Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 04, 2016 09:57PM |

Registered: 8 years ago Posts: 10 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 04, 2016 10:26PM |

Registered: 8 years ago Posts: 276 |

Quick poll - what speed/layer height do you guys usually print with? I'm at 45mm/s and 0.2mm layer height.

Edit: Apparently I can print at 90mm/s with no problems. Nice.

Edited 1 time(s). Last edit at 04/05/2016 12:52AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Edit: Apparently I can print at 90mm/s with no problems. Nice.

Edited 1 time(s). Last edit at 04/05/2016 12:52AM by therippa.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 05, 2016 08:49AM |

Registered: 8 years ago Posts: 541 |

Quote

therippa

Quick poll - what speed/layer height do you guys usually print with? I'm at 45mm/s and 0.2mm layer height.

Edit: Apparently I can print at 90mm/s with no problems. Nice.

40 mm/sec and 0.3 mostly because I'm printing practical things that don't need to look pretty and I'm in no hurry.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 05, 2016 08:53AM |

Registered: 8 years ago Posts: 541 |

Quote

SgtRauksauff

so, I got my replacement SK8 mount and plastics today!!

measured the inside of the single-bearing holders that hold the bed:

two of them, I was able to fit bearings into before, I didn't want to undo it:

I wonder if it's not the plastics themselves that are off, as they seem to have a closer grouping of measurements overall than the bearings. makes me wish metal filings weren't bad for bearings, otherwise I'd just file down the end of the bearing, it's easier than finding something to trim the plastic...

Anyone know what the tolerance between the plastic and the bearing, as far as how much smaller the plastic can be before it just wont' fit anymore?

Clearly, FT has not compensated correctly for shrinkage. If they made them out of PETG, the bearings snap right in. ABS shrinks more.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 05, 2016 09:37AM |

Registered: 8 years ago Posts: 130 |

Quote

therippa

Quick poll - what speed/layer height do you guys usually print with? I'm at 45mm/s and 0.2mm layer height.

Edit: Apparently I can print at 90mm/s with no problems. Nice.

If I need overhangs with nice clean edges, I print at height = 0.2mm, in the 40-50 mm/s range.

When whipping-out square-ish parts, I use h=0.32mm at 60mm/sec.

Do we really see 90 mm/sec? With acceleration and deceleration what does the math do? At some point I would like to see some crazy speed printing big cylinders.

I have my acceleration limited to 800 mm/s² in the firmware. It would be cool to have a E3D volcano printing at 90 mm/sec with a 0.8mm nozzle.

With higher speeds my extruder stepper gets hot.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 05, 2016 12:17PM |

Registered: 9 years ago Posts: 251 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 05, 2016 04:32PM |

Registered: 8 years ago Posts: 314 |

If I increase my speed to 90mm/s do I need to change other settings? Have you guys changed the acceleration speed in the firmware?

Edited 1 time(s). Last edit at 04/05/2016 04:36PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

Edited 1 time(s). Last edit at 04/05/2016 04:36PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 05, 2016 06:06PM |

Registered: 8 years ago Posts: 130 |

Quote

UltiFix

If I increase my speed to 90mm/s do I need to change other settings? Have you guys changed the acceleration speed in the firmware?

Probably jerk and acceleration, if you really want that speed. If you have smooth sweeping bends the machine may see those speeds without changing jerk and acceleration. Can our little machines take the punishment? For the most part there's a limit to how fast a stepper will accelerate and decelerate. As it stands, my stock extruder stepper wouldn't keep up with 90 mm/s. I see BattleBots happening, ha ha, ha. I have enough trouble keeping maintenance up on a 60mm/s machine. I changed my acceleration to a lower value, not what you seem to be looking for. See Tom's video on speed settings:

[www.youtube.com]

Have Fun! Post videos of the carnage

.

.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 05, 2016 06:43PM |

Registered: 8 years ago Posts: 314 |

Before I read this post I just went for it, set my printers to 90mm/s and walked off... Started reading your post, then went and checked my print. Here are some pics of the carnage! I guess 90mm/s is a bit fast! Also I might have some leakage in my heat block.Quote

flatlander

Quote

UltiFix

If I increase my speed to 90mm/s do I need to change other settings? Have you guys changed the acceleration speed in the firmware?

Probably jerk and acceleration, if you really want that speed. If you have smooth sweeping bends the machine may see those speeds without changing jerk and acceleration. Can our little machines take the punishment? For the most part there's a limit to how fast a stepper will accelerate and decelerate. As it stands, my stock extruder stepper wouldn't keep up with 90 mm/s. I see BattleBots happening, ha ha, ha. I have enough trouble keeping maintenance up on a 60mm/s machine. I changed my acceleration to a lower value, not what you seem to be looking for. See Tom's video on speed settings:

[www.youtube.com]

Have Fun! Post videos of the carnage.

Those are some crappy prints!! I will retest at 70mm/s and post pics.

p.s

Those were done at the same time

Edited 1 time(s). Last edit at 04/05/2016 06:43PM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 05, 2016 08:46PM |

Registered: 8 years ago Posts: 19 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 05, 2016 09:47PM |

Registered: 8 years ago Posts: 92 |

Quote

therippa

Quick poll - what speed/layer height do you guys usually print with? I'm at 45mm/s and 0.2mm layer height.

Edit: Apparently I can print at 90mm/s with no problems. Nice.

Almost always .2 mm layer hight, but .32 if I want something quick (still looks OK) and very occasionally .1 mm if I want the best detail, but I usually don't want to wait that long.

Speed: Almost always 60mm/sec, 1/2 for first layer, 80% for outer perimeter. PLA min. layer time of 8 sec.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 05, 2016 10:01PM |

Registered: 8 years ago Posts: 9 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 06, 2016 12:39PM |

Registered: 9 years ago Posts: 251 |

Quote

Trilithon

Just got my kit, everything looks good. Time to do some reading before building.

Also, thanks for the pack of Jelly Belly jelly beans .... I ate them, were they supposed to be used for something else?

Tril

You ate them?!? Those are part of the build...

...the delicious part.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 06, 2016 07:06PM |

Registered: 8 years ago Posts: 9 |

Hmmm, I think this may put my horizontal rod in a bind....

Who do I contact? Or I'll just 'adjust' it......

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 06, 2016 08:57PM |

Registered: 8 years ago Posts: 130 |

Quote

Trilithon

[attachment 76072 20160406_180042_resized.jpg]

Hmmm, I think this may put my horizontal rod in a bind....

Who do I contact? Or I'll just 'adjust' it......

What is that? Oh wait I get it. That is really screwed up. Get a replacement from Folger Tech. I don' think there is any active monitoring of this forum from the company.

"SK8 8mm Linear Rail Shaft Guide Support is defective see picture, please send a replacement."

There would be a whole lot of milling to fix that.

alternatives:

[www.adafruit.com]

Edited 1 time(s). Last edit at 04/06/2016 09:02PM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 07, 2016 08:46AM |

Registered: 8 years ago Posts: 19 |

Quote

Trilithon

[attachment 76072 20160406_180042_resized.jpg]

Hmmm, I think this may put my horizontal rod in a bind....

Who do I contact? Or I'll just 'adjust' it......

Could you print these locally until you get replacements? SK8 Rod Mounts>>> [www.thingiverse.com]

Edited 1 time(s). Last edit at 04/07/2016 08:47AM by bmays.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 07, 2016 10:07AM |

Registered: 8 years ago Posts: 16 |

Quote

therippa

Quick poll - what speed/layer height do you guys usually print with? I'm at 45mm/s and 0.2mm layer height.

Edit: Apparently I can print at 90mm/s with no problems. Nice.

I have been using your same original settings, 45mm/s and 0.2mm layer height for PLA, but I'm still just starting out. I'm trying some PETG now and I slowed it down to 35mm/s.

Prints are better than I expected without much tweaking of settings. I may try going faster now.

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 07, 2016 06:06PM |

Registered: 8 years ago Posts: 10 |

Aha, i wasn't the only one.Quote

Trilithon

Just got my kit, everything looks good. Time to do some reading before building.

Also, thanks for the pack of Jelly Belly jelly beans .... I ate them, were they supposed to be used for something else?

Tril

I ate mine after I finished the build lol

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 08, 2016 09:20AM |

Registered: 8 years ago Posts: 19 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 08, 2016 02:02PM |

Registered: 8 years ago Posts: 314 |

I did thisQuote

Fiddleback

For those of you using a glass plate, what's the best way of securing it to the heat board?

[www.thingiverse.com]

Exept didn't use magnets... Just binder clips, maybe someday if I ever get around to getting my hands on those magnets ill try it!

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 08, 2016 02:57PM |

Registered: 8 years ago Posts: 12 |

Ooh, added to my List of Things to Think About.

Most of the pictures of Prusa Mendels I've seen use medium sized binder clips to hold down the plate. The trouble with those is that it's easy for the printhead to run into them, moving everything out of alignment and possibly inflicting damage as well.

Most of the pictures of Prusa Mendels I've seen use medium sized binder clips to hold down the plate. The trouble with those is that it's easy for the printhead to run into them, moving everything out of alignment and possibly inflicting damage as well.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 08, 2016 05:09PM |

Registered: 8 years ago Posts: 10 |

Trilithon: I had a similar issue with my SK8s: they sent me three sk8's and one sk10. I just sent them an email, and included the picture. They sent a replacment right away. Once it came in, I was able to start on the rest of the build, and then I found that one of the 395mm rods for the y-axis was slightly bent, binding at one end. They asked for a picture of that, but it's really hard to photograph shiny chrome to show a bend. Instead, I took a short 40-second video instead. Once their Claims Department saw it, they shipped me out a new one, it's in the mail right now, hopefully arriving tomorrow.

here's the link to the vid: You might want to test your chrome shafts before getting to that assembly part, just in case one or more of yours is bent also.

after I got the email that they were sending a new one, i tried straightening this one, enough to put the rest of the system together. its still bent, but works well enough that I can still hook everything up and test basic functionality.

So here's where I was at after I found the sk8 mount was the wrong one:

worked on the electronics side a bit to make sure they were fine. Loaded Merlin, played with it a bit:

bent the rod straight(er) and put things together, and this is where I ended up last night:

still have to wire the heat bed, mount the end stops, wire the hot end / fan, but then I should be able to start making things move.

Interestingly enough, on my main PC, i was able to flash Marlin and had no problems. I used my laptop to load the RAMPS test program, and everything worked fine. Went to re-load Marlin, and got an error; re-tried my PC, and no error. On the laptop, I reinstalled, changed port speeds, changed drivers and back again, tried going through a powered hub, running power to the 12V on the RAMPS, but whatever I tried, it just would not work without an error when using the laptop. No worries really, but was a bit disconcerting. Might just not be the 10-ish year old laptop...

now I think I'm also going to get a R-pi and set up Octopi, but that's later.

--sarge

Edited 3 time(s). Last edit at 04/08/2016 05:11PM by SgtRauksauff.

here's the link to the vid: You might want to test your chrome shafts before getting to that assembly part, just in case one or more of yours is bent also.

after I got the email that they were sending a new one, i tried straightening this one, enough to put the rest of the system together. its still bent, but works well enough that I can still hook everything up and test basic functionality.

So here's where I was at after I found the sk8 mount was the wrong one:

worked on the electronics side a bit to make sure they were fine. Loaded Merlin, played with it a bit:

bent the rod straight(er) and put things together, and this is where I ended up last night:

still have to wire the heat bed, mount the end stops, wire the hot end / fan, but then I should be able to start making things move.

Interestingly enough, on my main PC, i was able to flash Marlin and had no problems. I used my laptop to load the RAMPS test program, and everything worked fine. Went to re-load Marlin, and got an error; re-tried my PC, and no error. On the laptop, I reinstalled, changed port speeds, changed drivers and back again, tried going through a powered hub, running power to the 12V on the RAMPS, but whatever I tried, it just would not work without an error when using the laptop. No worries really, but was a bit disconcerting. Might just not be the 10-ish year old laptop...

now I think I'm also going to get a R-pi and set up Octopi, but that's later.

--sarge

Edited 3 time(s). Last edit at 04/08/2016 05:11PM by SgtRauksauff.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 08, 2016 05:34PM |

Registered: 8 years ago Posts: 314 |

Wow, that stinks you had to have so much stuff resent!Quote

SgtRauksauff

Trilithon: I had a similar issue with my SK8s: they sent me three sk8's and one sk10. I just sent them an email, and included the picture. They sent a replacment right away. Once it came in, I was able to start on the rest of the build, and then I found that one of the 395mm rods for the y-axis was slightly bent, binding at one end. They asked for a picture of that, but it's really hard to photograph shiny chrome to show a bend. Instead, I took a short 40-second video instead. Once their Claims Department saw it, they shipped me out a new one, it's in the mail right now, hopefully arriving tomorrow.

here's the link to the vid: You might want to test your chrome shafts before getting to that assembly part, just in case one or more of yours is bent also.

after I got the email that they were sending a new one, i tried straightening this one, enough to put the rest of the system together. its still bent, but works well enough that I can still hook everything up and test basic functionality.

So here's where I was at after I found the sk8 mount was the wrong one:

worked on the electronics side a bit to make sure they were fine. Loaded Merlin, played with it a bit:

bent the rod straight(er) and put things together, and this is where I ended up last night:

still have to wire the heat bed, mount the end stops, wire the hot end / fan, but then I should be able to start making things move.

Interestingly enough, on my main PC, i was able to flash Marlin and had no problems. I used my laptop to load the RAMPS test program, and everything worked fine. Went to re-load Marlin, and got an error; re-tried my PC, and no error. On the laptop, I reinstalled, changed port speeds, changed drivers and back again, tried going through a powered hub, running power to the 12V on the RAMPS, but whatever I tried, it just would not work without an error when using the laptop. No worries really, but was a bit disconcerting. Might just not be the 10-ish year old laptop...

now I think I'm also going to get a R-pi and set up Octopi, but that's later.

--sarge

Edited 1 time(s). Last edit at 04/10/2016 12:40AM by UltiFix.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 10, 2016 12:22AM |

Registered: 8 years ago Posts: 9 |

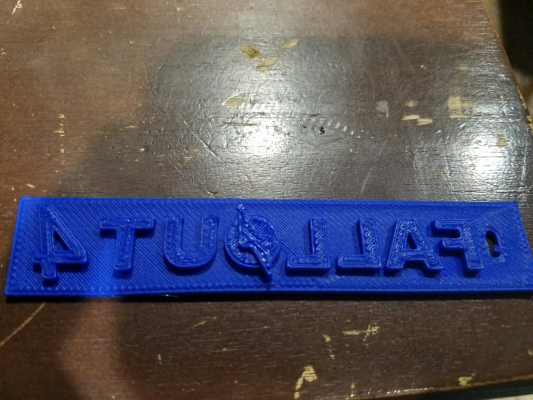

Ok, what do I have setup incorrectly to cause reverse lettering?

It displayed correctly in Repetier.

I am using the default files from the Folger google drive.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 10, 2016 10:32AM |

Registered: 8 years ago Posts: 130 |

Quote

Trilithon

[attachment 76207 20160409_231457_resized.jpg]

Ok, what do I have setup incorrectly to cause reverse lettering?

It displayed correctly in Repetier.

I am using the default files from the Folger google drive.

Try Mirror Object for a "dirty fix." It's the triangle icon with the dashed lines and an arrow within the Object Placement Tab. Longer term, change the axis direction in firmware. Start with the axis running the same direction as your lettering.

If the text runs along the x-axis, some or all of the following lines may need changing:

const bool X_ENDSTOPS_INVERTING = true; // toggle this true or false

#define INVERT_X_DIR false // toggle this true or false, edit: I think that flipping motors wires will do the same thing.

#define X_HOME_DIR -1 // toggle this 1 or -1

That's a best guess not seeing the endstops and object while printing.

Edited 2 time(s). Last edit at 04/10/2016 02:31PM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 10, 2016 04:57PM |

Registered: 8 years ago Posts: 541 |

Quote

Trilithon

[attachment 76207 20160409_231457_resized.jpg]

Ok, what do I have setup incorrectly to cause reverse lettering?

It displayed correctly in Repetier.

I am using the default files from the Folger google drive.

Did you plug the X Stepper motor into the Ramps board with the color coding as shown in the picture?

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 11, 2016 02:13PM |

Registered: 8 years ago Posts: 70 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 11, 2016 05:26PM |

Registered: 8 years ago Posts: 314 |

Was gonna ask if your trolling, but I guess it's a thing.Quote

Mopar99

question: does anyone season their Hotend's? like dab some olive oil on filament before they print?

No I never do it lol

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 11, 2016 06:07PM |

Registered: 8 years ago Posts: 28 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 11, 2016 06:18PM |

Registered: 8 years ago Posts: 130 |

Quote

Mopar99

question: does anyone season their Hotend's? like dab some olive oil on filament before they print?

I've heard of pre-treating hotends like one does with a new cast iron skillet. On our stock hotends, with the PTFE liner against the tip, it probably isn't necessary. With some of the E3D V6 and clones, the barrels have more metal exposed to the filament. The PTFE liner goes into the barrel only part way (from the top.) The filament is able to contact barrel metal before the tip. That setup might benefit from seasoning. $0.02

(from Filastruder website E3D hotend barrel cutaway)

If I ever go to a V6 hotend I may do some seasoning.

Edited 1 time(s). Last edit at 04/11/2016 06:22PM by flatlander.

Sorry, only registered users may post in this forum.