Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 02, 2016 10:59PM |

Registered: 8 years ago Posts: 16 |

Quote

iamquestar

Hmm, I forgot that you had mentioned this was only a problem with PETG. So I assume you do not hear the extruder skipping? Unfortunately with the stock hot end, you can't really see the extruder in action. I designed my own mount for the stock extruder and the E3D lite6 for the v-Slot X axis Gantry plate, and the front of the extruder is now open and visible. It's great to be able to see the motor turning, and be able to see if it skips or grinds against the filament. If there was some way to see that, it could help you troubleshoot further...

What about this: Can you manually push the filament through the hot end at the end of the print? It is harder to do this, than at the beginning? If so, it's definitely a nozzle problem. If not, it's got to be something with the electronics, or possibly gcode...

What about your filament path... is there anything that would cause it be harder to feed, as the Z axis raises up? Might it catch on anything, or kink, or bind?

I'm just tossing out anything that occurs to me here...

To be honest I have yet to print with PETG... I do have a roll, so I'll try to break that out this week and see how it prints for me.

I really like the cooler you posted a link to. I've been looking for something to replace my old setup with. I don't have a print cooling fan running right now, because my old one doesn't fit the new hotend setup I'm using. I think I can adapt that one, and I love that it blows from all directions. Maybe I'll try printing that with PETG.

--Andrew

Sorry, you did ask this before and I forgot to answer. I DO hear the extruder motor skipping steps. It makes a clicking noise, maybe one every 0.5 - 0.75 secs. It doesn't do this at the beginning of the print, but when I catch it underextruding, its skipping steps. So this makes me think something is making the filament difficult to push through the nozzle. I don't think its a printer arrangement problem (like filament getting caught), since PLA and ABS print fine. I think its something wrong I have in the slic3r settings, like temperature, speed, or something like that, which is making this particular type of model not print well. I think I'm just going to have to keep trying different settings.

Can I ask, how do you like the E3D Lite6? I've also done the X and Y axis OpenBuild v-slot upgrades and was considering trying a new hot end next. But I wasn't sure how much benefit you get.

The DiiiCooler is pretty good, the guy did a nice job of shaping the internal fins so the air is directed inward and downward, right on the print without cooling the nozzle too much. And there are several adapter plates that people have made for it. There's one for the stock FolgerTech hot end. Mine is printed with PETG and is holding up ok next to the heater block. There are some discolored areas and a little deformation from the nearby heat, but its still good. Easy enough to print a new one when this one melts too much.

Thanks again for all the help.

-Geoff

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2016 12:52AM |

Registered: 8 years ago Posts: 92 |

Quote

pizzachef

Quote

iamquestar

Hmm, I forgot that you had mentioned this was only a problem with PETG. So I assume you do not hear the extruder skipping? Unfortunately with the stock hot end, you can't really see the extruder in action. I designed my own mount for the stock extruder and the E3D lite6 for the v-Slot X axis Gantry plate, and the front of the extruder is now open and visible. It's great to be able to see the motor turning, and be able to see if it skips or grinds against the filament. If there was some way to see that, it could help you troubleshoot further...

What about this: Can you manually push the filament through the hot end at the end of the print? It is harder to do this, than at the beginning? If so, it's definitely a nozzle problem. If not, it's got to be something with the electronics, or possibly gcode...

What about your filament path... is there anything that would cause it be harder to feed, as the Z axis raises up? Might it catch on anything, or kink, or bind?

I'm just tossing out anything that occurs to me here...

To be honest I have yet to print with PETG... I do have a roll, so I'll try to break that out this week and see how it prints for me.

I really like the cooler you posted a link to. I've been looking for something to replace my old setup with. I don't have a print cooling fan running right now, because my old one doesn't fit the new hotend setup I'm using. I think I can adapt that one, and I love that it blows from all directions. Maybe I'll try printing that with PETG.

--Andrew

Sorry, you did ask this before and I forgot to answer. I DO hear the extruder motor skipping steps. It makes a clicking noise, maybe one every 0.5 - 0.75 secs. It doesn't do this at the beginning of the print, but when I catch it underextruding, its skipping steps. So this makes me think something is making the filament difficult to push through the nozzle. I don't think its a printer arrangement problem (like filament getting caught), since PLA and ABS print fine. I think its something wrong I have in the slic3r settings, like temperature, speed, or something like that, which is making this particular type of model not print well. I think I'm just going to have to keep trying different settings.

Can I ask, how do you like the E3D Lite6? I've also done the X and Y axis OpenBuild v-slot upgrades and was considering trying a new hot end next. But I wasn't sure how much benefit you get.

The DiiiCooler is pretty good, the guy did a nice job of shaping the internal fins so the air is directed inward and downward, right on the print without cooling the nozzle too much. And there are several adapter plates that people have made for it. There's one for the stock FolgerTech hot end. Mine is printed with PETG and is holding up ok next to the heater block. There are some discolored areas and a little deformation from the nearby heat, but its still good. Easy enough to print a new one when this one melts too much.

Thanks again for all the help.

-Geoff

Well, no doubt about it, there is something that's preventing the filament from flowing smoothly. I can't imagine what it would be that would only show up well into a print, but if the extruder is clicking, that's the problem with the under extrusion. Each skip means filament not put onto the model. You've mentioned that the nozzle temp stays steady, so that shouldn't be the issue. What happens if you lift the Z, heat up the hotend to printing temp, and using your host (are you using Repetier?) manually extrude a few hundred mm. It should extrude smoothly the whole time.

The only time I've had a problem with the extruder skipping, was when I had a gap between the heatbreak tube, and the nozzle. But since you don't have a problem with ABS or PLA, that's obviously not going on. Have you tried the lower temperature? If too much heat is getting up into the heat break, then that could cause difficulty in pushing the filament through. Perhaps make sure the heat sink is clean and is firmly mated with the cold-end block, and the fan is blowing well.

That's one thing I do like about the lite6. I think the heat sink and fan design do a better job of keeping the cold end cool (although I printed an adapter to use a 40mm fan on it, instead of the 30mm it comes with).The other benefit I like about the E3D Lite6 is having a teflon tube run from the very bottom of the extruder, all the way through the hot end to the top of the nozzle. This means I can't go above 245c without significantly degrading the teflon, but I don't plan on printing polycarbonate or Nylon at this point. The path gives me filament support for all but about 1mm from the drive gear, which means flexible filaments are possible.(which I have had some good success with).

I'm ready to share my extruder mount with the world, and will be posting it this week. I've designed it so that the motor sits ABOVE the vslot gantry (more or less), which keeps from having this big weight hanging off the front of the Xaxis, and reclaims some Z height. I have about 175mm of Z height, even with an E3D hotend.

I'm printing the DiiiCooler now, but I'm a little concerned about making it fit. I'll see how it goes. I'm printing in PLA right now, as I have tons of that. Once I confirm fit, and make any needed tweaks, I'll print it in ABS or PETG. I may need to rework the mounting scheme, and scale down the Z a little.

|

Re: counterfeit Arduinos August 03, 2016 09:38AM |

Registered: 7 years ago Posts: 6 |

Quote

av8r1

Arduino publishes an identification guide here: [www.arduino.cc]

The silk screening on the boards received from FT doesn't hold up to scrutiny.

Wow - that is interesting (and helpful to know)

To be fair to Folger Tech, I went and looked at their site, and it states "Arduino Mega 2560 R3 Clone" on the product page, so they are not really hiding that fact.

Edited 1 time(s). Last edit at 08/03/2016 09:39AM by 3333dddd.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2016 12:34PM |

Registered: 7 years ago Posts: 4 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2016 07:08PM |

Registered: 8 years ago Posts: 92 |

Quote

mrbill

Bit the bullet, ordered the kit, the 2004 LCD, and the extension cable for the LCD.

I'll either buy a better Arduino and RAMPS (links/suggestions encouraged) before I build it, or expect to have to do that at some point.

Welcome to the club! I ordered mine just before new years, and started building it around mid-January. My wife quickly became a 3D printing widow. All my free time was given to the printer.

Enjoy the process, and enjoy the opportunity to learn all the ins and outs about your printer. Two benefits of building a kit are: 1. If somethings breaks, you'll have a good idea of how to fix it. 2. If you want to make improvements, you won't be afraid (as much) of pulling things apart to build them better.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2016 08:10PM |

Registered: 7 years ago Posts: 129 |

It's good to have spare electronics. I ended up repairing my FT Arduino with a new regulator, and I use it as intended--as a workbench playtoy and tryer outer. The chips on board are genuine Atmel AVRs, so for most uses they're fine. Running a 3D printer is demanding on the regulator, and these weren't up to snuff. I have yet another set of electronics laying around ready to be swapped out. RAMPS board all built up and everything.

Figured out my problem with OctoPrint: Damaged SD card. Used another SD card, it fired right up. Haven't attached it to the printer yet. C'est le Semiconductor.

Got my own PET-G in today. It's doing much better than PLA for me. I have noticed that very small details are a bit of a struggle for it. I'm printing a stegosaurus for my niece, and the plates on the back are coming out a little rough. I'll have to dial in temperature.

Figured out my problem with OctoPrint: Damaged SD card. Used another SD card, it fired right up. Haven't attached it to the printer yet. C'est le Semiconductor.

Got my own PET-G in today. It's doing much better than PLA for me. I have noticed that very small details are a bit of a struggle for it. I'm printing a stegosaurus for my niece, and the plates on the back are coming out a little rough. I'll have to dial in temperature.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 03, 2016 11:37PM |

Registered: 8 years ago Posts: 314 |

My arduino from ft has worked great! Have fun building it and dont rush through it like meQuote

mrbill

Bit the bullet, ordered the kit, the 2004 LCD, and the extension cable for the LCD.

I'll either buy a better Arduino and RAMPS (links/suggestions encouraged) before I build it, or expect to have to do that at some point.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2016 02:50PM |

Registered: 8 years ago Posts: 92 |

Quote

UltiFix

My arduino from ft has worked great! Have fun building it and dont rush through it like meQuote

mrbill

Bit the bullet, ordered the kit, the 2004 LCD, and the extension cable for the LCD.

I'll either buy a better Arduino and RAMPS (links/suggestions encouraged) before I build it, or expect to have to do that at some point.

I too had an issue with the regulator on my original... (I think). I had just done a lot of re-routing of wires, and hooked everything back up, then fired up the printer, started a printjob, and about 10 min, in, it just stopped. The LCD display was solid white (although if you looked closely, you could see the characters within, very faint). If I had the main power off, but the Arduino plugged into USB, everything looked fine, but power up the 12v PS, and bang - problems. I thought at first I had messed up and wired something wrong, but after a complete check, everything was OK.

Fortunately I had another set of RAMPS/Mega on hand. I flashed it, swapped it in, and am running fine. On the problem set, I think that I will try cutting the 12v feed from the Ramps to the Mega, and try the original electronics again, now that I am running a Ras Pi. It's always plugged in via USB now, so it may work fine that way.

In summary: It's not a bad idea to have a spare controller on hand. They're cheap, and it beats waiting a couple days to a couple weeks waiting for an order to come in. Have one on-hand and you're back up and running in 20 min.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 04, 2016 03:00PM |

Registered: 7 years ago Posts: 4 |

Quote

iamquestar

Two benefits of building a kit are: 1. If somethings breaks, you'll have a good idea of how to fix it. 2. If you want to make improvements, you won't be afraid (as much) of pulling things apart to build them better.

That's exactly why, when I built a Printrbot Jr. in 2013 (and a Printrbot Simple in 2014 and a Printrbot Play last year) that I chose the kits instead of preassembled.

I know exactly how everything fits together, and aren't afraid to take bits apart, print better pieces, tweak things, etc.

My FT kit shipped today!

|

Re: counterfeit Arduinos August 04, 2016 08:47PM |

Registered: 8 years ago Posts: 130 |

Quote

3333dddd

Quote

av8r1

Arduino publishes an identification guide here: [www.arduino.cc]

The silk screening on the boards received from FT doesn't hold up to scrutiny.

Wow - that is interesting (and helpful to know)

To be fair to Folger Tech, I went and looked at their site, and it states "Arduino Mega 2560 R3 Clone" on the product page, so they are not really hiding that fact.

It's a bit of a roll-of-the-dice, as to whether or not you get a good board, from any clone supplier (FT included). My Mega clone, that was included in the kit, from FT has a visible, burnt, pinhole in the regulator. It also functioned strangely. If you look at old regulators on boards they had big heat sinks. There are youtube videos out there that show how to revive fried regulators on the mega.

Adafruit is manufacturing the 'real' Mega in the US but, ouch that's pricey. There doesn't seem to be any performance/reliability in clones versus authentic Mega boards. I guess if I paid mega bucks I would want a warranty.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 05, 2016 10:16PM |

Registered: 8 years ago Posts: 62 |

Thanks for the info, I'm already working on the modifications of the Marlin Firmware and I will tomorrow work on the modifications of the arm to fit the small servo that I got for it (HXT500).

I have a question, I will install a small microswitch to use at the end of the probe, if I'm correct I need to unplug the Z endstop and connect the microswitch, I will be connecting only the C and NC legs on the microswitch (red and black wires from the original endstop wiring harness?) and can I use the current endstop PCB and enjoy the LED light confirming contact? (even if the whole thing looks bulky)

Thanks!!!

Mr.Fus

<------------------------------------------------->

Green M3D (Running v.1.3.6.3Beta)

FolgerTech Prusa i3 (2020 Frame)

<------------------------------------------------>

I have a question, I will install a small microswitch to use at the end of the probe, if I'm correct I need to unplug the Z endstop and connect the microswitch, I will be connecting only the C and NC legs on the microswitch (red and black wires from the original endstop wiring harness?) and can I use the current endstop PCB and enjoy the LED light confirming contact? (even if the whole thing looks bulky)

Thanks!!!

Mr.Fus

<------------------------------------------------->

Green M3D (Running v.1.3.6.3Beta)

FolgerTech Prusa i3 (2020 Frame)

<------------------------------------------------>

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 06, 2016 05:43AM |

Registered: 8 years ago Posts: 65 |

I have been using my LCD display just to read temps and time remaining. Now I am wanting to free up my laptop during long prints. I have a formatted SD card in the slot but the printer will not boot or run if I disconnect the USB cable from my laptop. I have loaded the u8glib library and the display seems to be working. Is there something I need to have on the SD card to get the printer to run standalone?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 07, 2016 10:21PM |

Registered: 7 years ago Posts: 129 |

So the display works when the USB cable is plugged into your laptop, but not when unplugged. I bet the 5v regulator on your board has gone. I know I harp on that a lot, but it's been a BIG issue with me, and if you do ANYTHING wrong with the machine, that regulator will let the smoke out. There are three ways to power an Arduino: You can put up to 5.5V on the 5V pin (basically don't do that. The pin(s) marked 5V are INSIDE the regulator and meant to SUPPLY power, so if you get it wrong, you can hurt the Arduino and anything hooked to it.) You can put power on the Vin pin or the barrel jack, which then gets regulated by the regulator. Or, you can plug it in USB, which bypasses the regulator because USB is regulated to 5V. If the regulator is blown, the board will work fine when plugged into USB, but not when it's on other power. Look at the regulator and see if it looks like it blew up.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 08, 2016 01:03AM |

Registered: 8 years ago Posts: 92 |

Quote

av8r1

So the display works when the USB cable is plugged into your laptop, but not when unplugged. I bet the 5v regulator on your board has gone. I know I harp on that a lot, but it's been a BIG issue with me, and if you do ANYTHING wrong with the machine, that regulator will let the smoke out. There are three ways to power an Arduino: You can put up to 5.5V on the 5V pin (basically don't do that. The pin(s) marked 5V are INSIDE the regulator and meant to SUPPLY power, so if you get it wrong, you can hurt the Arduino and anything hooked to it.) You can put power on the Vin pin or the barrel jack, which then gets regulated by the regulator. Or, you can plug it in USB, which bypasses the regulator because USB is regulated to 5V. If the regulator is blown, the board will work fine when plugged into USB, but not when it's on other power. Look at the regulator and see if it looks like it blew up.

I agree with this diagnosis. If you have a spare usb charger, you can plug the USB cable into that to provider power to the electronics HOWEVER, make sure it is a quality one. Pretty much all of the cheep ones don't have good regulated power. (also, some tablet charges put out a higher voltage (5.1-5.2v) which could cause some issues too).

There doesn't need to be anything on the SD card for it to work stand alone. Just copy your gcode files onto it, then you'll be able to select them from the LCD and print away.

Another option you may want to consider (aside from replacing the Arduino) would be to go with a Raspberry Pi and Octoprint. The printer electronics will then get its power from the RPi thru USB. A Pi 3, good powersupply and case bundle will set you back about $50 on Amazon. I am so glad I took this step. I was quite excited to start printing from an SD card, but that got old really quick. Particularly when I would start a print, and find that I needed to change some slicer settings, so it's pull the SD from the printer, stick it in the reader, save new gcode, pull it out and put it back in the printer, then repeat... Sending the gcode over to the Pi (I have a script that does it automatically as soon as I save it out of Simplify3D) and starting the print is so much easier, not to mention the easy monitoring the print with a webcam from anywhere in the house....

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 08, 2016 01:37PM |

Registered: 8 years ago Posts: 314 |

Im thinking about doing this, would it work ok with the cura slicer? (new version) I have the money for a Pi 3 but definetly not for the Simplify3DQuote

iamquestar

Quote

av8r1

So the display works when the USB cable is plugged into your laptop, but not when unplugged. I bet the 5v regulator on your board has gone. I know I harp on that a lot, but it's been a BIG issue with me, and if you do ANYTHING wrong with the machine, that regulator will let the smoke out. There are three ways to power an Arduino: You can put up to 5.5V on the 5V pin (basically don't do that. The pin(s) marked 5V are INSIDE the regulator and meant to SUPPLY power, so if you get it wrong, you can hurt the Arduino and anything hooked to it.) You can put power on the Vin pin or the barrel jack, which then gets regulated by the regulator. Or, you can plug it in USB, which bypasses the regulator because USB is regulated to 5V. If the regulator is blown, the board will work fine when plugged into USB, but not when it's on other power. Look at the regulator and see if it looks like it blew up.

I agree with this diagnosis. If you have a spare usb charger, you can plug the USB cable into that to provider power to the electronics HOWEVER, make sure it is a quality one. Pretty much all of the cheep ones don't have good regulated power. (also, some tablet charges put out a higher voltage (5.1-5.2v) which could cause some issues too).

There doesn't need to be anything on the SD card for it to work stand alone. Just copy your gcode files onto it, then you'll be able to select them from the LCD and print away.

Another option you may want to consider (aside from replacing the Arduino) would be to go with a Raspberry Pi and Octoprint. The printer electronics will then get its power from the RPi thru USB. A Pi 3, good powersupply and case bundle will set you back about $50 on Amazon. I am so glad I took this step. I was quite excited to start printing from an SD card, but that got old really quick. Particularly when I would start a print, and find that I needed to change some slicer settings, so it's pull the SD from the printer, stick it in the reader, save new gcode, pull it out and put it back in the printer, then repeat... Sending the gcode over to the Pi (I have a script that does it automatically as soon as I save it out of Simplify3D) and starting the print is so much easier, not to mention the easy monitoring the print with a webcam from anywhere in the house....

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 08, 2016 04:48PM |

Registered: 8 years ago Posts: 92 |

Quote

UltiFix

Im thinking about doing this, would it work ok with the cura slicer? (new version) I have the money for a Pi 3 but definetly not for the Simplify3D

Octoprint will work with any slicer, you'll just need to upload the gcode generated (very easy: web interface). Further, Octoprint actually embeds Cura (I'm not sure of the version, I haven't played with this yet) and you can send your STL right to Octoprint, and it'll slice and start printing in one step. I'm not sure what options there are for multiple settings profiles, there may be only one set of settings you can use. As I said, I haven't played with this, but it looks promising.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 08, 2016 04:53PM |

Registered: 8 years ago Posts: 65 |

Thanks again guys. Your right. AlI the jacking around I did with the BLTouch I must of fried the board. Have a USB port on the power strip on the bench. Plugged into that and it boots up. Doing a major overhaul on the printer tonight. Have a new Ramps 1.4 and a Arduino compatible board to put on it. Should be fun.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 08, 2016 05:04PM |

Registered: 8 years ago Posts: 367 |

Quote

iamquestar

Quote

UltiFix

Im thinking about doing this, would it work ok with the cura slicer? (new version) I have the money for a Pi 3 but definetly not for the Simplify3D

Octoprint will work with any slicer, you'll just need to upload the gcode generated (very easy: web interface). Further, Octoprint actually embeds Cura (I'm not sure of the version, I haven't played with this yet) and you can send your STL right to Octoprint, and it'll slice and start printing in one step. I'm not sure what options there are for multiple settings profiles, there may be only one set of settings you can use. As I said, I haven't played with this, but it looks promising.

Another option you could consider is Repetier Server. I use the setup of Repetier Host on my main PC, talking to Repetier Server on a Pi, talking over USB to the printer. It works quite seamlessly, just like local printing directly from Repetier Host to the printer, but you can also upload gcode files to Rep Server and then have it print them autonomously. Rep Server lacks some features of Octopi unless you pay for them, for example using a camera for monitoring.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 09, 2016 02:44PM |

Registered: 8 years ago Posts: 25 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 09, 2016 05:31PM |

Registered: 8 years ago Posts: 92 |

Quote

jabu32

Got Octoprint working....LOVE IT!

Excellent! I have really appreciated the ease it gives me, not to mention, I can initiate a print from the bedroom using my phone (I did this last night when I realized I had forgotten to start it).

I also added a relay control module ($7 from amazon) and can actually control power to the printer, and turn the LED lights I added to my enclosure on/off from the octoprint interface. It rocks!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 09, 2016 10:53PM |

Registered: 8 years ago Posts: 16 |

Quote

iamquestar

I'm ready to share my extruder mount with the world, and will be posting it this week. I've designed it so that the motor sits ABOVE the vslot gantry (more or less), which keeps from having this big weight hanging off the front of the Xaxis, and reclaims some Z height. I have about 175mm of Z height, even with an E3D hotend.

I'm printing the DiiiCooler now, but I'm a little concerned about making it fit. I'll see how it goes. I'm printing in PLA right now, as I have tons of that. Once I confirm fit, and make any needed tweaks, I'll print it in ABS or PETG. I may need to rework the mounting scheme, and scale down the Z a little.

I still haven't had any improvements with PETG, although I haven't tried everything yet. I still need to try printing even more slowly and maybe turning up the extruder motor driver current. I had some other PLA prints to make, those are coming out well. Incidentally, when I was printing in PETG, I tried a lower temp, 225C, and it started skipping steps during the print. I tried 220C and it still clicked (maybe even worse). I went back up to 235C, still clicked (doesn't click at 225-235 in the first 20 or so layers of the print), so I cancelled it. Then I made it extrude 50mm and watched the filament come out. When the motor clicked, I could see the extruded filament briefly pause at each click.

Seems like the teflon tube is getting soft or sticky when it starts to warm up. Maybe a better cooling fan would help, or maybe the teflon tube is not very good. I'm going to keep trying things.

Did you publish your E3D mount yet for the v-slot gantry? I'm interested!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 10, 2016 02:01AM |

Registered: 8 years ago Posts: 92 |

Quote

pizzachef

Quote

iamquestar

I'm ready to share my extruder mount with the world, and will be posting it this week. I've designed it so that the motor sits ABOVE the vslot gantry (more or less), which keeps from having this big weight hanging off the front of the Xaxis, and reclaims some Z height. I have about 175mm of Z height, even with an E3D hotend.

I'm printing the DiiiCooler now, but I'm a little concerned about making it fit. I'll see how it goes. I'm printing in PLA right now, as I have tons of that. Once I confirm fit, and make any needed tweaks, I'll print it in ABS or PETG. I may need to rework the mounting scheme, and scale down the Z a little.

I still haven't had any improvements with PETG, although I haven't tried everything yet. I still need to try printing even more slowly and maybe turning up the extruder motor driver current. I had some other PLA prints to make, those are coming out well. Incidentally, when I was printing in PETG, I tried a lower temp, 225C, and it started skipping steps during the print. I tried 220C and it still clicked (maybe even worse). I went back up to 235C, still clicked (doesn't click at 225-235 in the first 20 or so layers of the print), so I cancelled it. Then I made it extrude 50mm and watched the filament come out. When the motor clicked, I could see the extruded filament briefly pause at each click.

Seems like the teflon tube is getting soft or sticky when it starts to warm up. Maybe a better cooling fan would help, or maybe the teflon tube is not very good. I'm going to keep trying things.

Did you publish your E3D mount yet for the v-slot gantry? I'm interested!

No, not yet. The free time I had anticipated evaporated with a change in plans, but I'll be home alone starting Saturday evening, thru Tuesday, so I plan on taking the time to get things polished and published then. I've only had my current setup in place for the past few weeks, and already I am considering changes. I'm thinking about adding a 2nd extruder (sort of). I have been a little frustrated with some surface quality issues that have come back since moving away from a boden. (patterns and such, probably due to vibration) My research indicates that is one of the problems with the higher mass moving around on the X axis. So I'm thinking about adding a 2nd extruder motor for a switchable boden/direct drive setup. To pull the direct drive motor/extruder off only takes 2 screws. I could then attach a bowden tube to the hot end, and go to town. When I want to print flexible, I could then switch back to the direct drive with very little fuss. So it's not REALLY dual extrusion, really just a quick change between Direct and Bowden...

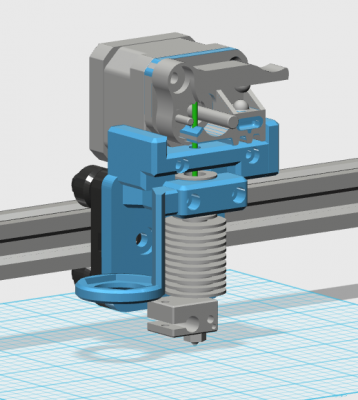

Here's a preview of my extruder design. I used parts of sonnylowe's vslot E3D mount found here: [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 10, 2016 11:46AM |

Registered: 8 years ago Posts: 25 |

Quote

iamquestar

Quote

jabu32

Got Octoprint working....LOVE IT!

Excellent! I have really appreciated the ease it gives me, not to mention, I can initiate a print from the bedroom using my phone (I did this last night when I realized I had forgotten to start it).

I also added a relay control module ($7 from amazon) and can actually control power to the printer, and turn the LED lights I added to my enclosure on/off from the octoprint interface. It rocks!

How do you wire up the relay?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 10, 2016 11:57AM |

Registered: 8 years ago Posts: 65 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 10, 2016 01:02PM |

Registered: 8 years ago Posts: 92 |

Quote

WilberMaker

Is there a better 8" bearing to use than the LM8UU linear bearings. The ones from Folger Tech seem cheep and are rough. When replacing the Z I lose several ball out of them and would like to go back with something better.

There are a number a quality bearing suppliers out there. Good LM8UU bearings will cost a lot more. You can expect to pay from $6-$12 each for good ones. You can search the RepRap forums for some places to get quality bearings. A lot of other RepRapers have had good results from Delrin bushings. Delrin is a so-called self-lubricating plastic material that slides very smoothly on chrome rod. I don't have any specific supplier to recommend, For my printer, I chose to upgrade x and y axis' to v-slot wheeled gantries (Sonnylowe's design). Those are smooth as silk... but I have heard similar reports from changing out for the delrin bushings. Personally, I prefer the greater rigidity of the v-slot extrusion over the 8mm rods. (but, of course that will cost a lot more).

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 10, 2016 01:13PM |

Registered: 8 years ago Posts: 92 |

Quote

jabu32

Quote

iamquestar

Quote

jabu32

Got Octoprint working....LOVE IT!

Excellent! I have really appreciated the ease it gives me, not to mention, I can initiate a print from the bedroom using my phone (I did this last night when I realized I had forgotten to start it).

I also added a relay control module ($7 from amazon) and can actually control power to the printer, and turn the LED lights I added to my enclosure on/off from the octoprint interface. It rocks!

How do you wire up the relay?

It was not as difficult as I thought it was going to be. I'll get a post typed up with all the details, and photos in the next few days. You can also check out this WIKI entry: [github.com] which is what I followed (unfortunately) to get up and running.

DO NOT TRUST the wiring guide on this!!!!! It is WRONG, WRONG, WRONG. I fried the built in WiFi on 2 Raspberry Pi 3's by hooking it up according to this guide. If you follow the guide, you end up feeding 5v back to the 3.3v pin on the Pi. This is a BAD idea. While (surprisingly) it worked, it killed the on-board WiFi (and probably Bluetooth as well).

Unfortunately, I didn't take the time to understand the relay board before starting. Had I done so, I would have realized the mistakes in the guide, and would have been able to avoid them. Since the other Pi's still work, but without the WiFi, I will be using them for some other projects...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 12, 2016 01:29PM |

Registered: 8 years ago Posts: 314 |

Thats sick! I also have a led strip above my printer and would LOVE to be able to control the printers power and the led strips! Can you link me to them on amazon? Ill just buy it all together when I order the pi.Quote

iamquestar

Quote

jabu32

Got Octoprint working....LOVE IT!

Excellent! I have really appreciated the ease it gives me, not to mention, I can initiate a print from the bedroom using my phone (I did this last night when I realized I had forgotten to start it).

I also added a relay control module ($7 from amazon) and can actually control power to the printer, and turn the LED lights I added to my enclosure on/off from the octoprint interface. It rocks!

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 14, 2016 11:22PM |

Registered: 8 years ago Posts: 65 |

Got my lead screws installed. Having a problem with the steps. Seems that if I raise the x axis 40mm it is actually moving around 10mm. This would say the steps are to low, But when I level the bed and set the offset the nozzle will dig into the bed. Below is my setting for steps. Am I missing something else or is it possible I am binding on the leads and missing steps on the steppers.

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,400,89.839}

WilberMaker

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,400,89.839}

WilberMaker

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 15, 2016 07:53PM |

Registered: 8 years ago Posts: 92 |

Quote

WilberMaker

Got my lead screws installed. Having a problem with the steps. Seems that if I raise the x axis 40mm it is actually moving around 10mm. This would say the steps are to low, But when I level the bed and set the offset the nozzle will dig into the bed. Below is my setting for steps. Am I missing something else or is it possible I am binding on the leads and missing steps on the steppers.

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,400,89.839}

WilberMaker

If your lead screws are a 4 start @ 2mm pitch (resulting in a move of 8mm/reolution), and your stepper drivers are 1/16 micro stepping (the standard from FT) then 400 is correct for the steps/mm. However, if you got single start lead screws at 2mm pitch (which I wish I had) then a 10mm move on a 40mm command would make sense, and you'd want to set your steps/mm to 1600.

If you were binding on the lead screws, then I would expect your X axis to go out of level, as the 2 motors would bind/skip differently.

I would guess that the digging into the bed is a different issue. Since you mention offset, can I assume you are running auto level? It would require more info to troubleshoot that. For instance, when is it digging in? After homing, as it starts the print? Or something else?

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) August 15, 2016 08:03PM |

Registered: 8 years ago Posts: 92 |

Quote

UltiFix

Thats sick! I also have a led strip above my printer and would LOVE to be able to control the printers power and the led strips! Can you link me to them on amazon? Ill just buy it all together when I order the pi.Quote

iamquestar

Quote

jabu32

Got Octoprint working....LOVE IT!

Excellent! I have really appreciated the ease it gives me, not to mention, I can initiate a print from the bedroom using my phone (I did this last night when I realized I had forgotten to start it).

I also added a relay control module ($7 from amazon) and can actually control power to the printer, and turn the LED lights I added to my enclosure on/off from the octoprint interface. It rocks!

Here's the Pi kit I bought: [www.amazon.com]

Here's the relay board: [www.amazon.com]

I bought these LEDs: [www.amazon.com]

The LEDs are a 12 volt, I cut them to lengeth (you can cut @ every 3rd LED) and I'm running them directly off the printer power supply.

I'll be typing up a detailed post on all of these customizations this evening. Hopefully I'll get it done and posted tonight.

--Andrew

Sorry, only registered users may post in this forum.