Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 08, 2016 02:06AM |

Registered: 7 years ago Posts: 5 |

I have mine up and running sort of. I'm using the forked marlin firmware and have everything working. II have added an inductive sensor and have it working as a z endstop, I'm not able to get the probe to check multiple points before printing it just drives the z axis down until the inductive sensor is activated and then begins printing from there. I switched to auto leveling because my print surface became warped trying to level the bed. I'm using an aluminum bed. I don't know what I'm missing I have the code in the firmware un-commented for the grid probing but I cannot get the printer to probe more than one location. Any help would be greatly appreciated,

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 08, 2016 06:00PM |

Registered: 7 years ago Posts: 5 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 08, 2016 06:19PM |

Registered: 8 years ago Posts: 130 |

Quote

wild.bill

To address the heat problem when I had a short time on layers I found a fan that will mount on the MK9 so I printed and installed it. I seems do help.

I addressed another small problem where the hot end would sometimes hit one of the clips holding the glass down.

I cut a new piece of glass that was 8 1/2" x 8" so it would hang over the sides of the hot plate. Now I can get the clips

a lot further away from the print area. So far no hits.

I purchased borosilicate; at least that's what the seller sold it as, ha, ha, ha. If I had glass cutting skills...

My reduced my bed size in configuration.h. I chose expedience over elegance.

// Travel limits after homing //changed this to 180 so I won't crash into my binder clips #define X_MAX_POS 180 #define X_MIN_POS 0 #define Y_MAX_POS 180 #define Y_MIN_POS 0 #define Z_MAX_POS 175 #define Z_MIN_POS 0

Sonny's magnetic setup is way good:

[www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 08, 2016 07:56PM |

Registered: 8 years ago Posts: 15 |

Quote

flatlander

I purchased borosilicate; at least that's what the seller sold it as, ha, ha, ha. If I had glass cutting skills...

My reduced my bed size in configuration.h. I chose expedience over elegance.

Sonny's magnetic setup is way good: ...

[www.thingiverse.com]

Actually cutting glass is real easy, I learned how when I was doing picture framing.

I mark the glass with a sharpy where I want the cut, score it using a $7 cutting wheel from home depot (only one pass) using a straight edge.

Put on the edge of a table and press lightly until it snaps, then I dress the edges with a stone made to clean the edges of cut tiles.

The only important part is to use heavy gloves.

I like the magnetic idea but haven't been able to get the image of how it implement it.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 09, 2016 12:39PM |

Registered: 8 years ago Posts: 65 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 09, 2016 05:02PM |

Registered: 8 years ago Posts: 541 |

Quote

WilberMaker

Up and printing! Thanks for all the help. Only problem I am have is the layers on the print seem to separate making large cracks the part. What kind of problem causes this? I can send photos if needed.

1: Did you level the bed to the nozzle in all four corners? 0.1 mm or 0.004" clearance when in the Z = 0 position using your Z endstop?

2: Did you calibrate your extruder and change the EStep number in your firmware with Arduino?

3: Is your slicer set for 1.75 and not 3.0 mm?

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 09, 2016 07:04PM |

Registered: 8 years ago Posts: 65 |

I got the bed leveled perfectly. I did not do either of your other to suggestions. Let me do some Google study before I ask stupid questions. thanks for the direction.

What filament guide did you use? I can all ready see that is a problem.

Edited 1 time(s). Last edit at 05/09/2016 07:06PM by WilberMaker.

What filament guide did you use? I can all ready see that is a problem.

Edited 1 time(s). Last edit at 05/09/2016 07:06PM by WilberMaker.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 09, 2016 10:53PM |

Registered: 8 years ago Posts: 65 |

Quote

tjnamtiw

1: Did you level the bed to the nozzle in all four corners? 0.1 mm or 0.004" clearance when in the Z = 0 position using your Z endstop?

2: Did you calibrate your extruder and change the EStep number in your firmware with Arduino?

3: Is your slicer set for 1.75 and not 3.0 mm?[/quote

Is this the line I should be changing to calibrate the extruder? Not sure what "RUNOUT" is.

" #define EXTRUDER_RUNOUT_ESTEPS 19. //mm filament "

Edited 1 time(s). Last edit at 05/09/2016 11:18PM by WilberMaker.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 09, 2016 11:10PM |

Registered: 8 years ago Posts: 541 |

Quote

WilberMaker

Quote

tjnamtiw

1: Did you level the bed to the nozzle in all four corners? 0.1 mm or 0.004" clearance when in the Z = 0 position using your Z endstop?

2: Did you calibrate your extruder and change the EStep number in your firmware with Arduino?

3: Is your slicer set for 1.75 and not 3.0 mm?

Is this the line I should be changing to calibrate the extruder? Not sure what "RUNOUT" is.

" #define EXTRUDER_RUNOUT_ESTEPS 19. //mm filament "

NO, you need to find this one > #define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,3950,99} // default steps per unit for Ultimaker

The last number is for your extruder. There are a bunch of YouTube videos explaining how to calibrate your extruder > [www.youtube.com] for example.

I didn't like the filament roll hanging on the side as most people don't. I made a simple holder out of PVC pipe and elbows that holds the reel right behind the machine and then I used my guide that is held in the aluminum extrusion with a T nut. > [www.thingiverse.com]

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 11, 2016 10:16PM |

Registered: 7 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 12, 2016 01:41AM |

Registered: 7 years ago Posts: 43 |

I found [support.3dverkstan.se] pretty useful.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 12, 2016 01:00PM |

Registered: 8 years ago Posts: 130 |

For the overhangs you presented I would need to keep layer height at 0.2mm. Contrary to what your article suggests, I would make sure that my outer perimeters were a bit wide at least 1.5 X height. This is close to default, but Slic3r has 'sane defaults' and reduces perimeter widths so that the finished part looks "cleaner.' I also make sure my part has three extrusion perimeters of thickness, i.e the part has three beads of filament wall. So I set my thickness in Cura to to 0.9mm for a print of height 0.20 and check the print preview for three perimeters.

I tend to get better overhang prints using Cura. It somehow recognizes that the top of a sphere needs more thickness/support. The Slic3r prints have gaps at the top even if a try to tell it to make the top thicker.

Sometimes these tough angles just need some infill.

A part cooling fan is a must for these tough prints. The top of your print looks too hot, you might try a few degrees cooler.

notes:

[manual.slic3r.org]

I tend to get better overhang prints using Cura. It somehow recognizes that the top of a sphere needs more thickness/support. The Slic3r prints have gaps at the top even if a try to tell it to make the top thicker.

Sometimes these tough angles just need some infill.

A part cooling fan is a must for these tough prints. The top of your print looks too hot, you might try a few degrees cooler.

notes:

[manual.slic3r.org]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 12, 2016 03:44PM |

Registered: 8 years ago Posts: 541 |

Quote

flatlander

For the overhangs you presented I would need to keep layer height at 0.2mm. Contrary to what your article suggests, I would make sure that my outer perimeters were a bit wide at least 1.5 X height. This is close to default, but Slic3r has 'sane defaults' and reduces perimeter widths so that the finished part looks "cleaner.' I also make sure my part has three extrusion perimeters of thickness, i.e the part has three beads of filament wall. So I set my thickness in Cura to to 0.9mm for a print of height 0.20 and check the print preview for three perimeters.

I tend to get better overhang prints using Cura. It somehow recognizes that the top of a sphere needs more thickness/support. The Slic3r prints have gaps at the top even if a try to tell it to make the top thicker.

Sometimes these tough angles just need some infill.

A part cooling fan is a must for these tough prints. The top of your print looks too hot, you might try a few degrees cooler.

notes:

[manual.slic3r.org]

You say that you set the 'thickness' in Cura to 0.9 mm". I assume you mean the wall thickness with three passes. BUT if you look at the beginning of your generated GCode, you will see IF YOU ARE USING A 0.4 mm nozzle, that the intended wall thickness is supposed to be 0.48 mm. That's why you run a single wall test piece and measure the top one or two layers to see if they are 0.48 mm. If not, ASSUMING you calibrated your extruder first, you should adjust your extrusion % or multiplier until you DO get 0.48 mm. That means that 3 layer wide outer wall would be 3 X 0.48 mm or 1.44 mm.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 12, 2016 04:16PM |

Registered: 7 years ago Posts: 43 |

Quote

tjnamtiw

You say that you set the 'thickness' in Cura to 0.9 mm". I assume you mean the wall thickness with three passes. BUT if you look at the beginning of your generated GCode, you will see IF YOU ARE USING A 0.4 mm nozzle, that the intended wall thickness is supposed to be 0.48 mm. That's why you run a single wall test piece and measure the top one or two layers to see if they are 0.48 mm. If not, ASSUMING you calibrated your extruder first, you should adjust your extrusion % or multiplier until you DO get 0.48 mm. That means that 3 layer wide outer wall would be 3 X 0.48 mm or 1.44 mm.

I have done this part, I calibrated the multiplier using the top layers of a single layer wall.

I'm printing some duct fan mount right now and give a try with Benchy to adjust other params. So far so good.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 13, 2016 07:48AM |

Registered: 8 years ago Posts: 130 |

Quote

tjnamtiw

Quote

flatlander

For the overhangs you presented I would need to keep layer height at 0.2mm. Contrary to what your article suggests, I would make sure that my outer perimeters were a bit wide at least 1.5 X height. This is close to default, but Slic3r has 'sane defaults' and reduces perimeter widths so that the finished part looks "cleaner.' I also make sure my part has three extrusion perimeters of thickness, i.e the part has three beads of filament wall. So I set my thickness in Cura to to 0.9mm for a print of height 0.20 and check the print preview for three perimeters.

I tend to get better overhang prints using Cura. It somehow recognizes that the top of a sphere needs more thickness/support. The Slic3r prints have gaps at the top even if a try to tell it to make the top thicker.

Sometimes these tough angles just need some infill.

A part cooling fan is a must for these tough prints. The top of your print looks too hot, you might try a few degrees cooler.

notes:

[manual.slic3r.org]

You say that you set the 'thickness' in Cura to 0.9 mm". I assume you mean the wall thickness with three passes. BUT if you look at the beginning of your generated GCode, you will see IF YOU ARE USING A 0.4 mm nozzle, that the intended wall thickness is supposed to be 0.48 mm. That's why you run a single wall test piece and measure the top one or two layers to see if they are 0.48 mm. If not, ASSUMING you calibrated your extruder first, you should adjust your extrusion % or multiplier until you DO get 0.48 mm. That means that 3 layer wide outer wall would be 3 X 0.48 mm or 1.44 mm.

Quote

tjnamtiw

You say that you set the 'thickness' in Cura to 0.9 mm". I assume you mean the wall thickness with three passes.

Yep, total wall thickness 0.9 mm, 0.3 mm per pass. This is an attempt to make Cura do what Slic3r does with Vertical shells, Perimeters: 3.

It's starting to feel like Spinal Tap in here..."These go to 11." Ha, ha, ha. [www.youtube.com]

It's my understanding that using a layer height 'setting' of 0.2 mm (resulting in a .3 mm width) is perfectly acceptable with a 0.4 mm nozzle. In my experience the prints with overhangs have better looking results at a 0.2 mm height setting.

I guess my point is that if Slic3r is making the outer perimeter narrow by default the next layer will just fall off the edge in spaghetti as seen in the lower part of a spherical object. That's why I suggest forcing the external perimeters to 0.48 mm, using your suggested layer width, by using Advanced >Extrusion width >External perimeters: 0.48. For me, "These go to .30 mm." Sticking with the Spinal Tap tone.

Hum, I need to print a glow-in-the-dark Stonehenge.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 13, 2016 08:43AM |

Registered: 8 years ago Posts: 541 |

Quote

flatlander

Quote

tjnamtiw

Quote

flatlander

For the overhangs you presented I would need to keep layer height at 0.2mm. Contrary to what your article suggests, I would make sure that my outer perimeters were a bit wide at least 1.5 X height. This is close to default, but Slic3r has 'sane defaults' and reduces perimeter widths so that the finished part looks "cleaner.' I also make sure my part has three extrusion perimeters of thickness, i.e the part has three beads of filament wall. So I set my thickness in Cura to to 0.9mm for a print of height 0.20 and check the print preview for three perimeters.

I tend to get better overhang prints using Cura. It somehow recognizes that the top of a sphere needs more thickness/support. The Slic3r prints have gaps at the top even if a try to tell it to make the top thicker.

Sometimes these tough angles just need some infill.

A part cooling fan is a must for these tough prints. The top of your print looks too hot, you might try a few degrees cooler.

notes:

[manual.slic3r.org]

You say that you set the 'thickness' in Cura to 0.9 mm". I assume you mean the wall thickness with three passes. BUT if you look at the beginning of your generated GCode, you will see IF YOU ARE USING A 0.4 mm nozzle, that the intended wall thickness is supposed to be 0.48 mm. That's why you run a single wall test piece and measure the top one or two layers to see if they are 0.48 mm. If not, ASSUMING you calibrated your extruder first, you should adjust your extrusion % or multiplier until you DO get 0.48 mm. That means that 3 layer wide outer wall would be 3 X 0.48 mm or 1.44 mm.

Quote

tjnamtiw

You say that you set the 'thickness' in Cura to 0.9 mm". I assume you mean the wall thickness with three passes.

Yep, total wall thickness 0.9 mm, 0.3 mm per pass. This is an attempt to make Cura do what Slic3r does with Vertical shells, Perimeters: 3.

It's starting to feel like Spinal Tap in here..."These go to 11." Ha, ha, ha. [www.youtube.com]

It's my understanding that using a layer height 'setting' of 0.2 mm (resulting in a .3 mm width) is perfectly acceptable with a 0.4 mm nozzle. In my experience the prints with overhangs have better looking results at a 0.2 mm height setting.

I guess my point is that if Slic3r is making the outer perimeter narrow by default the next layer will just fall off the edge in spaghetti as seen in the lower part of a spherical object. That's why I suggest forcing the external perimeters to 0.48 mm, using your suggested layer width, by using Advanced >Extrusion width >External perimeters: 0.48. For me, "These go to .30 mm." Sticking with the Spinal Tap tone.

Hum, I need to print a glow-in-the-dark Stonehenge.

Think about it. You have a 0.4 mm diameter nozzle and you are expecting the width of the single layer to be 0.3 mm. Aint' going to happen. With swell out of the nozzle, you will have OVER 0.4 mm. The only way you're going to MAYBE get 0.3 mm is if you try to stretch the 'string' but the firmware won't let you do that plus it's pushing the layer down onto the previous layer. You are not going to get 0.9 mm for 3 passes, or at least you shouldn't. If you are, you have not properly set up your extruder and extrusion rate. You'll have gaps and incomplete fill. Layer height does not dictate layer width.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 13, 2016 08:00PM |

Registered: 7 years ago Posts: 2 |

Hey fellow reprappers,

So I had issues when I received my folgertech 2020 printer, two of the motors were damaged during shipment. I took them apart and after messing with them awhile I was able to get them to spin when attached to the printer. I contacted folgertech about the two motors and they were kind enough to send replacements. While I was waiting I continued to try and print with the slightly damaged motors. Over the last week I feel they have been working great, as I am getting pretty quality prints. I just received a new y axis motor as well as another smaller motor used for the x and z. I've also noticed during my prints that the x axis motor gets really hot, depending on the print time between 40-60 degrees Celsius. When I've checked the y axis motor its significantly cooler. My question is has anyone attempted putting the larger motor on the x axis? Is there any reason I shouldn't try/do this with my extra motor that anyone knows about?

So I had issues when I received my folgertech 2020 printer, two of the motors were damaged during shipment. I took them apart and after messing with them awhile I was able to get them to spin when attached to the printer. I contacted folgertech about the two motors and they were kind enough to send replacements. While I was waiting I continued to try and print with the slightly damaged motors. Over the last week I feel they have been working great, as I am getting pretty quality prints. I just received a new y axis motor as well as another smaller motor used for the x and z. I've also noticed during my prints that the x axis motor gets really hot, depending on the print time between 40-60 degrees Celsius. When I've checked the y axis motor its significantly cooler. My question is has anyone attempted putting the larger motor on the x axis? Is there any reason I shouldn't try/do this with my extra motor that anyone knows about?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 13, 2016 08:19PM |

Registered: 8 years ago Posts: 130 |

Quote

tjnamtiw

Quote

flatlander

Quote

tjnamtiw

Quote

flatlander

For the overhangs you presented I would need to keep layer height at 0.2mm. Contrary to what your article suggests, I would make sure that my outer perimeters were a bit wide at least 1.5 X height. This is close to default, but Slic3r has 'sane defaults' and reduces perimeter widths so that the finished part looks "cleaner.' I also make sure my part has three extrusion perimeters of thickness, i.e the part has three beads of filament wall. So I set my thickness in Cura to to 0.9mm for a print of height 0.20 and check the print preview for three perimeters.

I tend to get better overhang prints using Cura. It somehow recognizes that the top of a sphere needs more thickness/support. The Slic3r prints have gaps at the top even if a try to tell it to make the top thicker.

Sometimes these tough angles just need some infill.

A part cooling fan is a must for these tough prints. The top of your print looks too hot, you might try a few degrees cooler.

notes:

[manual.slic3r.org]

You say that you set the 'thickness' in Cura to 0.9 mm". I assume you mean the wall thickness with three passes. BUT if you look at the beginning of your generated GCode, you will see IF YOU ARE USING A 0.4 mm nozzle, that the intended wall thickness is supposed to be 0.48 mm. That's why you run a single wall test piece and measure the top one or two layers to see if they are 0.48 mm. If not, ASSUMING you calibrated your extruder first, you should adjust your extrusion % or multiplier until you DO get 0.48 mm. That means that 3 layer wide outer wall would be 3 X 0.48 mm or 1.44 mm.

Quote

tjnamtiw

You say that you set the 'thickness' in Cura to 0.9 mm". I assume you mean the wall thickness with three passes.

Yep, total wall thickness 0.9 mm, 0.3 mm per pass. This is an attempt to make Cura do what Slic3r does with Vertical shells, Perimeters: 3.

It's starting to feel like Spinal Tap in here..."These go to 11." Ha, ha, ha. [www.youtube.com]

It's my understanding that using a layer height 'setting' of 0.2 mm (resulting in a .3 mm width) is perfectly acceptable with a 0.4 mm nozzle. In my experience the prints with overhangs have better looking results at a 0.2 mm height setting.

I guess my point is that if Slic3r is making the outer perimeter narrow by default the next layer will just fall off the edge in spaghetti as seen in the lower part of a spherical object. That's why I suggest forcing the external perimeters to 0.48 mm, using your suggested layer width, by using Advanced >Extrusion width >External perimeters: 0.48. For me, "These go to .30 mm." Sticking with the Spinal Tap tone.

Hum, I need to print a glow-in-the-dark Stonehenge.

Think about it. You have a 0.4 mm diameter nozzle and you are expecting the width of the single layer to be 0.3 mm. Aint' going to happen. With swell out of the nozzle, you will have OVER 0.4 mm. The only way you're going to MAYBE get 0.3 mm is if you try to stretch the 'string' but the firmware won't let you do that plus it's pushing the layer down onto the previous layer. You are not going to get 0.9 mm for 3 passes, or at least you shouldn't. If you are, you have not properly set up your extruder and extrusion rate. You'll have gaps and incomplete fill. Layer height does not dictate layer width.

Thank's, I still can't get Slic3r to perform well with overhangs...

Aha that's it! Best results are obtained when layer height < 80% of nozzle diameter, and extrusion width >= nozzle diameter. This is the 'magic' formula.

notes:

[reprap.org]

height: .80 X .40 = .32 width: .32 X 1.5 = .48 // using 1.5 for height:width conversion factor

minimum height for a .4 mm nozzle:

.267 mm // it seems to stay within parameters

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 14, 2016 07:47AM |

Registered: 8 years ago Posts: 130 |

Sorry, I'm in the mood to beat a dead horse. I knew that I had read about layer heights of .20 mm with a .40 mm nozzle. Slic3r is recommending 'out-of-bounds' layer heights for difficult overhangs. This page from the Slic3r manual goes as low as 0.15 mm:

[manual.slic3r.org]

So after thinking about it and letting my unconscious mind settle this. I am back to, "When in doubt, choose a smaller value for layer height."

[manual.slic3r.org]

So after thinking about it and letting my unconscious mind settle this. I am back to, "When in doubt, choose a smaller value for layer height."

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 14, 2016 08:17AM |

Registered: 8 years ago Posts: 130 |

Quote

gobinelli

Hey fellow reprappers,

So I had issues when I received my folgertech 2020 printer, two of the motors were damaged during shipment. I took them apart and after messing with them awhile I was able to get them to spin when attached to the printer. I contacted folgertech about the two motors and they were kind enough to send replacements. While I was waiting I continued to try and print with the slightly damaged motors. Over the last week I feel they have been working great, as I am getting pretty quality prints. I just received a new y axis motor as well as another smaller motor used for the x and z. I've also noticed during my prints that the x axis motor gets really hot, depending on the print time between 40-60 degrees Celsius. When I've checked the y axis motor its significantly cooler. My question is has anyone attempted putting the larger motor on the x axis? Is there any reason I shouldn't try/do this with my extra motor that anyone knows about?

My x-axis stepper ran hot too. Attempts at running a lower VREF resulted in skipped steps. In the end, I purchased a replacement stepper, model 17HS19-1684S1 from Stepper Online. If I recall correctly, I'm running a VREF of 0.65 V. You should be good using the extra y-axis stepper on your x-axis.

I guess a reason not to do this, is that the extra mass may cause more wear on the M5 threaded rods. Why not kick that hornets nest?

Edited 3 time(s). Last edit at 05/14/2016 08:35AM by flatlander.

|

Folger Tech 2020 Auto Bed Leveling May 14, 2016 04:36PM |

Registered: 8 years ago Posts: 552 |

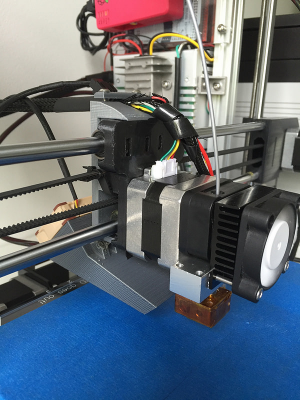

Attached is a modification for the Folger Tech 2020 i3 to facilitate Auto Bed Leveling.

You need a standard servo and micro-switch from eBay. You will also need several M3x45 bolts because the servo cage mounts behind the extruder's stepper motor and the bolts need to be 5mm longer than what came with your kit:

[www.ebay.com]

[www.ebay.com]

[www.ebay.com]

When engaged, the probe rests against the extruder's right hand feed lever. And the micro-switch should be mounted with the roller towards the back of the machine. This will greatly enhance your M48 repeatability because the slight amount of pressure to trigger the switch will help rotate the probe firmly against the release lever and insure a consistent position for each probed point.

Enjoy!

You need a standard servo and micro-switch from eBay. You will also need several M3x45 bolts because the servo cage mounts behind the extruder's stepper motor and the bolts need to be 5mm longer than what came with your kit:

[www.ebay.com]

[www.ebay.com]

[www.ebay.com]

When engaged, the probe rests against the extruder's right hand feed lever. And the micro-switch should be mounted with the roller towards the back of the machine. This will greatly enhance your M48 repeatability because the slight amount of pressure to trigger the switch will help rotate the probe firmly against the release lever and insure a consistent position for each probed point.

Enjoy!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 14, 2016 08:23PM |

Registered: 7 years ago Posts: 43 |

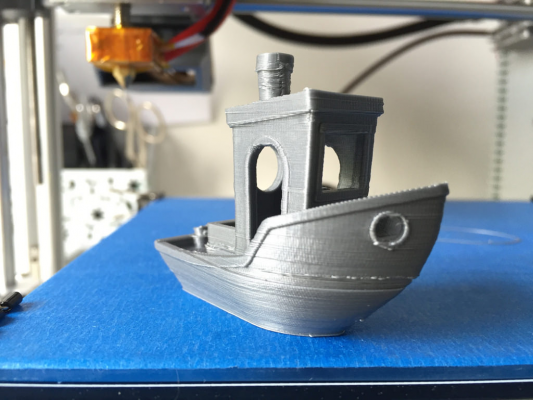

So I finally added a cooling fan, and printed a benchy with 0.1 as layer height, slowing done the speeds of perimeters to 60%. It came out pretty well particularly regarding the bridges even if I had a Y shifting (I guess this is my bad motor I managed to fixed myself).

Here are some pictures, let me know what do you think. (all the mesures are pretty good (around ~ 0.04 mm delta for some of them).

The chimney had some issue, not sure why, maybe not cooling enough between layers. The only missing part are the small writing on the back.

Here are some pictures, let me know what do you think. (all the mesures are pretty good (around ~ 0.04 mm delta for some of them).

The chimney had some issue, not sure why, maybe not cooling enough between layers. The only missing part are the small writing on the back.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 14, 2016 09:50PM |

Registered: 8 years ago Posts: 9 |

You have a link or STL file for that duct and mount?

Quote

Cyril

So I finally added a cooling fan, and printed a benchy with 0.1 as layer height, slowing done the speeds of perimeters to 60%. It came out pretty well particularly regarding the bridges even if I had a Y shifting (I guess this is my bad motor I managed to fixed myself).

Here are some pictures, let me know what do you think. (all the mesures are pretty good (around ~ 0.04 mm delta for some of them).

The chimney had some issue, not sure why, maybe not cooling enough between layers. The only missing part are the small writing on the back.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 14, 2016 10:00PM |

Registered: 7 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 14, 2016 10:21PM |

Registered: 7 years ago Posts: 2 |

Quote

flatlander

Quote

gobinelli

Hey fellow reprappers,

So I had issues when I received my folgertech 2020 printer, two of the motors were damaged during shipment. I took them apart and after messing with them awhile I was able to get them to spin when attached to the printer. I contacted folgertech about the two motors and they were kind enough to send replacements. While I was waiting I continued to try and print with the slightly damaged motors. Over the last week I feel they have been working great, as I am getting pretty quality prints. I just received a new y axis motor as well as another smaller motor used for the x and z. I've also noticed during my prints that the x axis motor gets really hot, depending on the print time between 40-60 degrees Celsius. When I've checked the y axis motor its significantly cooler. My question is has anyone attempted putting the larger motor on the x axis? Is there any reason I shouldn't try/do this with my extra motor that anyone knows about?

My x-axis stepper ran hot too. Attempts at running a lower VREF resulted in skipped steps. In the end, I purchased a replacement stepper, model 17HS19-1684S1 from Stepper Online. If I recall correctly, I'm running a VREF of 0.65 V. You should be good using the extra y-axis stepper on your x-axis.

I guess a reason not to do this, is that the extra mass may cause more wear on the M5 threaded rods. Why not kick that hornets nest?

Thanks flatlander! The extra mass had occurred to me, but I figured I'd ask anyways. Thanks for the stepper upgrade model I want to replace them all at some point down the road anyways.

|

Re: Folger Tech 2020 Auto Bed Leveling May 14, 2016 10:38PM |

Registered: 8 years ago Posts: 552 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 15, 2016 02:04AM |

Registered: 7 years ago Posts: 5 |

Success! I finished building my 2020 i3 this weekend, and tonight was my first attempt at 3D printing. As one of my old mentors used to say, "Even a blind squirrel finds an acorn once in a while." The first two things I printed came out great!

The calibration cube I downloaded from Thingiverse has 5mm sides, and I'm seeing around 5.05mm. I may need to tweak something on the Z axis. And I put together a quick design in SketchUp (a 2"x4" plaque with my ham radio call sign in raised letters) and it printed without a hitch. I was really surprised, as I had been prepared to spend a lot of time fighting with this thing.

Some random comments:

And finally, a question:

If I order the inductive sensor for auto bed leveling what kind of bed should I use? I'm currently using a thick piece of mirrored glass I got at Joann's, but I'm led to understand that I'll need a metal bed if I go with the inductive sensor, yes? This glass is dead flat, and the bed was fairly easy to level.

All in all a good first experience in the world of 3D printing. I'm still at the point where I don't know what I don't know, but it's fun learning.

The calibration cube I downloaded from Thingiverse has 5mm sides, and I'm seeing around 5.05mm. I may need to tweak something on the Z axis. And I put together a quick design in SketchUp (a 2"x4" plaque with my ham radio call sign in raised letters) and it printed without a hitch. I was really surprised, as I had been prepared to spend a lot of time fighting with this thing.

Some random comments:

- I spent a lot of time on construction, making sure things were square and making sure things moved smoothly. This printer is very quiet and smooth.

- The instructions are somewhat lacking. There are deficiencies that are known (like the stuff on the wiki) so why hasn't the documentation been updated?

- The order of assembly could be optimized.

- I had an open pin on my Arduino (A0 which drives the X stepper) wasn't soldered. Had to track that down.

- I have an open trace somewhere between the MEGA2560 and the connector for I/O 27 (which drives D6 on the display) so my display isn't working. (My Arduino looks like it was pre-owned and perhaps pre-abused.)

- Hanging the filament on the left side seems brain dead to me. I had to babysit it constantly. I need to fix that.

And finally, a question:

If I order the inductive sensor for auto bed leveling what kind of bed should I use? I'm currently using a thick piece of mirrored glass I got at Joann's, but I'm led to understand that I'll need a metal bed if I go with the inductive sensor, yes? This glass is dead flat, and the bed was fairly easy to level.

All in all a good first experience in the world of 3D printing. I'm still at the point where I don't know what I don't know, but it's fun learning.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 15, 2016 02:23AM |

Registered: 7 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 15, 2016 08:25AM |

Registered: 8 years ago Posts: 65 |

i have a Folger 20/20 i3 up and running. Wanting the add bed leveling. Found information on setting it up Marlin and the printed servo parts. I am needing some basic information from the start. Can't find an explanation of operation and parts needed. Can someone point me in the right direction?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 15, 2016 09:25AM |

Registered: 8 years ago Posts: 130 |

Sorry, only registered users may post in this forum.