Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 18, 2016 05:26PM |

Registered: 7 years ago Posts: 1 |

Quote

Toxic0n

2) My makeshift filament guides are not great - I can see them flexing under force when the print head moves. Mounting the filament on the top is not an option due to fire concerns. Does anyone have a workable solution with the stock side mount?

For me, getting the filament to feed smoothly from the side had more to do with the spool holder than the guides. I'm loving these, after printing them I was able to go back to the original Folger Tech method to guide the filament (tab attached to the motor that is in the build instructions).

Spool rollers with bearings for Folger Tech 2020:

www.thingiverse.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 18, 2016 08:12PM |

Registered: 8 years ago Posts: 314 |

I use those to, work great!Quote

GuruJoe

Quote

Toxic0n

2) My makeshift filament guides are not great - I can see them flexing under force when the print head moves. Mounting the filament on the top is not an option due to fire concerns. Does anyone have a workable solution with the stock side mount?

For me, getting the filament to feed smoothly from the side had more to do with the spool holder than the guides. I'm loving these, after printing them I was able to go back to the original Folger Tech method to guide the filament (tab attached to the motor that is in the build instructions).

Spool rollers with bearings for Folger Tech 2020:

www.thingiverse.com

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 18, 2016 11:15PM |

Registered: 8 years ago Posts: 130 |

Quote

Cyril

Quote

flatlander

Cyril's rig looks like a museum piece.

Can you be more specific? :p

It looks like it's on a pedestal and about to be enclosed in glass, all white background...the latest postmodern release from the artist know as Cyril. Maybe in a history museum 50 years from now, "This is what people did to create 3d parts." Your pictures struck me as an example of how to put these things together.

My setup is very much not that polished. Ha, ha, ha.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 18, 2016 11:38PM |

Registered: 8 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 19, 2016 04:44PM |

Registered: 7 years ago Posts: 12 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 21, 2016 05:43AM |

Registered: 8 years ago Posts: 276 |

Hey guys,

Long time since I logged in here, two things:

1. Is anyone thinking of getting the new Folgertech FT-5 CoreXY-style printer?

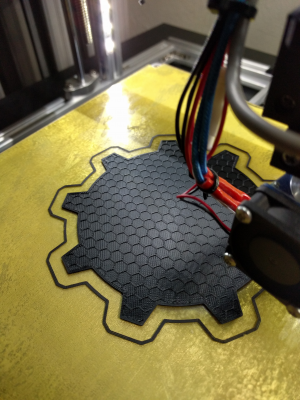

2. First print in about two months, not bad considering the filament definitely has some moisture in it...

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

Long time since I logged in here, two things:

1. Is anyone thinking of getting the new Folgertech FT-5 CoreXY-style printer?

2. First print in about two months, not bad considering the filament definitely has some moisture in it...

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 21, 2016 07:28AM |

Registered: 8 years ago Posts: 65 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 21, 2016 05:16PM |

Registered: 8 years ago Posts: 430 |

Quote

therippa

Hey guys,

Long time since I logged in here, two things:

1. Is anyone thinking of getting the new Folgertech FT-5 CoreXY-style printer?

2. First print in about two months, not bad considering the filament definitely has some moisture in it...

I think if I get another machine I will build it from scratch using someone elses plan like the cbot or the smartrap core. I really want to build a cnc router first anyway.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 21, 2016 06:38PM |

Registered: 8 years ago Posts: 367 |

Quote

msaeger

Quote

therippa

Hey guys,

Long time since I logged in here, two things:

1. Is anyone thinking of getting the new Folgertech FT-5 CoreXY-style printer?

2. First print in about two months, not bad considering the filament definitely has some moisture in it...

I think if I get another machine I will build it from scratch using someone elses plan like the cbot or the smartrap core. I really want to build a cnc router first anyway.

I recently build an Eclips3D. It not entirely a kit - there are some collections of parts you can buy and a BOM with recommendations for where to get the rest, and there is a fairly detailed instructable. So it's not quite as far as just working from plans. It ws a good compromise for me. I've yet to really get better quality of speed than I did from my Folger 2020, though I haven't spent nearly as long tuning and modifying it yet.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 22, 2016 10:57AM |

Registered: 8 years ago Posts: 130 |

Quote

WilberMaker

I have got the bed to park in the X and Y where I want but Z still stays in the position of the last print. Is this controlled on the same page in Repetier or is Arduino Marlin file controlling it? Still do not have a firm understanding of the responsibility of the two programs.

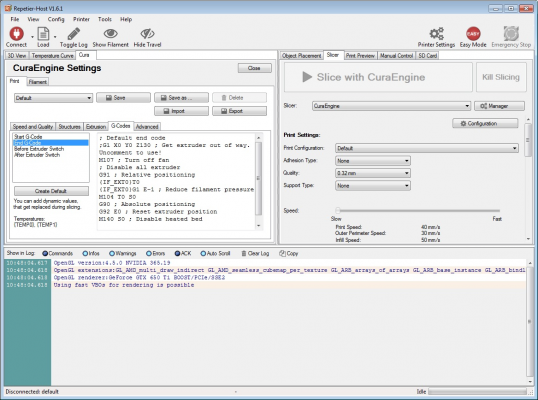

The following is a simplification. The marlin software basically helps the software know your physical machine specifications, we mostly just change the Configuration.h file. The slicer software (Cura, Slic3r, etc.) generates GCode and that is what tells the machine how to move around for a specific print. You probably just want the print head to go up 1 mm or so, home x and y, and then tell the print head to 'home' on the z-axis.

You might find the RepRap GCode Cheat Sheet helpful:

[thingiverse-production-new.s3.amazonaws.com]

In the *configuration area within Repetier-CuraEngine you will find the GCode settings for the end of a print. Comments are behind the ';' character.

Edited 1 time(s). Last edit at 05/22/2016 11:01AM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 22, 2016 04:05PM |

Registered: 8 years ago Posts: 65 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 22, 2016 04:08PM |

Registered: 8 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 22, 2016 05:08PM |

Registered: 7 years ago Posts: 2 |

Hi,

Just finishing putting together my 2020 i3, and I am hoping to get some help homing the x-axis.

Here is my problem:

I place the x-axis against the limit switch (right side of bed) and Repetier reads x = 0

From here, I can use Repetier to move the x-axis and things behave as I would expect (x = 100 is somewhere roughly in the center of the bed, +ve x moves cartridge to the left, -ve x moves cartridge to the right).

This is where things break down for me:

lets say I am at x = 100. I then hit the home button and Repetier changes to read x = 0, however the x-axis travels in the +ve x-direction, past the limit of 200, and crashes into the left end stop. I don't know where the hell it is going to...

Has anyone has a similar issue?

Just finishing putting together my 2020 i3, and I am hoping to get some help homing the x-axis.

Here is my problem:

I place the x-axis against the limit switch (right side of bed) and Repetier reads x = 0

From here, I can use Repetier to move the x-axis and things behave as I would expect (x = 100 is somewhere roughly in the center of the bed, +ve x moves cartridge to the left, -ve x moves cartridge to the right).

This is where things break down for me:

lets say I am at x = 100. I then hit the home button and Repetier changes to read x = 0, however the x-axis travels in the +ve x-direction, past the limit of 200, and crashes into the left end stop. I don't know where the hell it is going to...

Has anyone has a similar issue?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 22, 2016 05:12PM |

Registered: 7 years ago Posts: 2 |

Quote

mspeed1

Hi,

Just finishing putting together my 2020 i3, and I am hoping to get some help homing the x-axis.

Here is my problem:

I place the x-axis against the limit switch (right side of bed) and Repetier reads x = 0

From here, I can use Repetier to move the x-axis and things behave as I would expect (x = 100 is somewhere roughly in the center of the bed, +ve x moves cartridge to the left, -ve x moves cartridge to the right).

This is where things break down for me:

lets say I am at x = 100. I then hit the home button and Repetier changes to read x = 0, however the x-axis travels in the +ve x-direction, past the limit of 200, and crashes into the left end stop. I don't know where the hell it is going to...

Has anyone has a similar issue?

Changed X_HOME_DIR from 1 to -1 and that fixed things.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 22, 2016 05:13PM |

Registered: 8 years ago Posts: 65 |

Maybe your is lost. I'm in USA, Arkansas. Ordered it on May 15, tracking gave me a June 22 date. Was not expecting it and have not looked up any information yet. When I get time tonight I need to print a mount. Can you share in information? links..youtube...PDF

Quote

Cyril

Mine looks lost :/ when yours has been sent? To which country?

According to the tracking number mine is still on a plane since April 28th.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 22, 2016 05:21PM |

Registered: 8 years ago Posts: 541 |

Quote

WilberMaker

Maybe your is lost. I'm in USA, Arkansas. Ordered it on May 15, tracking gave me a June 22 date. Was not expecting it and have not looked up any information yet. When I get time tonight I need to print a mount. Can you share in information? links..youtube...PDF

[www.antclabs.com] is a good setup instruction.

If your head is stock for the 2020, this is the one you need. You can make it out of PLA too since it sits on the cooled block. [www.tinkercad.com]

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 22, 2016 08:35PM |

Registered: 8 years ago Posts: 65 |

Thank You very much for the information flatlander.

Quote

flatlander

Quote

WilberMaker

I have got the bed to park in the X and Y where I want but Z still stays in the position of the last print. Is this controlled on the same page in Repetier or is Arduino Marlin file controlling it? Still do not have a firm understanding of the responsibility of the two programs.

The following is a simplification. The marlin software basically helps the software know your physical machine specifications, we mostly just change the Configuration.h file. The slicer software (Cura, Slic3r, etc.) generates GCode and that is what tells the machine how to move around for a specific print. You probably just want the print head to go up 1 mm or so, home x and y, and then tell the print head to 'home' on the z-axis.

You might find the RepRap GCode Cheat Sheet helpful:

[thingiverse-production-new.s3.amazonaws.com]

In the *configuration area within Repetier-CuraEngine you will find the GCode settings for the end of a print. Comments are behind the ';' character.

[attachment 78491 End_GCode.jpg]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 23, 2016 07:37AM |

Registered: 8 years ago Posts: 65 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 23, 2016 08:16AM |

Registered: 8 years ago Posts: 552 |

Quote

flatlander

You probably just want the print head to go up 1 mm or so, home x and y, and then tell the print head to 'home' on the z-axis.Quote

WilberMaker

I have got the bed to park in the X and Y where I want but Z still stays in the position of the last print. Is this controlled on the same page in Repetier or is Arduino Marlin file controlling it? Still do not have a firm understanding of the responsibility of the two programs.

That sounds dangerous. Move the Z up a little bit and get the carriage out of the way by moving it to corner. Probably (X,Y) = (0,0). But do *NOT* home Z until the part is off of the print bed. Depending upon where the part is located on the print bed, you may smash the carriage into the part. Very typically, this is put into the Ending GCode by your Slic3r. That way the same thing happens on every part your print.

Edited 1 time(s). Last edit at 05/23/2016 08:19AM by Roxy.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 23, 2016 08:17AM |

Registered: 8 years ago Posts: 285 |

Quote

WilberMaker

Trying to print the mount for the BLTouch. The flange on the part is not supported but just protrudes out in the open. How do you get this to print? The Filament just falls in a birds nest until it gets big enough to support the flange. Sure I'm just missing something stupid.

Did you enable supports?

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 23, 2016 09:36AM |

Registered: 8 years ago Posts: 65 |

Enable Supports? Thanks, did not know about that. I see the option now and will give it a try tonight. I have been pleased with how much I have learned and figured out, but I fear there is a magnitude more that I am so ignorant about that I cannot even form the questions I need to answer. Bear with me I'll get there. However, still having fun.

Quote

Mach

Quote

WilberMaker

Trying to print the mount for the BLTouch. The flange on the part is not supported but just protrudes out in the open. How do you get this to print? The Filament just falls in a birds nest until it gets big enough to support the flange. Sure I'm just missing something stupid.

Did you enable supports?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 23, 2016 11:11AM |

Registered: 8 years ago Posts: 130 |

Quote

Roxy

Quote

flatlander

You probably just want the print head to go up 1 mm or so, home x and y, and then tell the print head to 'home' on the z-axis.Quote

WilberMaker

I have got the bed to park in the X and Y where I want but Z still stays in the position of the last print. Is this controlled on the same page in Repetier or is Arduino Marlin file controlling it? Still do not have a firm understanding of the responsibility of the two programs.

That sounds dangerous. Move the Z up a little bit and get the carriage out of the way by moving it to corner. Probably (X,Y) = (0,0). But do *NOT* home Z until the part is off of the print bed. Depending upon where the part is located on the print bed, you may smash the carriage into the part. Very typically, this is put into the Ending GCode by your Slic3r. That way the same thing happens on every part your print.

Good catch, probably best to leave the z axis height near end of print height. Homing z would make it easy for print head carriage 'attachments' to collide with the finished print. I think all of my prints to date are centered and small enough that it is unlikely an issue for me. It's always best to be on the correct side of caution.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 26, 2016 03:55PM |

Registered: 8 years ago Posts: 92 |

For my ending code, I have the X home and Y move the bed all the way forward, but first I raise the Z by 20 mm (assuming it's not too high of a print, and I'll have the room) This is the ending script code I use:

--Andrew

M104 S0 ; turn off extruder M140 S0 ; turn off bed G91 ; relative positioning G1 Z20 ; lift 20 mm G90 ; absolute positioning G1 X0 Y190 F4800 M84 ; disable motors

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 26, 2016 04:00PM |

Registered: 8 years ago Posts: 367 |

Quote

iamquestar

For my ending code, I have the X home and Y move the bed all the way forward, but first I raise the Z by 20 mm (assuming it's not too high of a print, and I'll have the room) This is the ending script code I use:

M104 S0 ; turn off extruder M140 S0 ; turn off bed G91 ; relative positioning G1 Z20 ; lift 20 mm G90 ; absolute positioning G1 X0 Y190 F4800 M84 ; disable motors

--Andrew

I do something very similar in my end G code, with the addition that I first call M400 to let any current moves complete. Without this I would sometimes lose a small part of the top layer.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 27, 2016 07:57AM |

Registered: 8 years ago Posts: 65 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 27, 2016 10:42AM |

Registered: 9 years ago Posts: 4 |

Hi all,

I received my 2nd I3 from Folger Tech, this time I went with the 2020 version.

I'm setting this one up for dual extruders. I printed the the one dual Z carriage I was able to find on Thingiverse but it won't work, the problem is that I am using a dual extruder block and the spacing for the nema 17s is not correct. The Thingiverse Z carriage is intended to use 2 individually assembled extruders and the spacing is to wide for use with the dual extruder block.

Does anyone have have a .stl for a Z carriage that will accommodate dual extruders with the dual extruder block? If not, do you have the critical dimensions for the single (engineering drawing, doodle napkin, 3d model in .ipt format - Autodesk Inventor) extruder so I can model a z carriage that will work?

I can do it on my own but if I had the dimensions it would save me a lot of time.

Thanks in advance, I will be working on it soon and will post the carraige I use on Thingiverse.

Cheers.

I received my 2nd I3 from Folger Tech, this time I went with the 2020 version.

I'm setting this one up for dual extruders. I printed the the one dual Z carriage I was able to find on Thingiverse but it won't work, the problem is that I am using a dual extruder block and the spacing for the nema 17s is not correct. The Thingiverse Z carriage is intended to use 2 individually assembled extruders and the spacing is to wide for use with the dual extruder block.

Does anyone have have a .stl for a Z carriage that will accommodate dual extruders with the dual extruder block? If not, do you have the critical dimensions for the single (engineering drawing, doodle napkin, 3d model in .ipt format - Autodesk Inventor) extruder so I can model a z carriage that will work?

I can do it on my own but if I had the dimensions it would save me a lot of time.

Thanks in advance, I will be working on it soon and will post the carraige I use on Thingiverse.

Cheers.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 27, 2016 10:29PM |

Registered: 7 years ago Posts: 129 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 27, 2016 10:44PM |

Registered: 8 years ago Posts: 367 |

Quote

av8r1

So why do my end stop mounts prevent the various parts of the printer from depressing the microswitch?

It's a problem several of us have had. You can try filing the endstop mount down a little, or attaching the switch at an angle to the endstop. Here is a hacked up replacement I did for the Z end stop: [www.thingiverse.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 28, 2016 11:51AM |

Registered: 8 years ago Posts: 65 |

I was trying to set up the BLTouch and ran into problems. My plan is to back up and take a systemic approach and make small changes and check them along the way this time. When I backed up I reloaded the original file and everything is working correctly. With the printer working I went to the Folger Wikia and started with upgrading Marlin from the provided link and got a verison stating "The Release branch contains the latest tagged version of Marlin (currently 1.0.2 – January 2015)". I was thinking I was wanting 1.1.0RC3. If that is correct can someone provide a link? Anyway I went with the Wikia verison. I had already moved the X endstop to the left side of the bed so that was not changed. in order to get x working properly I left the x end stop plugged into the last set of pins to the right on the Ramps board.

The settings:

In Repetier

Home X is set to MIN

Invert Direction under controls not checked

In Arduino

#define X_HOME_DIR -1

With these setting the endstop works and the head moves in the correct direction. My problem comes from when I try to print the extruder is not feeding filament but running backwards and unloading. Will a newer version of Marlin fix this or what settings need changing.

Thanks Sam

The settings:

In Repetier

Home X is set to MIN

Invert Direction under controls not checked

In Arduino

#define X_HOME_DIR -1

With these setting the endstop works and the head moves in the correct direction. My problem comes from when I try to print the extruder is not feeding filament but running backwards and unloading. Will a newer version of Marlin fix this or what settings need changing.

Thanks Sam

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 28, 2016 02:59PM |

Registered: 7 years ago Posts: 10 |

Sorry, only registered users may post in this forum.

Were do you find the version number of the Marlin file?

Were do you find the version number of the Marlin file?