Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 07:36PM |

Registered: 7 years ago Posts: 8 |

jhitesma, great info here. You have a very nice modded i3. I will get there. 8)

I will think about these changes. It will be very helpful in a near future. By now i prefer to start with a FW more close to the default Folger Prusa i3 (only with that 2004 LCD and bed autolevel).

Thank you for help. It will be useful in a very near future i'm sure.

{}s

CreativeBR

Edited 1 time(s). Last edit at 04/28/2016 07:39PM by CreativeBR.

I will think about these changes. It will be very helpful in a near future. By now i prefer to start with a FW more close to the default Folger Prusa i3 (only with that 2004 LCD and bed autolevel).

Thank you for help. It will be useful in a very near future i'm sure.

{}s

CreativeBR

Edited 1 time(s). Last edit at 04/28/2016 07:39PM by CreativeBR.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 09:20PM |

Registered: 7 years ago Posts: 15 |

I have been slow at build the printer because I have to many things going on. I't just finishing up the electronics hook up.

I found the instruction for building the frame to be poor. I didn't have any problems building it, but it could have

been a lot easier. There were a few places where I felt they were just wrong but the biggest issue is the order

that things were installed. I can't really see any reason why you would want to have the hot bed installed before

you are ready to wire it up. After a short time of always having its wires in the way I took it off until I was ready to

hook it up. Same with the hot end, why mount is and have it exposed to be damaged while mounting the X axes

frame. The X axes didn't come out as smooth as Y.

I should be able to start calibrating tomorrow and may be able to try printing.

Edited 1 time(s). Last edit at 04/28/2016 09:21PM by wild.bill.

I found the instruction for building the frame to be poor. I didn't have any problems building it, but it could have

been a lot easier. There were a few places where I felt they were just wrong but the biggest issue is the order

that things were installed. I can't really see any reason why you would want to have the hot bed installed before

you are ready to wire it up. After a short time of always having its wires in the way I took it off until I was ready to

hook it up. Same with the hot end, why mount is and have it exposed to be damaged while mounting the X axes

frame. The X axes didn't come out as smooth as Y.

I should be able to start calibrating tomorrow and may be able to try printing.

Edited 1 time(s). Last edit at 04/28/2016 09:21PM by wild.bill.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 10:48PM |

Registered: 7 years ago Posts: 4 |

I just received my kit yesterday, stayed up until 3:30 am building everything. About 9 hours straight. I waited until this morning to recheck the wiring and fire her up. Sadly all didn't go as planned and it looks like the RAMPS and Arduino are both bad?! Sad to say the least....sucks putting in all that work overnight to be left staring at this thing. Honestly though, quite a thing it is lol.

Other then the bad electronics, which hopefully Folger Tech will replace. The kit has been awesome. Yeah, yeah, the instructions aren't 100%. But all of us knew that was the case before buying the kit, so I'm not going to knock Folger Tech on that one. This is my first 3D printer, I didn't look into a whole lot of options to be honest, I read a few good reviews on the forums, saw the price, figured I'm not that dumb :/ lol

I honestly knew very little about 3D printing before receiving the kit, but assembling everything myself was extremely educational. I, probably like most of you, enjoy the tinkering. Hopefully I'll have more to add once I get the printer up and running.

I've read up on the calibration, but the images from the instructions, and the actual firmware of the current repetier software don't exactly match up. What am I doing?? I'd hoped to familiarize myself with the software, but I'm not really sure where to start. Also, when I tried uploading the config files through Slic3r, it crashes Slic3r every time, without fail. Do I need these config files? Is Cura an option? I know I need to read ALOT more before I can even hit print. But if someone could run by the basics so I know where to start reading?

Other then the bad electronics, which hopefully Folger Tech will replace. The kit has been awesome. Yeah, yeah, the instructions aren't 100%. But all of us knew that was the case before buying the kit, so I'm not going to knock Folger Tech on that one. This is my first 3D printer, I didn't look into a whole lot of options to be honest, I read a few good reviews on the forums, saw the price, figured I'm not that dumb :/ lol

I honestly knew very little about 3D printing before receiving the kit, but assembling everything myself was extremely educational. I, probably like most of you, enjoy the tinkering. Hopefully I'll have more to add once I get the printer up and running.

I've read up on the calibration, but the images from the instructions, and the actual firmware of the current repetier software don't exactly match up. What am I doing?? I'd hoped to familiarize myself with the software, but I'm not really sure where to start. Also, when I tried uploading the config files through Slic3r, it crashes Slic3r every time, without fail. Do I need these config files? Is Cura an option? I know I need to read ALOT more before I can even hit print. But if someone could run by the basics so I know where to start reading?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 11:28PM |

Registered: 8 years ago Posts: 85 |

Quote

CreativeBR

jhitesma, great info here. You have a very nice modded i3. I will get there. 8)

I will think about these changes. It will be very helpful in a near future. By now i prefer to start with a FW more close to the default Folger Prusa i3 (only with that 2004 LCD and bed autolevel).

Thank you for help. It will be useful in a very near future i'm sure.

Thanks, I have more mods planned but a backlog of stuff I want printed so I'm trying to finish that before digging in

If you're going to do autolevel then you're going to need the endstop moved anyway. And that's the hardest part of the config changes. The rest are just a number here and there.

Here's a version of an RC6 Configuration.h with those changes:

[gist.github.com]

That has the stock thermister setting, the maxtemp dropped to 245, z steps set for threaded rod with A4988 drivers, extruder steps set for stock folger extruder. So other than moving the X endstop to the left side and moving it over one spot to the xmin plug on the RAMPS this should work with a stock Folger setup. It also has the 2004 LCD setup but won't hurt to not have the LCD installed even with the code enabled.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 29, 2016 08:06AM |

Registered: 8 years ago Posts: 19 |

Quote

rojowe

I just received my kit yesterday, stayed up until 3:30 am building everything. About 9 hours straight. I waited until this morning to recheck the wiring and fire her up. Sadly all didn't go as planned and it looks like the RAMPS and Arduino are both bad?! Sad to say the least....sucks putting in all that work overnight to be left staring at this thing. Honestly though, quite a thing it is lol.

Other then the bad electronics, which hopefully Folger Tech will replace. The kit has been awesome. Yeah, yeah, the instructions aren't 100%. But all of us knew that was the case before buying the kit, so I'm not going to knock Folger Tech on that one. This is my first 3D printer, I didn't look into a whole lot of options to be honest, I read a few good reviews on the forums, saw the price, figured I'm not that dumb :/ lol

I honestly knew very little about 3D printing before receiving the kit, but assembling everything myself was extremely educational. I, probably like most of you, enjoy the tinkering. Hopefully I'll have more to add once I get the printer up and running.

I've read up on the calibration, but the images from the instructions, and the actual firmware of the current repetier software don't exactly match up. What am I doing?? I'd hoped to familiarize myself with the software, but I'm not really sure where to start. Also, when I tried uploading the config files through Slic3r, it crashes Slic3r every time, without fail. Do I need these config files? Is Cura an option? I know I need to read ALOT more before I can even hit print. But if someone could run by the basics so I know where to start reading?

Why do you assume both boards are bad? Its uncommon for a bad board, let alone both bad boards. Whats the issue?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 29, 2016 09:04AM |

Registered: 8 years ago Posts: 541 |

Quote

rojowe

I just received my kit yesterday, stayed up until 3:30 am building everything. About 9 hours straight. I waited until this morning to recheck the wiring and fire her up. Sadly all didn't go as planned and it looks like the RAMPS and Arduino are both bad?! Sad to say the least....sucks putting in all that work overnight to be left staring at this thing. Honestly though, quite a thing it is lol.

Other then the bad electronics, which hopefully Folger Tech will replace. The kit has been awesome. Yeah, yeah, the instructions aren't 100%. But all of us knew that was the case before buying the kit, so I'm not going to knock Folger Tech on that one. This is my first 3D printer, I didn't look into a whole lot of options to be honest, I read a few good reviews on the forums, saw the price, figured I'm not that dumb :/ lol

I honestly knew very little about 3D printing before receiving the kit, but assembling everything myself was extremely educational. I, probably like most of you, enjoy the tinkering. Hopefully I'll have more to add once I get the printer up and running.

I've read up on the calibration, but the images from the instructions, and the actual firmware of the current repetier software don't exactly match up. What am I doing?? I'd hoped to familiarize myself with the software, but I'm not really sure where to start. Also, when I tried uploading the config files through Slic3r, it crashes Slic3r every time, without fail. Do I need these config files? Is Cura an option? I know I need to read ALOT more before I can even hit print. But if someone could run by the basics so I know where to start reading?

It sure sounds like it was a bad idea to stay up half the night building it!!!!!!!!!!!! ''when I tried uploading the config files through Slic3r, it crashes Slic3r every time'' WHAT? You don't upload the firmware using SLIC3R! I think you better sit down with a level head, use the latest building and programming directions in the BETA section and start over checking every step, perhaps with a buddy to help. You don't mention, as BMAYS says, why you think the boards are bad.

Just start over SLOOOWLY.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 29, 2016 09:16AM |

Registered: 7 years ago Posts: 4 |

I agree, though I believe a fault in the RAMPS has caused the included Arduino to go bad. I was able to upload the firmware to the Arduino before mounting it to the acrylic mount, so I know it did work on arrival. However when I connected everything and turned on the system for the first time, and the extruder fan turned on. Nothing else happened. I took a multimeter to the various connections,

Wall Outlet to PSU --> 120v

PSU 12v Output -----> 12v

RAMPS 12v Connector from PSU ----> 12v

Arduino 5v Pins --------> ~1v !!!????

I took off the arduino and plugged it into my computer via USB, and it turns on for a few seconds, and then LEDs fade and it dies.

I took my clone arduino mega and uploaded the sketch to that, I've tried connecting it to the RAMPS, but the RAMPS is still not putting out power to anything. If I connect my clone mega to USB power, it powers the end-stops but obviously none of the stepper motors, etc. are working.

Best I can figure is there was something wrong with the RAMPS board, and when it powered up the first time, it malfunctioned and took out the arduino with it. Now that it has already malfunctioned, instead of outputting 5v to the Arduino, its only ~1v so it's not enough to damage the 2nd arduino.

Wall Outlet to PSU --> 120v

PSU 12v Output -----> 12v

RAMPS 12v Connector from PSU ----> 12v

Arduino 5v Pins --------> ~1v !!!????

I took off the arduino and plugged it into my computer via USB, and it turns on for a few seconds, and then LEDs fade and it dies.

I took my clone arduino mega and uploaded the sketch to that, I've tried connecting it to the RAMPS, but the RAMPS is still not putting out power to anything. If I connect my clone mega to USB power, it powers the end-stops but obviously none of the stepper motors, etc. are working.

Best I can figure is there was something wrong with the RAMPS board, and when it powered up the first time, it malfunctioned and took out the arduino with it. Now that it has already malfunctioned, instead of outputting 5v to the Arduino, its only ~1v so it's not enough to damage the 2nd arduino.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 29, 2016 09:25AM |

Registered: 7 years ago Posts: 4 |

Perhaps I should have clarified "firmware." I may be interchanging different words. The version of Repetier available to me, does not have the same appearance as the version of Repetier pictured in the calibration guide.

I sure as hell DID NOT stay up until 3am and try to fire up the printer. I actually spent about 3 hours the next day squaring the frame and truing each axis, rechecking all of my wiring.

Like I said in my post, I was attempting to upload the CONFIG files FOR Slic3r, done through Repetier.....not the FIRMWARE for the MEGA which goes through the Ardunio IDE. So my question still stands. Is anyone using any alternate software(s) or is familiar with this problem. I'm getting an error code signaling something is wrong with line 3 of the config file, both the ABS and PLA files from Folger Tech. I am using OSX.

Edited 1 time(s). Last edit at 04/29/2016 09:29AM by rojowe.

I sure as hell DID NOT stay up until 3am and try to fire up the printer. I actually spent about 3 hours the next day squaring the frame and truing each axis, rechecking all of my wiring.

Like I said in my post, I was attempting to upload the CONFIG files FOR Slic3r, done through Repetier.....not the FIRMWARE for the MEGA which goes through the Ardunio IDE. So my question still stands. Is anyone using any alternate software(s) or is familiar with this problem. I'm getting an error code signaling something is wrong with line 3 of the config file, both the ABS and PLA files from Folger Tech. I am using OSX.

Edited 1 time(s). Last edit at 04/29/2016 09:29AM by rojowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 29, 2016 10:38AM |

Registered: 8 years ago Posts: 541 |

'''''when I tried uploading the config files through Slic3r, it crashes Slic3r every time''''

Never said you tried to 'fire up' the printer. I said ""building"". I use the stand alone version of Cura to slice projects and make the GCode but it won't let you control the machine. I can't help you with your OS x MAC

You never did say what machine you are building..

Edited 2 time(s). Last edit at 04/29/2016 10:43AM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

Never said you tried to 'fire up' the printer. I said ""building"". I use the stand alone version of Cura to slice projects and make the GCode but it won't let you control the machine. I can't help you with your OS x MAC

You never did say what machine you are building..

Edited 2 time(s). Last edit at 04/29/2016 10:43AM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 29, 2016 11:44AM |

Registered: 7 years ago Posts: 4 |

Quote

tjnamtiw

'''''when I tried uploading the config files through Slic3r, it crashes Slic3r every time''''

Never said you tried to 'fire up' the printer. I said ""building"". I use the stand alone version of Cura to slice projects and make the GCode but it won't let you control the machine. I can't help you with your OS x MAC

You never did say what machine you are building..

1) this is the FOLGER TECH 2020 PRUSA i3 *OFFICIAL THREAD*.....I assumed it was implied that I have built the Folger Tech 2020 Prusa i3....but for clarification....I have the Folger Tech 2020 Prusa i3...from Folger Tech....The 2020 model, with the chrome rods and metal square frame....the Prusa i3....lol

2) STEP 6 of the Configuration PDF.... of the Folger Tech 2020 Prusa i3 official build files, linked from the Folger Tech product page....Clearly states to configure Slic3r settings in Repetier with the ABS/PLA config files included in the official build files....same link from Folger Tech. <---- these are the files that are causing "Slic3R" to crash within Repetier.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 29, 2016 08:08PM |

Registered: 8 years ago Posts: 541 |

Quote

rojowe

1) this is the FOLGER TECH 2020 PRUSA i3 *OFFICIAL THREAD*.....I assumed it was implied that I have built the Folger Tech 2020 Prusa i3....but for clarification....I have the Folger Tech 2020 Prusa i3...from Folger Tech....The 2020 model, with the chrome rods and metal square frame....the Prusa i3....lol

2) STEP 6 of the Configuration PDF.... of the Folger Tech 2020 Prusa i3 official build files, linked from the Folger Tech product page....Clearly states to configure Slic3r settings in Repetier with the ABS/PLA config files included in the official build files....same link from Folger Tech. <---- these are the files that are causing "Slic3R" to crash within Repetier.

It sure is the 2020 site BUT as your read the pages, the other models of FT are well represented. I can see your frustration, though, because I can't even download them from the google site!!! And in the configuration instructions, the link to them doesn't work for me either! Maybe they are changing them. It might be a good question to ask on the FaceBook Folger Tech page.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 29, 2016 09:40PM |

Registered: 7 years ago Posts: 5 |

Just received my 2020 i3 this week. First 3D printer, and I'm doing a lot of reading, reviewing the build instructions, and just found this forum and thread. I just have a few questions.

I suspect I'll start out with PLA and don't plan to move to ABS for a while.

Thanks for any tips. I'm eager to learn, I'm just trying to avoid the same problems that others have already solved.

- I'm planning to use Rippa's Marlin firmware right out of the chute instead of the firmware referenced by Folger Tech. Is this a good idea? Will it "just work" with the 2004 LCD? I'm familiar with the Arduino environment so if there are configuration changes I can make them, but it's not obvious to me that any are needed other than (I think) the X end stop stuff.

- I know I need an 8"x8" piece of glass for the print bed (because Folger Tech's web site said so.) But I can't find any documentation anywhere that tells how to attach it, or anything about it for that matter. Nothing in the build instructions. Did I miss something? Looks like people use paper clamps to clamp it to the heating element. Where is this discussed? Is there a recommended glass?

- Do I need a fan to cool the printed part? If so, which one is recommended and how is it attached? Is it controlled by the RAMPS board?

I suspect I'll start out with PLA and don't plan to move to ABS for a while.

Thanks for any tips. I'm eager to learn, I'm just trying to avoid the same problems that others have already solved.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 29, 2016 09:52PM |

Registered: 8 years ago Posts: 430 |

Quote

K4DSP

Just received my 2020 i3 this week. First 3D printer, and I'm doing a lot of reading, reviewing the build instructions, and just found this forum and thread. I just have a few questions.

- I'm planning to use Rippa's Marlin firmware right out of the chute instead of the firmware referenced by Folger Tech. Is this a good idea? Will it "just work" with the 2004 LCD? I'm familiar with the Arduino environment so if there are configuration changes I can make them, but it's not obvious to me that any are needed other than (I think) the X end stop stuff.

- I know I need an 8"x8" piece of glass for the print bed (because Folger Tech's web site said so.) But I can't find any documentation anywhere that tells how to attach it, or anything about it for that matter. Nothing in the build instructions. Did I miss something? Looks like people use paper clamps to clamp it to the heating element. Where is this discussed? Is there a recommended glass?

- Do I need a fan to cool the printed part? If so, which one is recommended and how is it attached? Is it controlled by the RAMPS board?

I suspect I'll start out with PLA and don't plan to move to ABS for a while.

Thanks for any tips. I'm eager to learn, I'm just trying to avoid the same problems that others have already solved.

Yes you hold down the glass with binder clips. There are more fancy ways out there but just keep it simple in the beginning and use the binder clips.

You can print stuff without a print cooling fan. You need the fan to improve bridges and overhangs when using pla. Don't just assume pla will be easier. I seem to have better luck with abs most of the time especially on smaller stuff that's less prone to warp.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 29, 2016 10:09PM |

Registered: 8 years ago Posts: 9 |

Quote

K4DSP

Just received my 2020 i3 this week. First 3D printer, and I'm doing a lot of reading, reviewing the build instructions, and just found this forum and thread. I just have a few questions.

- I'm planning to use Rippa's Marlin firmware right out of the chute instead of the firmware referenced by Folger Tech. Is this a good idea? Will it "just work" with the 2004 LCD? I'm familiar with the Arduino environment so if there are configuration changes I can make them, but it's not obvious to me that any are needed other than (I think) the X end stop stuff.

- I know I need an 8"x8" piece of glass for the print bed (because Folger Tech's web site said so.) But I can't find any documentation anywhere that tells how to attach it, or anything about it for that matter. Nothing in the build instructions. Did I miss something? Looks like people use paper clamps to clamp it to the heating element. Where is this discussed? Is there a recommended glass?

- Do I need a fan to cool the printed part? If so, which one is recommended and how is it attached? Is it controlled by the RAMPS board?

I suspect I'll start out with PLA and don't plan to move to ABS for a while.

Thanks for any tips. I'm eager to learn, I'm just trying to avoid the same problems that others have already solved.

I used the stock Folger firmware to get started, told it was a less steep learning curve.

Binder clips like stated above, I have printed some holddowns but aint installed them yet. Had a local glass store cut a 1/4" piece of plate for me.

Printed a fan duct to go between fan and heatsink and it helped tons with sag. Have only used PLA so far.

Edited 3 time(s). Last edit at 04/29/2016 10:17PM by Trilithon.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 29, 2016 11:23PM |

Registered: 8 years ago Posts: 65 |

What would cause my Z steppers to make loud growling noise while jogging? The .1 and 1 jog seem fine but any larger movement make loud noise and will even lock up some time. What causes this? If it was one of my brushless RC motors I would say it was a timing issue, same noise. Also, I connected the z stepper to the x driver and and the stepper motor seems to work fine.

Edited 1 time(s). Last edit at 04/30/2016 06:42AM by WilberMaker.

Edited 1 time(s). Last edit at 04/30/2016 06:42AM by WilberMaker.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 30, 2016 08:38AM |

Registered: 8 years ago Posts: 541 |

Quote

WilberMaker

What would cause my Z steppers to make loud growling noise while jogging? The .1 and 1 jog seem fine but any larger movement make loud noise and will even lock up some time. What causes this? If it was one of my brushless RC motors I would say it was a timing issue, same noise. Also, I connected the z stepper to the x driver and and the stepper motor seems to work fine.

Mine made that noise when I tried to speed them up in the configuration.h file. Some versions of the Marlin have the speed much higher than the value of 3, which keeps my motors happy.

#define DEFAULT_MAX_FEEDRATE {300, 300, 3, 25} // (mm/sec)

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 30, 2016 03:09PM |

Registered: 7 years ago Posts: 43 |

Bad news for me. Hot end thermistor is busted (actually broken because looks like it has been tight too much And fan also not working... I will try to reach them in order to get replacement parts.

Also I had hard time to make fit the bearing to the plastic parts. I had to cut them a bit to make them fit (even by pushing really hard...).

Also I had hard time to make fit the bearing to the plastic parts. I had to cut them a bit to make them fit (even by pushing really hard...).

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 30, 2016 11:06PM |

Registered: 8 years ago Posts: 541 |

Quote

Cyril

Bad news for me. Hot end thermistor is busted (actually broken because looks like it has been tight too much And fan also not working... I will try to reach them in order to get replacement parts.

Also I had hard time to make fit the bearing to the plastic parts. I had to cut them a bit to make them fit (even by pushing really hard...).

Yes, that was a very big problem for me too 6 months ago (bearings don't fit plastic parts). Why can't they fix that!! ???? I made replacements out of PETG and the bearings fit perfectly. A word of warning to you > if the bearings are not completely into the holders, you will have misalignment and real problems getting the X and Y sleds to move easily. I had drilled out the holes in the Y plate bigger so that the bearings could move into a better position and then tightened them down.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 02, 2016 10:41PM |

Registered: 7 years ago Posts: 5 |

I'm building my Prusa i3 2020. I noticed today that one of the connectors on the smart adapter board for the LCD appears to be installed backward, ie. it's reversed. I've attached a photo - can someone confirm that they should be the same, and that the photo below is wrong? I don't want to unsolder one of them or chop up the housing if it's really supposed to be this way.

Thanks!

Thanks!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 02, 2016 10:50PM |

Registered: 7 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 02, 2016 11:19PM |

Registered: 7 years ago Posts: 5 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 02, 2016 11:35PM |

Registered: 7 years ago Posts: 5 |

Quote

K4DSP

Quote

Cyril

Mine are in the same position.

Are you saying that's correct then? Is yours working that way?

Update: I've found a couple of photos of the smart adapter board on different sites that suggest mine is wrong, so unless I hear otherwise I'm going to unsolder the EXP2 connector and turn it around.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 02, 2016 11:58PM |

Registered: 7 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 03, 2016 12:19AM |

Registered: 7 years ago Posts: 5 |

HELP! I just put together my Prussa, and I set it all up except for one major problem: the Z axis won't move at all. I checked everything, its built to the instructions, but it won't move. I have been using the manual control on Repetier, and everything else works, (Fan, nozzle, heated bed, X/Y axis) and I probably am missing a main step or something dumb, but I obviously can't print anything without the Z axis. (And the motors both work, I checked).

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 03, 2016 12:46AM |

Registered: 8 years ago Posts: 38 |

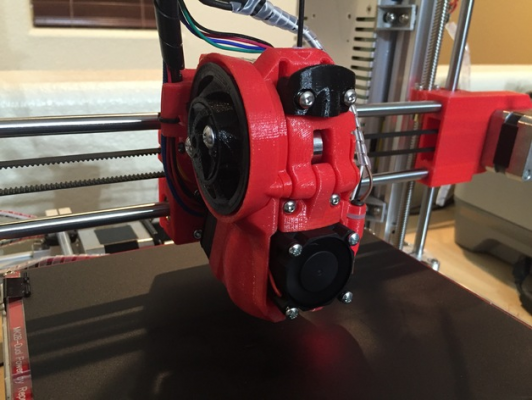

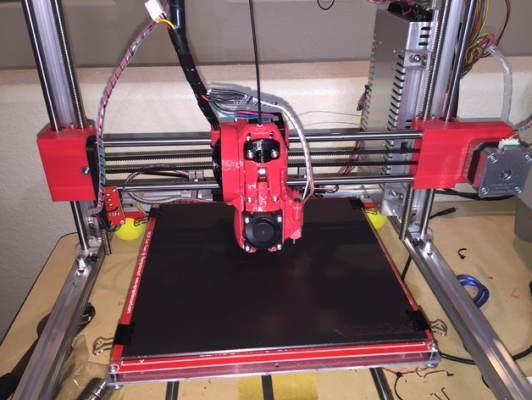

Hey everybody. It's been a while since I've posted. I've done some upgrades recently, so I thought I'd share. I finally did the lead screw upgrade along with a Toranado extruder and E3D V6 hot end. I'm still doing some calibration runs & test prints, but the printer's much quieter thanks to the lead screws and the print quality seems to be better with much more consistent filament flow.

Here's the new Toranado extruder & hot end:

Here's another image showing the lead screw upgrade (using a modified version of this):

The only down side so far is that the 30mm fan on the E3D V6 is pretty loud. I have a 40mm Noctua fan on the way, so I'm going to design an E3D heat sink 40mm fan mount that fits with the Toranado. (I also have another 30mm fan I'm going to try, but I'm guessing it'll still be loud.)

I also still have to connect the print fan, so I haven't tried that out yet. I use mostly PETG filament, so I haven't needed one so far. I'm looking forward to trying PLA with it though.

Progress!

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

Here's the new Toranado extruder & hot end:

Here's another image showing the lead screw upgrade (using a modified version of this):

The only down side so far is that the 30mm fan on the E3D V6 is pretty loud. I have a 40mm Noctua fan on the way, so I'm going to design an E3D heat sink 40mm fan mount that fits with the Toranado. (I also have another 30mm fan I'm going to try, but I'm guessing it'll still be loud.)

I also still have to connect the print fan, so I haven't tried that out yet. I use mostly PETG filament, so I haven't needed one so far. I'm looking forward to trying PLA with it though.

Progress!

Folger Tech 2020 i3 w/Misumi bearings, Borosilicate bed, BuildTak, BLTouch, 12864 LCD, lead screw z-axis, DRV8825, Toranado extruder & E3D V6 driven by Simplify3D and an Octopi.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 03, 2016 02:27AM |

Registered: 7 years ago Posts: 2 |

Purchased the Folger Tech 202 i3 in late March and received it in late April from the U.S to Australia, it took 3 days to build before I had my first prints and I was not rushing in the least to complete as I was in my element building it.

PLA is an ok material to start building with but i can see some of its issues, I was building some cable hiding chains and the irregularities that came out in the prints have had to have a lot of corrective maintenance done to them. I also created some filament holders to go on top of the 2020 and their size made a really nice print. Then i gave a smaller item a print, a Rubik's snake, the triangles have come out nicely and so have the joining pieces but as i printed it so small I'm struggling to join them together as the holes arent perfectly round.

Time to move on to the material I am most curious about TPE as I want to print some tires for a RC buggy and also print the whole thing eventually. TPE does not like to stick to the bed (celo tape), its difficult to get to print in a line without a wave (print speed) and many other issues.

The reason I'm posting today is the issue i had, whist preparing the bed I also left the extruder on and it ended up overheating and gave me the MAXTEMP error that wouldnt go away, unsure of how to fix this I unplugged everything plugged it back in re installed firmware, long story short i got rid of the error, tried to HOME all my axis's to create a new print but everytime I hit the X HOME the carriage would travel the wrong direction all the way left away from the endstop where it had been working perfectly with no issues since I built the printer. I used the printer reverse X function in the setup but when it hit the endstop it would sit there grinding the belt so I unchecked the reverse X and swapped the stepper plug on the ramps board and got the same result, swapped back, reinstalled FT-2020-NO-LCD(my firmware) and still had the issue of the carriage going to the wrong end and grinding the belt out (starting to swear at things now), I opened up Ardiuno and had a look in configuartion.h moved down to ENDSTOP SETTINGS and found this:

#define X_HOME_DIR 1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

Found the problem.........

After putting a - infront of the 1 for X, back to no issues again, the weird thing is that everything was working perfectly before the MAXTEMP issue and I never altered the file once to loose the -1 in the first place.......?

Hope I help someone with this issue.

BTW: The instructions are much better once you find the right ones...... Also if you had all the bolts, nuts and washers in individual packs where you dont have to sort them out you might find people more accepting of the instructions, I was constantly afraid that I didnt have the right ammount of parts, food for thought....

Edited 1 time(s). Last edit at 05/03/2016 02:38AM by Jorgo.

PLA is an ok material to start building with but i can see some of its issues, I was building some cable hiding chains and the irregularities that came out in the prints have had to have a lot of corrective maintenance done to them. I also created some filament holders to go on top of the 2020 and their size made a really nice print. Then i gave a smaller item a print, a Rubik's snake, the triangles have come out nicely and so have the joining pieces but as i printed it so small I'm struggling to join them together as the holes arent perfectly round.

Time to move on to the material I am most curious about TPE as I want to print some tires for a RC buggy and also print the whole thing eventually. TPE does not like to stick to the bed (celo tape), its difficult to get to print in a line without a wave (print speed) and many other issues.

The reason I'm posting today is the issue i had, whist preparing the bed I also left the extruder on and it ended up overheating and gave me the MAXTEMP error that wouldnt go away, unsure of how to fix this I unplugged everything plugged it back in re installed firmware, long story short i got rid of the error, tried to HOME all my axis's to create a new print but everytime I hit the X HOME the carriage would travel the wrong direction all the way left away from the endstop where it had been working perfectly with no issues since I built the printer. I used the printer reverse X function in the setup but when it hit the endstop it would sit there grinding the belt so I unchecked the reverse X and swapped the stepper plug on the ramps board and got the same result, swapped back, reinstalled FT-2020-NO-LCD(my firmware) and still had the issue of the carriage going to the wrong end and grinding the belt out (starting to swear at things now), I opened up Ardiuno and had a look in configuartion.h moved down to ENDSTOP SETTINGS and found this:

#define X_HOME_DIR 1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

Found the problem.........

After putting a - infront of the 1 for X, back to no issues again, the weird thing is that everything was working perfectly before the MAXTEMP issue and I never altered the file once to loose the -1 in the first place.......?

Hope I help someone with this issue.

BTW: The instructions are much better once you find the right ones...... Also if you had all the bolts, nuts and washers in individual packs where you dont have to sort them out you might find people more accepting of the instructions, I was constantly afraid that I didnt have the right ammount of parts, food for thought....

Edited 1 time(s). Last edit at 05/03/2016 02:38AM by Jorgo.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 03, 2016 06:05PM |

Registered: 8 years ago Posts: 130 |

Quote

Jorgo

The reason I'm posting today is the issue i had, whist preparing the bed I also left the extruder on and it ended up overheating and gave me the MAXTEMP error that wouldnt go away, unsure of how to fix this."

I wonder if your thermister is hosed/kaput.

With theRippa firmware V 1.0.2, I had to fiddle with the runaway protection.

// Parameters for all extruder heaters

#define THERMAL_RUNAWAY_PROTECTION_PERIOD 40 //in seconds

#define THERMAL_RUNAWAY_PROTECTION_HYSTERESIS 5 // in degree Celsius

Quote

Jorgo

I unplugged everything plugged it back in re installed firmware, long story short i got rid of the error, tried to HOME all my axis's to create a new print but everytime I hit the X HOME the carriage would travel the wrong direction all the way left away from the endstop where it had been working perfectly with no issues since I built the printer. I used the printer reverse X function in the setup but when it hit the endstop it would sit there grinding the belt so I unchecked the reverse X and swapped the stepper plug on the ramps board and got the same result, swapped back, reinstalled FT-2020-NO-LCD(my firmware) and still had the issue of the carriage going to the wrong end and grinding the belt out (starting to swear at things now), I opened up Ardiuno and had a look in configuartion.h moved down to ENDSTOP SETTINGS and found this:

#define X_HOME_DIR 1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

Found the problem.........

After putting a - infront of the 1 for X, back to no issues again, the weird thing is that everything was working perfectly before the MAXTEMP issue and I never altered the file once to loose the -1 in the first place.......?

Hope I help someone with this issue.

BTW: The instructions are much better once you find the right ones...... Also if you had all the bolts, nuts and washers in individual packs where you dont have to sort them out you might find people more accepting of the instructions, I was constantly afraid that I didnt have the right ammount of parts, food for thought....

I had to alter a bunch of the following, after running GCode commands. M119 was invaluable in returning the status of my triggered endstops:

#ifdef ENDSTOPPULLUPS

// #define ENDSTOPPULLUP_XMAX

// #define ENDSTOPPULLUP_YMAX

// #define ENDSTOPPULLUP_ZMAX

#define ENDSTOPPULLUP_XMIN

#define ENDSTOPPULLUP_YMIN

#define ENDSTOPPULLUP_ZMIN

#endif

// The pullups are needed if you directly connect a mechanical endswitch between the signal and ground pins.

const bool X_MIN_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

const bool Y_MIN_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

const bool Z_MIN_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

const bool X_MAX_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

const bool Y_MAX_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

const bool Z_MAX_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

#define DISABLE_MAX_ENDSTOPS // (my comments)changed this since I have no physical max_endstops

//#define DISABLE_MIN_ENDSTOPS

This website is very useful for sorting the logic of your machine:

[reprapandme.blogspot.com]

I also have a printed RepRap GCode Cheat Sheet close at hand.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 03, 2016 06:09PM |

Registered: 7 years ago Posts: 43 |

FolgerTech will send me replacement thermistor for the hot end... I don't know when but they will... (mine was shattered due to a too tight screw).

On another topic, I have the 12864 Full Graphic Controller, but I can't find a way to make the SD Card work... it's saying echo D init fail, I tried to reduce the SPI speed but no luck. My SD CARD is a 4GB Kensington SDHC with one partition in FAT16. (I tried FAT32 as well no luck).

D init fail, I tried to reduce the SPI speed but no luck. My SD CARD is a 4GB Kensington SDHC with one partition in FAT16. (I tried FAT32 as well no luck).

On another topic, I have the 12864 Full Graphic Controller, but I can't find a way to make the SD Card work... it's saying echo

D init fail, I tried to reduce the SPI speed but no luck. My SD CARD is a 4GB Kensington SDHC with one partition in FAT16. (I tried FAT32 as well no luck).

D init fail, I tried to reduce the SPI speed but no luck. My SD CARD is a 4GB Kensington SDHC with one partition in FAT16. (I tried FAT32 as well no luck).

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 03, 2016 07:47PM |

Registered: 8 years ago Posts: 541 |

Quote

Mindforrest

HELP! I just put together my Prussa, and I set it all up except for one major problem: the Z axis won't move at all. I checked everything, its built to the instructions, but it won't move. I have been using the manual control on Repetier, and everything else works, (Fan, nozzle, heated bed, X/Y axis) and I probably am missing a main step or something dumb, but I obviously can't print anything without the Z axis. (And the motors both work, I checked).

Z won't work until you HOME all axes.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 03, 2016 11:38PM |

Registered: 7 years ago Posts: 5 |

Thank you, Tjmantiw, however, I am not sure what you mean, as I have homed the axis' before I tried to move the Z axis. One thing I noticed was that my first stepper driver is way hotter than the rest (I made sure the voltages were as recommended). Not sure if that effects anything.Quote

tjnamtiw

Quote

Mindforrest

HELP! I just put together my Prussa, and I set it all up except for one major problem: the Z axis won't move at all. I checked everything, its built to the instructions, but it won't move. I have been using the manual control on Repetier, and everything else works, (Fan, nozzle, heated bed, X/Y axis) and I probably am missing a main step or something dumb, but I obviously can't print anything without the Z axis. (And the motors both work, I checked).

Z won't work until you HOME all axes.

Thanks!

Sorry, only registered users may post in this forum.

yours looks wrong.

yours looks wrong.