see about 1-2% shrinkage.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 18, 2016 03:04PM |

Registered: 8 years ago Posts: 93 |

Quote

marc2912

Quote

UltiFix

What about 90 vs 100Quote

marc2912

Quote

jag

My FolgerTech 2020 i3 printer was working great except for 2 issues. Prints were 4% short on the Z-axis, and on some prints it was clear that filament volume was too low. I fixed both my changing DEFAULT_AXIS_STEPS_PER_UNIT in configuration.h

Here's my question: Why does the firmware on the FolgerTech Google drive have these settings: {80,80,3840,90} ? My printer works much better with what seems to be 'normal' settings {80,80,4000,100} for this printer design.

I have this resolved, just curious about the settings published on the Google Drive

It seems that FT had a bad value for the threaded rods hence the issue there, it's been a reoccurring topic on this thread. 4K is correct.

If you really tune everything the numbers won't be 80, 80 4000, 90 anyways, it could be he actually tuned his printer accordingly.

Actually after tuning my extruder the E steps was 100.89, so it is pretty close to the calculated 100 steps. I'm not sure why 90 either.

Edited 1 time(s). Last edit at 03/18/2016 03:04PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 18, 2016 03:09PM |

Registered: 8 years ago Posts: 131 |

Quote

Bert3D

Quote

marc2912

Quote

UltiFix

What about 90 vs 100Quote

marc2912

Quote

jag

My FolgerTech 2020 i3 printer was working great except for 2 issues. Prints were 4% short on the Z-axis, and on some prints it was clear that filament volume was too low. I fixed both my changing DEFAULT_AXIS_STEPS_PER_UNIT in configuration.h

Here's my question: Why does the firmware on the FolgerTech Google drive have these settings: {80,80,3840,90} ? My printer works much better with what seems to be 'normal' settings {80,80,4000,100} for this printer design.

I have this resolved, just curious about the settings published on the Google Drive

It seems that FT had a bad value for the threaded rods hence the issue there, it's been a reoccurring topic on this thread. 4K is correct.

If you really tune everything the numbers won't be 80, 80 4000, 90 anyways, it could be he actually tuned his printer accordingly.

Actually after tuning my extruder the E steps was 100.89, so it is pretty close to the calculated 100 steps. I'm not sure why 90 either.

I'm closer to 110 but I think my extruder gear has a low spot in and it skips a tiny bit every revolution. looking to change it out.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 18, 2016 03:14PM |

Registered: 8 years ago Posts: 314 |

So the last number (90) is the extrusion multiplier?Quote

marc2912

Quote

Bert3D

Quote

marc2912

Quote

UltiFix

What about 90 vs 100Quote

marc2912

Quote

jag

My FolgerTech 2020 i3 printer was working great except for 2 issues. Prints were 4% short on the Z-axis, and on some prints it was clear that filament volume was too low. I fixed both my changing DEFAULT_AXIS_STEPS_PER_UNIT in configuration.h

Here's my question: Why does the firmware on the FolgerTech Google drive have these settings: {80,80,3840,90} ? My printer works much better with what seems to be 'normal' settings {80,80,4000,100} for this printer design.

I have this resolved, just curious about the settings published on the Google Drive

It seems that FT had a bad value for the threaded rods hence the issue there, it's been a reoccurring topic on this thread. 4K is correct.

If you really tune everything the numbers won't be 80, 80 4000, 90 anyways, it could be he actually tuned his printer accordingly.

Actually after tuning my extruder the E steps was 100.89, so it is pretty close to the calculated 100 steps. I'm not sure why 90 either.

I'm closer to 110 but I think my extruder gear has a low spot in and it skips a tiny bit every revolution. looking to change it out.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 18, 2016 03:25PM |

Registered: 8 years ago Posts: 93 |

Quote

UltiFix

So the last number (90) is the extrusion multiplier?Quote

marc2912

Quote

Bert3D

Quote

marc2912

Quote

UltiFix

What about 90 vs 100Quote

marc2912

Quote

jag

My FolgerTech 2020 i3 printer was working great except for 2 issues. Prints were 4% short on the Z-axis, and on some prints it was clear that filament volume was too low. I fixed both my changing DEFAULT_AXIS_STEPS_PER_UNIT in configuration.h

Here's my question: Why does the firmware on the FolgerTech Google drive have these settings: {80,80,3840,90} ? My printer works much better with what seems to be 'normal' settings {80,80,4000,100} for this printer design.

I have this resolved, just curious about the settings published on the Google Drive

It seems that FT had a bad value for the threaded rods hence the issue there, it's been a reoccurring topic on this thread. 4K is correct.

If you really tune everything the numbers won't be 80, 80 4000, 90 anyways, it could be he actually tuned his printer accordingly.

Actually after tuning my extruder the E steps was 100.89, so it is pretty close to the calculated 100 steps. I'm not sure why 90 either.

I'm closer to 110 but I think my extruder gear has a low spot in and it skips a tiny bit every revolution. looking to change it out.

Not the extrusion multiplier, but the extruder steps per mm. The extrusion multiplier is something you set in the slicer, and increases or decreases the amount it tells the extruder to extrude.

The steps in the firmware tell it how many steps your extruder stepper motor requires to extrude 1mm of filament.

The steps in the firmware configure the hardware. The extrusion multiplier is for tweaking specific prints that may need more or less extrusion, or for compensating for filament that is thinner or wider than 1.75, etc.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

Sorry, only registered users may post in this forum.