Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 29, 2016 09:59AM |

Registered: 8 years ago Posts: 130 |

I finally got around to installing the LCD/SD card reader, and discovered the voltage regulator is suspect on my Mega...It was the classic, blue, pulsating, LCD screen.

Short term solutions:

1. Use a 1.5 A USB phone charger for 'stand alone' power to the Mega.

2. Never send firmware with RAMPS powered up.

Long term:

Replace the regulator: [42bots.com]

Short term solutions:

1. Use a 1.5 A USB phone charger for 'stand alone' power to the Mega.

2. Never send firmware with RAMPS powered up.

Long term:

Replace the regulator: [42bots.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 29, 2016 10:30AM |

Registered: 8 years ago Posts: 131 |

Quote

flatlander

Have you tried heat; try print temperature. I have a partially disassembled hotend in a 'parts dish' that may need the toaster oven before I take it apart.Quote

LancelotL

Oh and one more thing. Any suggestions for getting the old throat out of the heater block? I think the Hulk inserted mine along with the extruder tip which was darn near impossible to get off too.

Do you have a solder station with a hot air rework gun? I find that they work great for this.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 29, 2016 01:36PM |

Registered: 8 years ago Posts: 46 |

Quote

LancelotL

Oh and one more thing. Any suggestions for getting the old throat out of the heater block? I think the Hulk inserted mine along with the extruder tip which was darn near impossible to get off too.

I hope this doesn't sound too stupid but I assume you're aware there is a set screw locking the throat into the heat block. My block has become so gunked up I wouldn't know it was there.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 29, 2016 02:58PM |

Registered: 8 years ago Posts: 3 |

I figured out the problem to my runaway bed temperatures. On the board, the mosfet heatsinks were touching causing the runaway temperature. Funny that I figured that out, THEN found this thread. ha runaway bed temps

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 29, 2016 04:34PM |

Registered: 8 years ago Posts: 130 |

Quote

DaveA

Quote

LancelotL

Oh and one more thing. Any suggestions for getting the old throat out of the heater block? I think the Hulk inserted mine along with the extruder tip which was darn near impossible to get off too.

I hope this doesn't sound too stupid but I assume you're aware there is a set screw locking the throat into the heat block. My block has become so gunked up I wouldn't know it was there.

Mine doesn't have a set screw in the heat block, but there is one in the stock heat-brake.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 29, 2016 06:16PM |

Registered: 8 years ago Posts: 93 |

Quote

LancelotL

Oh and one more thing. Any suggestions for getting the old throat out of the heater block? I think the Hulk inserted mine along with the extruder tip which was darn near impossible to get off too.

If the heat block heater and thermistor are still hooked up to the printer, heat it up to ABS temp, then use pliers. If that still doesn't work, while it the block is hot, put ice on the nozzle (being careful not to cool the aluminum block, or get anything electrical wet.) Should make it come loose.

If it is just the block and throat, you can use a torch to heat the block, while trying not to heat the throat more than necessary. Since you're not using that nozzle, clamp it tight in some vice grips to wick away heat and give you a better grip.

Use some good leather gloves or rags to hold the pliers, so you can grip tighter without burning yourself. You can use a open end wrench or wide pliers on the block, but try not to cool it by holding it until you are ready to twist.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 29, 2016 06:28PM |

Registered: 8 years ago Posts: 285 |

For those that have done upgrades using openbuilds' v-slot rail, will openbuilds delrin wheels work on the extrusion that folger tech made our printers out of?

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 29, 2016 06:33PM |

Registered: 8 years ago Posts: 131 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 29, 2016 06:58PM |

Registered: 8 years ago Posts: 70 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 29, 2016 07:56PM |

Registered: 8 years ago Posts: 46 |

Quote

flatlander

Quote

DaveA

Quote

LancelotL

Oh and one more thing. Any suggestions for getting the old throat out of the heater block? I think the Hulk inserted mine along with the extruder tip which was darn near impossible to get off too.

I hope this doesn't sound too stupid but I assume you're aware there is a set screw locking the throat into the heat block. My block has become so gunked up I wouldn't know it was there.

Mine doesn't have a set screw in the heat block, but there is one in the stock heat-brake.

Of course, I said I hoped it wouldn't sound too stupid. I was thinking of the heat brake while talking about the heater block. Sorry. Never mind....

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 29, 2016 10:44PM |

Registered: 8 years ago Posts: 130 |

Quote

Mopar99

Quote

marc2912

Quote

Mach

For those that have done upgrades using openbuilds' v-slot rail, will openbuilds delrin wheels work on the extrusion that folger tech made our printers out of?

I don't see why not, should be standard 20mm v slot.

yes it will, all the same size.

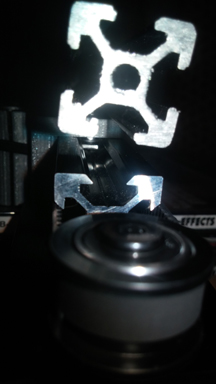

It isn't the same extrusion profile. V-Slot lower, Folger Tech 2020 Upper:

The wheels I have from openbuilds don't quite fit the 2020.

They have a bolt-on linear rail that can be attached to our rails which might work in some applications. After all the hardware it might be cheaper to buy their V-Slot.:

[cdn1.bigcommerce.com]

Edited 2 time(s). Last edit at 03/29/2016 10:58PM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 30, 2016 11:55AM |

Registered: 8 years ago Posts: 28 |

So I bought a proximity sensor ( LJ12A3-4-Z/AX NPN NC (because it's NPN NC I used: const bool Z_MIN_ENDSTOP_INVERTING = false; )) and got it all wired up last night. For the most part it's working. I updated to the latest firmware (and I kept my X-AXIS on the right side).

I did this in the firmware (basically these changes over stock:

#define ENDSTOPPULLUP_XMAX

#define X_HOME_DIR 1

It seems to home properly and everything.

Now the two issues I've run into I'm sure there's an easy way to figure it out...

When I Home all axis (G28) it goes to the front right of my bed (homes on X Max), and Z starts going down... but my proximity sensor is facing the front, so it's off the bed by about 2cm. So clearly it'll never read the foil tape I have up in that corner. So is there a way in the firmware to set it to home Z at a bit back and if so how?

Secondly G29 seems to hone in on only two locations, not the four I specified. I kept changing #define LEFT_PROBE_BED_POSITION and the other three, and it didn't seem to take into account any of the changes?

I've basically been reading these sites about proximity and getting most of my information from them:

[www.instructables.com]

[folgertech.wikia.com]

& tom's youtube video.

Anyone have any guidance or can point me into the right location?

I did this in the firmware (basically these changes over stock:

#define ENDSTOPPULLUP_XMAX

#define X_HOME_DIR 1

It seems to home properly and everything.

Now the two issues I've run into I'm sure there's an easy way to figure it out...

When I Home all axis (G28) it goes to the front right of my bed (homes on X Max), and Z starts going down... but my proximity sensor is facing the front, so it's off the bed by about 2cm. So clearly it'll never read the foil tape I have up in that corner. So is there a way in the firmware to set it to home Z at a bit back and if so how?

Secondly G29 seems to hone in on only two locations, not the four I specified. I kept changing #define LEFT_PROBE_BED_POSITION and the other three, and it didn't seem to take into account any of the changes?

I've basically been reading these sites about proximity and getting most of my information from them:

[www.instructables.com]

[folgertech.wikia.com]

& tom's youtube video.

Anyone have any guidance or can point me into the right location?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 30, 2016 12:28PM |

Registered: 8 years ago Posts: 46 |

Check out the Folger Tech 2020 i3 Wiki at [folgertech.wikia.com] There is a section on auto bed leveling. If you're using Marlin firmware I believe you must have the X axis end stop on the left or the software will no behave correctly.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 30, 2016 01:12PM |

Registered: 8 years ago Posts: 28 |

Quote

DaveA

Check out the Folger Tech 2020 i3 Wiki at [folgertech.wikia.com] There is a section on auto bed leveling. If you're using Marlin firmware I believe you must have the X axis end stop on the left or the software will no behave correctly.

So is it a bug or something? I mean X-homes correctly. I guess I'll probably have to try that as I have read that, but wasn't sure if that's just because of something else.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 30, 2016 02:06PM |

Registered: 8 years ago Posts: 541 |

Make sure you have Z_SAFE_HOMING enabled. Then it should home in the middle of the build plate.

I moved my X reluctantly over to the left and everything was a go. I don't know why but it was no big deal.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

I moved my X reluctantly over to the left and everything was a go. I don't know why but it was no big deal.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 30, 2016 03:32PM |

Registered: 8 years ago Posts: 10 |

Yay! A box was on my doorstep when I popped home for lunch!

There were all these horror stories about hard-to-tell-apart screws and such, so I was pretty happy to find that it's pretty much as any other thing I've built if all the parts are in one spot: Look at them, put them into separate piles, and proceed as usual.

nothing fancy, just a couple of ice cube trays.

Then I had to eat, and get back to work.

Work was moving along just fine before lunch, but now it's taking FOREVER to get to the end of teh day.....

There were all these horror stories about hard-to-tell-apart screws and such, so I was pretty happy to find that it's pretty much as any other thing I've built if all the parts are in one spot: Look at them, put them into separate piles, and proceed as usual.

nothing fancy, just a couple of ice cube trays.

Then I had to eat, and get back to work.

Work was moving along just fine before lunch, but now it's taking FOREVER to get to the end of teh day.....

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 30, 2016 05:30PM |

Registered: 8 years ago Posts: 92 |

Quote

Tenny

Quote

DaveA

Check out the Folger Tech 2020 i3 Wiki at [folgertech.wikia.com] There is a section on auto bed leveling. If you're using Marlin firmware I believe you must have the X axis end stop on the left or the software will no behave correctly.

So is it a bug or something? I mean X-homes correctly. I guess I'll probably have to try that as I have read that, but wasn't sure if that's just because of something else.

No, not a bug, but rather the way the feature was designed. Left-side x-end stop is the standard design. Why FT chose to stick it over on the right, who knows. If you consider how the X/Y coordinate system works, logic dictates you'd home to 0.0 which means put the stop on the left.

The auto-level feature calculates movements based on a 0,0 home location, so you need to move it to use auto level. This could also be causing the probe location issue. Another issue I had with probe locations was caused my the end stop max being read as triggered. This caused the head to not move past the home position, so I was getting 2 probes at each location, rather than the head moving to the right for the second. Send a m119 and see what the response is. It will tell you whether the end stops are triggered or not. If anything doesn't seem right there, you need to do some poking around.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 30, 2016 05:33PM |

Registered: 8 years ago Posts: 314 |

+1Quote

iamquestar

Quote

Tenny

Quote

DaveA

Check out the Folger Tech 2020 i3 Wiki at [folgertech.wikia.com] There is a section on auto bed leveling. If you're using Marlin firmware I believe you must have the X axis end stop on the left or the software will no behave correctly.

So is it a bug or something? I mean X-homes correctly. I guess I'll probably have to try that as I have read that, but wasn't sure if that's just because of something else.

No, not a bug, but rather the way the feature was designed. Left-side x-end stop is the standard design. Why FT chose to stick it over on the right, who knows. If you consider how the X/Y coordinate system works, logic dictates you'd home to 0.0 which means put the stop on the left.

The auto-level feature calculates movements based on a 0,0 home location, so you need to move it to use auto level. This could also be causing the probe location issue. Another issue I had with probe locations was caused my the end stop max being read as triggered. This caused the head to not move past the home position, so I was getting 2 probes at each location, rather than the head moving to the right for the second. Send a m119 and see what the response is. It will tell you whether the end stops are triggered or not. If anything doesn't seem right there, you need to do some poking around.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 30, 2016 05:35PM |

Registered: 8 years ago Posts: 92 |

Quote

SgtRauksauff

Yay! A box was on my doorstep when I popped home for lunch!

There were all these horror stories about hard-to-tell-apart screws and such, so I was pretty happy to find that it's pretty much as any other thing I've built if all the parts are in one spot: Look at them, put them into separate piles, and proceed as usual.

nothing fancy, just a couple of ice cube trays.

Then I had to eat, and get back to work.

Work was moving along just fine before lunch, but now it's taking FOREVER to get to the end of teh day.....

Welcome to the club! Enjoy the build.

I know what you mean about the day crawling.... It frequently happens to me when I get a new idea of a tweak or item I want to print. It seems like such a waste to be at work while the printer is sitting at home, idle. I really need to get a webcam setup with a Raspberry Pi and Octoprint. Then I can initiate prints from work.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 30, 2016 06:10PM |

Registered: 8 years ago Posts: 28 |

Quote

iamquestar

Quote

Tenny

Quote

DaveA

Check out the Folger Tech 2020 i3 Wiki at [folgertech.wikia.com] There is a section on auto bed leveling. If you're using Marlin firmware I believe you must have the X axis end stop on the left or the software will no behave correctly.

So is it a bug or something? I mean X-homes correctly. I guess I'll probably have to try that as I have read that, but wasn't sure if that's just because of something else.

No, not a bug, but rather the way the feature was designed. Left-side x-end stop is the standard design. Why FT chose to stick it over on the right, who knows. If you consider how the X/Y coordinate system works, logic dictates you'd home to 0.0 which means put the stop on the left.

The auto-level feature calculates movements based on a 0,0 home location, so you need to move it to use auto level. This could also be causing the probe location issue. Another issue I had with probe locations was caused my the end stop max being read as triggered. This caused the head to not move past the home position, so I was getting 2 probes at each location, rather than the head moving to the right for the second. Send a m119 and see what the response is. It will tell you whether the end stops are triggered or not. If anything doesn't seem right there, you need to do some poking around.

So I have made some progress.

The original problem turned out to be with the M119 that the max points were all triggered. Once I solved that with the commands:

#define ENDSTOPPULLUP_XMAX

#define ENDSTOPPULLUP_YMAX

#define ENDSTOPPULLUP_ZMAX

It began working.

So there is two problems left and I think both are related to eachother.

// set the rectangle in which to probe

#define LEFT_PROBE_BED_POSITION 0

#define RIGHT_PROBE_BED_POSITION 170

#define BACK_PROBE_BED_POSITION 195

#define FRONT_PROBE_BED_POSITION 40

I have that set "correctly", but when it actually does the probing it doesn't go to the right locations on Y. The X locations are right, but Y is off. I found the right "location" via M114 commands. and Y (front) should be at about 40. When it actually does it goes to Y 8.

Same thing for:

#define Z_SAFE_HOMING_X_POINT 80

#define Z_SAFE_HOMING_Y_POINT 40

I don't have an all metal bed (yet, it's OTW) so I'm using foil tape for now. THe tape is all along the front and back of the bed so the things don't have to be "exact". Once again when doing the safe Z, it takes it to around Y 8.

So I found Y of roughly 70, was where Y of 40 is via M114 (when gone directly from home point). So that seems to have solved the issue, although I don't think that is the "right" point. I honestly feel it's not taking the offset into account.

#define X_PROBE_OFFSET_FROM_EXTRUDER 0

#define Y_PROBE_OFFSET_FROM_EXTRUDER 32

#define Z_PROBE_OFFSET_FROM_EXTRUDER -0.6

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 31, 2016 12:35AM |

Registered: 8 years ago Posts: 314 |

I was printing in abs, then pla (Which might be low quality). And now my abs prints are not sticking... Should I clean my glass with isoprpyl alcohol? Never done it before, so I might have a lot of gunk on there.

Edited 1 time(s). Last edit at 03/31/2016 12:35AM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

Edited 1 time(s). Last edit at 03/31/2016 12:35AM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 31, 2016 03:30PM |

Registered: 8 years ago Posts: 10 |

Hmm.. looks like I got one SK10 and three SK8 mounts for the Y-axis, so full assembly will be delayed until I can get a replacement.

Also, the extruder carriage doesn't quite fit any of the bearings in all three spots, and one of the build plate bearing holders is the same.. the bearing is just a wee bit too long to fit in the recess.

I'm waiting till after work, then will see what I can find, maybe a small burr wheel for a dremel or something.

Using zipties for something as critical as keeping the moving parts aligned with the axes kind of hits me in the 'this is one of the first things I'm going to modify' button. Not to say I'm against zipties, though, they've saved my bacon a bunch, most noteably for affixing the TPS sensor in one of my cars when it decided to break, and then strip the threads on removal, at a time attack / trackday.

Since I can't really work on any of the axes right now, I'll move to the electronic side. Definitely going to raid my computer power supply stash to see what I can find for an IEC connector, and a switch.

Question, and I'll keep digging around a little bit between tasks at work: is there any issue with running power to the Ramps / SmartController and getting firmware installed/updated etc., without actually connecting the motors or end stops?

Also, the extruder carriage doesn't quite fit any of the bearings in all three spots, and one of the build plate bearing holders is the same.. the bearing is just a wee bit too long to fit in the recess.

I'm waiting till after work, then will see what I can find, maybe a small burr wheel for a dremel or something.

Using zipties for something as critical as keeping the moving parts aligned with the axes kind of hits me in the 'this is one of the first things I'm going to modify' button. Not to say I'm against zipties, though, they've saved my bacon a bunch, most noteably for affixing the TPS sensor in one of my cars when it decided to break, and then strip the threads on removal, at a time attack / trackday.

Since I can't really work on any of the axes right now, I'll move to the electronic side. Definitely going to raid my computer power supply stash to see what I can find for an IEC connector, and a switch.

Question, and I'll keep digging around a little bit between tasks at work: is there any issue with running power to the Ramps / SmartController and getting firmware installed/updated etc., without actually connecting the motors or end stops?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 31, 2016 06:57PM |

Registered: 8 years ago Posts: 28 |

So I think I figured out all my bed leveling issues, but despite all the work I've done on the printer in the past couple days... I'm running into the same issue as before. While it's printing, the Y Axis skips. The picture (below) is supposed to be a half sphere basically (with things sticking out the side, holes, etc). You can see it skipped twice, once near the bottom and then again near the top.

So far I have replaced the bearings, the belt (added a tensioner so it is of appropriate tension), stepper motor, firmware, etc. This doesn't happen on just this file too. I have tried a similar one that has printed before well and that exact same file (printed before fine) has issues too.

Any suggestions on where to look next?

So far I have replaced the bearings, the belt (added a tensioner so it is of appropriate tension), stepper motor, firmware, etc. This doesn't happen on just this file too. I have tried a similar one that has printed before well and that exact same file (printed before fine) has issues too.

Any suggestions on where to look next?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 31, 2016 07:31PM |

Registered: 8 years ago Posts: 92 |

Quote

Tenny

So I think I figured out all my bed leveling issues, but despite all the work I've done on the printer in the past couple days... I'm running into the same issue as before. While it's printing, the Y Axis skips. The picture (below) is supposed to be a half sphere basically (with things sticking out the side, holes, etc). You can see it skipped twice, once near the bottom and then again near the top.

So far I have replaced the bearings, the belt (added a tensioner so it is of appropriate tension), stepper motor, firmware, etc. This doesn't happen on just this file too. I have tried a similar one that has printed before well and that exact same file (printed before fine) has issues too.

Any suggestions on where to look next?

You may need to bump up the current on your Y motor (current is adjusted by rotating the pot on the stepper driver with the ceramic screwdriver shipped with the kit (make very small adjustments at a time)). To determine if this may be the problem, try moving the bed when the stepper is active. If you can make the motor skip without too much force, then that's probably the problem. I'm running my Y axis at about .650v reference. The motor is barely warm to the touch during a print, and has lots of power.

On the other hand this can also be caused by too much current. If the stepper driver overheats, it'll shut down briefly, causing a skip. Again, check the reference voltage on the driver. If this is really high, try bringing it down a bit, or you can try pointing a desk fan at the Ramps board while printing, and see if this makes a difference (also make sure all the heat sinks are securely attached).

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 31, 2016 07:58PM |

Registered: 8 years ago Posts: 541 |

Quote

SgtRauksauff

Hmm.. looks like I got one SK10 and three SK8 mounts for the Y-axis, so full assembly will be delayed until I can get a replacement.

Also, the extruder carriage doesn't quite fit any of the bearings in all three spots, and one of the build plate bearing holders is the same.. the bearing is just a wee bit too long to fit in the recess.

I'm waiting till after work, then will see what I can find, maybe a small burr wheel for a dremel or something.

Using zipties for something as critical as keeping the moving parts aligned with the axes kind of hits me in the 'this is one of the first things I'm going to modify' button. Not to say I'm against zipties, though, they've saved my bacon a bunch, most noteably for affixing the TPS sensor in one of my cars when it decided to break, and then strip the threads on removal, at a time attack / trackday.

It seems in the last six months since I got my 2020 that no one at FT has figured out how to properly calibrate their printers and print the bearing holders to the correct dimensions! NONE of my bearings fit the supplied parts and a lot of grinding, cutting and cussing was needed. This week after cutting my teeth on a roll of black PETG, I set the extrusion mulitplier to get the width called for in the GCode, printed the FT .stl files and the bearings snapped easily into place. If I wanted or needed another 2020, I wouldn't hesitate to buy an FT but I'd print my own printed parts since FT seems incapable of doing it. Sorry but the truth sucks sometimes.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 31, 2016 08:30PM |

Registered: 8 years ago Posts: 28 |

Quote

iamquestar

Quote

Tenny

So I think I figured out all my bed leveling issues, but despite all the work I've done on the printer in the past couple days... I'm running into the same issue as before. While it's printing, the Y Axis skips. The picture (below) is supposed to be a half sphere basically (with things sticking out the side, holes, etc). You can see it skipped twice, once near the bottom and then again near the top.

So far I have replaced the bearings, the belt (added a tensioner so it is of appropriate tension), stepper motor, firmware, etc. This doesn't happen on just this file too. I have tried a similar one that has printed before well and that exact same file (printed before fine) has issues too.

Any suggestions on where to look next?

You may need to bump up the current on your Y motor (current is adjusted by rotating the pot on the stepper driver with the ceramic screwdriver shipped with the kit (make very small adjustments at a time)). To determine if this may be the problem, try moving the bed when the stepper is active. If you can make the motor skip without too much force, then that's probably the problem. I'm running my Y axis at about .650v reference. The motor is barely warm to the touch during a print, and has lots of power.

On the other hand this can also be caused by too much current. If the stepper driver overheats, it'll shut down briefly, causing a skip. Again, check the reference voltage on the driver. If this is really high, try bringing it down a bit, or you can try pointing a desk fan at the Ramps board while printing, and see if this makes a difference (also make sure all the heat sinks are securely attached).

Ok, yeah that is something I forgot to include. So since I got the kit (nearly a year) I've been running it at the default driver settings which ended up being around the .650 iirc. So when it started having the problems with the y-axis I actually lowered it to the "recommended" .450 range.

I also swapped the stepper driver between the X & Y axis to ensure the stepper driver wasn't bad. Same issue around the same point (always + / - a little).

Edit: Just checked it again, it was at .460. I increased it to .584 to give it a shot.

Edited 1 time(s). Last edit at 03/31/2016 08:46PM by Tenny.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 31, 2016 08:35PM |

Registered: 8 years ago Posts: 130 |

Quote

SgtRauksauff

Hmm.. looks like I got one SK10

SK10??? Is there anything on our machines at 10mm? Beer can shim? Assuming that rail support, center point, is at the same height, probably not.

Quote

tjnamtiw

It seems in the last six months since I got my 2020 that no one at FT has figured out how to properly calibrate their printers and print the bearing holders to the correct dimensions! NONE of my bearings fit the supplied parts and a lot of grinding, cutting and cussing was needed. This week after cutting my teeth on a roll of black PETG, I set the extrusion mulitplier to get the width called for in the GCode, printed the FT .stl files and the bearings snapped easily into place. If I wanted or needed another 2020, I wouldn't hesitate to buy an FT but I'd print my own printed parts since FT seems incapable of doing it. Sorry but the truth sucks sometimes.

PETG is cheating a little, less shrinkage

Call it as you see it. I can't wait to test out PETG.

Call it as you see it. I can't wait to test out PETG.Edited 1 time(s). Last edit at 03/31/2016 08:38PM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 31, 2016 08:59PM |

Registered: 8 years ago Posts: 130 |

Quote

Tenny

Quote

iamquestar

Quote

Tenny

So I think I figured out all my bed leveling issues, but despite all the work I've done on the printer in the past couple days... I'm running into the same issue as before. While it's printing, the Y Axis skips. The picture (below) is supposed to be a half sphere basically (with things sticking out the side, holes, etc). You can see it skipped twice, once near the bottom and then again near the top.

So far I have replaced the bearings, the belt (added a tensioner so it is of appropriate tension), stepper motor, firmware, etc. This doesn't happen on just this file too. I have tried a similar one that has printed before well and that exact same file (printed before fine) has issues too.

Any suggestions on where to look next?

You may need to bump up the current on your Y motor (current is adjusted by rotating the pot on the stepper driver with the ceramic screwdriver shipped with the kit (make very small adjustments at a time)). To determine if this may be the problem, try moving the bed when the stepper is active. If you can make the motor skip without too much force, then that's probably the problem. I'm running my Y axis at about .650v reference. The motor is barely warm to the touch during a print, and has lots of power.

On the other hand this can also be caused by too much current. If the stepper driver overheats, it'll shut down briefly, causing a skip. Again, check the reference voltage on the driver. If this is really high, try bringing it down a bit, or you can try pointing a desk fan at the Ramps board while printing, and see if this makes a difference (also make sure all the heat sinks are securely attached).

Ok, yeah that is something I forgot to include. So since I got the kit (nearly a year) I've been running it at the default driver settings which ended up being around the .650 iirc. So when it started having the problems with the y-axis I actually lowered it to the "recommended" .450 range.

I also swapped the stepper driver between the X & Y axis to ensure the stepper driver wasn't bad. Same issue around the same point (always + / - a little).

I purchased a replacement stepper for the x-axis movement and I'm running at VREF = 0.56V on the x-axis.

My prints were good if I stayed under two hours but if I tried to push on, all weekend, things got really hairy, like this machine is going to rip itself apart, Stuxnet style.

I'm not sure that some of my problems aren't related to the voltage regulator on the Arduino clone. It would fit with something failing after it gets hot. I'm eyeballing a big 5V regulator with a monster heat sink. Too bad everything is surface mount.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 31, 2016 09:37PM |

Registered: 8 years ago Posts: 10 |

Yeah, it wasn't just a slightly-large diameter, it actually measured 10mm diameter. FT just needed a photo, for their claims department, and theyr'e sending me an SK8 and new plastics as well (even though I was prepared to start dremelling). Since I can't really work on the physical right now, I'll probably start on the electronics..

is it safe to hook up the RAMPS to power and a a PC for firmware loading, without actually connecting the motors/endstops?

pic of the SK8 vs SK10:

is it safe to hook up the RAMPS to power and a a PC for firmware loading, without actually connecting the motors/endstops?

pic of the SK8 vs SK10:

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) March 31, 2016 09:51PM |

Registered: 8 years ago Posts: 285 |

Quote

SgtRauksauff

Yeah, it wasn't just a slightly-large diameter, it actually measured 10mm diameter. FT just needed a photo, for their claims department, and theyr'e sending me an SK8 and new plastics as well (even though I was prepared to start dremelling). Since I can't really work on the physical right now, I'll probably start on the electronics..

is it safe to hook up the RAMPS to power and a a PC for firmware loading, without actually connecting the motors/endstops?

pic of the SK8 vs SK10:

Yes it's safe.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

Sorry, only registered users may post in this forum.