Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 03, 2016 02:11PM |

Registered: 8 years ago Posts: 8 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 03, 2016 04:14PM |

Registered: 8 years ago Posts: 285 |

Quote

cookg

Im having problems with the manual control. Whenever i click "Home" on the X axis, the extruder moves all the way to the left until it hits the side of the printer and it tries to keep going unless i stop it. Also, I tried just to print a cube, and it did the same thing. Any pointers?

Does it stop when you home and then manually press the endstop? If it does, does it move in the right direction when you manually move it in repetier after you have homed it?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 03, 2016 10:46PM |

Registered: 8 years ago Posts: 8 |

I got that sorta straightened out. Now I have some new problems. First, my print came out squished lengthwise (I was printing a cube but the raft started like a rectangle) AND when I stopped it, I noticed some red LEDs flashing on my ramps board. When inspected closer, I noticed that one (only one) of the transistors (I think it was a transistors) was almost too hot to touch. If the board is messed up, I can always buy a new one. What's wrong with it now?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 04, 2016 05:47AM |

Registered: 8 years ago Posts: 131 |

Quote

cookg

I got that sorta straightened out. Now I have some new problems. First, my print came out squished lengthwise (I was printing a cube but the raft started like a rectangle) AND when I stopped it, I noticed some red LEDs flashing on my ramps board. When inspected closer, I noticed that one (only one) of the transistors (I think it was a transistors) was almost too hot to touch. If the board is messed up, I can always buy a new one. What's wrong with it now?

Red LEDs flashing on the ramp board is normal and some components will get hot, sounds like your configuration might be messed up and it's not taking as many steps as it should on one of the axis.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 04, 2016 12:57PM |

Registered: 8 years ago Posts: 268 |

FT Upgrades...What's Next!?!?

With my Y and X Axis upgraded, E3D hotend, and Bowden Extruder (my preferred extruder), I honestly believe my printer is about as good as it's going to get mechanically. I am running S3D so the slicing software is good to go as well. So I'm assuming the next logical upgrade would be the Electronics - Control System!?!?

Is anyone running an alternative control system on their FT printer?

Smoothieboard, Duet, Rambo, it's a long list so I'll stop there...

What do you guys think...is a control system upgrade worth while!?!?

With my Y and X Axis upgraded, E3D hotend, and Bowden Extruder (my preferred extruder), I honestly believe my printer is about as good as it's going to get mechanically. I am running S3D so the slicing software is good to go as well. So I'm assuming the next logical upgrade would be the Electronics - Control System!?!?

Is anyone running an alternative control system on their FT printer?

Smoothieboard, Duet, Rambo, it's a long list so I'll stop there...

What do you guys think...is a control system upgrade worth while!?!?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 04, 2016 02:18PM |

Registered: 8 years ago Posts: 367 |

Quote

sonnylowe

FT Upgrades...What's Next!?!?

With my Y and X Axis upgraded, E3D hotend, and Bowden Extruder (my preferred extruder), I honestly believe my printer is about as good as it's going to get mechanically. I am running S3D so the slicing software is good to go as well. So I'm assuming the next logical upgrade would be the Electronics - Control System!?!?

Is anyone running an alternative control system on their FT printer?

Smoothieboard, Duet, Rambo, it's a long list so I'll stop there...

What do you guys think...is a control system upgrade worth while!?!?

I thought a bit about going to Smoothieboard. I like that you can adjust the motor setting in the config - no more messing around with the pots on the drivers. I've heard that the printing is sometimes smoother as the CPU on the board is much more powerful so it can go better conversion of the gcode into the specific signals sent to the motors, but I don't know if this is true. Most people who advocate for Smoothieboards and other controllers are using Delta printers where you have a lot more on-the-fly computation to do.

Is it worthwhile? I don't know. I couldn't quite convince myself, as my printer is fine for pretty much everything I need to do with it. The same goes for your X and Y redesigns - they are great, but I've haven't had quite enough problems to make the change.

The one thing that does still bug me is that my Z axes get a bit graunchy higher up. You can hear clunking noises and the alignment starts to go off. I think this is probably due to slightly miscut acrylic mounts, as someone mentioned a few pages back.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 04, 2016 05:43PM |

Registered: 8 years ago Posts: 84 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 04, 2016 07:26PM |

Registered: 8 years ago Posts: 38 |

Quote

sonnylowe

With my Y and X Axis upgraded, E3D hotend, and Bowden Extruder (my preferred extruder), I honestly believe my printer is about as good as it's going to get mechanically. I am running S3D so the slicing software is good to go as well. So I'm assuming the next logical upgrade would be the Electronics - Control System!?!?

Greedy noob speaking...I plan on doing several of the upgrades you've designed/done to my FT. For all us new guys, it'd be cool if you (and everyone with lots of time with these) would add a link in your signature to your current setup or a quick list of the mods you've done. Pretty please?

EDIT: Simplify3d profiles/setups would be great too!

Edited 1 time(s). Last edit at 01/04/2016 07:32PM by GrouchoDuke.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 04, 2016 08:54PM |

Registered: 8 years ago Posts: 8 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 04, 2016 10:18PM |

Registered: 8 years ago Posts: 285 |

Quote

cookg

Hey. I hope this is my final question post. For some reason, my extruder won't heat up. Then, if I fiddle with the thermoresistor connection (to the ramps board) it will start heating to about 60 degrees, then cool back down again. How do I fix this?

Look at the log in repetier and see if it is giving you decoupling errors.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 04, 2016 11:45PM |

Registered: 8 years ago Posts: 8 |

WOOHOO! Got my first print! But, another problem. I was looking at an instructable for calibration, and when I type M501 into the gcode bar (In Repetier), in the log it will just say "ok"

How do I get it to show the code I need?

Here's the instructable for you to look at:

[www.instructables.com]

How do I get it to show the code I need?

Here's the instructable for you to look at:

[www.instructables.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 12:13AM |

Registered: 8 years ago Posts: 84 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 08:15AM |

Registered: 8 years ago Posts: 32 |

Just wanted to put a positive post up as naturally a lot of the posts here are only when there are problems...

Finished my build last night and everything seems to be working correctly!

Have checked everything using manual controls in Repetier and all seems good! As a starting point I set the X, Z, E drivers to ~0.370v and Y driver to ~0.550v. X endstop on left hand side. All axes home correctly and move in both directions. Have heated bed to 40c, extruder to 80c and both seem to be working (hot to the touch, temperature reading rising in Repetier). Extruder motor turns when instructed (enabled cold extruding to test motor). I also installed a 12864 LCD controller and it's reporting the same info as Repetier and I can navigate the menus, although I haven't tried to control the printer using the LCD yet.

VERY HAPPY!

Still have a few things to do tonight (tweak endstops, possibly tweak drivers, calibrate). Then I can try printing something....

Some things to note for others about to build/order:

I used both the FolgerTech build guide and cyberkni's build guide (from folgertech subreddit). All steps referred to below are from the FolgerTech guide.

There were no missing parts and I had plenty of spare bolts/nuts/washers etc.

All electronics are working correctly (as far as I have tested). A few pins were bent on some of the boards but were easily straightened.

Ordered middle of November and received it a couple of weeks later (to the UK).

Hopefully this post will reassure anyone about to build or order this printer!

And finally a massive thanks to all the kind folk on here offering advice and assistance. All your posts have been a massive help!

Finished my build last night and everything seems to be working correctly!

Have checked everything using manual controls in Repetier and all seems good! As a starting point I set the X, Z, E drivers to ~0.370v and Y driver to ~0.550v. X endstop on left hand side. All axes home correctly and move in both directions. Have heated bed to 40c, extruder to 80c and both seem to be working (hot to the touch, temperature reading rising in Repetier). Extruder motor turns when instructed (enabled cold extruding to test motor). I also installed a 12864 LCD controller and it's reporting the same info as Repetier and I can navigate the menus, although I haven't tried to control the printer using the LCD yet.

VERY HAPPY!

Still have a few things to do tonight (tweak endstops, possibly tweak drivers, calibrate). Then I can try printing something....

Some things to note for others about to build/order:

I used both the FolgerTech build guide and cyberkni's build guide (from folgertech subreddit). All steps referred to below are from the FolgerTech guide.

- There is a step missing in cyberkni's guide (Step 13 in the FolgerTech guide) which is constructing the front pulley for the Y axis belt.

- The cyberkni guide suggests ordering M5 x 10mm bolts as the M5 x 8mm bolts supplied are too short. My order came with these already replaced (10mm bolts instead of 8mm bolts).

- In the end I only used the top 2 bolts for attaching the Z axis motor mounts, otherwise the vertical smooth chrome rods would NOT be parallel (Step 16).

- I attached the heated bed wires the correct way round according to the RAMPS board (the opposite of what Step 21 says) - red to positive terminal, black to negative. This shouldn't matter but it was annoying me.

- I mounted the X Axis End Stop on the left hand side of the printer (Step 23.6) - you may need change the way the End Stop is attached to the mount so that it functions correctly.

- My thermistor wires came with the molex connectors already crimped. (Step 22).

- There was one step where some nylock nuts were asked for but 3 (I think) were not used.

There were no missing parts and I had plenty of spare bolts/nuts/washers etc.

All electronics are working correctly (as far as I have tested). A few pins were bent on some of the boards but were easily straightened.

Ordered middle of November and received it a couple of weeks later (to the UK).

Hopefully this post will reassure anyone about to build or order this printer!

And finally a massive thanks to all the kind folk on here offering advice and assistance. All your posts have been a massive help!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 08:39AM |

Registered: 8 years ago Posts: 51 |

Quote

sonnylowe

FT Upgrades...What's Next!?!?

With my Y and X Axis upgraded, E3D hotend, and Bowden Extruder (my preferred extruder), I honestly believe my printer is about as good as it's going to get mechanically. I am running S3D so the slicing software is good to go as well. So I'm assuming the next logical upgrade would be the Electronics - Control System!?!?

Is anyone running an alternative control system on their FT printer?

Smoothieboard, Duet, Rambo, it's a long list so I'll stop there...

What do you guys think...is a control system upgrade worth while!?!?

Z Axis now

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 09:04AM |

Registered: 8 years ago Posts: 268 |

Quote

animoose

Quote

sonnylowe

FT Upgrades...What's Next!?!?

With my Y and X Axis upgraded, E3D hotend, and Bowden Extruder (my preferred extruder), I honestly believe my printer is about as good as it's going to get mechanically. I am running S3D so the slicing software is good to go as well. So I'm assuming the next logical upgrade would be the Electronics - Control System!?!?

Is anyone running an alternative control system on their FT printer?

Smoothieboard, Duet, Rambo, it's a long list so I'll stop there...

What do you guys think...is a control system upgrade worth while!?!?

I thought a bit about going to Smoothieboard. I like that you can adjust the motor setting in the config - no more messing around with the pots on the drivers. I've heard that the printing is sometimes smoother as the CPU on the board is much more powerful so it can go better conversion of the gcode into the specific signals sent to the motors, but I don't know if this is true. Most people who advocate for Smoothieboards and other controllers are using Delta printers where you have a lot more on-the-fly computation to do.

Is it worthwhile? I don't know. I couldn't quite convince myself, as my printer is fine for pretty much everything I need to do with it. The same goes for your X and Y redesigns - they are great, but I've haven't had quite enough problems to make the change.

The one thing that does still bug me is that my Z axes get a bit graunchy higher up. You can hear clunking noises and the alignment starts to go off. I think this is probably due to slightly miscut acrylic mounts, as someone mentioned a few pages back.

Thanks for the input. I just upgraded my X Mounts (again ;-) and I am incorporating anti-backlash into the setup. once I get a few screws in the mail I'll post the results.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 09:09AM |

Registered: 8 years ago Posts: 268 |

Quote

built350camaro

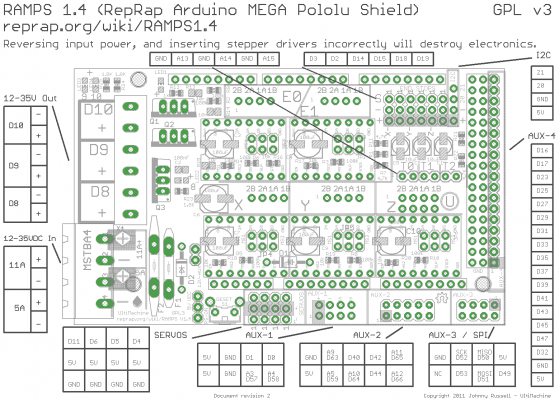

Ok I think I am ready to add auto bed leveling to my rig. I printed the new carriage with the servo at the bottom and have a servo to go there, where do I plug the servo on the Ramps board? I moved the endstop to the left side and got all the running the correct direction.

The servo plugs into the ramps board at the top (as installed-bottom in photo), just to the left of the reset button and power strips.

Make sure you add the jumper required to power the servo pins...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 09:19AM |

Registered: 8 years ago Posts: 268 |

Quote

GrouchoDuke

Quote

sonnylowe

With my Y and X Axis upgraded, E3D hotend, and Bowden Extruder (my preferred extruder), I honestly believe my printer is about as good as it's going to get mechanically. I am running S3D so the slicing software is good to go as well. So I'm assuming the next logical upgrade would be the Electronics - Control System!?!?

Greedy noob speaking...I plan on doing several of the upgrades you've designed/done to my FT. For all us new guys, it'd be cool if you (and everyone with lots of time with these) would add a link in your signature to your current setup or a quick list of the mods you've done. Pretty please?

EDIT: Simplify3d profiles/setups would be great too!

As soon as I have time (and they are finalized them) I'll be posting the X-Y upgrades on Thingi, along with a few other designs.

I think adding current mods-configurations to our signature is a great idea, and it would help people find there way much easier.

As far as S3D profiles, I change mine on the fly depending on what I'm printing...I don't save different profiles, I only have two...one for single extruder and one for duel extruders. I'd be happy to share those base profiles though.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 09:39AM |

Registered: 8 years ago Posts: 268 |

Quote

peeejayz

Quote

sonnylowe

FT Upgrades...What's Next!?!?

With my Y and X Axis upgraded, E3D hotend, and Bowden Extruder (my preferred extruder), I honestly believe my printer is about as good as it's going to get mechanically. I am running S3D so the slicing software is good to go as well. So I'm assuming the next logical upgrade would be the Electronics - Control System!?!?

Is anyone running an alternative control system on their FT printer?

Smoothieboard, Duet, Rambo, it's a long list so I'll stop there...

What do you guys think...is a control system upgrade worth while!?!?

Z Axis now

Working on it

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 10:26AM |

Registered: 8 years ago Posts: 51 |

Quote

sonnylowe

Quote

peeejayz

Quote

sonnylowe

FT Upgrades...What's Next!?!?

With my Y and X Axis upgraded, E3D hotend, and Bowden Extruder (my preferred extruder), I honestly believe my printer is about as good as it's going to get mechanically. I am running S3D so the slicing software is good to go as well. So I'm assuming the next logical upgrade would be the Electronics - Control System!?!?

Is anyone running an alternative control system on their FT printer?

Smoothieboard, Duet, Rambo, it's a long list so I'll stop there...

What do you guys think...is a control system upgrade worth while!?!?

Z Axis now

Working on it

Awesome my Y Axis parts are awaiting collection from the postoffice so I'll be installing that this week

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 12:01PM |

Registered: 8 years ago Posts: 1 |

Hi all! Just finished building this. The build was a fascinating exercise in engineering but I thoroughly enjoyed it! I'm waiting on my ABS and glass build plate to arrive but, in the meantime, couldn't help but steal a picture frame glass and print with the sample FT PLA. I'm extremely pleased with the results! I'm excited to further dial it in. In order to become more familiar with the firmware I decided to just download the vanilla latest version of Marlin and set it up myself. It wasn't terribly difficult and my first prints were well beyond my expectations.

A few notes:

Printed at 180C and 0.2mm layer height.

[imgur.com]

[imgur.com]

Edit: Removed img tags since they weren't working (size constraints?)

Edited 1 time(s). Last edit at 01/05/2016 12:02PM by kbarnette.

A few notes:

- I built it right off the bat with the x endstop on the left to be consistent with the standard Prusa i3 design.

- I also tuned the stepper drivers by "feel", if you will. I turned them down until they were skipping and then slowly turned them back up until they worked reliably. This also quieted them down quite a bit.

- For calibration I leveled my bed and set up the e-steps for the axes using the standard calculations. For the extruder e-steps I tested it empirically using the 100mm extrude method.

Printed at 180C and 0.2mm layer height.

[imgur.com]

[imgur.com]

Edit: Removed img tags since they weren't working (size constraints?)

Edited 1 time(s). Last edit at 01/05/2016 12:02PM by kbarnette.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 12:10PM |

Registered: 8 years ago Posts: 276 |

Quote

sonnylowe

FT Upgrades...What's Next!?!?

With my Y and X Axis upgraded, E3D hotend, and Bowden Extruder (my preferred extruder), I honestly believe my printer is about as good as it's going to get mechanically. I am running S3D so the slicing software is good to go as well. So I'm assuming the next logical upgrade would be the Electronics - Control System!?!?

Is anyone running an alternative control system on their FT printer?

Smoothieboard, Duet, Rambo, it's a long list so I'll stop there...

What do you guys think...is a control system upgrade worth while!?!?

I think the control system is fine. I like the idea of the rambo, but it seems unnecessarily expensive. You know what I'd like to see? An enclosure

Need help? Visit the Folgertech Wikia Page

The latest Marlin firmware with Folgertech Prusa i3 settings merged in, get it here

And check out my designs on Thingiverse, and follow me if you like what you see!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 01:28PM |

Registered: 8 years ago Posts: 5 |

Just printed my first two 20mm calibration cubes and I'm pretty amazed at how well it went. I did a totally stock build, using the included bearings and hot end.

For anyone as new to this as I am (read: totally new), I took my time on the build and found Charles Platt's book (Maintaining and Troubleshooting You 3D Printer) as well as this forum to be great resources. I followed Platt's calibration advice, and mostly the settings in the files on the Folger Prusa drive were good, though I had to alter the extruder steps/mm a bit.

One question: My cubes are about 5% small in the Z direction, and the roofs tend to sink down a bit using a 10% honeycomb fill. Folger blue PLA at 220 degrees. Is the sinking something that would be helped by a cooling fan on the PLA, or maybe a slightly lower extrusion temperature?

thanks

For anyone as new to this as I am (read: totally new), I took my time on the build and found Charles Platt's book (Maintaining and Troubleshooting You 3D Printer) as well as this forum to be great resources. I followed Platt's calibration advice, and mostly the settings in the files on the Folger Prusa drive were good, though I had to alter the extruder steps/mm a bit.

One question: My cubes are about 5% small in the Z direction, and the roofs tend to sink down a bit using a 10% honeycomb fill. Folger blue PLA at 220 degrees. Is the sinking something that would be helped by a cooling fan on the PLA, or maybe a slightly lower extrusion temperature?

thanks

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 02:02PM |

Registered: 8 years ago Posts: 367 |

Quote

jcantalupo

Just printed my first two 20mm calibration cubes and I'm pretty amazed at how well it went. I did a totally stock build, using the included bearings and hot end.

For anyone as new to this as I am (read: totally new), I took my time on the build and found Charles Platt's book (Maintaining and Troubleshooting You 3D Printer) as well as this forum to be great resources. I followed Platt's calibration advice, and mostly the settings in the files on the Folger Prusa drive were good, though I had to alter the extruder steps/mm a bit.

One question: My cubes are about 5% small in the Z direction, and the roofs tend to sink down a bit using a 10% honeycomb fill. Folger blue PLA at 220 degrees. Is the sinking something that would be helped by a cooling fan on the PLA, or maybe a slightly lower extrusion temperature?

thanks

220C is too hot for PLA. I had a similar issue. Try something more like 190, maybe 195 or 185.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 02:27PM |

Registered: 8 years ago Posts: 268 |

Quote

therippa

Quote

sonnylowe

FT Upgrades...What's Next!?!?

With my Y and X Axis upgraded, E3D hotend, and Bowden Extruder (my preferred extruder), I honestly believe my printer is about as good as it's going to get mechanically. I am running S3D so the slicing software is good to go as well. So I'm assuming the next logical upgrade would be the Electronics - Control System!?!?

Is anyone running an alternative control system on their FT printer?

Smoothieboard, Duet, Rambo, it's a long list so I'll stop there...

What do you guys think...is a control system upgrade worth while!?!?

I think the control system is fine. I like the idea of the rambo, but it seems unnecessarily expensive. You know what I'd like to see? An enclosure

Haha, my latest version of the X Axis mounts (which are much smaller and compact) were designed with that very thing in mind

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 03:14PM |

Registered: 8 years ago Posts: 26 |

OK, I read the entire thread, for other noobs it starts getting more informative (ie. less complaining about quality and shipping) in the page 30's and beyond. However, there is good information in the first 30 pages as well. There is one thing I do not recall seeing mentioned. If one plans to use the LCD, is it better for any reason to consider power up and downloading the programs in the configuration section before attaching the LCD? As opposed to connecting the LCD and then doing the SD card to get started? I have the build completed and have x end stop on the left, so left front corner is home. The build was very fun. Still need to get glass plate and sd card then on to configuration and power up.

Thanks

Jim

Thanks

Jim

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 04:17PM |

Registered: 8 years ago Posts: 57 |

Quote

sonnylowe

Quote

built350camaro

Ok I think I am ready to add auto bed leveling to my rig. I printed the new carriage with the servo at the bottom and have a servo to go there, where do I plug the servo on the Ramps board? I moved the endstop to the left side and got all the running the correct direction.

The servo plugs into the ramps board at the top (as installed-bottom in photo), just to the left of the reset button and power strips.

Make sure you add the jumper required to power the servo pins...

What he said! Are you using the carriage that I put on thingiverse?

I had a 5v regulator around - I powered the '5V' pin pictured with its output, it's the 5v pin next to the PS_ON pin, that powers the servos. The 5v bus as-is won't be able to handle the Servo if you try to power it without help.

Edited 1 time(s). Last edit at 01/05/2016 04:18PM by srcga.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 05:29PM |

Registered: 8 years ago Posts: 541 |

Quote

jcantalupo

Just printed my first two 20mm calibration cubes and I'm pretty amazed at how well it went. I did a totally stock build, using the included bearings and hot end.

For anyone as new to this as I am (read: totally new), I took my time on the build and found Charles Platt's book (Maintaining and Troubleshooting You 3D Printer) as well as this forum to be great resources. I followed Platt's calibration advice, and mostly the settings in the files on the Folger Prusa drive were good, though I had to alter the extruder steps/mm a bit.

One question: My cubes are about 5% small in the Z direction, and the roofs tend to sink down a bit using a 10% honeycomb fill. Folger blue PLA at 220 degrees. Is the sinking something that would be helped by a cooling fan on the PLA, or maybe a slightly lower extrusion temperature?

thanks

Yea, 220 is way to hot for PLA unless you are REALLY moving fast. Set 190 for the first layer and 185 for the rest with speeds around 40mm/sec. First layer at 1/2 speed and 150% extrusion. Use 15 or 20% infill and it will support the top better. Put 3 layers on the top.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 05, 2016 07:51PM |

Registered: 8 years ago Posts: 38 |

Quote

sonnylowe

As soon as I have time (and they are finalized them) I'll be posting the X-Y upgrades on Thingi, along with a few other designs.

I think adding current mods-configurations to our signature is a great idea, and it would help people find there way much easier.

As far as S3D profiles, I change mine on the fly depending on what I'm printing...I don't save different profiles, I only have two...one for single extruder and one for duel extruders. I'd be happy to share those base profiles though.

Awesome, that sounds great. I'll watch for your stuff on Thingiverse.

Since I don't have a printer yet, I'm going to start with just getting the stock printer going. Hopefully mod-time will come quickly.

Thanks!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 06, 2016 03:13AM |

Registered: 8 years ago Posts: 51 |

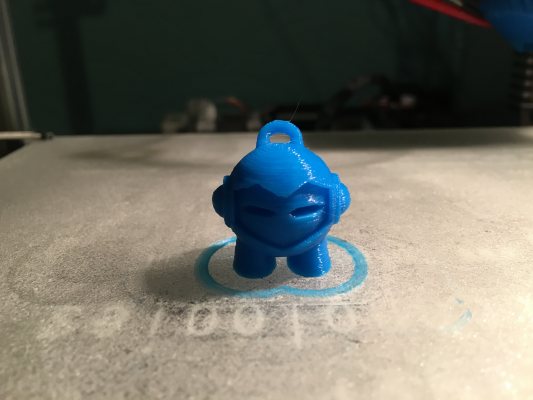

So I took a nice benchmark tonight before I start my Y axis upgrade. I think it came our pretty well and is my first attempt at my Marvin.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) January 06, 2016 07:08AM |

Registered: 8 years ago Posts: 32 |

Quote

Jim72

OK, I read the entire thread, for other noobs it starts getting more informative (ie. less complaining about quality and shipping) in the page 30's and beyond. However, there is good information in the first 30 pages as well. There is one thing I do not recall seeing mentioned. If one plans to use the LCD, is it better for any reason to consider power up and downloading the programs in the configuration section before attaching the LCD? As opposed to connecting the LCD and then doing the SD card to get started? I have the build completed and have x end stop on the left, so left front corner is home. The build was very fun. Still need to get glass plate and sd card then on to configuration and power up.

Thanks

Jim

Hi Jim, I have the LCD and connected it to the printer first, then I connected to the printer/Arduino via USB (with the printer powered off) and flashed the firmware. Then I powered up the printer after the firmware had finished uploading and connected with Repetier to test the axes. I haven't tried to print from the SD Card yet, but the menus work fine and the main LCD info screen is updating and displaying the same info as Repetier.

Hope this helps.

Sorry, only registered users may post in this forum.