Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 01:26AM |

Registered: 7 years ago Posts: 43 |

Quote

Bert3D

The extruder fan should be always on, or you will get nozzle clogs from heat rising too high up the heat break tube towards the extruder. It cools the extruder and heat break.

There are lots of things on thingiverse for attaching a second fan to blow on the extruded filament or the print itself. This is the one that you want controlled by Marlin.

This doesn't sound right to me. Once the hot end passed the threshold it can either start or stop the fan to blow.

A friend of mine has the original prusa i3 by Josef, and the fans on the hot end get on only when it starts to print and get off some time after the end of the print.

The Marlin code looks to show this behavior as well. I'm confused.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 08:24AM |

Registered: 8 years ago Posts: 541 |

If the original printer was set up like that, and now the fan is left on, obviously it was learned that this would result in extruder clogs. It's called progress. Just leave the fan on and move on.

Edited 1 time(s). Last edit at 04/27/2016 08:25AM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

Edited 1 time(s). Last edit at 04/27/2016 08:25AM by tjnamtiw.

Folger Tech 2020 i3 and FT-5 as well as modified JGAurora A5 with direct drive E3D/Titan. All running the BLTOUCH.

Great kits. Having fun and running the heck out of them.

Running Marlin 1.1.0 RC8 on the i3 and FT5. Custom firmware on A5.

Folger Tech Wiki board >[folgertech.wikia.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 10:14AM |

Registered: 8 years ago Posts: 130 |

Quote

Cyril

Quote

Bert3D

The extruder fan should be always on, or you will get nozzle clogs from heat rising too high up the heat break tube towards the extruder. It cools the extruder and heat break.

There are lots of things on thingiverse for attaching a second fan to blow on the extruded filament or the print itself. This is the one that you want controlled by Marlin.

This doesn't sound right to me. Once the hot end passed the threshold it can either start or stop the fan to blow.

A friend of mine has the original prusa i3 by Josef, and the fans on the hot end get on only when it starts to print and get off some time after the end of the print.

The Marlin code looks to show this behavior as well. I'm confused.

Mine is setup the way Bert3d describes, and the way the build instructions suggest. The hotend fan is on when the power supply gets powered up. The 'optional' part/print cooling fan turns on and off, with speed control, by GCode instructions or manually in Repetier-Host.

Don't quote me on this, but I think the two pins near the two yellow fuses might be another fan control. That looked like too much custom Marlin adjustment for me. Although powering a single fan seems a big waste of the direct output terminals on the power supply

.

.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 04:09PM |

Registered: 8 years ago Posts: 93 |

Quote

Cyril

Quote

Bert3D

The extruder fan should be always on, or you will get nozzle clogs from heat rising too high up the heat break tube towards the extruder. It cools the extruder and heat break.

There are lots of things on thingiverse for attaching a second fan to blow on the extruded filament or the print itself. This is the one that you want controlled by Marlin.

This doesn't sound right to me. Once the hot end passed the threshold it can either start or stop the fan to blow.

A friend of mine has the original prusa i3 by Josef, and the fans on the hot end get on only when it starts to print and get off some time after the end of the print.

The Marlin code looks to show this behavior as well. I'm confused.

Marlin isn't designed to control the hot end fan, just a print cooling fan. I know the marlin code. I wrote some of the fixes in the latest release. Marlin doesn't actually make the decisions on the fan. The fan is controlled by the code produced by the slicer software. It would be a waste to use the single marlin/slicer controlled fan just to blow on the heat sink for the hot end. It is the print itself that needs intelligent cooling. By using the fan control for that, the slicer can increaser the cooling for bridges, etc., and keep the fan off during the lower layers where it might keep the print from sticking to the heatbed, or cool the heatbed excessively.

There is no harm at all in the heatsink fan blowing constantly.

Edited 2 time(s). Last edit at 04/27/2016 04:11PM by Bert3D.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 04:16PM |

Registered: 7 years ago Posts: 43 |

Quote

Bert3D

Marlin isn't designed to control the hot end fan, just an print cooling fan. I know the marlin code. I wrote some of the fixes in the latest release. Marlin doesn't actually make the decisions on the fan. The fan is controlled by the code produced by the slicer software. It would be a waste to use the single marlin/slicer controlled fan just to blow on the heat sink for the hot end. it is the print itself that needs intelligent cooling. By using the fan control for that, the slicer can increaser the cooling for bridges, etc., and keep the fan off during the lower layers where it might keep the print from sticking to the heatbed. There is no harm at all in the heatsink fan blowing constantly.

I spent some time in the Marlin configuration files, in the advanced one:

// @section extruder // Extruder cooling fans // Configure fan pin outputs to automatically turn on/off when the associated // extruder temperature is above/below EXTRUDER_AUTO_FAN_TEMPERATURE. // Multiple extruders can be assigned to the same pin in which case // the fan will turn on when any selected extruder is above the threshold. #define EXTRUDER_0_AUTO_FAN_PIN 9 #define EXTRUDER_1_AUTO_FAN_PIN -1 #define EXTRUDER_2_AUTO_FAN_PIN -1 #define EXTRUDER_3_AUTO_FAN_PIN -1 #define EXTRUDER_AUTO_FAN_TEMPERATURE 35 #define EXTRUDER_AUTO_FAN_SPEED 255 // == full speed

as nothing to deal with a print fan.

A print FAN should be triggered in GCODE if needed either at start of for specific slices like bridges (and maybe one day slicers will add this feature when slicing).

Any way, I will try my own settings and provide some feedback. I know there is no harm to make the fan blow constantly, this is just annoying when the printer is powered for a while without any print job.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 05:23PM |

Registered: 8 years ago Posts: 93 |

Quote

Cyril

Quote

Bert3D

Marlin isn't designed to control the hot end fan, just an print cooling fan. I know the marlin code. I wrote some of the fixes in the latest release. Marlin doesn't actually make the decisions on the fan. The fan is controlled by the code produced by the slicer software. It would be a waste to use the single marlin/slicer controlled fan just to blow on the heat sink for the hot end. it is the print itself that needs intelligent cooling. By using the fan control for that, the slicer can increaser the cooling for bridges, etc., and keep the fan off during the lower layers where it might keep the print from sticking to the heatbed. There is no harm at all in the heatsink fan blowing constantly.

I spent some time in the Marlin configuration files, in the advanced one:

// @section extruder // Extruder cooling fans // Configure fan pin outputs to automatically turn on/off when the associated // extruder temperature is above/below EXTRUDER_AUTO_FAN_TEMPERATURE. // Multiple extruders can be assigned to the same pin in which case // the fan will turn on when any selected extruder is above the threshold. #define EXTRUDER_0_AUTO_FAN_PIN 9 #define EXTRUDER_1_AUTO_FAN_PIN -1 #define EXTRUDER_2_AUTO_FAN_PIN -1 #define EXTRUDER_3_AUTO_FAN_PIN -1 #define EXTRUDER_AUTO_FAN_TEMPERATURE 35 #define EXTRUDER_AUTO_FAN_SPEED 255 // == full speed

as nothing to deal with a print fan.

A print FAN should be triggered in GCODE if needed either at start of for specific slices like bridges (and maybe one day slicers will add this feature when slicing).

Any way, I will try my own settings and provide some feedback. I know there is no harm to make the fan blow constantly, this is just annoying when the printer is powered for a while without any print job.

This can be done, but you are repurposing a pin just for that. Just be sure you don't use up any pins that output to an FET that you might want for something else later. You just have D8, D9 and D10 to control fans and heaters. Most people use them for heat bed, extruder heater, and print fan. Unless you want to make your own fan driver circuit and tap it to an aux pin output that isn't used for anything else. Lot of work for no real benefit.

If you print anything but ABS you will want to add a print fan.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 05:27PM |

Registered: 8 years ago Posts: 130 |

Quote

Cyril

Quote

Bert3D

Marlin isn't designed to control the hot end fan, just an print cooling fan. I know the marlin code. I wrote some of the fixes in the latest release. Marlin doesn't actually make the decisions on the fan. The fan is controlled by the code produced by the slicer software. It would be a waste to use the single marlin/slicer controlled fan just to blow on the heat sink for the hot end. it is the print itself that needs intelligent cooling. By using the fan control for that, the slicer can increaser the cooling for bridges, etc., and keep the fan off during the lower layers where it might keep the print from sticking to the heatbed. There is no harm at all in the heatsink fan blowing constantly.

I spent some time in the Marlin configuration files, in the advanced one:

// @section extruder // Extruder cooling fans // Configure fan pin outputs to automatically turn on/off when the associated // extruder temperature is above/below EXTRUDER_AUTO_FAN_TEMPERATURE. // Multiple extruders can be assigned to the same pin in which case // the fan will turn on when any selected extruder is above the threshold. #define EXTRUDER_0_AUTO_FAN_PIN 9 #define EXTRUDER_1_AUTO_FAN_PIN -1 #define EXTRUDER_2_AUTO_FAN_PIN -1 #define EXTRUDER_3_AUTO_FAN_PIN -1 #define EXTRUDER_AUTO_FAN_TEMPERATURE 35 #define EXTRUDER_AUTO_FAN_SPEED 255 // == full speed

as nothing to deal with a print fan.

A print FAN should be triggered in GCODE if needed either at start of for specific slices like bridges (and maybe one day slicers will add this feature when slicing).

Any way, I will try my own settings and provide some feedback. I know there is no harm to make the fan blow constantly, this is just annoying when the printer is powered for a while without any print job.

Questions:

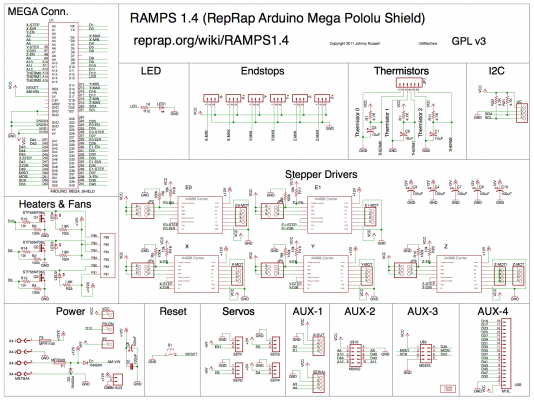

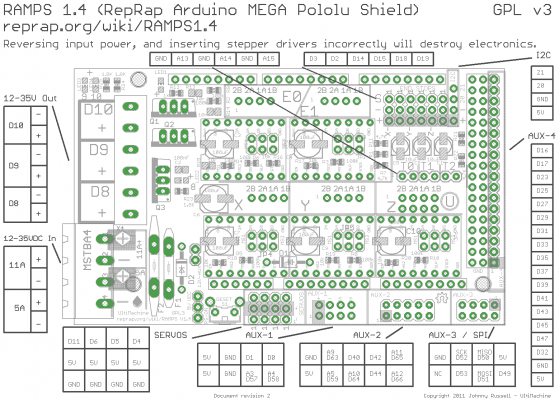

Which pins are are physically FAN_PIN 9 from the configuration.h file?

What physical pins are controlled with M106 M107? I think this is the part/print cooling control, which would be physically the D9 pins on Ramps 1.4.

What physical pins are controlled with M245 and M246? If I could get control of the 12V-AUX pins near the fuses and Diode D2 (or empty holes on some Ramps boards) that would be great.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 05:29PM |

Registered: 7 years ago Posts: 43 |

Quote

Bert3D

This can be done, but you are repurposing a pin just for that. Just be sure you don't use up any pins that output to an FET that you might want for something else later. You just have D8, D9 and D10 to control fans and heaters. Most people use them for heat bed, extruder heater, and print fan. Unless you want to make your own fan driver circuit and tap it to an aux pin output that isn't used for anything else. Lot of work for no real benefit.

If you print anything but ABS you will want to add a print fan.]

Yep I don't need the a second extruder for now so I think I will use those pins. If I want to add a print fan, then I will repurpose the usage of this line (or use the sane line for both dan).

This is not a big deal, few connection and some variables to updates :p

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 05:37PM |

Registered: 7 years ago Posts: 43 |

This is D9 (this is not the default value I set if for my own purpose).Quote

flatlander

Which pins are are physically FAN_PIN 9 from the configuration.h file?

For RAMPS 1.4 this is D9 as well.Quote

flatlander

What physical pins are controlled with M106 M107? I think this is the part/print cooling control, which would be physically the D9 pins on Ramps 1.4.

Quote

flatlander

What physical pins are controlled with M245 and M246? If I could get control of the 12V-AUX pins near the fuses and Diode D2 (or empty holes on some Ramps boards) that would be great.

Those are not supported by Marlin. I don't hink the 12V aux is meant for that. Looks like a secondary 12V input to me but I may be wrong.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 05:44PM |

Registered: 8 years ago Posts: 93 |

Quote

flatlander

Quote

Cyril

Quote

Bert3D

Marlin isn't designed to control the hot end fan, just an print cooling fan. I know the marlin code. I wrote some of the fixes in the latest release. Marlin doesn't actually make the decisions on the fan. The fan is controlled by the code produced by the slicer software. It would be a waste to use the single marlin/slicer controlled fan just to blow on the heat sink for the hot end. it is the print itself that needs intelligent cooling. By using the fan control for that, the slicer can increaser the cooling for bridges, etc., and keep the fan off during the lower layers where it might keep the print from sticking to the heatbed. There is no harm at all in the heatsink fan blowing constantly.

I spent some time in the Marlin configuration files, in the advanced one:

// @section extruder // Extruder cooling fans // Configure fan pin outputs to automatically turn on/off when the associated // extruder temperature is above/below EXTRUDER_AUTO_FAN_TEMPERATURE. // Multiple extruders can be assigned to the same pin in which case // the fan will turn on when any selected extruder is above the threshold. #define EXTRUDER_0_AUTO_FAN_PIN 9 #define EXTRUDER_1_AUTO_FAN_PIN -1 #define EXTRUDER_2_AUTO_FAN_PIN -1 #define EXTRUDER_3_AUTO_FAN_PIN -1 #define EXTRUDER_AUTO_FAN_TEMPERATURE 35 #define EXTRUDER_AUTO_FAN_SPEED 255 // == full speed

as nothing to deal with a print fan.

A print FAN should be triggered in GCODE if needed either at start of for specific slices like bridges (and maybe one day slicers will add this feature when slicing).

Any way, I will try my own settings and provide some feedback. I know there is no harm to make the fan blow constantly, this is just annoying when the printer is powered for a while without any print job.

Questions:

Which pins are are physically FAN_PIN 9 from the configuration.h file?

What physical pins are controlled with M106 M107? I think this is the part/print cooling control, which would be physically the D9 pins on Ramps 1.4.

What physical pins are controlled with M245 and M246? If I could get control of the 12V-AUX pins near the fuses and Diode D2 (or empty holes on some Ramps boards) that would be great.

Pin 9 from the header file is D9 in the RAMPS diagram you posted. The folgertech config and build guide will have your heat bed hooked to D8 and the extruder on D10, leaving D9 for a print fan if you add one later. This is the one you are proposing to repurpose as an extruder control. These are only these 3 pins on a RAMPS board that output 12v power for such things as heaters and fans.

You can use the settings you were describing to control this by tying it to the extruder temp, but them you lose the ability to control a fan via the gcode. Marlin probably won't work right if you leave both the gcode fan mapped to pin 9 and map the extruder controlled fan to pin 9. The settings you are talking about in Marlin aren't intended to be used together when using a ramps board. You can use D9 for one or the other. If you try to use both, unpredictable things will happen. I don't think the code checks for this situation - it just assumes you wouldn't map two unrelated controls to the same pin. Remember, Marlin is written to be configurable to work with many boards, not just a RAMPS board. Not all configuration options will make sense on all boards.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 05:58PM |

Registered: 7 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 06:13PM |

Registered: 7 years ago Posts: 8 |

Is it a good idea to use Rippa's Marlin in a first time build (moving X-endstop plug to position 6 and changing the X-Endstop settings MAX)? Let me explain: - I have that vanilla 2004 LCD and an inductive sensor to be installed in a near future (not in the first days or week i suppose) so i'm in doubt if i should flash a default Marlin and only when decide to install the sensor update the FW to Rippa's or if i should go directly to Rippa's FW.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 06:17PM |

Registered: 8 years ago Posts: 93 |

Quote

Cyril

Thanks Bert, that's know crystal clear for me.

Regarding the print fan, is it better to turn it on all along the print or only for certain slices? And is it ABS related only or will it be great for PLA as well.

Still noob in 3D printing (and waiting for my kit to be delivered).

I don't use a fan at all for ABS. For PLA I have it turn on full above the 3rrd layer.

Ok, that is a bit of an oversimplification. I actually change it sometimes depending on what the print is, and which slicer I'm using. Some slicers have better/more fan control options.

As a general rule, though, you don't want it on when too close to the bed, and certainly not on the first layer. You absolutely want it when you are bridging or printing tall thin parts. it will generally improve the quality of any PLA print. The deal on PLA is that it has such a low melting point, that it stays soft and pliable too long unless cooled. It can distort a little from the bed moving, or the head moving across it, and will droop badly on bridging. Bridging refers to printing across an area of the print with nothing under where you are printing, like when printing above the holes in the side of something.

ABS needs more heat to melt, and becomes solid much faster. It doesn't have the same problems. In fact it has the opposite problem. Keeping it warm enough to stick to the bed, and keeping it from warping from cooling unevenly. That's why most people turn the fan off when printing ABS. Many people who print a lot of ABS enclose their printer to keep the heat in.

Most people have the best luck printing by using PLA and a cooling fan. PLA is easier to get right than ABS, and the fan solves most of the few problems with PLA.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 06:25PM |

Registered: 8 years ago Posts: 93 |

Quote

CreativeBR

Is it a good idea to use Rippa's Marlin in a first time build (moving X-endstop plug to position 6 and changing the X-Endstop settings MAX)? Let me explain: - I have that vanilla 2004 LCD and an inductive sensor to be installed in a near future (not in the first days or week i suppose) so i'm in doubt if i should flash a default Marlin and only when decide to install the sensor update the FW to Rippa's or if i should go directly to Rippa's FW.

I would always use Rippa's Marlin for a first time build. Once you have everything working well, and are familiar with how everything works, you might want to go to a later version of marlin and tweak some settings yourself, but out of the box his build is your best bet.

The version of Marlin that folgertech has is pretty old and doesn't support a lot of things, but it will also work ok for a stock build.

I also recommend just putting the X endstop on the left in the beginning, or at least leave your wires long for that endstop so it will be easy to move it later. Too many things just work better with it on the left.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 06:38PM |

Registered: 7 years ago Posts: 8 |

Quote

Bert3D

I would always use Rippa's Marlin for a first time build. Once you have everything working well, and are familiar with how everything works, you might want to go to a later version of marlin and tweak some settings yourself, but out of the box his build is your best bet.Quote

CreativeBR

Is it a good idea to use Rippa's Marlin in a first time build (moving X-endstop plug to position 6 and changing the X-Endstop settings MAX)? Let me explain: - I have that vanilla 2004 LCD and an inductive sensor to be installed in a near future (not in the first days or week i suppose) so i'm in doubt if i should flash a default Marlin and only when decide to install the sensor update the FW to Rippa's or if i should go directly to Rippa's FW.

The version of Marlin that folgertech has is pretty old and doesn't support a lot of things, but it will also work ok for a stock build.

I also recommend just putting the X endstop on the left in the beginning, or at least leave your wires long for that endstop so it will be easy to move it later. Too many things just work better with it on the left.

Thank you Bert3D. If i put the X endstop on the left i dont need to change it's settings to MAX / plug position ?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 06:43PM |

Registered: 8 years ago Posts: 93 |

If the endstop is on the left, it is at the min position. That's what makes it better, because, it marks x=0.

Just put it in the min plug slot. You may have to set it in the firmware too. I can't remember the default in TheRippa's code.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

Just put it in the min plug slot. You may have to set it in the firmware too. I can't remember the default in TheRippa's code.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 07:31PM |

Registered: 7 years ago Posts: 8 |

The wiki page says:

"Please note that you will need to make some changes to your printer to get this working correctly/properly (unless you moved your X-endstop to the left side):

- Move your X-endstop connection on your RAMPS board one set of pins over, to position 6

- In your host software, change X-endstop setting to MAX"

So it seems that the X endstop to the left side is enough...

"Please note that you will need to make some changes to your printer to get this working correctly/properly (unless you moved your X-endstop to the left side):

- Move your X-endstop connection on your RAMPS board one set of pins over, to position 6

- In your host software, change X-endstop setting to MAX"

So it seems that the X endstop to the left side is enough...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 07:43PM |

Registered: 8 years ago Posts: 9 |

Quote

CreativeBR

The wiki page says:

"Please note that you will need to make some changes to your printer to get this working correctly/properly (unless you moved your X-endstop to the left side):

- Move your X-endstop connection on your RAMPS board one set of pins over, to position 6

- In your host software, change X-endstop setting to MAX"

So it seems that the X endstop to the left side is enough...

Exactly what I did to fix backwards lettering.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 27, 2016 08:20PM |

Registered: 8 years ago Posts: 93 |

Quote

CreativeBR

The wiki page says:

"Please note that you will need to make some changes to your printer to get this working correctly/properly (unless you moved your X-endstop to the left side):

- Move your X-endstop connection on your RAMPS board one set of pins over, to position 6

- In your host software, change X-endstop setting to MAX"

So it seems that the X endstop to the left side is enough...

Yeah. You only have to set the slicer to max if you DON'T move it to the left.

The folger build guide says to plug it in at the min pins, even though the guide had you mount the sensor at the max position. It won't work unless you either move the plug or the sensor from what th he build guide says.

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

My Thingiverse Designs

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 07:44AM |

Registered: 7 years ago Posts: 8 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 12:38PM |

Registered: 7 years ago Posts: 43 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 01:10PM |

Registered: 8 years ago Posts: 85 |

Well guys looks like I win the moron of the week award. Figured out why I was having issues with every arudino mega I flashed. My RAMPS wasn't killing them...I was just being dense and had it in my head that Marlin used 115200 baud by default. Um...no...it uses 250000 from the Marlin page in the reprap wiki:

[reprap.org]

Which explains why my attempts to connect manually or from rep-host were failing but rep-server was successful. rep-server was autodetecting the baud - rep-host and manually I was setting it at 115200

There's still something wrong with my original mega that came with my printer...it still won't connect reliably at any baud. Still prints from SD ok but won't connect over USB even though I can still reflash it. Haven't figured out just what went wrong there.

But all the other Mega boards I have work just fine as long as I use the right baud rate to talk to them.

Seems I may have bumped something on my stepper driver or extruder while swapping boards around though. First test print was overextruding like crazy. Did a single wall test and my requested 0.48 wall came out at 0.91 - ugh. So will probably have to redo my extruder steps cal and re-run my single wall tests to fine tune my multiplier tonight. I also must have bumped something as my z-offset for my inductive probe shifted a few tenth's of a mm and had to be re-tuned.

That said...the latest rep-server has some nice updates - it now updates the message on the LCD and cycles through ETE/ETA/Layers and I think one other display. There's a minor bug where ETA is shows in UTC instead of local time but I can live with that.

I also updated to Marlin RC6 (here's my branch for it on Github: [github.com] I actually had to make a few more minor changes to the configuration.h after that, I'll try to remember to push them up at lunch. And as with my other setups this is with leadscrews and inductive sensor using my latest mount: [www.thingiverse.com] on this extruder: [www.thingiverse.com] )

LCD seems to work much nicer in RC6 and I like the new option to run PID autotunes right from the LCD - slick!

And since I did the updates to my C.H.I.P. I now have a webcam working and doing automatic timelapses of my prints as well.

It's been a week of frustration getting here...but once I finish redoing some calibrations things are looking better than ever. I should probably go ahead and install my sonnylowe y axis upgrade while I'm at it...but enough has changed this week that I don't really need to toss that into the mix just yet

[reprap.org]

Quote

The default baudrate is 250000. Because this baudrate is directly derived from the usual 16MHz clock of the Arduino MCU, it has less jitter and hence fewer errors than the usual 115200 baud, but 250000 baud is not as well supported by drivers and host-environments.

Which explains why my attempts to connect manually or from rep-host were failing but rep-server was successful. rep-server was autodetecting the baud - rep-host and manually I was setting it at 115200

There's still something wrong with my original mega that came with my printer...it still won't connect reliably at any baud. Still prints from SD ok but won't connect over USB even though I can still reflash it. Haven't figured out just what went wrong there.

But all the other Mega boards I have work just fine as long as I use the right baud rate to talk to them.

Seems I may have bumped something on my stepper driver or extruder while swapping boards around though. First test print was overextruding like crazy. Did a single wall test and my requested 0.48 wall came out at 0.91 - ugh. So will probably have to redo my extruder steps cal and re-run my single wall tests to fine tune my multiplier tonight. I also must have bumped something as my z-offset for my inductive probe shifted a few tenth's of a mm and had to be re-tuned.

That said...the latest rep-server has some nice updates - it now updates the message on the LCD and cycles through ETE/ETA/Layers and I think one other display. There's a minor bug where ETA is shows in UTC instead of local time but I can live with that.

I also updated to Marlin RC6 (here's my branch for it on Github: [github.com] I actually had to make a few more minor changes to the configuration.h after that, I'll try to remember to push them up at lunch. And as with my other setups this is with leadscrews and inductive sensor using my latest mount: [www.thingiverse.com] on this extruder: [www.thingiverse.com] )

LCD seems to work much nicer in RC6 and I like the new option to run PID autotunes right from the LCD - slick!

And since I did the updates to my C.H.I.P. I now have a webcam working and doing automatic timelapses of my prints as well.

It's been a week of frustration getting here...but once I finish redoing some calibrations things are looking better than ever. I should probably go ahead and install my sonnylowe y axis upgrade while I'm at it...but enough has changed this week that I don't really need to toss that into the mix just yet

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 01:17PM |

Registered: 7 years ago Posts: 43 |

You have some merge conflict that needs to be fixed if you want to make it works [github.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 01:17PM |

Registered: 7 years ago Posts: 43 |

You have some merge conflict that needs to be fixed if you want to make it works [github.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 02:52PM |

Registered: 7 years ago Posts: 8 |

Quote

jhitesma

That said...the latest rep-server has some nice updates - it now updates the message on the LCD and cycles through ETE/ETA/Layers and I think one other display. There's a minor bug where ETA is shows in UTC instead of local time but I can live with that.

I also updated to Marlin RC6 (here's my branch for it on Github: [github.com] I actually had to make a few more minor changes to the configuration.h after that, I'll try to remember to push them up at lunch. And as with my other setups this is with leadscrews and inductive sensor using my latest mount: [www.thingiverse.com] on this extruder: [www.thingiverse.com] )

LCD seems to work much nicer in RC6 and I like the new option to run PID autotunes right from the LCD - slick!

And since I did the updates to my C.H.I.P. I now have a webcam working and doing automatic timelapses of my prints as well.

It's been a week of frustration getting here...but once I finish redoing some calibrations things are looking better than ever. I should probably go ahead and install my sonnylowe y axis upgrade while I'm at it...but enough has changed this week that I don't really need to toss that into the mix just yet

Uau... A RC6 adapted to our 2020 i3 will be nice. Let us know when you update it.

{} and thanks

CreativeBR

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 03:03PM |

Registered: 7 years ago Posts: 8 |

Quote

Cyril

It's pretty straightforward to use the latest Marlin release as there is only a few changes to do in configuration.h.

Cyril, would you mind in give me a direction of which changes have to be done? Is there a post here talking about it?

Thank you

CreativeBR

Edited 1 time(s). Last edit at 04/28/2016 03:12PM by CreativeBR.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 03:05PM |

Registered: 8 years ago Posts: 85 |

Quote

Cyril

You have some merge conflict that needs to be fixed if you want to make it works [github.com]

Yeah, I fixed those locally last night but forgot to push it to github when I was done. I'll be taking lunch in an hour or so and will try to remember to push my latest changes. Would do it from remote but apparently that computer rebooted overnight and I have to login again to get RDP re-enabled

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 03:11PM |

Registered: 7 years ago Posts: 8 |

Quote

jhitesma

I also updated to Marlin RC6 (here's my branch for it on Github: [github.com] I actually had to make a few more minor changes to the configuration.h after that, I'll try to remember to push them up at lunch. And as with my other setups this is with leadscrews and inductive sensor using my latest mount: [www.thingiverse.com] on this extruder: [www.thingiverse.com] )

LCD seems to work much nicer in RC6 and I like the new option to run PID autotunes right from the LCD - slick!

That's nice. A RC6 ready to the 2020 i3. Please let us know when you up these last updates to config.h.

Thank you.

CreativeBR

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 04:55PM |

Registered: 7 years ago Posts: 43 |

Just got my kit :p everything looks ok, PLA part looks good too, does'nt seems to miss anything :p

This is RevA, not sure what the difference is with the RevB.

Steppers already mounted on RAMPS and the Mega already plugged to daughter board.

Edited 1 time(s). Last edit at 04/28/2016 05:01PM by Cyril.

This is RevA, not sure what the difference is with the RevB.

Steppers already mounted on RAMPS and the Mega already plugged to daughter board.

Edited 1 time(s). Last edit at 04/28/2016 05:01PM by Cyril.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) April 28, 2016 05:24PM |

Registered: 8 years ago Posts: 85 |

Quote

CreativeBR

Quote

jhitesma

I also updated to Marlin RC6 (here's my branch for it on Github: [github.com] I actually had to make a few more minor changes to the configuration.h after that, I'll try to remember to push them up at lunch. And as with my other setups this is with leadscrews and inductive sensor using my latest mount: [www.thingiverse.com] on this extruder: [www.thingiverse.com] )

LCD seems to work much nicer in RC6 and I like the new option to run PID autotunes right from the LCD - slick!

That's nice. A RC6 ready to the 2020 i3. Please let us know when you up these last updates to config.h.

Thank you.

CreativeBR

I pushed the corrections - but be warned there are a few things in the configuration you'll probably want to change.

default steps: I'm running lead screws and DRV8825's with 32 step microstepping on my Z axis so I've got 800 steps for Z, with leadscrews and stock A4988 16 microstep drivers you'd want 400. With stock threaded rod and stock drivers IIRC it's 4000 IIRC and with stock threaded rod ad 32 microstep drivers it would be 8000. Also the extruder steps in my config file are at 200 - which is why I was overextruding so bad...forgot I had swapped back to a A4988 on my extruder (no real reason just experimenting to see if my extruder stepper ran cooler on one vs. the other) so that should have been 100 and would be 100 for most setups. (at least 100 is a good starting point - you'll want to do a calibration on that for sure.)

X endstop: Mine is on the left not the right so this config file is setup for it on the left.

autolevel: I'm running an inductive sensor instead of a z endstop - so that's setup in here as well.

LCD: This is currently setup for a full graphic LCD

Temp Sensor: I'm using an e3d v6 so I'm on sensor type 5, for a stock folger setup you'd want 1

Heater max temps: again mine is a bit higher since I'm on an all metal v6 you may want to lower that if you've got a teflon lined hot end.

In configuration_adv.h I also have quick home enabled (so it moves in x and y simultaneously instead of X first then Y) and I have the experimental M600 filament change gcode option enabled.

make sure you're looking at my jth-rc6 branch not the default "release" branch on the repo which is the same as theRippas RC3 which I initially forked from.

You can see the changes between stock RC6 and my setup with this link: [github.com]

Sorry, only registered users may post in this forum.