Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 28, 2016 07:24PM |

Registered: 8 years ago Posts: 130 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 28, 2016 10:08PM |

Registered: 7 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 28, 2016 11:13PM |

Registered: 8 years ago Posts: 65 |

Thanks guys. Spent a lot of time today working with the Configuration.h file and understand it a little better. Got up and running with Marlin 1.1.0-RC3. (Without bed leveling) Started working with the BLTouch and back to digging for answers. Can you tell me if I have a Ramps 1.3 or a 1.4? Looks like I had it configured for a 1.3 and the BLTouch instructions want you to select a Ramps 1.4. What is the difference?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 29, 2016 08:27AM |

Registered: 8 years ago Posts: 65 |

Doesn't seem to mater if it is Ramps 1.3 or 1.4 are used. Both seem to work, but using 1.4. Got the BLTouch functioning, but now I have changed something that will not allow X and Y homing. Moving in the correct direction but will only move about 10mm and the endstops not controlling anything. Any clue what I should check?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 29, 2016 10:51AM |

Registered: 8 years ago Posts: 130 |

Quote

WilberMaker

Doesn't seem to mater if it is Ramps 1.3 or 1.4 are used. Both seem to work, but using 1.4. Got the BLTouch functioning, but now I have changed something that will not allow X and Y homing. Moving in the correct direction but will only move about 10mm and the endstops not controlling anything. Any clue what I should check?

I have similar glitchyness until I get all axes homed for the first time. M119 is my friend for this issue. M114 (Get Current Position) would be my go to for checking where the machine thinks it the nozzle is.

Also, I had to fiddle with the ENDSTOPPULLUP block of code...unfortunately I don't remember what needing tweaking.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 29, 2016 11:44PM |

Registered: 7 years ago Posts: 2 |

I actually had to swap two of the wires in the harness going to my extruder motor. A standard harness to an extruder has a wire order of red-yellow-grey-green. My extruder harness was red-grey-yellow-green. Once I swapped the two inner wires, the extruder worked fine with no changes to Marlin. Good luck!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 30, 2016 05:38PM |

Registered: 8 years ago Posts: 65 |

Still beating my head against the wall. Thought I about had the BLTouch working Now the printer refuses to do any homeing at all. I give it G28 and the Z axis starts going up. This is before it trys to do anything with X or Y. Would someone be so kind as to take a look at my configration.h file and see if you can identify the problem. Also, might be nice to see someone else's 2020 i3 configration.h file if I may.

Thanks

Thanks

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 30, 2016 06:25PM |

Registered: 7 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 30, 2016 07:51PM |

Registered: 7 years ago Posts: 129 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 30, 2016 08:01PM |

Registered: 7 years ago Posts: 43 |

Quote

av8r1

I'm going to email Folger directly about this, but I'll post it here, too: Why did my 2020 kit come with so much extra hardware?

Same for me, but still good to have spare parts.

For example I had like 20 m3x30 that I never used when assembling the kit... Here is a picture of what was left after full assembly.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 30, 2016 09:10PM |

Registered: 8 years ago Posts: 65 |

@ Cyril - Your Marlin Configuration.h looks a lot different then mine. Is it a different branch? Notice even hardware selections are different, you have a 2020i3 right? How old?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 30, 2016 09:15PM |

Registered: 8 years ago Posts: 65 |

Looks like the same items and count that I had left over. I'm thankful for it, used a lot of it already. Your not complaining about spares are you?

Quote

Cyril

Quote

av8r1

I'm going to email Folger directly about this, but I'll post it here, too: Why did my 2020 kit come with so much extra hardware?

Same for me, but still good to have spare parts.

For example I had like 20 m3x30 that I never used when assembling the kit... Here is a picture of what was left after full assembly.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 30, 2016 09:15PM |

Registered: 7 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 31, 2016 11:41AM |

Registered: 7 years ago Posts: 9 |

Hi, i built my 2020 this last weekend and have a couple of questions:

1) mine seemed to have the X axis flipped so everything i printed was backwards. I figured this out by looking in this thread and following a solution that was posted. Now it homes correctly to X but when it does it moves over, clicks the switch, goes back a little to the left then goes right again and clicks the switch. It doesn't bother me too much, but it would be nice if it didn't. Does anyone have this behavior on theirs? None of my other stops do that when they home, very odd.

2) My power supply died already - a day and a half after i first ran it. Has anyone run one of these with an XBOX ps, or any other power supplies? I'd really like one that is in the form factor that shipped with the printer. I am looking at maybe a Mean Well SPV-300-12.

Otherwise I have really enjoyed putting this together and am very anxious to get it running again, as is my son.

1) mine seemed to have the X axis flipped so everything i printed was backwards. I figured this out by looking in this thread and following a solution that was posted. Now it homes correctly to X but when it does it moves over, clicks the switch, goes back a little to the left then goes right again and clicks the switch. It doesn't bother me too much, but it would be nice if it didn't. Does anyone have this behavior on theirs? None of my other stops do that when they home, very odd.

2) My power supply died already - a day and a half after i first ran it. Has anyone run one of these with an XBOX ps, or any other power supplies? I'd really like one that is in the form factor that shipped with the printer. I am looking at maybe a Mean Well SPV-300-12.

Otherwise I have really enjoyed putting this together and am very anxious to get it running again, as is my son.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 31, 2016 07:37PM |

Registered: 8 years ago Posts: 130 |

Quote

OneSprague

Hi, i built my 2020 this last weekend and have a couple of questions:

1) mine seemed to have the X axis flipped so everything i printed was backwards. I figured this out by looking in this thread and following a solution that was posted. Now it homes correctly to X but when it does it moves over, clicks the switch, goes back a little to the left then goes right again and clicks the switch. It doesn't bother me too much, but it would be nice if it didn't. Does anyone have this behavior on theirs? None of my other stops do that when they home, very odd.

I'm getting some 'bouncing' when the x axis home's, while using Repetier-host just like you describe. It homes with extreme velocity and the it 'complies'. It's a new-ish glitch that wasn't there about a month ago.

Just after loading repetiier-host The x-axis appears to be "TRIGGERED' (M119 GCode) when it is not on my machine...

Once I get everything "homed' the prints do work. I plan to bang my head against this at some point.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 31, 2016 07:42PM |

Registered: 7 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 31, 2016 07:48PM |

Registered: 8 years ago Posts: 367 |

Quote

Cyril

Mine is bouncing twice on all axis as well when reaching the end stops, I think that's a normal behaviour in Marlin code.

I think the idea is to do a fast homing move to find roughly where the limit is, then a slower one to find the position more accurately. However, it seems like this would only matter if you want to get the home position exactly right in a repeatable way. So it matter for the Z axes, but less for X and Y.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 31, 2016 07:49PM |

Registered: 8 years ago Posts: 92 |

Quote

OneSprague

Hi, i built my 2020 this last weekend and have a couple of questions:

1) mine seemed to have the X axis flipped so everything i printed was backwards. I figured this out by looking in this thread and following a solution that was posted. Now it homes correctly to X but when it does it moves over, clicks the switch, goes back a little to the left then goes right again and clicks the switch. It doesn't bother me too much, but it would be nice if it didn't. Does anyone have this behavior on theirs? None of my other stops do that when they home, very odd.

2) My power supply died already - a day and a half after i first ran it. Has anyone run one of these with an XBOX ps, or any other power supplies? I'd really like one that is in the form factor that shipped with the printer. I am looking at maybe a Mean Well SPV-300-12.

Otherwise I have really enjoyed putting this together and am very anxious to get it running again, as is my son.

Call or email Folger Tech about the power supply. I'm sure they will send you a replacement. My kit had a bad hot end thermistor, and the stepper drivers were installed with the pins OVER the socket, so nothing would work. I explained the problem with the hot end, included pics of the poorly assembled controller, and they sent me a whole new hot end and full arduino/ramps/drivers setup, without being asked. I was floored by their efforts to make things right. (I really only expected a new thermistor, as I thought I could bend pins and sockets back into alignment to make the RAMPS work.)

I have seen vids where an xbox PS was used, but haven't done so myself. Really all you need to something to supply plenty of 12v. current. Depending on where you are, the biggest issue with the replacement from FT is the shipping time. My replacement parts took a week (to the west coast). If you're more in a hurry, and have Amazon Prime (or are willing to pay for the faster shipping) you can have this is a couple days for $22 (+shipping w/o Prime):

eTopxizu 12v 30a Dc Universal Regulated Switching Power Supply 360w: [www.amazon.com]

It looks almost exactly like the one shipped with the printer.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 31, 2016 08:14PM |

Registered: 8 years ago Posts: 92 |

So something happened to my electronics over the weekend, and I really don't have a clue what did it. I built an enclosure to help with heat retention during ABS prints. In the process, I disconnected most things from the RAMPS and made all my wires nice and neat. I was extremely cautious about making sure everything was hooked up correctly.

Once all was reassembled, and did several tests with axis motion, hot end heating etc. Homing and auto leveling all worked great. When it finally came time to print some parts is when things died. The only thing I hadn't done at this point was heating of the bed. I hadn't actually disconnected the bed from the ramps. These were ABS parts, so I saved the gcode to the SD card, and started the print. The bed takes several min. to get up to 100c so as I was waiting for the print to start, I was puttering around, organizing my work bench, and cleaning up the general clutter that so quickly overwhelms my maker space. I glanced over at the printer, and the display (a 2004) was all white. I could just barely make out the info text was still there, and the bed was at 60c and falling (both temps set at 0 now).

After a short expletive, I turned the machine off then back on again. The LCD was still almost all white, with really faint letter on the info screen. I could navigate menus, but couldn't access the SD card. It would show card inserted, then would state there was no card, when I selected the print from SD option. It seems like it was just the display that died, so I decided to give it a shot via USB.

The short of it: USB didn't work. When only powering the arduino via USB, it works fine, and connects to the computer fine. The host is able to see the thermistor readings etc. Oh, also the display looks fine when like this as well. As soon as I turn on main power (for the printer), the display goes all white, and I can no longer communicate with the arduino.

Thankfully I had a spare arduino/RAMPS kit I was able to swap in. (I connected everything exactly as before, so I know there wasn't a problem there). I flashed the new setup with the current firmware I'm using, and am back up and running, but I'm still puzzled at what could have happened to the other one.

I can understand if it died as soon as powering it up, or even immediately upon starting a heater, but for it be fine for a few minutes, then die... It's strange. I did not hear anything, nor see/smell any of the magic smoke. A visual inspection of both boards showed no obvious damage.

Any ideas? I was really hoping to use this spare controller on my next project: a CNC router. I'll obviously have to purchase a new one, but I'd like some idea of what I need to be careful of in the future, or if there is a way to determine the problem is with the RAMPS or Arduino.

Thanks in advance for any words of wisdom.

--Andrew

Once all was reassembled, and did several tests with axis motion, hot end heating etc. Homing and auto leveling all worked great. When it finally came time to print some parts is when things died. The only thing I hadn't done at this point was heating of the bed. I hadn't actually disconnected the bed from the ramps. These were ABS parts, so I saved the gcode to the SD card, and started the print. The bed takes several min. to get up to 100c so as I was waiting for the print to start, I was puttering around, organizing my work bench, and cleaning up the general clutter that so quickly overwhelms my maker space. I glanced over at the printer, and the display (a 2004) was all white. I could just barely make out the info text was still there, and the bed was at 60c and falling (both temps set at 0 now).

After a short expletive, I turned the machine off then back on again. The LCD was still almost all white, with really faint letter on the info screen. I could navigate menus, but couldn't access the SD card. It would show card inserted, then would state there was no card, when I selected the print from SD option. It seems like it was just the display that died, so I decided to give it a shot via USB.

The short of it: USB didn't work. When only powering the arduino via USB, it works fine, and connects to the computer fine. The host is able to see the thermistor readings etc. Oh, also the display looks fine when like this as well. As soon as I turn on main power (for the printer), the display goes all white, and I can no longer communicate with the arduino.

Thankfully I had a spare arduino/RAMPS kit I was able to swap in. (I connected everything exactly as before, so I know there wasn't a problem there). I flashed the new setup with the current firmware I'm using, and am back up and running, but I'm still puzzled at what could have happened to the other one.

I can understand if it died as soon as powering it up, or even immediately upon starting a heater, but for it be fine for a few minutes, then die... It's strange. I did not hear anything, nor see/smell any of the magic smoke. A visual inspection of both boards showed no obvious damage.

Any ideas? I was really hoping to use this spare controller on my next project: a CNC router. I'll obviously have to purchase a new one, but I'd like some idea of what I need to be careful of in the future, or if there is a way to determine the problem is with the RAMPS or Arduino.

Thanks in advance for any words of wisdom.

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 31, 2016 08:56PM |

Registered: 7 years ago Posts: 129 |

A couple extra of this and that are okay, but some of this stuff is really excessive. We never used one of those springs, for example. I guess we're supposed to CAD up and print out some clips to hold the glass plate down? And I'm still not sure where those jelly beans are supposed to go.

One thing that wasn't in the kit that should be: An off switch!

There are a few things I'll have to figure out, like I'd like it to shut down the bed heater when it finishes a print. Right now it sits around wasting power.

One thing that wasn't in the kit that should be: An off switch!

There are a few things I'll have to figure out, like I'd like it to shut down the bed heater when it finishes a print. Right now it sits around wasting power.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 31, 2016 10:12PM |

Registered: 8 years ago Posts: 541 |

Quote

WilberMaker

Looks like the same items and count that I had left over. I'm thankful for it, used a lot of it already. Your not complaining about spares are you?

Quote

Cyril

Quote

av8r1

I'm going to email Folger directly about this, but I'll post it here, too: Why did my 2020 kit come with so much extra hardware?

Same for me, but still good to have spare parts.

For example I had like 20 m3x30 that I never used when assembling the kit... /quote]

Those long bolts come in handy. You can cut them down to any size you need using wire cutters/stripper.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 31, 2016 10:16PM |

Registered: 8 years ago Posts: 541 |

Quote

WilberMaker

Still beating my head against the wall. Thought I about had the BLTouch working Now the printer refuses to do any homeing at all. I give it G28 and the Z axis starts going up. This is before it trys to do anything with X or Y. Would someone be so kind as to take a look at my configration.h file and see if you can identify the problem. Also, might be nice to see someone else's 2020 i3 configration.h file if I may.

Thanks

Is your BLTOUCH flashing when Z goes up? It's sending an error code that for some reason tells Z to go up. You have to get rid of the error code/flashing light. Push the pin up before powering the BLTOUCH and it should go up and down 3 times and then stay up with the light on solid. If it doesn't, you may be like me and need an external 5 volt supply for it.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 31, 2016 10:30PM |

Registered: 8 years ago Posts: 285 |

Quote

av8r1

A couple extra of this and that are okay, but some of this stuff is really excessive. We never used one of those springs, for example. I guess we're supposed to CAD up and print out some clips to hold the glass plate down? And I'm still not sure where those jelly beans are supposed to go.

One thing that wasn't in the kit that should be: An off switch!

There are a few things I'll have to figure out, like I'd like it to shut down the bed heater when it finishes a print. Right now it sits around wasting power.

There is a setting in rep-host to automatically disable the bed. printer settings > printer > disable heated bed after job/kill. You can also do this by adding M140 S0 to your custom end gcode.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) May 31, 2016 11:22PM |

Registered: 8 years ago Posts: 65 |

tjnamtiw, I think you might be right. It is flashing while going up. I did not know the error would cause that. I have problems getting it to repeat the same problem enough to figure out what exactly it is doing. That also says voltage problem. Have a power strip on the bench behind the printer with two 2.1A USB plugs. That should be enough power. Have to try it later, connected the Z endstop back up tonight so I can play with the printer some more.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 01, 2016 12:54AM |

Registered: 8 years ago Posts: 92 |

Have any of you who have built an enclosure had issues with overheating motors?

I just finished an enclosure, and it only helped a little with warping on an ABS print that was commissioned. The part has a fairly significant amount of material in the first 15mm of Z (XY dimensions are ~70x120).and as the upper layers get further from the bed, they are cooling too much, and pulling one end off the bed. I'm using BuildTek and it's HARD to get parts off most of the time.

I've built an enclosure, but I don't think it's keeping it hot enough in there because it only helped a little. I'm thinking about adding a heater for warming the space, but I'm worried about the motors. If they are operating in an ambient temp of 60-70c, will they overheat? Is that hot enough to eliminate or limit warping?

(BTW, the power supply and controller board are outside the enclosure)

--Andrew

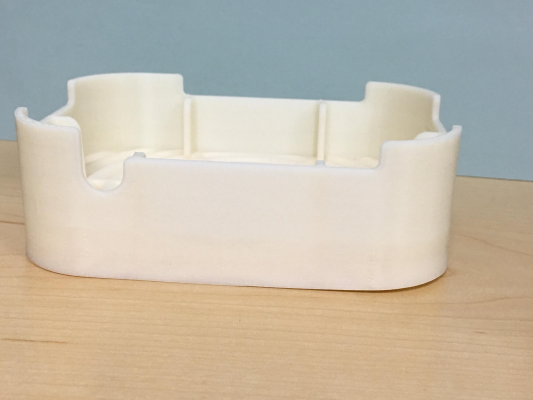

Part with warping:

Edited 1 time(s). Last edit at 06/01/2016 01:04AM by iamquestar.

I just finished an enclosure, and it only helped a little with warping on an ABS print that was commissioned. The part has a fairly significant amount of material in the first 15mm of Z (XY dimensions are ~70x120).and as the upper layers get further from the bed, they are cooling too much, and pulling one end off the bed. I'm using BuildTek and it's HARD to get parts off most of the time.

I've built an enclosure, but I don't think it's keeping it hot enough in there because it only helped a little. I'm thinking about adding a heater for warming the space, but I'm worried about the motors. If they are operating in an ambient temp of 60-70c, will they overheat? Is that hot enough to eliminate or limit warping?

(BTW, the power supply and controller board are outside the enclosure)

--Andrew

Part with warping:

Edited 1 time(s). Last edit at 06/01/2016 01:04AM by iamquestar.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 01, 2016 01:41AM |

Registered: 8 years ago Posts: 93 |

Quote

WilberMaker

tjnamtiw, I think you might be right. It is flashing while going up. I did not know the error would cause that. I have problems getting it to repeat the same problem enough to figure out what exactly it is doing. That also says voltage problem. Have a power strip on the bench behind the printer with two 2.1A USB plugs. That should be enough power. Have to try it later, connected the Z endstop back up tonight so I can play with the printer some more.

The flashing means the BLTouch is in an error state. When it is in an error state, for safety it will always report that it is touching the bed. That's what makes Marlin go up and up. It activates the probe and immediately gets a signal that it is touching, so it things the current height is 0 and goes up to the "raise between z probes" height for the next check. The next check will also immediately report contact, and thus it just keeps going up until it is done checking.

The important thing is to figure out why it is getting into an error state.

It can happen if the z is too low when the printer turns on or resets. If the BLTouch tries to self-test, and can't deploy the pin completely, it will go into an error state.

It can have an error if the pin sticks and doesn't deploy. This can happen if you raise it up too high using the setscrew in the top of the BLTouch, or if the pin gets glue or hairspray, or whatever other bed adhesive you use on it.

Like tjnamtiw said, it can also happen if you don't have enough current for the BLTouch. I never had this problem with mine. Many others have also had it work fine with power from the ramps board. My only difference from stock in this regard, is that I'm not using the original Folger Arduino board. A short in my original LCD fried mine, and I swapped it with another I had lying around. It might be the one I'm using has a better voltage regulator, although that seems unlikely.

Once it is in an error state, it won't work correctly until it is reset. I put the reset command in my start gcode in my slicers.

M280 P0 S160 ; Reset BLTouch

Be sure you put it before the Home (G28) and autolevel (G29). I also like to add a raise before the reset, to make sure the probe has room to deploy.

Here's my full start code for Cura:

;Sliced at: {day} {date} {time}

;Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density}

;Print time: {print_time}

;Filament used: {filament_amount}m {filament_weight}g

;Filament cost: {filament_cost}

M140 S{print_bed_temperature} ; Start heating bed

G1 Z10 ; Raise head 10

M400 ; Wait for all moves to finish

M280 P0 S160 ; Reset BLTouch

G28 ; Home all axis

G29 ; Auto Level

G21 ;metric values

G90 ;absolute positioning

M107 ;start with the fan off

M82 ;set extruder to absolute mode

G1 X25 Y0 F{travel_speed} ; Move to start wipe position

G1 Z0.05 ; move nozzle close to bed (0.05)

M109 S{print_temperature} ; Heat nozzle and wait until ready

M190 S{print_bed_temperature} ; Now wait until bed is hot

G92 E0 ; zero the extruder position

G1 X25 Y0 Z.35 F900 ; Move up to 0.35

G1 X0 Y0 Z.15 E5 F225 ; Move the 25mm to 0,0 lowering head as you go, and extruding 5mm

G1 X0 Y25 Z5 F3600 ; Move 25mm to 0,25 raising head to 5mm

M400 ; wait until we get there

G92 E0 ; zero the extruder position

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing...

For Slic3r the only difference is the variable names for the temperatures and stuff:

M140 S[first_layer_bed_temperature] ; start heating bed G1 Z10 ; Raise head 10 M400 ; Wait for all moves to finish M280 P0 S160 ; Reset BLTouch G28 ; home all axes G29 ; Auto Level G90; absolute coordinates G1 X25 Y0 ; Move to start position of wipe 25,0 G1 Z0.05 ; move nozzle close to bed (0.05) M109 S[first_layer_temperature] ; heat nozzle and wait until reached M190 S[first_layer_bed_temperature] ; wait for bed temperature M82 ; use absolute distances for extruder G92 E0 ; zero the extruder position G1 X25 Y0 Z.35 F900 ; Move up to 0.35 G1 X0 Y0 Z.15 E5 F225 ; Move the 25mm to 0,0 lowering head as you go, and extruding 5mm G1 X0 Y25 Z5 F3600 ; Move 25mm to 0,25 raising head to 5mm M400 ; wait until we get there G92 E0 ; zero the extruder position M117 Printing...

Also, just for completeness, here is what my end code looks like:

M400 ; Wait for the buffer to clear M104 S0 ; turn off nozzle heater M140 S0 ; turn off heat bed G91 ; Switch to relative movement G1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure G1 Z10 F5000 ; move z up 10 G90 ; Back to absolute positioning G1 X0 Y185 F5000 ; Move bed forward and head to left M400 ; Wait for movements to finish M84 ; disable motors

The same end code should work for Cura or Slic3r.

Edited 3 time(s). Last edit at 06/01/2016 01:53AM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 01, 2016 01:54AM |

Registered: 7 years ago Posts: 129 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 01, 2016 08:39AM |

Registered: 7 years ago Posts: 1 |

Ok so i tried looking through the forum before posting my question, but it seems that it would be like finding a needle in a hay stack with the amount of post on here. So i got my printer put together and installed all the software, but when i get to the configuration set up, go through all the printer configurations and then try to CONNECT to the printer i get a fatal error " correct error then continue." So i dont want to go switching wires around trying to figure out what is wrong, I did notice that are some inconsistencies between the beta, and released manuals on top of some conflicting instructions in the release manual itself.

1) The heated bed is shown wired two different ways in the released manual

2) The End stop for the y axis i think is shown in both the 7th and 6th column of pins, between the beta and released manual.

Those are all the errors in the latest version of the manual. Which both or none could be causing my error.\

In the Arduino IDE i did notice that you can now only pick between either the Mega 2550 or the Mega ADK but not both that could also cause the issue.

One more bit of info is that the heated bed is not getting hot and in the fetal Error Box i get, The message also says that the temp has been reset, and that i can use m9696 to reset the printer. Well that is what i have so far. seems that this community is pretty helpful. hope i can use my printer at least once before it breaks.

1) The heated bed is shown wired two different ways in the released manual

2) The End stop for the y axis i think is shown in both the 7th and 6th column of pins, between the beta and released manual.

Those are all the errors in the latest version of the manual. Which both or none could be causing my error.\

In the Arduino IDE i did notice that you can now only pick between either the Mega 2550 or the Mega ADK but not both that could also cause the issue.

One more bit of info is that the heated bed is not getting hot and in the fetal Error Box i get, The message also says that the temp has been reset, and that i can use m9696 to reset the printer. Well that is what i have so far. seems that this community is pretty helpful. hope i can use my printer at least once before it breaks.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 01, 2016 10:19AM |

Registered: 9 years ago Posts: 4 |

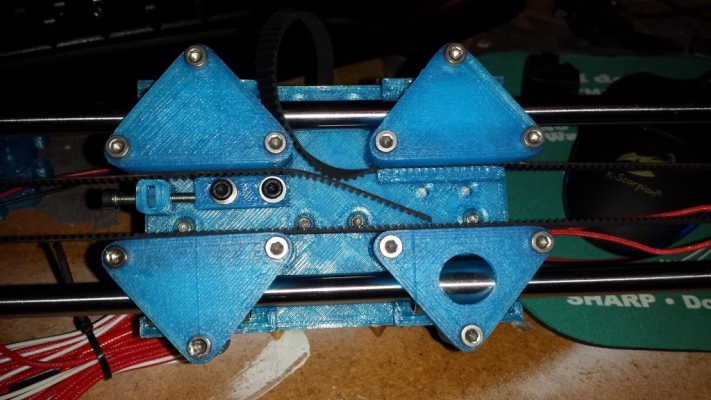

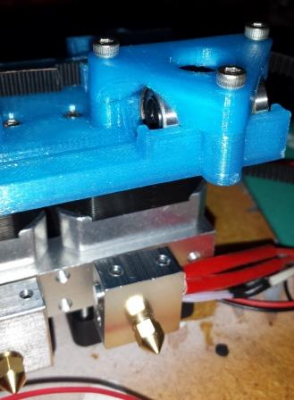

I heard back from Folger Tech and they aren't supporting dual head yet, and since I haven't heard back from anyone here I had to take matters into my own hands and create a dual extruder carriage. Here's the result so far; I still have a few tweaks and need to finish assembly to test but I'm pretty happy with it so far. It works with the Folger Tech dual block, uses 4 bearings and I have eliminated zip ties. It also has a belt tensioner built in.

Edited 2 time(s). Last edit at 06/01/2016 12:01PM by betteron2wheels.

Edited 2 time(s). Last edit at 06/01/2016 12:01PM by betteron2wheels.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 01, 2016 10:25AM |

Registered: 8 years ago Posts: 130 |

Quote

iamquestar

So something happened to my electronics over the weekend, and I really don't have a clue what did it. I built an enclosure to help with heat retention during ABS prints. In the process, I disconnected most things from the RAMPS and made all my wires nice and neat. I was extremely cautious about making sure everything was hooked up correctly.

Once all was reassembled, and did several tests with axis motion, hot end heating etc. Homing and auto leveling all worked great. When it finally came time to print some parts is when things died. The only thing I hadn't done at this point was heating of the bed. I hadn't actually disconnected the bed from the ramps. These were ABS parts, so I saved the gcode to the SD card, and started the print. The bed takes several min. to get up to 100c so as I was waiting for the print to start, I was puttering around, organizing my work bench, and cleaning up the general clutter that so quickly overwhelms my maker space. I glanced over at the printer, and the display (a 2004) was all white. I could just barely make out the info text was still there, and the bed was at 60c and falling (both temps set at 0 now).

After a short expletive, I turned the machine off then back on again. The LCD was still almost all white, with really faint letter on the info screen. I could navigate menus, but couldn't access the SD card. It would show card inserted, then would state there was no card, when I selected the print from SD option. It seems like it was just the display that died, so I decided to give it a shot via USB.

The short of it: USB didn't work. When only powering the arduino via USB, it works fine, and connects to the computer fine. The host is able to see the thermistor readings etc. Oh, also the display looks fine when like this as well. As soon as I turn on main power (for the printer), the display goes all white, and I can no longer communicate with the arduino.

Thankfully I had a spare arduino/RAMPS kit I was able to swap in. (I connected everything exactly as before, so I know there wasn't a problem there). I flashed the new setup with the current firmware I'm using, and am back up and running, but I'm still puzzled at what could have happened to the other one.

I can understand if it died as soon as powering it up, or even immediately upon starting a heater, but for it be fine for a few minutes, then die... It's strange. I did not hear anything, nor see/smell any of the magic smoke. A visual inspection of both boards showed no obvious damage.

Any ideas? I was really hoping to use this spare controller on my next project: a CNC router. I'll obviously have to purchase a new one, but I'd like some idea of what I need to be careful of in the future, or if there is a way to determine the problem is with the RAMPS or Arduino.

Thanks in advance for any words of wisdom.

--Andrew

I have a suspect 5V regulator on my Mega. A 2.0A powered USB hub is my band-aid for now. There's no telling how much amperage my PC's USB can provide. If you look at the 5V regulators on devices, from like 15 years ago, they are huge, with a hole for a monster heatsink. Our little ole surface mount regulators barely stand a chance.

Sorry, only registered users may post in this forum.