Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 11, 2016 09:02PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 11, 2016 10:29PM |

Registered: 8 years ago Posts: 171 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 03:13AM |

Registered: 8 years ago Posts: 51 |

Quote

sonnylowe

Quote

peeejayz

Quote

sonnylowe

Quote

peeejayz

Quote

sonnylowe

Quote

peeejayz

Quote

sonnylowe

SNIP

WOW. I love it!

Awesome design. Can't wait to see some results and video of it printing.

Just in the middle of my Y one now. All the old parts are off just about to drill the bed to fit it on the carriage.

Do you know what you changed your Y esteps to with a 16t pully?

Hmmm, that's weird, I'm not using a 16 tooth pulley, I'm running the stock 20 tooth pulley as indicated HERE I did adjust my e-steps but it was a really small amount like 80.21!?!?

Dam I missed that. I got a 16 on it working fine, might go back to the 20 the 16 is a little tight.

Its working and printing now thoMega happy with the difference. Cheers for all of your hard work.

Haha, yeah we all miss stuff now and then, so glad to hear it's up and running, and even more so that you like the upgrade

Yea I found the stock folger alu bed to flexible to level correctly so I have ordered one of the openbuilds ones so I'll put that in to help stiffen it all up. Just awaiting alu bed and sensor for auto leveling too now.

Sounds good, but please keep in mind that OB bed will lessens the length of the bed travel by quite a bit, make sure you leave the rail long enough to compensate...

I'm still going to use the smaller plate for the actual wheels ect, just putting the larger open builds plate on the 6mm spacers instead.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 06:44AM |

Registered: 8 years ago Posts: 268 |

Quote

Jim72

Quote

marc2912

Quote

Jim72

Quote

marc2912

Not in front of my printer right now but it sounds like the thermistor is working correctly. It sounds like either the heating element isn't working or the board isn't powering itQuote

Jim72

Good morning. I finished the build, got the firmware straightened out with your help, all 3 axis home and move properly. I leveled the bed and next tried to get the bed and extruder to heat. The bed heats fine. The extruder never heated, the reading on the LCD without heat was 23, with heat it got to 26 (30 min), I am sure that is radiant heat from the bed which was at 70 deg C. I assumed the thermister may be an issue. I checked the folgertech help site and they recommend checking resistance, which I did and it was showing 114k ohms (they say normal 80k to 120k). So, I assume the thermister is probably not the problem? Next I put the hot end back together and opened repetier and tried again to get the extruder to heat without success. I then turned on the bed heat and again it got to 70 in minutes ( less than 10 min). I decided while I had it all turned on to try and read some voltages. I read 12v at the green plug screws, and at D08 12 v when the led was lit, at D10 voltage was 0 and there I assume was supposed to be an led that comes on with that circuit and I saw no other led except those that are always on when the board is powered. Bad board? Bad heating element? Firmware related? What do you think? Thanks for any input, Jim.

Did you check the voltage going to the heating element from the board when it's supposed to be on ?

Yes, I tested where the wires for the extruder heater enter the plugs (D 10) on the board by contacting the screws that tighten the wires in the plug, with the wires plugged in. The board was powered up and hotend was "on" to heat it up. I would think more likely the board, I guess I could move the wires to another plug to test the heater, but I am not sure if I should, unsure of amps required and available at the other positions. I don't want to cause any smoke.

If you're getting no power when it's supposed to be on reach out to folgertech and tell them your board is bad, most likely they'll replace it.

Okay, I will contact them, Thanks for your input marc.

I would suggest moving the the leads from the bed to the hotend output on the Ramps, it the bed heats you know it's the heater cartridge, if not it's the board...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 07:00AM |

Registered: 8 years ago Posts: 268 |

Quote

peeejayz

Quote

sonnylowe

Quote

peeejayz

Quote

sonnylowe

Quote

peeejayz

Quote

sonnylowe

Quote

peeejayz

Quote

sonnylowe

SNIP

WOW. I love it!

Awesome design. Can't wait to see some results and video of it printing.

Just in the middle of my Y one now. All the old parts are off just about to drill the bed to fit it on the carriage.

Do you know what you changed your Y esteps to with a 16t pully?

Hmmm, that's weird, I'm not using a 16 tooth pulley, I'm running the stock 20 tooth pulley as indicated HERE I did adjust my e-steps but it was a really small amount like 80.21!?!?

Dam I missed that. I got a 16 on it working fine, might go back to the 20 the 16 is a little tight.

Its working and printing now thoMega happy with the difference. Cheers for all of your hard work.

Haha, yeah we all miss stuff now and then, so glad to hear it's up and running, and even more so that you like the upgrade

Yea I found the stock folger alu bed to flexible to level correctly so I have ordered one of the openbuilds ones so I'll put that in to help stiffen it all up. Just awaiting alu bed and sensor for auto leveling too now.

Sounds good, but please keep in mind that OB bed will lessens the length of the bed travel by quite a bit, make sure you leave the rail long enough to compensate...

I'm still going to use the smaller plate for the actual wheels ect, just putting the larger open builds plate on the 6mm spacers instead.

That's a great idea...Love it!! It should really beef up the bed a lot...I might just have to order one myself ;-)

BYI: I just made an assembly attaching the UBP to the 20-80 Gantry. The four holes you'll need to use don't quite line up...they are off by ~1mm so at the most you'd need to chase the holes with 5mm drill.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 09:04AM |

Registered: 8 years ago Posts: 26 |

Quote

sonnylowe

Quote

Jim72

Quote

marc2912

Quote

Jim72

Quote

marc2912

Not in front of my printer right now but it sounds like the thermistor is working correctly. It sounds like either the heating element isn't working or the board isn't powering itQuote

Jim72

Good morning. I finished the build, got the firmware straightened out with your help, all 3 axis home and move properly. I leveled the bed and next tried to get the bed and extruder to heat. The bed heats fine. The extruder never heated, the reading on the LCD without heat was 23, with heat it got to 26 (30 min), I am sure that is radiant heat from the bed which was at 70 deg C. I assumed the thermister may be an issue. I checked the folgertech help site and they recommend checking resistance, which I did and it was showing 114k ohms (they say normal 80k to 120k). So, I assume the thermister is probably not the problem? Next I put the hot end back together and opened repetier and tried again to get the extruder to heat without success. I then turned on the bed heat and again it got to 70 in minutes ( less than 10 min). I decided while I had it all turned on to try and read some voltages. I read 12v at the green plug screws, and at D08 12 v when the led was lit, at D10 voltage was 0 and there I assume was supposed to be an led that comes on with that circuit and I saw no other led except those that are always on when the board is powered. Bad board? Bad heating element? Firmware related? What do you think? Thanks for any input, Jim.

Did you check the voltage going to the heating element from the board when it's supposed to be on ?

Yes, I tested where the wires for the extruder heater enter the plugs (D 10) on the board by contacting the screws that tighten the wires in the plug, with the wires plugged in. The board was powered up and hotend was "on" to heat it up. I would think more likely the board, I guess I could move the wires to another plug to test the heater, but I am not sure if I should, unsure of amps required and available at the other positions. I don't want to cause any smoke.

If you're getting no power when it's supposed to be on reach out to folgertech and tell them your board is bad, most likely they'll replace it.

Okay, I will contact them, Thanks for your input marc.

I would suggest moving the the leads from the bed to the hotend output on the Ramps, it the bed heats you know it's the heater cartridge, if not it's the board...

Thanks sonnylowe, that confirmed it. Switched the leads to D08 (bed leads) and the extruder heated in just a couple min. I emailed folgertech yesterday, waiting to hear back. I appreciate the input!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 09:45AM |

Registered: 8 years ago Posts: 80 |

You need to enable the pull-up resistor for the zmax endstop in the config file.Quote

nontech_3der

Quote

Mach

Quote

nontech_3der

Quote

Mach

Quote

nontech_3der

Need help

Just Built my Printer finished setting the voltage on the motors now my issue is when move the z axis is see the log says "endstops hit: Z:0.00"

Not sure where I need to edit the config file to fix this.. any help and or guidance will be greatly appreciated

I am guessing that you are trying to move the Z axis up? Is the axis triggering the endstop? Could you paste your config to pastebin and give a link, I could not open your config file.

Yes I am trying to move the Z axis up. axis is not triggering the endstop, I only have an end stop at the bottom. Question should the kit have two endstops for the Z axis? here is the link [pastebin.com]

I did not see anything anything wrong with the Z axis configs, so the only thing I can think of is that the Z axis was not homed before trying to move it.

Ok not sure why my last quote did show up. First I do apologize for my delayed response i had to travel for work.. Next I rehomed the axis's and still when i try to move the z axis up I see in the logs endstop triggered.. what am I missing or doing wrong.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 03:52PM |

Registered: 8 years ago Posts: 93 |

Quote

therippa

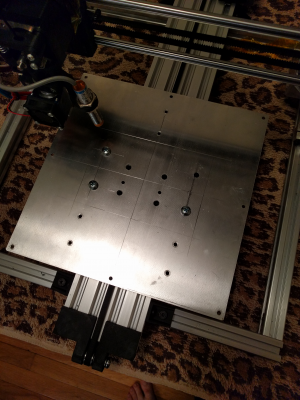

Here is a picture from the back and of the holes I drilled into the folgertech bed plate (and you get to see the sassy towel I use when working on the printer so I don't scratch the kitchen table):

The new endstop works well (if someone is going to build the y-axis, let me know and I'll give you the STL). Whatever length I eyeballed the piece to be cut at worked out perfectly... after putting it all together with the idler end flush with the frame bottom, I learned the openbuild gantry would run in to it and I lost about 25mm of build space. No problem though, I had about 35mm on the other side to spare, so things are back to normal and it looks perfectly "fitted".

This brings up a question I have. How much overall length does the Y mod add to the printer? I have my printer in a cabinet that has just enough room for the bed to move the full distance front-to-back with the stock setup. Does the Y rail mod make it much deeper? Does it have to extend more on the front than the old setup?

I've ordered the parts to do the mod, and based on Sonny's photos, I thought I could make it fit, but if the front can't be flush with the frame, that might not work. Rippa's photos have it sticking out pretty far on both ends. I've got maybe only 18mm extra room in front with the printer against the back of the cabinet. If it doesn't extend too far beyond the frame on the back, I might be able to relocate the ramps board to let it scoot back a little further, but not much.

Also, how did you guys solve the bed mounting issue? I see you just drilled the aluminum instead of using the rails Sonny made. Did you need spacers?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 04:26PM |

Registered: 8 years ago Posts: 93 |

Quote

bstern

So I'm on step 26 of the Folger Guide (Attach Wire Extension to Extruder Fan and Wire it to the Power Supply), and it just seems sort of weird to me to wire the fan so that it is always on. Is this what you guys have done?

You want the extruder cooling fan to run all the time. It keeps the filament from melting higher up in the throat and jamming the extruder.

If you add a filament cooling fan, that blows on the print after it comes out the nozzle, then you want that fan switched by software, so it only runs for PLA, and only comes on after the first few layers are printed.

Edited 2 time(s). Last edit at 01/12/2016 04:31PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 04:39PM |

Registered: 8 years ago Posts: 276 |

Quote

Bert3D

Quote

therippa

Here is a picture from the back and of the holes I drilled into the folgertech bed plate (and you get to see the sassy towel I use when working on the printer so I don't scratch the kitchen table):

The new endstop works well (if someone is going to build the y-axis, let me know and I'll give you the STL). Whatever length I eyeballed the piece to be cut at worked out perfectly... after putting it all together with the idler end flush with the frame bottom, I learned the openbuild gantry would run in to it and I lost about 25mm of build space. No problem though, I had about 35mm on the other side to spare, so things are back to normal and it looks perfectly "fitted".

This brings up a question I have. How much overall length does the Y mod add to the printer? I have my printer in a cabinet that has just enough room for the bed to move the full distance front-to-back with the stock setup. Does the Y rail mod make it much deeper? Does it have to extend more on the front than the old setup?

I've ordered the parts to do the mod, and based on Sonny's photos, I thought I could make it fit, but if the front can't be flush with the frame, that might not work. Rippa's photos have it sticking out pretty far on both ends. I've got maybe only 18mm extra room in front with the printer against the back of the cabinet. If it doesn't extend too far beyond the frame on the back, I might be able to relocate the ramps board to let it scoot back a little further, but not much.

Also, how did you guys solve the bed mounting issue? I see you just drilled the aluminum instead of using the rails Sonny made. Did you need spacers?

The length you see on my printer is actually the smallest the Y-axis can be cut down to without losing build space. This was a fortunate coincidence, I didn't think of clearance issues when I marked the piece to be cut and it ended up being exactly the size needed. At Y0 the endstop switch has just a few mm to spare before it can't go back any further, and at Y190 the gantry is a few mm from hitting the idler. This might actually cause a problem for me in the future when if/when I go for sonny's X-axis upgrade, because the adapter I will have to make to mount a NEMA on the gantry will add 5mm or so, and I'm not sure I have enough room to push the plate back to compensate for it. I had my 395mm bar cut from a length of 1000m extrusion, so in that case I'll use the other piece.

I did just drill holes. I didn't need any spacers beyond what sonny lists in the BOM for the project. You can see from the pencil lines how I lined up the gantry and which holes I used. I wished I had ordered some longer low-profile M5 screws from openbuilds instead of using the pan-head screws from the hardware store. I can't remember how long they need to be though, but you have to make sure they are long enough to go through the gantry+spacers+plate, but not long enough that they get in the way of the delrin wheels on the gantry.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 06:29PM |

Registered: 8 years ago Posts: 33 |

Has anyone had issues using a bowden extruder?

I have the bowden setup with the e3d lite but i can not get consistent extrusion. The extruder works fine in the bowden tubing until it reaches the hotend.

When it reaches the hotend the extruder drive gear gets stuck and the motor clicks. I have tried everything to decrease the force needed for extrusion, no angles in bowden tubing, increasesd hotend temperature, and turned the stepper motor voltage all the way up.

I am almost at the point of scrapping the bowden and reverting back to direct drive.

I have the bowden setup with the e3d lite but i can not get consistent extrusion. The extruder works fine in the bowden tubing until it reaches the hotend.

When it reaches the hotend the extruder drive gear gets stuck and the motor clicks. I have tried everything to decrease the force needed for extrusion, no angles in bowden tubing, increasesd hotend temperature, and turned the stepper motor voltage all the way up.

I am almost at the point of scrapping the bowden and reverting back to direct drive.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 06:50PM |

Registered: 8 years ago Posts: 276 |

Quote

Keary123

Has anyone had issues using a bowden extruder?

I have the bowden setup with the e3d lite but i can not get consistent extrusion. The extruder works fine in the bowden tubing until it reaches the hotend.

When it reaches the hotend the extruder drive gear gets stuck and the motor clicks. I have tried everything to decrease the force needed for extrusion, no angles in bowden tubing, increasesd hotend temperature, and turned the stepper motor voltage all the way up.

I am almost at the point of scrapping the bowden and reverting back to direct drive.

Which bowden extruder are you using? The tension on the gear/filament might be too tight.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 06:52PM |

Registered: 8 years ago Posts: 51 |

Quote

therippa

Quote

Bert3D

Quote

therippa

Here is a picture from the back and of the holes I drilled into the folgertech bed plate (and you get to see the sassy towel I use when working on the printer so I don't scratch the kitchen table):

The new endstop works well (if someone is going to build the y-axis, let me know and I'll give you the STL). Whatever length I eyeballed the piece to be cut at worked out perfectly... after putting it all together with the idler end flush with the frame bottom, I learned the openbuild gantry would run in to it and I lost about 25mm of build space. No problem though, I had about 35mm on the other side to spare, so things are back to normal and it looks perfectly "fitted".

This brings up a question I have. How much overall length does the Y mod add to the printer? I have my printer in a cabinet that has just enough room for the bed to move the full distance front-to-back with the stock setup. Does the Y rail mod make it much deeper? Does it have to extend more on the front than the old setup?

I've ordered the parts to do the mod, and based on Sonny's photos, I thought I could make it fit, but if the front can't be flush with the frame, that might not work. Rippa's photos have it sticking out pretty far on both ends. I've got maybe only 18mm extra room in front with the printer against the back of the cabinet. If it doesn't extend too far beyond the frame on the back, I might be able to relocate the ramps board to let it scoot back a little further, but not much.

Also, how did you guys solve the bed mounting issue? I see you just drilled the aluminum instead of using the rails Sonny made. Did you need spacers?

The length you see on my printer is actually the smallest the Y-axis can be cut down to without losing build space. This was a fortunate coincidence, I didn't think of clearance issues when I marked the piece to be cut and it ended up being exactly the size needed. At Y0 the endstop switch has just a few mm to spare before it can't go back any further, and at Y190 the gantry is a few mm from hitting the idler. This might actually cause a problem for me in the future when if/when I go for sonny's X-axis upgrade, because the adapter I will have to make to mount a NEMA on the gantry will add 5mm or so, and I'm not sure I have enough room to push the plate back to compensate for it. I had my 395mm bar cut from a length of 1000m extrusion, so in that case I'll use the other piece.

I did just drill holes. I didn't need any spacers beyond what sonny lists in the BOM for the project. You can see from the pencil lines how I lined up the gantry and which holes I used. I wished I had ordered some longer low-profile M5 screws from openbuilds instead of using the pan-head screws from the hardware store. I can't remember how long they need to be though, but you have to make sure they are long enough to go through the gantry+spacers+plate, but not long enough that they get in the way of the delrin wheels on the gantry.

16mm ones appears to be about right for mine.

I did get go slightly shorter on my Extrusion its 450mm and offers full build bed.

I have just got in the post : [openbuildspartstore.com] this is to replace the silver alu plate. as I found with 4 screens on the small plate its too flexy to get a group level bed.

The post here: [www.openbuilds.com] is a little out of date Sonny recommended a 16t here and now recommends the same stock 20. I do have the 16 and it works fine. I havn't tried a 20 on this mod.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 07:23PM |

Registered: 8 years ago Posts: 33 |

Quote

therippa

Quote

Keary123

Has anyone had issues using a bowden extruder?

I have the bowden setup with the e3d lite but i can not get consistent extrusion. The extruder works fine in the bowden tubing until it reaches the hotend.

When it reaches the hotend the extruder drive gear gets stuck and the motor clicks. I have tried everything to decrease the force needed for extrusion, no angles in bowden tubing, increasesd hotend temperature, and turned the stepper motor voltage all the way up.

I am almost at the point of scrapping the bowden and reverting back to direct drive.

Which bowden extruder are you using? The tension on the gear/filament might be too tight.

I have been using this one [www.amazon.com] .

Originally i printedone but was having the same exact issue so i purchased this one to see if it would help.

If there is too much tension the motor skips and does not rotate if there is not enough tension the gear rotates but no filament is extruded.

I cant find a happy medium for the tension.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 08:18PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 09:03PM |

Registered: 8 years ago Posts: 276 |

Quote

Keary123

Quote

therippa

Quote

Keary123

Has anyone had issues using a bowden extruder?

I have the bowden setup with the e3d lite but i can not get consistent extrusion. The extruder works fine in the bowden tubing until it reaches the hotend.

When it reaches the hotend the extruder drive gear gets stuck and the motor clicks. I have tried everything to decrease the force needed for extrusion, no angles in bowden tubing, increasesd hotend temperature, and turned the stepper motor voltage all the way up.

I am almost at the point of scrapping the bowden and reverting back to direct drive.

Which bowden extruder are you using? The tension on the gear/filament might be too tight.

I have been using this one [www.amazon.com] .

Originally i printedone but was having the same exact issue so i purchased this one to see if it would help.

If there is too much tension the motor skips and does not rotate if there is not enough tension the gear rotates but no filament is extruded.

I cant find a happy medium for the tension.

Does this happen if the hotend is not pressed up against the print bed? Like if you raised your hotend 10mm, heated it up, and extruded, does the motor still skip steps?

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 09:40PM |

Registered: 8 years ago Posts: 367 |

@keary123

I had a clicking problem on my E3D lite6 recently in a direct drive. There was a partial blockage because the PTFE liner wasn't pushed down as far as it needed to go. So plastic was accumulating in the gap between the end of the liner and the nozzle, and it was not hot enough to flow out the nozzle, but not completely solid. You could try taking it apart and seeing if the PTFE goes all the way to the end of the heatsink.

See my blog at [moosteria.blogspot.com].

I had a clicking problem on my E3D lite6 recently in a direct drive. There was a partial blockage because the PTFE liner wasn't pushed down as far as it needed to go. So plastic was accumulating in the gap between the end of the liner and the nozzle, and it was not hot enough to flow out the nozzle, but not completely solid. You could try taking it apart and seeing if the PTFE goes all the way to the end of the heatsink.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 10:18PM |

Registered: 8 years ago Posts: 33 |

Quote

therippa

Quote

Keary123

Quote

therippa

Quote

Keary123

Has anyone had issues using a bowden extruder?

I have the bowden setup with the e3d lite but i can not get consistent extrusion. The extruder works fine in the bowden tubing until it reaches the hotend.

When it reaches the hotend the extruder drive gear gets stuck and the motor clicks. I have tried everything to decrease the force needed for extrusion, no angles in bowden tubing, increasesd hotend temperature, and turned the stepper motor voltage all the way up.

I am almost at the point of scrapping the bowden and reverting back to direct drive.

Which bowden extruder are you using? The tension on the gear/filament might be too tight.

I have been using this one [www.amazon.com] .

Originally i printedone but was having the same exact issue so i purchased this one to see if it would help.

If there is too much tension the motor skips and does not rotate if there is not enough tension the gear rotates but no filament is extruded.

I cant find a happy medium for the tension.

Does this happen if the hotend is not pressed up against the print bed? Like if you raised your hotend 10mm, heated it up, and extruded, does the motor still skip steps?

Yes it does, it happens as soon as the filament goes inside of the e3d.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 12, 2016 10:19PM |

Registered: 8 years ago Posts: 33 |

Quote

animoose

@keary123

I had a clicking problem on my E3D lite6 recently in a direct drive. There was a partial blockage because the PTFE liner wasn't pushed down as far as it needed to go. So plastic was accumulating in the gap between the end of the liner and the nozzle, and it was not hot enough to flow out the nozzle, but not completely solid. You could try taking it apart and seeing if the PTFE goes all the way to the end of the heatsink.

Okay I will have to check this out tomorrow and let you know.

That would honestly make sense because I know there isn't a blockage in the hotened and also it extrudes just fine when i remove the bowden tubing from the hot end.

I will keep you posted, thanks.

Edited 1 time(s). Last edit at 01/12/2016 10:21PM by Keary123.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 08:09AM |

Registered: 8 years ago Posts: 268 |

Quote

peeejayz

Quote

therippa

Quote

Bert3D

Quote

therippa

Here is a picture from the back and of the holes I drilled into the folgertech bed plate (and you get to see the sassy towel I use when working on the printer so I don't scratch the kitchen table):

The new endstop works well (if someone is going to build the y-axis, let me know and I'll give you the STL). Whatever length I eyeballed the piece to be cut at worked out perfectly... after putting it all together with the idler end flush with the frame bottom, I learned the openbuild gantry would run in to it and I lost about 25mm of build space. No problem though, I had about 35mm on the other side to spare, so things are back to normal and it looks perfectly "fitted".

This brings up a question I have. How much overall length does the Y mod add to the printer? I have my printer in a cabinet that has just enough room for the bed to move the full distance front-to-back with the stock setup. Does the Y rail mod make it much deeper? Does it have to extend more on the front than the old setup?

I've ordered the parts to do the mod, and based on Sonny's photos, I thought I could make it fit, but if the front can't be flush with the frame, that might not work. Rippa's photos have it sticking out pretty far on both ends. I've got maybe only 18mm extra room in front with the printer against the back of the cabinet. If it doesn't extend too far beyond the frame on the back, I might be able to relocate the ramps board to let it scoot back a little further, but not much.

Also, how did you guys solve the bed mounting issue? I see you just drilled the aluminum instead of using the rails Sonny made. Did you need spacers?

The length you see on my printer is actually the smallest the Y-axis can be cut down to without losing build space. This was a fortunate coincidence, I didn't think of clearance issues when I marked the piece to be cut and it ended up being exactly the size needed. At Y0 the endstop switch has just a few mm to spare before it can't go back any further, and at Y190 the gantry is a few mm from hitting the idler. This might actually cause a problem for me in the future when if/when I go for sonny's X-axis upgrade, because the adapter I will have to make to mount a NEMA on the gantry will add 5mm or so, and I'm not sure I have enough room to push the plate back to compensate for it. I had my 395mm bar cut from a length of 1000m extrusion, so in that case I'll use the other piece.

I did just drill holes. I didn't need any spacers beyond what sonny lists in the BOM for the project. You can see from the pencil lines how I lined up the gantry and which holes I used. I wished I had ordered some longer low-profile M5 screws from openbuilds instead of using the pan-head screws from the hardware store. I can't remember how long they need to be though, but you have to make sure they are long enough to go through the gantry+spacers+plate, but not long enough that they get in the way of the delrin wheels on the gantry.

16mm ones appears to be about right for mine.

I did get go slightly shorter on my Extrusion its 450mm and offers full build bed.

I have just got in the post : [openbuildspartstore.com] this is to replace the silver alu plate. as I found with 4 screens on the small plate its too flexy to get a group level bed.

The post here: [www.openbuilds.com] is a little out of date Sonny recommended a 16t here and now recommends the same stock 20. I do have the 16 and it works fine. I havn't tried a 20 on this mod.

Thanks for pointing out the Toothed Pulley error in the OB build (I did originally design it for that size, but changed my mind during the build) ...I have corrected it.

As far as the length of the Y rail, it could be as short as the old 8mm rods, it would however require the belt and stepper be setup in the same manner as the old setup, it would have to run beside the rail and not through it. If you guys are interested in that setup let me know and I can take a look at designing another version...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 11:13AM |

Registered: 8 years ago Posts: 268 |

Quote

Bert3D

Quote

therippa

Here is a picture from the back and of the holes I drilled into the folgertech bed plate (and you get to see the sassy towel I use when working on the printer so I don't scratch the kitchen table):

The new endstop works well (if someone is going to build the y-axis, let me know and I'll give you the STL). Whatever length I eyeballed the piece to be cut at worked out perfectly... after putting it all together with the idler end flush with the frame bottom, I learned the openbuild gantry would run in to it and I lost about 25mm of build space. No problem though, I had about 35mm on the other side to spare, so things are back to normal and it looks perfectly "fitted".

This brings up a question I have. How much overall length does the Y mod add to the printer? I have my printer in a cabinet that has just enough room for the bed to move the full distance front-to-back with the stock setup. Does the Y rail mod make it much deeper? Does it have to extend more on the front than the old setup?

I've ordered the parts to do the mod, and based on Sonny's photos, I thought I could make it fit, but if the front can't be flush with the frame, that might not work. Rippa's photos have it sticking out pretty far on both ends. I've got maybe only 18mm extra room in front with the printer against the back of the cabinet. If it doesn't extend too far beyond the frame on the back, I might be able to relocate the ramps board to let it scoot back a little further, but not much.

Also, how did you guys solve the bed mounting issue? I see you just drilled the aluminum instead of using the rails Sonny made. Did you need spacers?

I took a quick look at the OP site, THIS is a basic example of how you could run the drive system on the Y-Carriage. I think you could basically use the old FT belt, stepper and idler pulley mounts and make it work. I'll try to model something in the few days, see what it looks like. The only possible issue I see would be running the belt off center, although I wouldn't suggest it with the old setup, I think with the V-Slot guides it would be fine...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 11:49AM |

Registered: 8 years ago Posts: 268 |

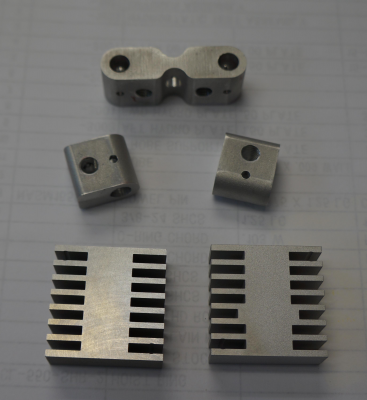

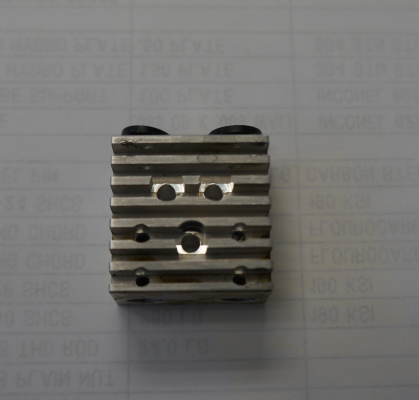

I must admit, it's pretty damn nice having access to a full blown machine shop

New double and single heater blocks for my E3D Chimera, and a remix of the Chimera/Cyclops Heat Sink to run as a single extruder (currently only wire cut, still need some conventional machining)...I did this to take advantage of the Chimera/Cyclops easy nozzle height adjustment

I modified the stock heat sink to allow the use mounting screw installed from the front of the heat sink, it also allows adjustment of the nozzle height from the front (a must for the new X-Gantry. This makes mounting the hotend to the new X-Gantry much simpler as well...

Edited 1 time(s). Last edit at 01/13/2016 01:28PM by sonnylowe.

New double and single heater blocks for my E3D Chimera, and a remix of the Chimera/Cyclops Heat Sink to run as a single extruder (currently only wire cut, still need some conventional machining)...I did this to take advantage of the Chimera/Cyclops easy nozzle height adjustment

I modified the stock heat sink to allow the use mounting screw installed from the front of the heat sink, it also allows adjustment of the nozzle height from the front (a must for the new X-Gantry. This makes mounting the hotend to the new X-Gantry much simpler as well...

Edited 1 time(s). Last edit at 01/13/2016 01:28PM by sonnylowe.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 06:34PM |

Registered: 8 years ago Posts: 33 |

Quote

Keary123

Quote

animoose

@keary123

I had a clicking problem on my E3D lite6 recently in a direct drive. There was a partial blockage because the PTFE liner wasn't pushed down as far as it needed to go. So plastic was accumulating in the gap between the end of the liner and the nozzle, and it was not hot enough to flow out the nozzle, but not completely solid. You could try taking it apart and seeing if the PTFE goes all the way to the end of the heatsink.

Okay I will have to check this out tomorrow and let you know.

That would honestly make sense because I know there isn't a blockage in the hotened and also it extrudes just fine when i remove the bowden tubing from the hot end.

I will keep you posted, thanks.

Turns out filament was accumulating at the bottom of the heat sink. I have taken it apart and I am currently working on removing the stuck filament towards the bottom of the heat sink.

How did you push the PTFE liner down?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 06:37PM |

Registered: 8 years ago Posts: 367 |

Quote

Keary123

Quote

Keary123

Quote

animoose

@keary123

I had a clicking problem on my E3D lite6 recently in a direct drive. There was a partial blockage because the PTFE liner wasn't pushed down as far as it needed to go. So plastic was accumulating in the gap between the end of the liner and the nozzle, and it was not hot enough to flow out the nozzle, but not completely solid. You could try taking it apart and seeing if the PTFE goes all the way to the end of the heatsink.

Okay I will have to check this out tomorrow and let you know.

That would honestly make sense because I know there isn't a blockage in the hotened and also it extrudes just fine when i remove the bowden tubing from the hot end.

I will keep you posted, thanks.

Turns out filament was accumulating at the bottom of the heat sink. I have taken it apart and I am currently working on removing the stuck filament towards the bottom of the heat sink.

How did you push the PTFE liner down?

I held it gently with a pair of fine nose pliers and pushed. You have to apply more force than you would expect. I did this with the heatsink unscrewed from the heater block. This isn't how the E3D Lite assembly instructions show it, but it allows you to really see what is going on.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 06:42PM |

Registered: 8 years ago Posts: 541 |

Quote

sonnylowe

Quote

tjnamtiw

Where did you buy the BLTouch? From the promotion site or elsewhere? I haven't found it anywhere else.

You can purchase the White (updated) version directly from Charles, it's $33.00 shipped. I followed the instructions below. Charles was quick to respond and provided tracking info quickly as well. It took about 2 weeks to get here...

From the comment section of their Indigogo page

"Hello, everyone who are interested in BLTouch!

Since eBay's policy and we are beginner of eBay, it is very difficult to sell the products at eBay.

So while we finding the way to sell BLTouch at online shopping site, please send us an e-mail including the quantity, your address, zip code, phone number and name who want to buy BLTouch.

And, we are keep the retail price policy.

Price : $33

PayPal Account & E-mail adress : charlesleeok@naver.com

Thank you,

BLTouch Team"

I got my new BLTouch last Friday, so that was really quick from Korea! It came extremely well protected and with all the hardware to mount it as well as hardware to construct wiring extensions of any length you desire. You supply the wire but they give you all the end pieces and the pins. Really no instructions came with it other than the spec sheet so HERE WE GO! I moved the X stop over to the left as a first step (swallowed my pride) and modified the FT Marlin. I printed out a test piece to be sure nothing was mirrored. Now I downloaded the newer C2 Marlin you suggested that has better leveling processes and I'm changing settings in it to mirror those in the FT that works. I'll install that and then make sure everything is still good before I jump into the BLTouch setup. As I write this, I'm printing out the little mount that goes on the side of the block that the heat sink mounts on. I added 1mm to it's offset since the BLTouch pin drags with the original I found on Thingiverse. Once I get the C2 version working, I'll give the auto level a go but I might be back looking for some guidance.

If you have any suggestions on things to uncomment or comment out in the auto leveling section, I'm all ears. Thanks!

If you have any suggestions on things to uncomment or comment out in the auto leveling section, I'm all ears. Thanks!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 07:20PM |

Registered: 8 years ago Posts: 276 |

Quote

tjnamtiw

Quote

sonnylowe

Quote

tjnamtiw

Where did you buy the BLTouch? From the promotion site or elsewhere? I haven't found it anywhere else.

You can purchase the White (updated) version directly from Charles, it's $33.00 shipped. I followed the instructions below. Charles was quick to respond and provided tracking info quickly as well. It took about 2 weeks to get here...

From the comment section of their Indigogo page

"Hello, everyone who are interested in BLTouch!

Since eBay's policy and we are beginner of eBay, it is very difficult to sell the products at eBay.

So while we finding the way to sell BLTouch at online shopping site, please send us an e-mail including the quantity, your address, zip code, phone number and name who want to buy BLTouch.

And, we are keep the retail price policy.

Price : $33

PayPal Account & E-mail adress : charlesleeok@naver.com

Thank you,

BLTouch Team"

I got my new BLTouch last Friday, so that was really quick from Korea! It came extremely well protected and with all the hardware to mount it as well as hardware to construct wiring extensions of any length you desire. You supply the wire but they give you all the end pieces and the pins. Really no instructions came with it other than the spec sheet so HERE WE GO! I moved the X stop over to the left as a first step (swallowed my pride) and modified the FT Marlin. I printed out a test piece to be sure nothing was mirrored. Now I downloaded the newer C2 Marlin you suggested that has better leveling processes and I'm changing settings in it to mirror those in the FT that works. I'll install that and then make sure everything is still good before I jump into the BLTouch setup. As I write this, I'm printing out the little mount that goes on the side of the block that the heat sink mounts on. I added 1mm to it's offset since the BLTouch pin drags with the original I found on Thingiverse. Once I get the C2 version working, I'll give the auto level a go but I might be back looking for some guidance.If you have any suggestions on things to uncomment or comment out in the auto leveling section, I'm all ears. Thanks!

If you get stuck migrating settings, you can always try my firmware fork

It has the latest autolevel

It has the latest autolevelNeed help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 07:34PM |

Registered: 8 years ago Posts: 541 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 08:18PM |

Registered: 8 years ago Posts: 276 |

Quote

tjnamtiw

Thanks, Rippa! I'll check it out. I don't know if the logic of the BLTouch is any different than prox sensors. Thanks. I've peeked around your github site but didn't see anything labeled 'auto level'.

The autolevel stuff is commented out in the configuration file, but the logic is there (autolevel in general, you have to tweak it for your specific setup). The FL Marlin pre-dates autolevel being added to the project.

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 08:26PM |

Registered: 8 years ago Posts: 268 |

Quote

tjnamtiw

Thanks, Rippa! I'll check it out. I don't know if the logic of the BLTouch is any different than prox sensors. Thanks. I've peeked around your github site but didn't see anything labeled 'auto level'.

Sounds like you're going at this perfectly..."one step at a time"

Unfortunately I made like three changes at once...it was not fun!!! I believe Charles addressed all the issue with the Yellow version before putting out the White...so hopefully you'll have an easier go of it.

Unfortunately I made like three changes at once...it was not fun!!! I believe Charles addressed all the issue with the Yellow version before putting out the White...so hopefully you'll have an easier go of it. The only difference between the proximity senor and the BLt is you setup the BLtouch like a servo/micro setup. You may also have to speed up the second probe a bit...the Yellow BLt didn't like moving slowly between probes ;-)

Check out this VIDEO, it has a lot of the settings you will need for 1.1.0 RC...there is also some dialog between Greg I as I was trying to get this to work initially. Turned out the time between the first and second hit was too long...

Not sure if it will work, but I have attached my config.h file...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 13, 2016 08:52PM |

Registered: 8 years ago Posts: 19 |

Hi, Has anybody seen their printer magically jump and start to print shifted from where it was supposed to print? I had a problem last week and then lubed all the bearing surfaces and made sure that the motor connections were all tightened and got a decent fairly large print (5x4x1), but then I tried to print an enclosure that's 6.25x6.25x2 and got a shift in the surface again, but this time I noticed something from the Repetier software: Did the shift occur because of some software glitch?

15:36:24.627 : Printing layer 4 of 127

15:45:28.337 : Printing layer 5 of 127

15:52:32.225 : Printing layer 6 of 127

15:55:04.609 : echo:Unknown command: "@"

15:55:04.610 : Error:No Line Number with checksum, Last Line: 16773

15:55:04.610 : Error:Line Number is not Last Line Number+1, Last Line: 16773

15:55:04.613 : Resend: 16774

15:55:04.622 : Error:Line Number is not Last Line Number+1, Last Line: 16773

15:55:04.622 : Resend: 16774

15:55:04.634 : Error:Line Number is not Last Line Number+1, Last Line: 16775

15:55:04.634 : Resend: 16776

16:12:33.221 : Printing layer 7 of 127

16:43:20.610 : Printing layer 8 of 127

17:14:10.562 : Printing layer 9 of 127

17:15:32.611 : Error:checksum mismatch, Last Line: 25041

17:15:32.611 : Resend: 25042

17:15:32.628 : Error:Line Number is not Last Line Number+1, Last Line: 25041

17:15:32.628 : Resend: 25042

17:15:32.652 : Error:checksum mismatch, Last Line: 25044

17:15:32.656 : Resend: 25045

17:15:32.665 : Error:Line Number is not Last Line Number+1, Last Line: 25044

17:15:32.665 : Resend: 25045

17:15:32.671 : Error:No Line Number with checksum, Last Line: 25044

17:15:32.677 : Error:Line Number is not Last Line Number+1, Last Line: 25044

17:15:32.681 : Resend: 25045

17:15:32.686 : Error:Line Number is not Last Line Number+1, Last Line: 25044

17:15:32.686 : Resend: 25045

17:15:32.710 : Error:Line Number is not Last Line Number+1, Last Line: 25047

17:15:32.710 : Resend: 25048

17:15:32.715 : Error:No Line Number with checksum, Last Line: 25047

17:17:21.513 : Printing layer 10 of 127

17:20:28.495 : Printing layer 11 of 127

17:23:40.724 : Printing layer 12 of 127

17:26:34.508 : Printer reset detected - initalizing

Thanks,

Dave

15:36:24.627 : Printing layer 4 of 127

15:45:28.337 : Printing layer 5 of 127

15:52:32.225 : Printing layer 6 of 127

15:55:04.609 : echo:Unknown command: "@"

15:55:04.610 : Error:No Line Number with checksum, Last Line: 16773

15:55:04.610 : Error:Line Number is not Last Line Number+1, Last Line: 16773

15:55:04.613 : Resend: 16774

15:55:04.622 : Error:Line Number is not Last Line Number+1, Last Line: 16773

15:55:04.622 : Resend: 16774

15:55:04.634 : Error:Line Number is not Last Line Number+1, Last Line: 16775

15:55:04.634 : Resend: 16776

16:12:33.221 : Printing layer 7 of 127

16:43:20.610 : Printing layer 8 of 127

17:14:10.562 : Printing layer 9 of 127

17:15:32.611 : Error:checksum mismatch, Last Line: 25041

17:15:32.611 : Resend: 25042

17:15:32.628 : Error:Line Number is not Last Line Number+1, Last Line: 25041

17:15:32.628 : Resend: 25042

17:15:32.652 : Error:checksum mismatch, Last Line: 25044

17:15:32.656 : Resend: 25045

17:15:32.665 : Error:Line Number is not Last Line Number+1, Last Line: 25044

17:15:32.665 : Resend: 25045

17:15:32.671 : Error:No Line Number with checksum, Last Line: 25044

17:15:32.677 : Error:Line Number is not Last Line Number+1, Last Line: 25044

17:15:32.681 : Resend: 25045

17:15:32.686 : Error:Line Number is not Last Line Number+1, Last Line: 25044

17:15:32.686 : Resend: 25045

17:15:32.710 : Error:Line Number is not Last Line Number+1, Last Line: 25047

17:15:32.710 : Resend: 25048

17:15:32.715 : Error:No Line Number with checksum, Last Line: 25047

17:17:21.513 : Printing layer 10 of 127

17:20:28.495 : Printing layer 11 of 127

17:23:40.724 : Printing layer 12 of 127

17:26:34.508 : Printer reset detected - initalizing

Thanks,

Dave

Sorry, only registered users may post in this forum.