Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 01, 2016 11:29AM |

Registered: 8 years ago Posts: 130 |

Quote

Ozenith65OrDie

Ok so i tried looking through the forum before posting my question, but it seems that it would be like finding a needle in a hay stack with the amount of post on here. So i got my printer put together and installed all the software, but when i get to the configuration set up, go through all the printer configurations and then try to CONNECT to the printer i get a fatal error " correct error then continue." So i dont want to go switching wires around trying to figure out what is wrong, I did notice that are some inconsistencies between the beta, and released manuals on top of some conflicting instructions in the release manual itself.

1) The heated bed is shown wired two different ways in the released manual

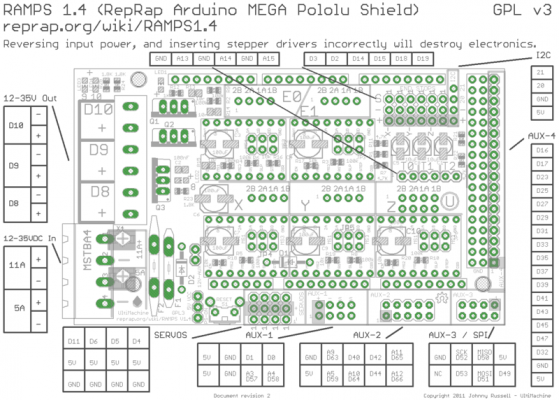

For my heatbed I have pins 2 and 3 soldered together with the black wire (16 Guage) going to the negative connector of D8 on the ramps board. The red wire (16 guage) goes to the positive D8 connector.

I'm am using the following in Arduino:Quote

Ozenith65OrDie

2) The End stop for the y axis i think is shown in both the 7th and 6th column of pins, between the beta and released manual.

Those are all the errors in the latest version of the manual. Which both or none could be causing my error.\

In the Arduino IDE i did notice that you can now only pick between either the Mega 2550 or the Mega ADK but not both that could also cause the issue.

Quote

Ozenith65OrDie

One more bit of info is that the heated bed is not getting hot and in the fetal Error Box i get, The message also says that the temp has been reset, and that i can use m9696 to reset the printer. Well that is what i have so far. seems that this community is pretty helpful. hope i can use my printer at least once before it breaks.

Could you give the links for the manuals you are using.

It sounds like there is a thermal runaway issue either in the Configuration.h file or the thermistor is damaged or miswired. The machine may not be able to find the thermistor...

I had to change the thermal runaway hysteresis as follows:

// Parameters for all extruder heaters #define THERMAL_RUNAWAY_PROTECTION_PERIOD 40 //in seconds #define THERMAL_RUNAWAY_PROTECTION_HYSTERESIS 5 // in degree Celsius // If you want to enable this feature for your bed heater, // uncomment the 2 defines below: // Parameters for the bed heater #define THERMAL_RUNAWAY_PROTECTION_BED_PERIOD 60 //in seconds #define THERMAL_RUNAWAY_PROTECTION_BED_HYSTERESIS 5 // in degree Celsius

These are my best guesses without seeing the machine.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 01, 2016 09:05PM |

Registered: 8 years ago Posts: 541 |

Quote

Bert3D

Quote

WilberMaker

tjnamtiw, I think you might be right. It is flashing while going up. I did not know the error would cause that. I have problems getting it to repeat the same problem enough to figure out what exactly it is doing. That also says voltage problem. Have a power strip on the bench behind the printer with two 2.1A USB plugs. That should be enough power. Have to try it later, connected the Z endstop back up tonight so I can play with the printer some more.

The flashing means the BLTouch is in an error state. When it is in an error state, for safety it will always report that it is touching the bed. That's what makes Marlin go up and up. It activates the probe and immediately gets a signal that it is touching, so it things the current height is 0 and goes up to the "raise between z probes" height for the next check. The next check will also immediately report contact, and thus it just keeps going up until it is done checking.

The important thing is to figure out why it is getting into an error state.

It can happen if the z is too low when the printer turns on or resets. If the BLTouch tries to self-test, and can't deploy the pin completely, it will go into an error state.

It can have an error if the pin sticks and doesn't deploy. This can happen if you raise it up too high using the setscrew in the top of the BLTouch, or if the pin gets glue or hairspray, or whatever other bed adhesive you use on it.

Like tjnamtiw said, it can also happen if you don't have enough current for the BLTouch. I never had this problem with mine. Many others have also had it work fine with power from the ramps board. My only difference from stock in this regard, is that I'm not using the original Folger Arduino board. A short in my original LCD fried mine, and I swapped it with another I had lying around. It might be the one I'm using has a better voltage regulator, although that seems unlikely.

Once it is in an error state, it won't work correctly until it is reset. I put the reset command in my start gcode in my slicers.

M280 P0 S160 ; Reset BLTouch

Be sure you put it before the Home (G28) and autolevel (G29). I also like to add a raise before the reset, to make sure the probe has room to deploy.

Here's my full start code for Cura:

;Sliced at: {day} {date} {time} ;Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density} ;Print time: {print_time} ;Filament used: {filament_amount}m {filament_weight}g ;Filament cost: {filament_cost} M140 S{print_bed_temperature} ; Start heating bed G1 Z10 ; Raise head 10 M400 ; Wait for all moves to finish M280 P0 S160 ; Reset BLTouch G28 ; Home all axis G29 ; Auto Level G21 ;metric values G90 ;absolute positioning M107 ;start with the fan off M82 ;set extruder to absolute mode G1 X25 Y0 F{travel_speed} ; Move to start wipe position G1 Z0.05 ; move nozzle close to bed (0.05) M109 S{print_temperature} ; Heat nozzle and wait until ready M190 S{print_bed_temperature} ; Now wait until bed is hot G92 E0 ; zero the extruder position G1 X25 Y0 Z.35 F900 ; Move up to 0.35 G1 X0 Y0 Z.15 E5 F225 ; Move the 25mm to 0,0 lowering head as you go, and extruding 5mm G1 X0 Y25 Z5 F3600 ; Move 25mm to 0,25 raising head to 5mm M400 ; wait until we get there G92 E0 ; zero the extruder position G1 F{travel_speed} ;Put printing message on LCD screen M117 Printing...

For Slic3r the only difference is the variable names for the temperatures and stuff:

M140 S[first_layer_bed_temperature] ; start heating bed G1 Z10 ; Raise head 10 M400 ; Wait for all moves to finish M280 P0 S160 ; Reset BLTouch G28 ; home all axes G29 ; Auto Level G90; absolute coordinates G1 X25 Y0 ; Move to start position of wipe 25,0 G1 Z0.05 ; move nozzle close to bed (0.05) M109 S[first_layer_temperature] ; heat nozzle and wait until reached M190 S[first_layer_bed_temperature] ; wait for bed temperature M82 ; use absolute distances for extruder G92 E0 ; zero the extruder position G1 X25 Y0 Z.35 F900 ; Move up to 0.35 G1 X0 Y0 Z.15 E5 F225 ; Move the 25mm to 0,0 lowering head as you go, and extruding 5mm G1 X0 Y25 Z5 F3600 ; Move 25mm to 0,25 raising head to 5mm M400 ; wait until we get there G92 E0 ; zero the extruder position M117 Printing...

Also, just for completeness, here is what my end code looks like:

M400 ; Wait for the buffer to clear M104 S0 ; turn off nozzle heater M140 S0 ; turn off heat bed G91 ; Switch to relative movement G1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure G1 Z10 F5000 ; move z up 10 G90 ; Back to absolute positioning G1 X0 Y185 F5000 ; Move bed forward and head to left M400 ; Wait for movements to finish M84 ; disable motors

The same end code should work for Cura or Slic3r.

You beat me to it! Yes, just put that reset code in the GCode before home and test. I also sometimes found that the alarm didn't clear so I put a slight pause in there to give it time >> G4 P1000 : wait for alarm reset to clear

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 05, 2016 07:44PM |

Registered: 7 years ago Posts: 4 |

Hey all!

I'm having one MAJOR issue with my printer. Ever since I got this printer a few months ago, I have not been able to get a good print since my first print. The filament will not extrude for some reason. I'm using a 2020 Prusa i3. Any pointers?

Some issues that I'm running into are the following -

- Filament won't extrude when I command it to do so using Repetier

- Filament will not stick to build plate (tape, glue, no grip aids)

- Filament will stick and then will become stringy within the same build layer

Any guidance would be greatly appreciated. I'm extremely frustrated because I want to print so many things but can't even get a calibration print going.

Thanks,

yayforwaffles

I'm having one MAJOR issue with my printer. Ever since I got this printer a few months ago, I have not been able to get a good print since my first print. The filament will not extrude for some reason. I'm using a 2020 Prusa i3. Any pointers?

Some issues that I'm running into are the following -

- Filament won't extrude when I command it to do so using Repetier

- Filament will not stick to build plate (tape, glue, no grip aids)

- Filament will stick and then will become stringy within the same build layer

Any guidance would be greatly appreciated. I'm extremely frustrated because I want to print so many things but can't even get a calibration print going.

Thanks,

yayforwaffles

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 05, 2016 08:03PM |

Registered: 8 years ago Posts: 367 |

@yayforwaffles - what material and temperature are you using? The ones in the Folger settings are not too good. The temperature could make a big difference to the second and third points. It might be the cause of the first point as well, and something else to check for this point is that the gear in the extruder is securely screwed down to the motors shaft (that is, he grub screws are tight).

A trick for checking the extruder and its gear is to draw a line on the end of both the motor shaft and the gear and make sure they rotate together. If neither rotates, there's a problem in the extruder such as too low current to the motor; if the shaft rotates more than the gear, then the gear is slipping and you need to tighten the screws; if they both rotate but jump back, there are several possible causes.

See my blog at [moosteria.blogspot.com].

A trick for checking the extruder and its gear is to draw a line on the end of both the motor shaft and the gear and make sure they rotate together. If neither rotates, there's a problem in the extruder such as too low current to the motor; if the shaft rotates more than the gear, then the gear is slipping and you need to tighten the screws; if they both rotate but jump back, there are several possible causes.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 06, 2016 07:07AM |

Registered: 8 years ago Posts: 65 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 06, 2016 01:05PM |

Registered: 7 years ago Posts: 9 |

I apologize for posting this on an earlyer thread before I saw this dedicated one!

Hello I have built the Folger 2020 about a month ago and have been enjoying amazing prints!

However everything printed was all relative to itself so dimensions where never important.

I have a project that requires precise sizes to be fitted onto a model I am making.

I printed a 60mm x 60mm x 60mm cube (20% infill)

The resulting cube was 60.4 x 60 x 57mm sad smiley

57 on the Z

I looked in the configuration for marlin and Z was set to 4000. I change dit to 3840 and then ended up with 58.6 which is better but not correct.

Rather than playing with this number is there a better way to gain the accuracy or other things I can look at ?

Belts are both snug. Frame is Square.

Thanks!

Hello I have built the Folger 2020 about a month ago and have been enjoying amazing prints!

However everything printed was all relative to itself so dimensions where never important.

I have a project that requires precise sizes to be fitted onto a model I am making.

I printed a 60mm x 60mm x 60mm cube (20% infill)

The resulting cube was 60.4 x 60 x 57mm sad smiley

57 on the Z

I looked in the configuration for marlin and Z was set to 4000. I change dit to 3840 and then ended up with 58.6 which is better but not correct.

Rather than playing with this number is there a better way to gain the accuracy or other things I can look at ?

Belts are both snug. Frame is Square.

Thanks!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 06, 2016 06:20PM |

Registered: 8 years ago Posts: 65 |

Easy formula for steps ( (expected length) x steps = (actual length) x new steps ). That works good with calibrating the extruder . But X and Y steppers were on spot with the factory setting for me. Check your calibration on the extruder. Too much or to little will effect height as much as a stepper. Check out Tom's YouTubes [youtu.be]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 07, 2016 01:52PM |

Registered: 8 years ago Posts: 92 |

Quote

s0laris

I apologize for posting this on an earlyer thread before I saw this dedicated one!

Hello I have built the Folger 2020 about a month ago and have been enjoying amazing prints!

However everything printed was all relative to itself so dimensions where never important.

I have a project that requires precise sizes to be fitted onto a model I am making.

I printed a 60mm x 60mm x 60mm cube (20% infill)

The resulting cube was 60.4 x 60 x 57mm sad smiley

57 on the Z

I looked in the configuration for marlin and Z was set to 4000. I change it to 3840 and then ended up with 58.6 which is better but not correct.

Rather than playing with this number is there a better way to gain the accuracy or other things I can look at ?

Belts are both snug. Frame is Square.

Thanks!

Something is not right. Changing from 4000 to 3840 should have resulted in SMALLER Z size. (motors are not moving as far for the same intended distance). At 4000 - a 60mm move would require 240,000 steps. Changing this setting to 3840 would have resulted in the printer only sending 230,400 steps, attempting to make the same move. BUT at 0.8 mm thread pitch, the actual move would have been 57.6mm.

Z steps per mm should be 4000, as X and Y should be 80.

As long as the belts are not stretched out, that should get you spot-on. The GT2 belts have one "tooth" every 2mm. The pulley on the motor has 20. One complete rotation will move the X or Y 40 mm (20 teeth x 2 mm). At 1/16 micro stepping - that's 3200 steps per revolution. 3200/40 = 80 (micro)steps per mm.

For the Z - assuming you're stock - you have a 0.8 mm pitch on the 5mm threaded rod, meaning the Z will move 0.8 mm per revolution. At 3200 steps per rev, = 3200/0.8 = 4000 (micro)steps per mm.

When I first got my printer up and running, I initially thought to adjust steps per mm to correct size problems I was having (similar to yours), but it was a problem with over-extrusion that was causing my objects to be too large on the X/Y.

So what is going on with your printer? It's hard to guess. Do you have a LCD display? If so, then you can verify what your steps per mm settings are (Menu>Control>Motion). I have made mistakes in the past when I thought I had changed a setting in the firmware, and uploaded it, but in fact didn't. Verifying on the display has been very useful. (If you don't have a display (get one. they're $10) there may be a G Code to get that setting sent back to the computer host, but I'm not sure).

I bet the X over size is caused by over-extrusion. You should do a full extruder calibration - Tom's youtube vids are a fantastic resource (linked by WilberMaker above) Even after doing this, I usually have to make adjustments to the extrusion multiplier in the slicer settings. This is generally unique to each different spool of filament. This is a great video on how to do this (each new spool I open get's this test done, with the results then written on the spool) [www.youtube.com]

Since you are seeing less Z movement that you should, you may be missing steps on the Z access. This could be caused by too little, or too much current to the motors. If it was a too-little issue, I would think the 2 motors would get out of sync, and the x access would no longer be parallel with the bed. With too much current, the stepper driver could be overheating and shutting down very briefly, causing missed steps. How hot are your z motors? How hot is the Z driver? If both are cool, try bumping up the current, and see if this helps. If they are hot, try turning it down. If this fails, try swapping our the Z driver for the spare one, and see if it corrects.

For confirming Z movement, you don't need to print, simply measure the height from the frame, then command a move from the LCD or host, then remeasure (with calipers, preferably). The actual movement should reflect your commanded movement.

The more I think about the inconsistent results, I think it likely it's a missed steps issue.

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 07, 2016 02:01PM |

Registered: 8 years ago Posts: 92 |

Quote

yayforwaffles

Hey all!

I'm having one MAJOR issue with my printer. Ever since I got this printer a few months ago, I have not been able to get a good print since my first print. The filament will not extrude for some reason. I'm using a 2020 Prusa i3. Any pointers?

Some issues that I'm running into are the following -

- Filament won't extrude when I command it to do so using Repetier

- Filament will not stick to build plate (tape, glue, no grip aids)

- Filament will stick and then will become stringy within the same build layer

Any guidance would be greatly appreciated. I'm extremely frustrated because I want to print so many things but can't even get a calibration print going.

Thanks,

yayforwaffles

There's so much that could be happening. Are you heating your hotend before trying to extrude with Repetier? (the firmware will prevent extrusion unless the nozzle is at least 170-180 deg.)

After you've checked your extruder as animoose describes, if you are still having trouble, can you post a video of the printer in action? Maybe upload your configuration.h and slicer settings too.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 07, 2016 06:20PM |

Registered: 8 years ago Posts: 130 |

Quote

iamquestar

Quote

yayforwaffles

Hey all!

I'm having one MAJOR issue with my printer. Ever since I got this printer a few months ago, I have not been able to get a good print since my first print. The filament will not extrude for some reason. I'm using a 2020 Prusa i3. Any pointers?

Some issues that I'm running into are the following -

- Filament won't extrude when I command it to do so using Repetier

- Filament will not stick to build plate (tape, glue, no grip aids)

- Filament will stick and then will become stringy within the same build layer

Any guidance would be greatly appreciated. I'm extremely frustrated because I want to print so many things but can't even get a calibration print going.

Thanks,

yayforwaffles

There's so much that could be happening. Are you heating your hotend before trying to extrude with Repetier? (the firmware will prevent extrusion unless the nozzle is at least 170-180 deg.)

After you've checked your extruder as animoose describes, if you are still having trouble, can you post a video of the printer in action? Maybe upload your configuration.h and slicer settings too.

Ditto for what others have said. It sounds like your bed and extruder aren't getting to high enough temperatures for the filament you are using.

Quote

yayforwaffles

- Filament will stick and then will become stringy within the same build layer

What about a good'ole clog? "Stringy in the first layer"...the extrusion is messed up because of temperature or a plug.

Are you running a drill or guitar string into your nozzle when the hotend is it at print temperatures?

Hang in there. Let's get this thing going!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 08, 2016 12:23PM |

Registered: 7 years ago Posts: 12 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 08, 2016 02:15PM |

Registered: 7 years ago Posts: 9 |

So i have been printing with mine for a while and have been working on some upgrade parts. I am making a new X Ideler piece as my lower bearing keeps falling out of it. Only problem is my circles printed in the Z axis are sort of squished down.

I have noticed this before and it really didn't mater as nothing had to be precise in that axis, but this piece will need to be or the rods won't be parallel.

Any advice on that. I will try to post a picture later. - THANKS!

I have noticed this before and it really didn't mater as nothing had to be precise in that axis, but this piece will need to be or the rods won't be parallel.

Any advice on that. I will try to post a picture later. - THANKS!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 08, 2016 03:12PM |

Registered: 8 years ago Posts: 92 |

Quote

OneSprague

So i have been printing with mine for a while and have been working on some upgrade parts. I am making a new X Ideler piece as my lower bearing keeps falling out of it. Only problem is my circles printed in the Z axis are sort of squished down.

I have noticed this before and it really didn't mater as nothing had to be precise in that axis, but this piece will need to be or the rods won't be parallel.

Any advice on that. I will try to post a picture later. - THANKS!

It sounds like a steps per mm issue, or over extrusion (or both). If you used the stock FT firmware, its Z steps is wrong. It should be 4000. Check my post a little higher on this page for resources on extruder calibration. Post that photo, and we can perhaps help further.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 08, 2016 03:23PM |

Registered: 7 years ago Posts: 9 |

Thanks Andrew..

You are correct about the Z axis.

I simply forgot to SAVE the config file before compiling and uploading. It is at 4000 and its spot on..

I did a 60mmx60xmm60mm cube and ended up with

60.10, 60.16, 60.01

thats good enough!

Whatever the config was BEFORE 4000 I dont know and I just changed it to 4000 compiled and uploaded without anything been sent to printer. I set to 3850 thinking it was getting better but was just making it seem better in my mind

Edited 1 time(s). Last edit at 06/08/2016 03:25PM by s0laris.

You are correct about the Z axis.

I simply forgot to SAVE the config file before compiling and uploading. It is at 4000 and its spot on..

I did a 60mmx60xmm60mm cube and ended up with

60.10, 60.16, 60.01

thats good enough!

Whatever the config was BEFORE 4000 I dont know and I just changed it to 4000 compiled and uploaded without anything been sent to printer. I set to 3850 thinking it was getting better but was just making it seem better in my mind

Edited 1 time(s). Last edit at 06/08/2016 03:25PM by s0laris.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 08, 2016 04:29PM |

Registered: 7 years ago Posts: 9 |

Ok these are the settings in mine:

// default settings

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,3840,90} // default steps per unit for ultimaker {78.7402,78.7402,200*8/3,760*1.1}920

#define DEFAULT_MAX_FEEDRATE {250, 250, 2, 22} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {1000,1000,5,1000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 500 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 500 // X, Y, Z and E max acceleration in mm/s^2 for r retracts

// Offset of the extruders (uncomment if using more than one and relying on firmware to position when changing).

// The offset has to be X=0, Y=0 for the extruder 0 hotend (default extruder).

// For the other hotends it is their distance from the extruder 0 hotend.

// #define EXTRUDER_OFFSET_X {0.0, 20.00} // (in mm) for each extruder, offset of the hotend on the X axis

// #define EXTRUDER_OFFSET_Y {0.0, 5.00} // (in mm) for each extruder, offset of the hotend on the Y axis

// The speed change that does not require acceleration (i.e. the software might assume it can be done instanteneously)

#define DEFAULT_XYJERK 20.0 // (mm/sec)

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 09, 2016 12:37AM |

Registered: 7 years ago Posts: 9 |

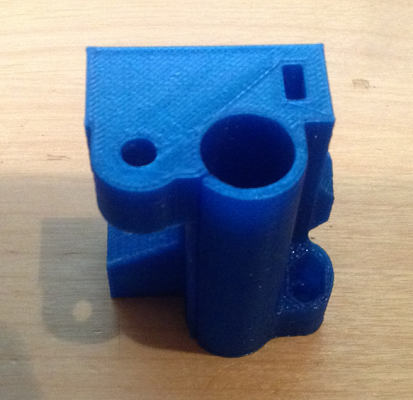

The piece is printed standing up like this:

So it's hard to see from this photo, but the circles and the hex hole is squeezed in the z-axis - this is more apparent in person, and the piece is not quite as tall as the one that's getting replaced.

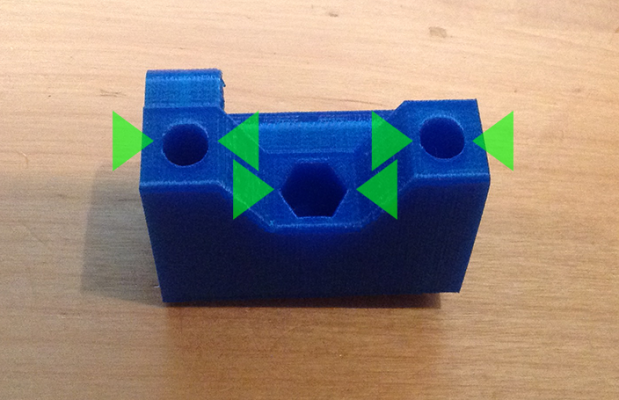

I'm making a replacement one as the stock one looses it's bearing all the time, it just drops out of it like so:

So it's hard to see from this photo, but the circles and the hex hole is squeezed in the z-axis - this is more apparent in person, and the piece is not quite as tall as the one that's getting replaced.

I'm making a replacement one as the stock one looses it's bearing all the time, it just drops out of it like so:

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 09, 2016 12:43AM |

Registered: 7 years ago Posts: 9 |

I just re-read the posts above mine. I will change it to 4000. I must have read that wrong the last time - sorry.

I should say - i was really impressed with the print quality of the piece I just posted. This machine is pretty cool!!!!!

Edited 1 time(s). Last edit at 06/09/2016 12:46AM by OneSprague.

I should say - i was really impressed with the print quality of the piece I just posted. This machine is pretty cool!!!!!

Edited 1 time(s). Last edit at 06/09/2016 12:46AM by OneSprague.

|

Anybody using Cura 2.1.1 yet? June 09, 2016 03:33PM |

Registered: 7 years ago Posts: 6 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 09, 2016 05:09PM |

Registered: 8 years ago Posts: 92 |

Quote

OneSprague

I just re-read the posts above mine. I will change it to 4000. I must have read that wrong the last time - sorry.

I should say - i was really impressed with the print quality of the piece I just posted. This machine is pretty cool!!!!!

The 3840 setting is the culprit. The change should take care of your problem.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 11, 2016 02:30PM |

Registered: 7 years ago Posts: 4 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 11, 2016 02:59PM |

Registered: 7 years ago Posts: 4 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 11, 2016 04:07PM |

Registered: 7 years ago Posts: 4 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 11, 2016 04:18PM |

Registered: 8 years ago Posts: 367 |

Quote

yayforwaffles

@animoose - Got it! Working on a build right now! My issue was that the set screws keeping the gear in place with the shaft weren't tightened whatsoever. Once I tightened those bad boys up, it extrudes perfectly fine now! Thanks so much for the help.

Glad to hear it is working. You aren't the first person to have been hit by this problem.

To answer your question on temperature (which might not be so relevant now). Usually for PLA I use 185-195. It varies a bit from one filament to another.

See my blog at [moosteria.blogspot.com].

|

Filament jaming June 12, 2016 03:53PM |

Registered: 8 years ago Posts: 314 |

This doesnt happen very often, but lately its happend twice in a row. My filament will jam in the middle of a print, and I can hear clicking noises coming out of the extruder... I noticed filament was jammed inside my hotend, so I just heated the hotend up really hot and pushed out the plastic.

1. Im wondering what causes this to happen randomely?

2. Is it time for me to get a new hotend?

3.A few things I noticed, my hotend seeps plastic, especially when im extruding really fast. When I heat up my hotend to say, 250C its loose, it can be turned both directions easily. Should it be tightened all the way to the right?

I just want to say this printer has been a workhorse for me for awhile now, it prints just fine and has required low maintence. Its probably time to give it an upgrade

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

1. Im wondering what causes this to happen randomely?

2. Is it time for me to get a new hotend?

3.A few things I noticed, my hotend seeps plastic, especially when im extruding really fast. When I heat up my hotend to say, 250C its loose, it can be turned both directions easily. Should it be tightened all the way to the right?

I just want to say this printer has been a workhorse for me for awhile now, it prints just fine and has required low maintence. Its probably time to give it an upgrade

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Filament jaming June 12, 2016 09:45PM |

Registered: 8 years ago Posts: 430 |

Quote

UltiFix

This doesnt happen very often, but lately its happend twice in a row. My filament will jam in the middle of a print, and I can hear clicking noises coming out of the extruder... I noticed filament was jammed inside my hotend, so I just heated the hotend up really hot and pushed out the plastic.

1. Im wondering what causes this to happen randomely?

2. Is it time for me to get a new hotend?

3.A few things I noticed, my hotend seeps plastic, especially when im extruding really fast. When I heat up my hotend to say, 250C its loose, it can be turned both directions easily. Should it be tightened all the way to the right?

I just want to say this printer has been a workhorse for me for awhile now, it prints just fine and has required low maintence. Its probably time to give it an upgrade

I would just get the e3d. You could probably fix old one by replacing the threaded tube with the liner if you want to stay with the stock one. That liner breaks down and you start getting jams especially if you are running at 250c.

For leaking you should heat up the hotend then tighten the nozzle with it hot.

I would actually get the e3d and the titan extruder then you won't get anymore extruder clicking. I think there needs to be some gearing in the extruder to make it work with the motor they are using.

Edited 1 time(s). Last edit at 06/12/2016 09:50PM by msaeger.

Newbie with Folgertech 2020 i3.

|

Re: Filament jaming June 12, 2016 10:50PM |

Registered: 8 years ago Posts: 541 |

Quote

UltiFix

This doesnt happen very often, but lately its happend twice in a row. My filament will jam in the middle of a print, and I can hear clicking noises coming out of the extruder... I noticed filament was jammed inside my hotend, so I just heated the hotend up really hot and pushed out the plastic.

1. Im wondering what causes this to happen randomely?

2. Is it time for me to get a new hotend?

3.A few things I noticed, my hotend seeps plastic, especially when im extruding really fast. When I heat up my hotend to say, 250C its loose, it can be turned both directions easily. Should it be tightened all the way to the right?

I just want to say this printer has been a workhorse for me for awhile now, it prints just fine and has required low maintence. Its probably time to give it an upgrade

The stock hot end will serve you well for quite a while. If it's spinning, the set screw holding the threaded tube is loose or the nozzle/threaded tube junction isn't correct. That tube should be run up several turns above the heat break block so it's closer to the extruder gear and prevent jams. Then it should be run far enough down into the hot end so that when you screw in the nozzle, the nozzle hits it before it bottoms out. You should have a thread or two showing on the nozzle, Tighten the nozzle against the threaded tube, which gives you the seal to prevent any leakage. Retighten when it's way up in temperature again. NO LEAKS and no need for a new hot end yet! Just get it set up correctly.

Edited 2 time(s). Last edit at 06/12/2016 10:54PM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Filament jaming June 13, 2016 02:24PM |

Registered: 8 years ago Posts: 92 |

Quote

tjnamtiw

Quote

UltiFix

This doesnt happen very often, but lately its happend twice in a row. My filament will jam in the middle of a print, and I can hear clicking noises coming out of the extruder... I noticed filament was jammed inside my hotend, so I just heated the hotend up really hot and pushed out the plastic.

1. Im wondering what causes this to happen randomely?

2. Is it time for me to get a new hotend?

3.A few things I noticed, my hotend seeps plastic, especially when im extruding really fast. When I heat up my hotend to say, 250C its loose, it can be turned both directions easily. Should it be tightened all the way to the right?

I just want to say this printer has been a workhorse for me for awhile now, it prints just fine and has required low maintence. Its probably time to give it an upgrade

The stock hot end will serve you well for quite a while. If it's spinning, the set screw holding the threaded tube is loose or the nozzle/threaded tube junction isn't correct. That tube should be run up several turns above the heat break block so it's closer to the extruder gear and prevent jams. Then it should be run far enough down into the hot end so that when you screw in the nozzle, the nozzle hits it before it bottoms out. You should have a thread or two showing on the nozzle, Tighten the nozzle against the threaded tube, which gives you the seal to prevent any leakage. Retighten when it's way up in temperature again. NO LEAKS and no need for a new hot end yet! Just get it set up correctly.

I will second all of these instructions. I recently installed a E3D Lite6 (to replace the knockoff V6 I had tried - it worked, but the boden connector died and I couldn't find a properly sized replacement). After installing the Lite6 I was very frustrated due to extruder skipping. I tried upping the temp, but that didn't work. I then tried slowing the speed down - this worked for the most part, but still had some skipping. Cranking up the stepper current didn't work.

After lots of frustration, I decided to tear the whole hot end apart, and found that I didn't have a good seal between the nozzle and the heat break. When I got the filament out, there was a blob on the end. I think it was pooling at the joint, and blocking things up. So I heated up the block and screwed in the nozzle all the way, then backed it out 1 turns. I then screwed in the heat break until it butted up against the nozzle. I then tightened up the nozzle very tight, and put evey thing back together. This solved ALL the problems I was seeing. Since then, everything is working great. I was able to return to normal temps, speeds, and motor current.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 14, 2016 10:58PM |

Registered: 8 years ago Posts: 65 |

|

BLTouch sensor Marlin configuration for the 2020 i3 Folger Tech June 15, 2016 10:14AM |

Registered: 7 years ago Posts: 6 |

Anybody have BLTouch sensor Marlin setup working properly on the 2020 i3 Folger Tech ?

[www.indiegogo.com]

[www.indiegogo.com]

|

Re: BLTouch sensor Marlin configuration for the 2020 i3 Folger Tech June 15, 2016 11:56AM |

Registered: 8 years ago Posts: 93 |

Quote

3333dddd

Anybody have BLTouch sensor Marlin setup working properly on the 2020 i3 Folger Tech ?

[www.indiegogo.com]

I have had it working for a while. I'd share mine, but I'm currently running a customized version of Marlin with some new beta features that I haven't finished or merged. Plus I have a lot of other hardware changes, so my config wouldn't just drop in for anyone else anyway. That's the reason we can't just share config files - you'd have to be running exactly all the same hardware, and most of us have modified our machines.

The BLTouch setup is documented in the wiki that is maintained by some of us in this forum.

Scroll down, and you'll find all the necessary config file changes included. You should be able to just paste them into your config.

Folger Tech i3 Wiki

If you have specific questions, I can help.

Edited 1 time(s). Last edit at 06/15/2016 12:53PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

Sorry, only registered users may post in this forum.