Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 22, 2016 10:38AM |

Registered: 8 years ago Posts: 171 |

Quote

flatlander

Quote

marc2912

Quote

flatlander

Is there any reason not to use a stainless feed gear as a replacement? By the way, thanks for the heads-up.

[www.amazon.com]

Folger Tech sells a replacement described as steel.

Personally I wouldn't order anything other than the printer on FT's site. They're a great starting point but past that their prices and quality are not really competitive.

As for getting a new one look at products with reviews and remember to re run calibration on your extruder after. Also make sure you get the right gear for the right extruder.

I'm likely to keep using FT for some things. Their shipping is pretty fast and once I have something in the the cart I may as well add a few things because it's the shipping that gets me. It has to be a brutal business model with margins near zero... death by a thousand Amazon/Ebay cuts. Kudos for sticking his neck out; I hope it remains intact.

I'm in the same boat. Even if they are a couple bucks more expensive, at least their slow shipping gets to me in a day or two since I'm in the next state over from them!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 22, 2016 11:44AM |

Registered: 8 years ago Posts: 276 |

Why are you guys ordering extruders? You have a 3d printer sitting right next to you...

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 22, 2016 12:32PM |

Registered: 8 years ago Posts: 131 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 22, 2016 01:30PM |

Registered: 8 years ago Posts: 46 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 22, 2016 01:33PM |

Registered: 8 years ago Posts: 85 |

Quote

DaveA

Has anyone else had issues with the stock Folger extruder drive gear becoming worn? I've had my printer for about 2+ months and have run maybe 21/2 spools through. 1 spool PLA, 1 spool PETG and a bit of ABS. In the last week or so I've noticed a lot of clicking from the extruder and the prints are becoming pretty bad. Examining the gear shows there is hardly any "tooth" left. They are all worn down to the point the gear almost feels smooth. Are these gears considered expendable items? They are advertised as being made from copper which doesn't seem be a good gear material for long term use.

Any recommendations on a good replacement direct drive extruder that supports mounting the BLTouch sensor?

I actually switched to the gear from the metal extruder a few weeks before I switched to the metal extruder. The teeth seemed to have a bit more bite so I figured it would be a decent halfway upgrade with the stock extruder. While doing that I did notice that the idler was pretty gunked up with bits of filament so I did some serious cleaning in there. But the stock gear didn't really show any signs of wear.

I got my printer a few days after Christmas and have put almost 3 rolls of PLA about 1 roll of ABS and almost a roll of PETG through it most with the stock gear. The teeth on the stock gear weren't well defined to begin with but don't really look any worse after all that.

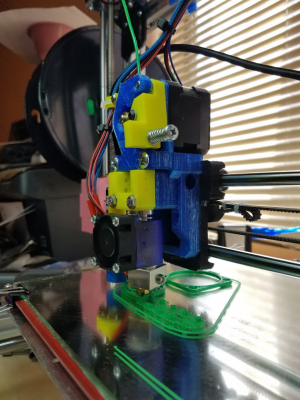

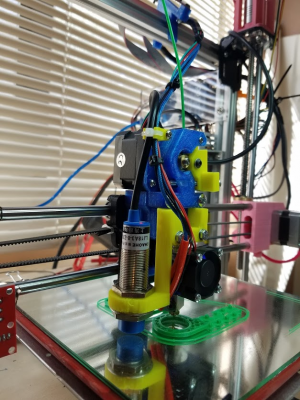

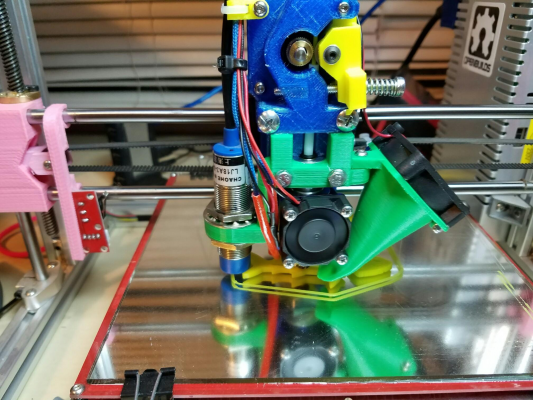

I just got an e3d v6 (full all metal version because I want to print Nylon and eventually polycarbonate) and switched to this extruder: [www.thingiverse.com]

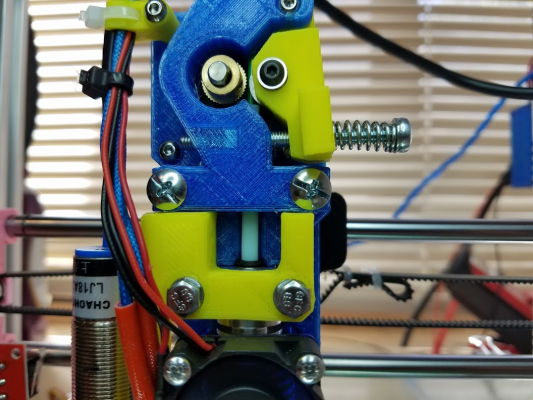

If you look closely you can see that I'm actually using the stock folger gear on it:

There are a couple of things I'm liking about this extruder...but I'm not entirely happy with it.

Pros:

Lifts the motor up and back so there's less stuff cantilevered off the X carriage, the nozzle is much more rigid.

Uses the stock folger extruder bearing, gear and spring so minimal parts needed.

With the back of the stepper exposed I can put the stock extruder heat sink on the back of the stepper to help keep it cool.

Tension is adjustable.

I gained Z height because despite the length of the e3d this mounts everything higher so the nozzle sits higher on the X carriage - while the upper bar of the frame is far enough back that nothing interferes with it at the top.

Cons:

The tension arm is a little short so you have to really crank on the spring to get enough tension.

There was no way to release tension without changing the setting so I remixed the idler arm: [www.thingiverse.com]

Even with the tension as high as I feel safe taking it I don't get quite as clean of a print as I did with the metal extruder. The banding in the extrusion is back...not as bad as with the factory extruder but if I turn the tension any higher the stepper starts skipping and I already have the current higher than I feel safe going.

The filament is constrained in the PTFE...but I'd still like to see a shorter distance from the gear to the melt zone. The clamp area could be remixed to remove about 1-1.5cm of distance, if I was going to stick with this extruder I'd probably try to do that.

I also made up an inductive sensor mount for it: [www.thingiverse.com]

I actually have an even newer (my 4th revision) version of the sensor mount that also adds a fan mount and is what I'm currently using but haven't had a chance to upload it yet:

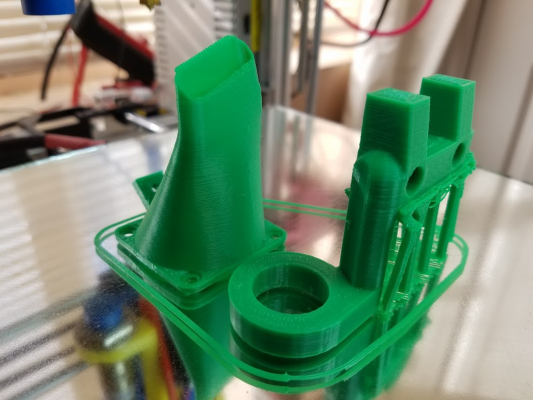

FWIW - The blue is PETG from Atomic filament printed with my original Folger extruder. The yellow is PLA from MakerGeeks printed with the new extruder but no cooling fan. The green is Hatchbox ABS printed with the new extruder when I got frustrated with how PLA was printing without a fan

PETG and ABS are printing GREAT with the new extruder - the higher temps I can reach with the all metal e3d really helped the PETG and the MakerGeeks PLA...I actually think I was running higher temps than I thought with my original hot end due to the thermister being kind of loose in it's hole. With the original hot end I printed PETG at 225 which was lower than what Atomic suggested...but any hotter and I got strings like crazy, but with the e3d at 225 it was barely extruding and printing horribly, getting MUCH better results in the 235-240 range. Same with the MakerGeeks PLA - I had to turn the temp up some to get the same results I was seeing before.

I want to try a geared extruder next and am leaning towards this design: [www.thingiverse.com] In the meantime I may swap the gear from my metal extruder onto this setup. If I was going to stick with a non-geared extruder I'd probably order an actual mk8 gear or a hobgoblin gear as a replacement. May still do that because I'm planning on putting my original extruder on the MPCNC I've been printing so I can use it as a backup machine

Also thinking about swapping to a 40mm fan on the e3d because that little 30mm one is crazy loud...does seem to move a lot more air than my 40's though so I'm worried about cooling if I switch to a 40mm.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 22, 2016 01:45PM |

Registered: 8 years ago Posts: 85 |

Quote

marc2912

I'd like to run an informal poll here. I wish the forum had an easy way to run a poll within a thread... Are you running a bed leveling system and if so which?

Thanks

Like you I found I had to relevel almost every time I touched the bed. So I ended up going autolevel. I started with the 4mm distance sensor from Folger and a sheet of 28ga galvanized steel under my glass. It worked...but the sense distance was so short it made me nervous and the steel curled a little when I cut it so it didn't lay perfectly flat and one corner always read a little higher. I liked that it worked at 5v, and that it worked at all...but the steel made heating my glass enough for ABS tough and I didn't like the one corner always reading high.

I swapped to a 8mm distance sensor and it almost kind of sometimes worked on 5v...so I also swapped to running at 12v with a few resistors to drop the voltage (it's an NPN sensor but I still checked and the output had 12v on it - even if the arduino should be pushing current rather than pulling with an NPN setup that made me nervous and the resistors are cheap and good insurance.) The 8mm sensor was so sensitive I was able to remove the steel and actually read the heater plate with nothing extra...but it was so sensitive that if I read over one of the screws mounting the bearing blocks to the aluminum sub-bed then that spot would read high. So I added a sheet of heavy duty aluminum foil between the glass and heated bed - it now triggers off that and since the foil is so thin I get VERY reliable even readings.

I have however noticed that my initial layer can drift by about 0.1mm from day to day. My best guess is that this is due to the mount changing dimensions slightly based on the ambient temperature in the room I print. (Days when it's hot I get a shorter initial layer, days when it's cold I get a slightly shorter layer - which would make sense if it's thermal expansion...but I live in the desert and it's been hitting the mid 90's(f) already and still down in the lower 50's at night so the ambient temperature swings I get are pretty extreme because it's freaking March and I can't bring myself to turn on the AC this early in the year.)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 22, 2016 01:51PM |

Registered: 8 years ago Posts: 85 |

Quote

therippa

Why are you guys ordering extruders? You have a 3d printer sitting right next to you...

I tried the metal ebay one for a couple of reasons:

1) It was suggested to me by someone who's print quality I was impressed by.

2) It was <$15 so cheap to try.

3) I figured if nothing else it would give me a spare bearing and gear even if I tossed the rest.

4) I worried about printing one because when I print ABS there's a lot of heat in that area...I wouldn't trust PLA...ABS I don't trust for dimensionaly accurate parts due to shrinkage, and PETG at the time wasn't printing well enough for me that I wanted to try it (I've since got PETG printing so well even on the stock hot end/extruder that it's probably my favorite material.)

Now that I have my e3d though I'm having fun printing various extruder designs

I almost tried your tinyflex setup but liked the way the motor is moved on the one I tried instead, and I don't have any flexible filament to try...yet. Now that I've got a better hot end and an extruder that should handle it I'm looking forward to trying some!

I almost tried your tinyflex setup but liked the way the motor is moved on the one I tried instead, and I don't have any flexible filament to try...yet. Now that I've got a better hot end and an extruder that should handle it I'm looking forward to trying some!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 22, 2016 02:54PM |

Registered: 9 years ago Posts: 251 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 22, 2016 03:11PM |

Registered: 8 years ago Posts: 85 |

Quote

widespreaddeadhead

@jhitesma

I use that same hotend/extruder mount and it works well for me. I like your remixed idler also.

Thanks. Oh, and just in case I came across too harsh...Overall I like it and would say it's an improvement over stock. My criticisms are just because I'm pretty much never satisfied and always looking to make things better - which means first identifying what can be improved

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 22, 2016 04:29PM |

Registered: 8 years ago Posts: 131 |

Quote

jhitesma

Quote

marc2912

I'd like to run an informal poll here. I wish the forum had an easy way to run a poll within a thread... Are you running a bed leveling system and if so which?

Thanks

Like you I found I had to relevel almost every time I touched the bed. So I ended up going autolevel. I started with the 4mm distance sensor from Folger and a sheet of 28ga galvanized steel under my glass. It worked...but the sense distance was so short it made me nervous and the steel curled a little when I cut it so it didn't lay perfectly flat and one corner always read a little higher. I liked that it worked at 5v, and that it worked at all...but the steel made heating my glass enough for ABS tough and I didn't like the one corner always reading high.

I swapped to a 8mm distance sensor and it almost kind of sometimes worked on 5v...so I also swapped to running at 12v with a few resistors to drop the voltage (it's an NPN sensor but I still checked and the output had 12v on it - even if the arduino should be pushing current rather than pulling with an NPN setup that made me nervous and the resistors are cheap and good insurance.) The 8mm sensor was so sensitive I was able to remove the steel and actually read the heater plate with nothing extra...but it was so sensitive that if I read over one of the screws mounting the bearing blocks to the aluminum sub-bed then that spot would read high. So I added a sheet of heavy duty aluminum foil between the glass and heated bed - it now triggers off that and since the foil is so thin I get VERY reliable even readings.

I have however noticed that my initial layer can drift by about 0.1mm from day to day. My best guess is that this is due to the mount changing dimensions slightly based on the ambient temperature in the room I print. (Days when it's hot I get a shorter initial layer, days when it's cold I get a slightly shorter layer - which would make sense if it's thermal expansion...but I live in the desert and it's been hitting the mid 90's(f) already and still down in the lower 50's at night so the ambient temperature swings I get are pretty extreme because it's freaking March and I can't bring myself to turn on the AC this early in the year.)

What material can the sensor work with? What happens if you cover the glass with spray or blue tape?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 22, 2016 05:21PM |

Registered: 8 years ago Posts: 85 |

Quote

marc2912

What material can the sensor work with? What happens if you cover the glass with spray or blue tape?

An inductive sensor needs metal. It works best with ferrous metal like steel, but can detect aluminum as well.

I use hairspray on my glass but there'd be no problem with glue or blue tape either...unless...

If you're using a 4mm distance sensor then it may not be sensitive enough to clear the extra height added by blue tape. It's not much...but the 4mm barely works as it is.

Keep in mind that the quoted 4/8mm distance is for detecting a rather large chunk of ferrous material, aluminum doesn't sense as well/closely so you loose some distance when aluminum is what you're detecting. And glass is usually 3mm thick so right there you loose 3mm from what you're sensing. So with a 4mm sensor you only have about 1mm of clearance in the best of conditions - and if you're using aluminum under the bed or just thin steel you don't even have 1mm of clearance above the glass. With my 8mm sensor and HD aluminum foil under the glass I run a Z offset of between 2.5 and 3mm depending on how I position my sensor. It's not a lot but it's enough and I easily have room for blue tape.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 22, 2016 05:30PM |

Registered: 8 years ago Posts: 131 |

Quote

jhitesma

Quote

marc2912

What material can the sensor work with? What happens if you cover the glass with spray or blue tape?

An inductive sensor needs metal. It works best with ferrous metal like steel, but can detect aluminum as well.

I use hairspray on my glass but there'd be no problem with glue or blue tape either...unless...

If you're using a 4mm distance sensor then it may not be sensitive enough to clear the extra height added by blue tape. It's not much...but the 4mm barely works as it is.

Keep in mind that the quoted 4/8mm distance is for detecting a rather large chunk of ferrous material, aluminum doesn't sense as well/closely so you loose some distance when aluminum is what you're detecting. And glass is usually 3mm thick so right there you loose 3mm from what you're sensing. So with a 4mm sensor you only have about 1mm of clearance in the best of conditions - and if you're using aluminum under the bed or just thin steel you don't even have 1mm of clearance above the glass. With my 8mm sensor and HD aluminum foil under the glass I run a Z offset of between 2.5 and 3mm depending on how I position my sensor. It's not a lot but it's enough and I easily have room for blue tape.

Thanks a lot for the info.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 23, 2016 12:50AM |

Registered: 8 years ago Posts: 85 |

I wrote up some more details about my experiences setting up auto level on my blog: [www.nevermindthesand.com]

I also included links at the end to a number of other sources of information that I relied on when figuring out how to get it working.

Please feel free to point out anything I left out or any glaring errors - I just tossed this post together since it's such a popular topic. I didn't try to rehash the existing detailed setup instructions but instead tried to give my own perspective on the options and why I went with the choices I did. I'll gladly add links to any other auto level resources I overlooked that people have found helpful the ones I included were just those that immediately came to mind as helping me when I did my setup.

I also included links at the end to a number of other sources of information that I relied on when figuring out how to get it working.

Please feel free to point out anything I left out or any glaring errors - I just tossed this post together since it's such a popular topic. I didn't try to rehash the existing detailed setup instructions but instead tried to give my own perspective on the options and why I went with the choices I did. I'll gladly add links to any other auto level resources I overlooked that people have found helpful the ones I included were just those that immediately came to mind as helping me when I did my setup.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 23, 2016 07:44AM |

Registered: 8 years ago Posts: 131 |

Quote

jhitesma

I wrote up some more details about my experiences setting up auto level on my blog: [www.nevermindthesand.com]

I also included links at the end to a number of other sources of information that I relied on when figuring out how to get it working.

Please feel free to point out anything I left out or any glaring errors - I just tossed this post together since it's such a popular topic. I didn't try to rehash the existing detailed setup instructions but instead tried to give my own perspective on the options and why I went with the choices I did. I'll gladly add links to any other auto level resources I overlooked that people have found helpful the ones I included were just those that immediately came to mind as helping me when I did my setup.

Awesome, thanks a lot for the info. I have a LJ18A3-8-Z/BX that I have done nothing with yet, it's a 8mm NPN NO Switch 6-36VDC, I was thinking of just doing a mount for it and giving it a try. Would gluing some HD aluminum sheets to the back side of the glass work? I'm thinking that since the glass surface is what I want level making sure the aluminum sensed is parallel to the glass is crucial.

Would you recommend multiple layers of aluminum?

Thx

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 23, 2016 09:53AM |

Registered: 9 years ago Posts: 251 |

Quote

jhitesma

Thanks. Oh, and just in case I came across too harsh...Overall I like it and would say it's an improvement over stock. My criticisms are just because I'm pretty much never satisfied and always looking to make things better - which means first identifying what can be improved

No worries! I actually have the same issues with this: "The filament is constrained in the PTFE...but I'd still like to see a shorter distance from the gear to the melt zone. The clamp area could be remixed to remove about 1-1.5cm of distance, if I was going to stick with this extruder I'd probably try to do that."

If you switch extruders let me know, I'd like to follow your progress.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 23, 2016 11:08AM |

Registered: 8 years ago Posts: 85 |

Quote

marc2912

Awesome, thanks a lot for the info. I have a LJ18A3-8-Z/BX that I have done nothing with yet, it's a 8mm NPN NO Switch 6-36VDC, I was thinking of just doing a mount for it and giving it a try. Would gluing some HD aluminum sheets to the back side of the glass work? I'm thinking that since the glass surface is what I want level making sure the aluminum sensed is parallel to the glass is crucial.

Would you recommend multiple layers of aluminum?

Thx

I'm just using one sheet of aluminum. Like I said it was sensitive enough to be sensing the heated bed with nothing else, but also so sensitive that the screw heads for the bearings under that were apparently throwing it off. I put in the aluminum foil hoping it would trigger off that before the screw heads could affect things and so far (almost 2 months) it seems to be working great. I didn't glue or attach the foil, just placed it loose under the glass. The pressure of the binder clips holding the glass to the heated bed is enough to keep it flat.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 23, 2016 11:10AM |

Registered: 8 years ago Posts: 85 |

Quote

widespreaddeadhead

Quote

jhitesma

Thanks. Oh, and just in case I came across too harsh...Overall I like it and would say it's an improvement over stock. My criticisms are just because I'm pretty much never satisfied and always looking to make things better - which means first identifying what can be improved

No worries! I actually have the same issues with this: "The filament is constrained in the PTFE...but I'd still like to see a shorter distance from the gear to the melt zone. The clamp area could be remixed to remove about 1-1.5cm of distance, if I was going to stick with this extruder I'd probably try to do that."

If you switch extruders let me know, I'd like to follow your progress.

I don't plan on going anywhere anytime soon

So I'll definitely follow up as I continue to experiment. Will probably be late next week before I have all the parts for a geared extruder printed...I'm also working on this MPCNC and had to redo a few 8hr prints which is taking up all the time on my printer right now.

So I'll definitely follow up as I continue to experiment. Will probably be late next week before I have all the parts for a geared extruder printed...I'm also working on this MPCNC and had to redo a few 8hr prints which is taking up all the time on my printer right now.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 23, 2016 12:30PM |

Registered: 9 years ago Posts: 251 |

Quote

jhitesma

I don't plan on going anywhere anytime soonSo I'll definitely follow up as I continue to experiment. Will probably be late next week before I have all the parts for a geared extruder printed...I'm also working on this MPCNC and had to redo a few 8hr prints which is taking up all the time on my printer right now.

I just finished the printed parts for the MPCNC for a customer too! Great printers work alike?!?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 23, 2016 07:48PM |

Registered: 8 years ago Posts: 130 |

Quote

jhitesma

Yeah I have one of those metal ones on my machine right now. I do like the higher tension it gives on the idler, that cleaned up a pattern I was seeing in my prints. But my stepper has been running about 10-15 degrees hotter since the change and started skipping. I initially thought it was due to the aluminum extruder letting more hot end heat get into the stepper...but now I think it's the extra tension making the stepper work harder - I turned up the current on my stepper driver a bit (doing the math I'm now over the 0.4a the stepper is rated for...but still under 0.5a so not much over) and even though I'm apparently over the current limit the stepper is running cooler and not skipping steps anymore so I'm going with it...close to 30 hours of printing at that setting so far and still working great.)

I also had some issues with the idler not lining up with the entrance to the heat break and with the tensioner not moving well if I tightened the screw it mounts with enough that I didn't worry about the screw falling out. I solved both problems by putting a 3mm washer between the tensioner and the body of the extruder with a dab of super lube grease on it:

[attachment 74737 20160312_152715.jpg]

To try and stop heat from the hot end getting into the stepper I added a gasket cut from some high temp gasket material I picked up for a few bucks at tractor supply for another project and had plenty of extra on hand:

[attachment 74738 20160312_151646.jpg]

The gasket didn't really help much, but the washer got the idler lined up with the heat break much better so it's much easier to load filament now and it has a straight path through the extruder - you can see the gasket and the washer here if you look closely:

[attachment 74739 IMG_20160313_115611.jpg]

But my e3d v6 (full all metal version since I want to try nylon) should be here tomorrow so I've got this printing right now: [www.thingiverse.com] It should be done in about half an hour. Not sure how I'll mount my inductive sensor though...may have to rig something up. I'm a little worried about the stepper hitting the top bar and costing me some Z...but we'll just have to see how that goes. I do like that the stepper is exposed so I can put the stock heat sink on the back of it to help cool it some. I want to do the compact geared extruder: [www.thingiverse.com] but that will take a bit more work to collect the vitamins for since I'll have to make a hobbed bolt so won't tackle that until this weekend at the earliest.

I may just go with animoose's mount and the stock extruder - I'm starting to think the issues I had with the stock extruder may be more related to stepper current than they were tension. I printed his mount and this remix: [www.thingiverse.com] to fit my inductive sensor. So I should have two options to try tomorrow. Doubt I'll get the e3d on and printing tomorrow but at least I'll have a few extruders to experiment with.

I purchased Heat Sink washers + a 30mm hot end barrel:

[www.ebay.com]

Hopefully a little pre-cooling, before the heat hits my all metal extruder, will be enough to keep the heat off the stepper. Although, My current extruder-stepper gets pretty hot if I try to print at speed above 60 mm/s. It is very likely that these steppers can't keep up. I'll get some pics when Frankenhotend is assembled.

Side note: I put my washer on the idler/feed pully. It made the holes, top and bottom line up better.

Edited 3 time(s). Last edit at 03/24/2016 09:52AM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 23, 2016 08:22PM |

Registered: 10 years ago Posts: 477 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 23, 2016 09:00PM |

Registered: 8 years ago Posts: 430 |

Quote

SteveRoy

A question for all the auto-level people - with auto level when your printer is printing in a layer in the x and y plane is the z-axis also moving the nozzle up and down during this layer?

Yes that's how it works.

[www.youtube.com]

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 23, 2016 10:42PM |

Registered: 8 years ago Posts: 541 |

And this is mine working with the BLTOUCH.

[www.youtube.com]

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

[www.youtube.com]

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 23, 2016 10:51PM |

Registered: 8 years ago Posts: 541 |

For 6 months, I've been strictly running PLA. Today a threw a roll of ESUN PET up there. It said the temp range was 230 -250, so I tried the 230 while running my single wall test. The thing came apart like a SLINKY.

So I upped it to 240 and got my test piece to stay together no matter how hard I pulled. I also got wall thickness of 0.49 to 0.52 when the GCode called for 0.48. My extrusion multiplier is still at 0.85 so the only change I made was the temperature. Still using the glass plate and hair spray.

I did notice in my single wall part that there were some small gaps that almost looked like air bubbles or where the extrusion stopped for just a split second. I ran the test again feeling and listening for any skipping but didn't hear anything. I printed out a part with Cura as the slicer because I had supports. They came out no problem and the part is great. I then sliced it with SLIC3R and I couldn't get the supports out. That's pretty much the norm for me.

This stuff is pretty nice AT FIRST GLANCE. We shall see.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

So I upped it to 240 and got my test piece to stay together no matter how hard I pulled. I also got wall thickness of 0.49 to 0.52 when the GCode called for 0.48. My extrusion multiplier is still at 0.85 so the only change I made was the temperature. Still using the glass plate and hair spray.

I did notice in my single wall part that there were some small gaps that almost looked like air bubbles or where the extrusion stopped for just a split second. I ran the test again feeling and listening for any skipping but didn't hear anything. I printed out a part with Cura as the slicer because I had supports. They came out no problem and the part is great. I then sliced it with SLIC3R and I couldn't get the supports out. That's pretty much the norm for me.

This stuff is pretty nice AT FIRST GLANCE. We shall see.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 24, 2016 01:40AM |

Registered: 8 years ago Posts: 38 |

Alright, can somebody give me some jam advice? I pulled apart my hot end to fix a jam/clog. The nozzle itself is clear, but the liner on the hot side of the heat break is sticking out quite a bit. Has anyone seen this before?

I've been printing mostly PETG at 245C for the last couple months. Did that kill the stock hot end?

Thanks for the help!

I've been using eSun PETG and I like it too. At 245C, the prints come out shiny & very strong. I use 75C on my bed with BuildTak and that sticks great.

Edited 2 time(s). Last edit at 03/24/2016 02:18AM by GrouchoDuke.

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

I've been printing mostly PETG at 245C for the last couple months. Did that kill the stock hot end?

Thanks for the help!

Quote

tjnamtiw

For 6 months, I've been strictly running PLA. Today a threw a roll of ESUN PET up there...This stuff is pretty nice AT FIRST GLANCE. We shall see.

I've been using eSun PETG and I like it too. At 245C, the prints come out shiny & very strong. I use 75C on my bed with BuildTak and that sticks great.

Edited 2 time(s). Last edit at 03/24/2016 02:18AM by GrouchoDuke.

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 24, 2016 08:21AM |

Registered: 8 years ago Posts: 541 |

Quote

GrouchoDuke

Alright, can somebody give me some jam advice? I pulled apart my hot end to fix a jam/clog. The nozzle itself is clear, but the liner on the hot side of the heat break is sticking out quite a bit. Has anyone seen this before?

I've been printing mostly PETG at 245C for the last couple months. Did that kill the stock hot end?

Thanks for the help!

Quote

tjnamtiw

For 6 months, I've been strictly running PLA. Today a threw a roll of ESUN PET up there...This stuff is pretty nice AT FIRST GLANCE. We shall see.

I've been using eSun PETG and I like it too. At 245C, the prints come out shiny & very strong. I use 75C on my bed with BuildTak and that sticks great.

There shouldn't be any liner on the hot end side of the tube. At least that's the way mine are. The liner must have been pushed down and out. I don't have any real answers, just questions like you!

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 24, 2016 08:29AM |

Registered: 8 years ago Posts: 131 |

Quote

tjnamtiw

Quote

GrouchoDuke

Alright, can somebody give me some jam advice? I pulled apart my hot end to fix a jam/clog. The nozzle itself is clear, but the liner on the hot side of the heat break is sticking out quite a bit. Has anyone seen this before?

I've been printing mostly PETG at 245C for the last couple months. Did that kill the stock hot end?

Thanks for the help!

Quote

tjnamtiw

For 6 months, I've been strictly running PLA. Today a threw a roll of ESUN PET up there...This stuff is pretty nice AT FIRST GLANCE. We shall see.

I've been using eSun PETG and I like it too. At 245C, the prints come out shiny & very strong. I use 75C on my bed with BuildTak and that sticks great.

There shouldn't be any liner on the hot end side of the tube. At least that's the way mine are. The liner must have been pushed down and out. I don't have any real answers, just questions like you!

Don't fight it, liner could be damaged, it probably got weak with the high temp, you can get a 5 pack on prime for pretty cheap. I found that these cheap parts are not worth fighting and to keep spares on hand.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 24, 2016 09:02AM |

Registered: 8 years ago Posts: 38 |

Quote

marc2912

[Don't fight it, liner could be damaged, it probably got weak with the high temp, you can get a 5 pack on prime for pretty cheap. I found that these cheap parts are not worth fighting and to keep spares on hand.

I'll get a replacement - thanks!

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 24, 2016 09:10AM |

Registered: 8 years ago Posts: 130 |

Quote

marc2912

Quote

tjnamtiw

Quote

GrouchoDuke

Alright, can somebody give me some jam advice? I pulled apart my hot end to fix a jam/clog. The nozzle itself is clear, but the liner on the hot side of the heat break is sticking out quite a bit. Has anyone seen this before?

I've been printing mostly PETG at 245C for the last couple months. Did that kill the stock hot end?

Thanks for the help!

Quote

tjnamtiw

For 6 months, I've been strictly running PLA. Today a threw a roll of ESUN PET up there...This stuff is pretty nice AT FIRST GLANCE. We shall see.

I've been using eSun PETG and I like it too. At 245C, the prints come out shiny & very strong. I use 75C on my bed with BuildTak and that sticks great.

There shouldn't be any liner on the hot end side of the tube. At least that's the way mine are. The liner must have been pushed down and out. I don't have any real answers, just questions like you!

Don't fight it, liner could be damaged, it probably got weak with the high temp, you can get a 5 pack on prime for pretty cheap. I found that these cheap parts are not worth fighting and to keep spares on hand.

I have no firsthand knowledge but ran across this stuff doing research for my future setup. For filaments requiring higher temps you need to go with barrels without liners. Those barrels need to be polished and then seasoned, with oil, like a cast iron skillet. Before I start using PETG I'll have a barrel, polished and seasoned, like the following:

(image from [e3d-online.com])

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 24, 2016 09:27AM |

Registered: 8 years ago Posts: 130 |

Ouch, I found a source $17.99: [www.filastruder.com]

Similar:

[www.amazon.com]

Edited 1 time(s). Last edit at 03/24/2016 09:29AM by flatlander.

Similar:

[www.amazon.com]

Edited 1 time(s). Last edit at 03/24/2016 09:29AM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 24, 2016 10:39AM |

Registered: 8 years ago Posts: 130 |

I just noticed that the threads for the above are M7 going into the cooling fins, most of us need a M6 solution... I still having a plumbing problem.

It looks like the tap drill size is 6mm. A 7mm X 1 should tap just fine into what I have

Edited 1 time(s). Last edit at 03/24/2016 10:55AM by flatlander.

It looks like the tap drill size is 6mm. A 7mm X 1 should tap just fine into what I have

Edited 1 time(s). Last edit at 03/24/2016 10:55AM by flatlander.

Sorry, only registered users may post in this forum.