Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 04:22PM |

Registered: 8 years ago Posts: 314 |

Thanks for posting a pic! It speaks a thousand wordsQuote

Bert3D

Quote

UltiFix

So let me get this straight, there are 2 kinds of autolevel, one were this are servos moving the bed, and the other is a sensor and the z axis just moves up and down to compensate for bed level changes, im assuming the second choice is cheaper. Right? What are most of you guys doing?

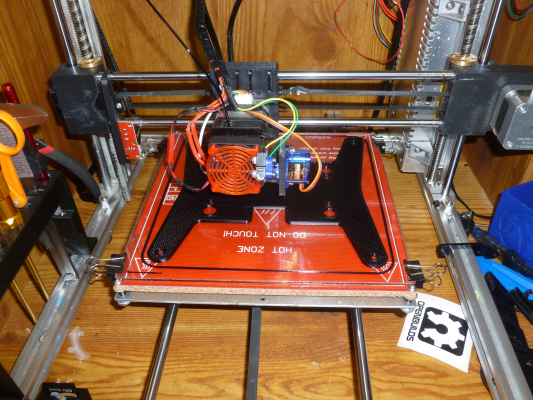

No, the servo method has a servo mounted on the print head, with an arm attached and an endstop type switch on the end of the arm. When it is time to home Z, or probe, the servo arm swings down and the head lowers until the switch closes. When the probing is done, the servo arm goes up, so the switch is out of the way, and the head can go on down to print.

I don't have a good photo, but you can see it in this one:

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 04:24PM |

Registered: 8 years ago Posts: 314 |

Awesome! I will go back and find the capactive sensor and favorite it, once I get this printer running im going to go upgrade crazyQuote

sonnylowe

Quote

UltiFix

So let me get this straight, there are 2 kinds of autolevel, one were this are servos moving the bed, and the other is a sensor and the z axis just moves up and down to compensate for bed level changes, im assuming the second choice is cheaper. Right? What are most of you guys doing?Quote

Bert3D

Quote

peeejayz

Quote

sonnylowe

Quote

therippa

So I just ordered a BLTouch to replace my inductive sensor, would someone mind updating the wiki page with the basic instructions?

Done

Are they that much better than inductive sensors? Just wondering it its worth getting one. I have an inductive on the way, but if its better I'll keep the inductive as a spare.

That's what I was wondering as well. I have a BLTouch on the way, and I'm sure it is better than the servo setup I'm using now, and should be easier than the switch to an aluminum print bed to make an inductive sensor work.

If you have a working inductive sensor setup, the only advantage I can see would be that it measures to the top of the surface, where the inductive sensor measures to the metal plate. That means you need to insure whatever you put on top of the metal plate is always the same thickness. That's probably not really a huge limitation, but one time I accidentally put my glass plate on top of one of the corner screw heads, and because the autolevel probed it and just adjusted, I didn't even notice it wasn't flat. Prints worked fine anyway. If it was sensing the bed underneath, that would have been a problem.

I haven't gotten my BLTouch, or tried an inductive setup, so I'd love to hear from others how they have worked for them.

They both work exactly the same, they just use different means to check the levelness of the bed. Either way the Z motor make the adjustment while printing.

The BLtouch and Servo/Micro Switch Setup work by actually touching the surface you are printing on. An Inductive Proximity Sensor measure how close you are to a metallic surface without actually touching it. A Capacitive Sensor measure density changes in almost anything, so it can read the glass, BuildTak, or possibly the Kapton Tape surface, otherwise it works just like the Inductive Sensor. If you look through the thread you will find lots of info and lots of opinions on both.

As far as cost, the Inductive Sensor and BLtouch cost about the same if you buy an aluminum build plate. If you can find the Capacitive Sensor I suggested earlier it can be as little as $15.00 with no need to buy any other build plate material.

There is success with all three setups, every person running them likes their choice for one reason or another, they all do the basically the same thing, it's really just your preference...

EDIT:

Goodness, the search function is awful! I searched and went back and looked at previous pages and can't find it.

[www.ebay.com]

Would something like this work ok?

Edited 2 time(s). Last edit at 01/20/2016 04:32PM by UltiFix.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 04:27PM |

Registered: 8 years ago Posts: 285 |

Quote

Jim72

I have a question regarding printing. Still waiting on parts to get this going. My question is this. I have read where people will set their firmware to print at 0.1mm or 0.2mm for better quality. The printer comes with a 0.4mm extruder tip, does this need to be changed to a smaller opening to facilitate printing thinner layers?

Thanks, Jim

The layer height is something that you changed in the slicer, not the firmware. Nothing in the firmware needs to be changed in regards to the diameter of the nozzle's orifice to print at different heights.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 04:32PM |

Registered: 8 years ago Posts: 367 |

Quote

Jim72

I have a question regarding printing. Still waiting on parts to get this going. My question is this. I have read where people will set their firmware to print at 0.1mm or 0.2mm for better quality. The printer comes with a 0.4mm extruder tip, does this need to be changed to a smaller opening to facilitate printing thinner layers?

Thanks, Jim

I have a 0.4mm nizzle and usually print at 0.3mm or 0.2mm layers, and occasionally at 0.1mm. I have done a few test prints at 0.05mm. At the smaller layer heights, it becomes more important to make sure that the bed is level and at the right height. This isn't a firmware setting, it's a parameter to the slicer.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 04:33PM |

Registered: 8 years ago Posts: 285 |

Quote

UltiFix

Awesome! I will go back and find the capactive sensor and favorite it, once I get this printer running im going to go upgrade crazyQuote

sonnylowe

Quote

UltiFix

So let me get this straight, there are 2 kinds of autolevel, one were this are servos moving the bed, and the other is a sensor and the z axis just moves up and down to compensate for bed level changes, im assuming the second choice is cheaper. Right? What are most of you guys doing?Quote

Bert3D

Quote

peeejayz

Quote

sonnylowe

Quote

therippa

So I just ordered a BLTouch to replace my inductive sensor, would someone mind updating the wiki page with the basic instructions?

Done

Are they that much better than inductive sensors? Just wondering it its worth getting one. I have an inductive on the way, but if its better I'll keep the inductive as a spare.

That's what I was wondering as well. I have a BLTouch on the way, and I'm sure it is better than the servo setup I'm using now, and should be easier than the switch to an aluminum print bed to make an inductive sensor work.

If you have a working inductive sensor setup, the only advantage I can see would be that it measures to the top of the surface, where the inductive sensor measures to the metal plate. That means you need to insure whatever you put on top of the metal plate is always the same thickness. That's probably not really a huge limitation, but one time I accidentally put my glass plate on top of one of the corner screw heads, and because the autolevel probed it and just adjusted, I didn't even notice it wasn't flat. Prints worked fine anyway. If it was sensing the bed underneath, that would have been a problem.

I haven't gotten my BLTouch, or tried an inductive setup, so I'd love to hear from others how they have worked for them.

They both work exactly the same, they just use different means to check the levelness of the bed. Either way the Z motor make the adjustment while printing.

The BLtouch and Servo/Micro Switch Setup work by actually touching the surface you are printing on. An Inductive Proximity Sensor measure how close you are to a metallic surface without actually touching it. A Capacitive Sensor measure density changes in almost anything, so it can read the glass, BuildTak, or possibly the Kapton Tape surface, otherwise it works just like the Inductive Sensor. If you look through the thread you will find lots of info and lots of opinions on both.

As far as cost, the Inductive Sensor and BLtouch cost about the same if you buy an aluminum build plate. If you can find the Capacitive Sensor I suggested earlier it can be as little as $15.00 with no need to buy any other build plate material.

There is success with all three setups, every person running them likes their choice for one reason or another, they all do the basically the same thing, it's really just your preference...

EDIT:

Goodness, the search function is awful!

lol, I would agree it is pretty bad. Animoose made a custom google search for the thread that works much better.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 04:37PM |

Registered: 8 years ago Posts: 131 |

Quote

Bert3D

Quote

UltiFix

So let me get this straight, there are 2 kinds of autolevel, one were this are servos moving the bed, and the other is a sensor and the z axis just moves up and down to compensate for bed level changes, im assuming the second choice is cheaper. Right? What are most of you guys doing?

No, the servo method has a servo mounted on the print head, with an arm attached and an endstop type switch on the end of the arm. When it is time to home Z, or probe, the servo arm swings down and the head lowers until the switch closes. When the probing is done, the servo arm goes up, so the switch is out of the way, and the head can go on down to print.

I don't have a good photo, but you can see it in this one:

Is that print ABS? I'm printing on glass the same way and can't stop the warping on the corners.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 04:43PM |

Registered: 8 years ago Posts: 314 |

Wow, thats nice of him! Off to use it!Quote

Mach

Quote

UltiFix

Awesome! I will go back and find the capactive sensor and favorite it, once I get this printer running im going to go upgrade crazyQuote

sonnylowe

Quote

UltiFix

So let me get this straight, there are 2 kinds of autolevel, one were this are servos moving the bed, and the other is a sensor and the z axis just moves up and down to compensate for bed level changes, im assuming the second choice is cheaper. Right? What are most of you guys doing?Quote

Bert3D

Quote

peeejayz

Quote

sonnylowe

Quote

therippa

So I just ordered a BLTouch to replace my inductive sensor, would someone mind updating the wiki page with the basic instructions?

Done

Are they that much better than inductive sensors? Just wondering it its worth getting one. I have an inductive on the way, but if its better I'll keep the inductive as a spare.

That's what I was wondering as well. I have a BLTouch on the way, and I'm sure it is better than the servo setup I'm using now, and should be easier than the switch to an aluminum print bed to make an inductive sensor work.

If you have a working inductive sensor setup, the only advantage I can see would be that it measures to the top of the surface, where the inductive sensor measures to the metal plate. That means you need to insure whatever you put on top of the metal plate is always the same thickness. That's probably not really a huge limitation, but one time I accidentally put my glass plate on top of one of the corner screw heads, and because the autolevel probed it and just adjusted, I didn't even notice it wasn't flat. Prints worked fine anyway. If it was sensing the bed underneath, that would have been a problem.

I haven't gotten my BLTouch, or tried an inductive setup, so I'd love to hear from others how they have worked for them.

They both work exactly the same, they just use different means to check the levelness of the bed. Either way the Z motor make the adjustment while printing.

The BLtouch and Servo/Micro Switch Setup work by actually touching the surface you are printing on. An Inductive Proximity Sensor measure how close you are to a metallic surface without actually touching it. A Capacitive Sensor measure density changes in almost anything, so it can read the glass, BuildTak, or possibly the Kapton Tape surface, otherwise it works just like the Inductive Sensor. If you look through the thread you will find lots of info and lots of opinions on both.

As far as cost, the Inductive Sensor and BLtouch cost about the same if you buy an aluminum build plate. If you can find the Capacitive Sensor I suggested earlier it can be as little as $15.00 with no need to buy any other build plate material.

There is success with all three setups, every person running them likes their choice for one reason or another, they all do the basically the same thing, it's really just your preference...

EDIT:

Goodness, the search function is awful!

lol, I would agree it is pretty bad. Animoose made a custom google search for the thread that works much better.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 05:05PM |

Registered: 8 years ago Posts: 93 |

Quote

marc2912

Quote

Bert3D

Quote

UltiFix

So let me get this straight, there are 2 kinds of autolevel, one were this are servos moving the bed, and the other is a sensor and the z axis just moves up and down to compensate for bed level changes, im assuming the second choice is cheaper. Right? What are most of you guys doing?

No, the servo method has a servo mounted on the print head, with an arm attached and an endstop type switch on the end of the arm. When it is time to home Z, or probe, the servo arm swings down and the head lowers until the switch closes. When the probing is done, the servo arm goes up, so the switch is out of the way, and the head can go on down to print.

I don't have a good photo, but you can see it in this one:

Is that print ABS? I'm printing on glass the same way and can't stop the warping on the corners.

That one is PLA. Try adding a ramp and brim in your slicer, and see if that helps.

Also, there is no adhesive at all on the glass for that print, and it was still hard to get off.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 05:07PM |

Registered: 8 years ago Posts: 93 |

Quote

Mach

lol, I would agree it is pretty bad. Animoose made a custom google search for the thread that works much better.

I agree that the forum search is less than worthless. We should link his search in our sigs, just like the wiki. And maybe put it on the wiki, if he doesn't mind.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 05:11PM |

Registered: 8 years ago Posts: 14 |

Some progress I set my endstops to Machs suggestions everything is moving in the right direction but when I home any one of the axis there is no more movement with any axis ?

If I disconnect and manually move away from the offending stop then reconnect it all moves again, my com port is staying connected now.

Count me in as well for the search function, I have been searching for days with no luck.

Edited 1 time(s). Last edit at 01/20/2016 05:21PM by nobrakes.

If I disconnect and manually move away from the offending stop then reconnect it all moves again, my com port is staying connected now.

Count me in as well for the search function, I have been searching for days with no luck.

Edited 1 time(s). Last edit at 01/20/2016 05:21PM by nobrakes.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 05:22PM |

Registered: 8 years ago Posts: 367 |

Quote

Bert3D

Quote

Mach

lol, I would agree it is pretty bad. Animoose made a custom google search for the thread that works much better.

I agree that the forum search is less than worthless. We should link his search in our sigs, just like the wiki. And maybe put it on the wiki, if he doesn't mind.

There is a different link that I would prefer:

[cse.google.com]

I set up the original search engine using my work account, and the new one with my personal account. The work account would go away if I left the company, while the personal one should stay around indefinitely.

BTW, setting these up is really easy - it takes about 2 minutes.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 05:27PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 05:48PM |

Registered: 8 years ago Posts: 93 |

Quote

animoose

Quote

Bert3D

Quote

Mach

lol, I would agree it is pretty bad. Animoose made a custom google search for the thread that works much better.

I agree that the forum search is less than worthless. We should link his search in our sigs, just like the wiki. And maybe put it on the wiki, if he doesn't mind.

There is a different link that I would prefer:

[cse.google.com]

I set up the original search engine using my work account, and the new one with my personal account. The work account would go away if I left the company, while the personal one should stay around indefinitely.

BTW, setting these up is really easy - it takes about 2 minutes.

I changed my sig to include that URL. That's for setting it up. The forum search is so broken.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 05:52PM |

Registered: 8 years ago Posts: 285 |

Quote

nobrakes

M119 shows all endstops open, min and max, Is this correct ?

The endstops should show open when untriggered, and triggered when triggered. What does it tell you when you enter the command while manually pressing the endstops.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 06:04PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 06:11PM |

Registered: 8 years ago Posts: 285 |

Quote

nobrakes

Manually pressing the stop and sending M119 does nothing, no report ?

Is your arduino connecting with repetier?

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 06:14PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 06:18PM |

Registered: 8 years ago Posts: 285 |

Quote

nobrakes

Yes I can manually move everything, do they all need to be triggered to get the report ?

no. Try resending the command

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 06:20PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 06:24PM |

Registered: 8 years ago Posts: 51 |

Quote

sonnylowe

Quote

UltiFix

So let me get this straight, there are 2 kinds of autolevel, one were this are servos moving the bed, and the other is a sensor and the z axis just moves up and down to compensate for bed level changes, im assuming the second choice is cheaper. Right? What are most of you guys doing?Quote

Bert3D

Quote

peeejayz

Quote

sonnylowe

Quote

therippa

So I just ordered a BLTouch to replace my inductive sensor, would someone mind updating the wiki page with the basic instructions?

Done

Are they that much better than inductive sensors? Just wondering it its worth getting one. I have an inductive on the way, but if its better I'll keep the inductive as a spare.

That's what I was wondering as well. I have a BLTouch on the way, and I'm sure it is better than the servo setup I'm using now, and should be easier than the switch to an aluminum print bed to make an inductive sensor work.

If you have a working inductive sensor setup, the only advantage I can see would be that it measures to the top of the surface, where the inductive sensor measures to the metal plate. That means you need to insure whatever you put on top of the metal plate is always the same thickness. That's probably not really a huge limitation, but one time I accidentally put my glass plate on top of one of the corner screw heads, and because the autolevel probed it and just adjusted, I didn't even notice it wasn't flat. Prints worked fine anyway. If it was sensing the bed underneath, that would have been a problem.

I haven't gotten my BLTouch, or tried an inductive setup, so I'd love to hear from others how they have worked for them.

They both work exactly the same, they just use different means to check the levelness of the bed. Either way the Z motor make the adjustment while printing.

The BLtouch and Servo/Micro Switch Setup work by actually touching the surface you are printing on. An Inductive Proximity Sensor measure how close you are to a metallic surface without actually touching it. A Capacitive Sensor measure density changes in almost anything, so it can read the glass, BuildTak, or possibly the Kapton Tape surface, otherwise it works just like the Inductive Sensor. If you look through the thread you will find lots of info and lots of opinions on both.

As far as cost, the Inductive Sensor and BLtouch cost about the same if you buy an aluminum build plate. If you can find the Capacitive Sensor I suggested earlier it can be as little as $15.00 with no need to buy any other build plate material.

There is success with all three setups, every person running them likes their choice for one reason or another, they all do the basically the same thing, it's really just your preference...

Ah I'm with you. I'll give the inductive a go, I'm running alu bed now and love it. If no lucky I'll try a BLtouch.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 06:30PM |

Registered: 8 years ago Posts: 285 |

Quote

nobrakes

No joy, tried with all tripped as well.

Thanks by the way.

No problem

Not sure what could be wrong. The arduino should always send back a report after entering the command. Maybe trying reflashing marlin to see if it helps

Not sure what could be wrong. The arduino should always send back a report after entering the command. Maybe trying reflashing marlin to see if it helpsFolger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 06:38PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 06:45PM |

Registered: 8 years ago Posts: 285 |

Quote

nobrakes

Reflashed it shows them open but nothing when closed ? I sure would like to print something !

Maybe a bad RAMPS I will send an email to FT, it's a new build.

I would double check to make sure your endstops are non plugged in backwards on the ramps, green wire should be downwards. Otherwise, yeah it is probably the ramps or the arduino.

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 07:03PM |

Registered: 8 years ago Posts: 26 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 07:17PM |

Registered: 8 years ago Posts: 51 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 07:34PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 08:07PM |

Registered: 8 years ago Posts: 268 |

Quote

UltiFix

Awesome! I will go back and find the capactive sensor and favorite it, once I get this printer running im going to go upgrade crazyQuote

sonnylowe

Quote

UltiFix

So let me get this straight, there are 2 kinds of autolevel, one were this are servos moving the bed, and the other is a sensor and the z axis just moves up and down to compensate for bed level changes, im assuming the second choice is cheaper. Right? What are most of you guys doing?Quote

Bert3D

Quote

peeejayz

Quote

sonnylowe

Quote

therippa

So I just ordered a BLTouch to replace my inductive sensor, would someone mind updating the wiki page with the basic instructions?

Done

Are they that much better than inductive sensors? Just wondering it its worth getting one. I have an inductive on the way, but if its better I'll keep the inductive as a spare.

That's what I was wondering as well. I have a BLTouch on the way, and I'm sure it is better than the servo setup I'm using now, and should be easier than the switch to an aluminum print bed to make an inductive sensor work.

If you have a working inductive sensor setup, the only advantage I can see would be that it measures to the top of the surface, where the inductive sensor measures to the metal plate. That means you need to insure whatever you put on top of the metal plate is always the same thickness. That's probably not really a huge limitation, but one time I accidentally put my glass plate on top of one of the corner screw heads, and because the autolevel probed it and just adjusted, I didn't even notice it wasn't flat. Prints worked fine anyway. If it was sensing the bed underneath, that would have been a problem.

I haven't gotten my BLTouch, or tried an inductive setup, so I'd love to hear from others how they have worked for them.

They both work exactly the same, they just use different means to check the levelness of the bed. Either way the Z motor make the adjustment while printing.

The BLtouch and Servo/Micro Switch Setup work by actually touching the surface you are printing on. An Inductive Proximity Sensor measure how close you are to a metallic surface without actually touching it. A Capacitive Sensor measure density changes in almost anything, so it can read the glass, BuildTak, or possibly the Kapton Tape surface, otherwise it works just like the Inductive Sensor. If you look through the thread you will find lots of info and lots of opinions on both.

As far as cost, the Inductive Sensor and BLtouch cost about the same if you buy an aluminum build plate. If you can find the Capacitive Sensor I suggested earlier it can be as little as $15.00 with no need to buy any other build plate material.

There is success with all three setups, every person running them likes their choice for one reason or another, they all do the basically the same thing, it's really just your preference...

EDIT:

Goodness, the search function is awful! I searched and went back and looked at previous pages and can't find it.

[www.ebay.com]

Would something like this work ok?

That would work, however I think they are all 18mm in diameter...that's pretty damn big if you ask me...

Edit: I think one of these is your better option...China...US

Edited 1 time(s). Last edit at 01/20/2016 09:31PM by sonnylowe.

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 08:10PM |

Registered: 8 years ago Posts: 268 |

Quote

peeejayz

Quote

sonnylowe

Quote

therippa

So I just ordered a BLTouch to replace my inductive sensor, would someone mind updating the wiki page with the basic instructions?

Done

Are they that much better than inductive sensors? Just wondering it its worth getting one. I have an inductive on the way, but if its better I'll keep the inductive as a spare.

It efforts you more options in bed surfaces which I think it's much better, and I really like the clickie, clickie sound it makes when it hits the glass

My Stuff on Thingi

FolgerTech Wikia Page

Custom Search by Animoose

MakerSL.com

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 09:15PM |

Registered: 8 years ago Posts: 14 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 20, 2016 10:30PM |

Registered: 8 years ago Posts: 15 |

oh my god your glorious man! you had me confused for awhile,but all the end stops are working and homing! i love you! haha. so now a few more questions lol. my home is the front right corner,is this going to mess with anything? i have heard about mirroring. im guna test print with me luck! i guess ill figure it out. thank you so much! you have no idea.Quote

Mach

Quote

Zeegzeigler

Quote

Mach

Quote

Zeegzeigler

[qoute=Mach]

Quote

Zeegzeigler

Move your X and Y endstop connector one place to the left on the ramps board. The printer will not move until you homes it. If the endstops are not setup properly, the printer will hit them, and then keep trying to move in that direction since it will never get the signal to stop. If you ever want to move your endstops, look at the comments I added in the configs above and that should give you a good idea what to uncomment and comment.

thanks! so i do i just delete the old? i moved the end stops,ill have to do this part later hopefully works! thanks. is there a way to mount the x endstop on the left with the existing printed part? idont have acess to a printer right now. thanks!

The above configs are just segments of the endstop config section, so they replace of the configs that look similar to them, not the entire endstop section. You should be able to put the endstop holder that comes with the printer on the left until you can print a better one. Just keep in mind that the above config will have to be changed to match the printer if you put it on the left since it is set to be on the right.

thanks! ill keep in on the right for now,but for some reason the end stops still dont work. i moved them a,ll to the left 1 slot. so they are in 1,3 and 5. also the y home moved to the front of the printer,is that correct? ill see if i can start to understand what the configs mean lol. i really appreciate the help.

Move only the X and Y connectors if you want the Z to home to the bottom. If the Y endstop is in the back, but the bed moves to the front, just reverse the Y motor connector on the ramps.

Sorry, only registered users may post in this forum.