|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2016 06:47AM |

Registered: 8 years ago Posts: 65 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 22, 2016 01:22PM |

Registered: 7 years ago Posts: 3 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 24, 2016 08:01AM |

Registered: 8 years ago Posts: 130 |

Quote

Keary123

Quote

tjnamtiw

Quote

UltiFix

When I hit the home all button on rep host it homes x and y then does the safehome thing where x and y center then z homes, here is my configuration.h to compare to yours. PLEASE do not just copy mine, its setup specifically for my printer.Quote

Keary123

I finally found some more time to work on my printer. I just switched my autoleveling sensor from the right side of the extruder to the left side. Since the endstop is on the left I can get closer to the left edge of the bed with the sensor hanging off of the bed. But now i am having issues getting G28/G29 to work correctly. Before this autobed leveling had been working for the past three months.

First a G28 X0 Y0 is sent, the extruder moves to the front left position of the bed (this works correctly).

Second G28 Z0 is sent (printer head crash because the probe is not on the bed).

I have safe homing enabled and entered correct probe offset values but this doesn't seem to help.

I am wondering if anyone has figured out how to home X/Y and then move the probe to the right so it can home Z.

Thanks.

Yea, you're missing something in the Safe Homing routine. It should go into the center to home Z, like UltiFix said.

Okay awesome thanks for the help. I guess G28 is case sensitive because when I do a g28 x0 y0 it homes in the center like you stated but when I do a G28 X0 Y0 it homes at the orgin in the front left side of the bed.

I don't get expected G28 movement until my machine has seen all three endstops triggered at least once. Case sensitivity seems strange, GCode should be in capital letters, right? I use M114 to Get Current Position. At least then I have some idea as to where it 'thinks' the nozzle is.

Edited 1 time(s). Last edit at 06/24/2016 08:13AM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 24, 2016 08:37AM |

Registered: 8 years ago Posts: 130 |

Quote

Yakantosh

I am having a bit of trouble setting up my printer to use the sd card support. Using repetier and slicr, I can save the g-code of an object to the card. However, when I put the card into the sd slot in the 2004 lcd display, it will not recognize any files. Is this a firmware issue?

If you are able to manually control the machine with the knob I would look at incompatibility of your sdcard or incorrect formatting. Mine is formatted FAT32.

After boot and one button press do you see "print from SD" or do you see "No SD card"(at the bottom)? I use SDFormatter. Letting Windows 'have at' an SD Card might be bad. Hopefully you have an old card around...something old and small in capacity, 4GB is way more than enough.

Check that the following are unquoted (remove //) in Configuration.h:

#define EEPROM_SETTINGS

#define EEPROM_CHITCHAT

Edited 1 time(s). Last edit at 06/24/2016 08:45AM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 24, 2016 10:21AM |

Registered: 8 years ago Posts: 33 |

@flatlander

I agree. Using Marlin 1.6.5 G28 homes in the middle then G29 moves to front right position and probes, then front left (where x end stop

Is located, then back left, and then back right. It seems to be working correctly though!

Edited 1 time(s). Last edit at 06/24/2016 10:22AM by Keary123.

I agree. Using Marlin 1.6.5 G28 homes in the middle then G29 moves to front right position and probes, then front left (where x end stop

Is located, then back left, and then back right. It seems to be working correctly though!

Edited 1 time(s). Last edit at 06/24/2016 10:22AM by Keary123.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 24, 2016 11:59PM |

Registered: 8 years ago Posts: 25 |

I am having a little quality issue.

I am using the following:

0.3 nozzle

head temp 230

bed temp 105

printing on kapton tape/glue stick

BLTouch autolevel

Hatchbox Copper ABS

So as you can see I am not sure if my head is too close to the bed or it is over extruding. The other picture shows the sidewall has some missing lines.

Any help would be appreciated.

Edited 1 time(s). Last edit at 06/25/2016 12:00AM by jabu32.

I am using the following:

0.3 nozzle

head temp 230

bed temp 105

printing on kapton tape/glue stick

BLTouch autolevel

Hatchbox Copper ABS

So as you can see I am not sure if my head is too close to the bed or it is over extruding. The other picture shows the sidewall has some missing lines.

Any help would be appreciated.

Edited 1 time(s). Last edit at 06/25/2016 12:00AM by jabu32.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2016 04:54PM |

Registered: 8 years ago Posts: 130 |

Quote

jabu32

I am having a little quality issue.

I am using the following:

0.3 nozzle

head temp 230

bed temp 105

printing on kapton tape/glue stick

BLTouch autolevel

Hatchbox Copper ABS

So as you can see I am not sure if my head is too close to the bed or it is over extruding. The other picture shows the sidewall has some missing lines.

Any help would be appreciated.

[attachment 80316 20160624_231831.jpg]

[attachment 80317 20160624_231824.jpg]

Usually when there are gaps it's because the extrusion temperature is too cold or under-extrusion. The first layer should look like glass, or in your case tape. That first image looks like there isn't enough filament in the first layer. It's also irregular like the nozzle might have an obstruction or the filament is too "wet". I would experiment with over-extrusion and bump the temps up.

What are the temp ranges for Hatchbox Copper ABS?

Edited 1 time(s). Last edit at 06/25/2016 05:10PM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2016 09:45PM |

Registered: 8 years ago Posts: 121 |

I hope someone can help. My friend just purchased this machine and built it but we can not get the x-axis to move. I have placed it on the Y axis of the ramps board to test it and it works fine there. I tried another ramps adrino board with the same result. I have changed direction from 1 to -1. m119 shows x-max trigged. Can any one help?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2016 10:39PM |

Registered: 7 years ago Posts: 1 |

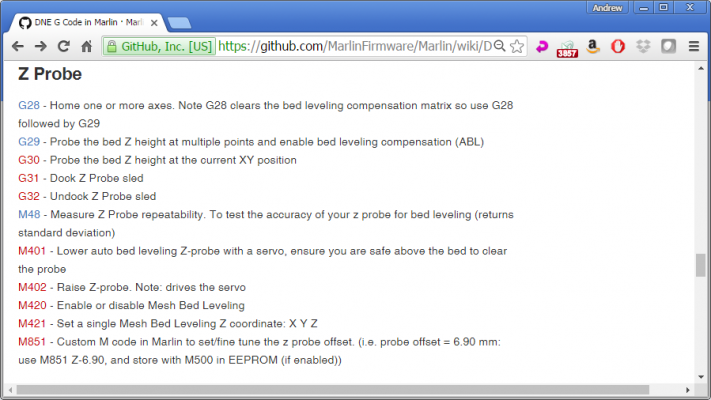

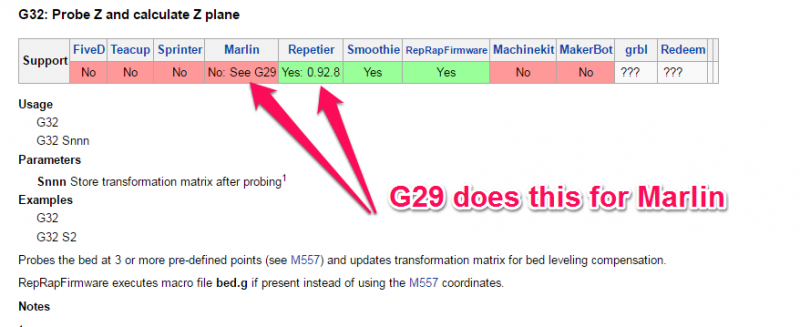

Hi All, I have skulked on here for some time since before I bought my 2020 i3. I can't say how much i love this thing and it easily outperforms some of my printers at work that are 10x more expensive. I have also loved customizing this rig. The problem I am hitting now is autoleveling (not that that EVER comes up on here /s). I have it working with a contact switch just fine and am using the beta firmware from folgertech which is based on Marlin 1.0.2. It has the correct section to define it in configuration.h and I have everything setup just so that it prints perfectly at 300 micron which is my normal, albeit course, setting. I noticed an issue when i moved out my grid to encompass the entire bed, when i did so suddenly the head is almost crashing into the bed instead of being where I want it from the tighter spread I originally tested with. When I looked at the wiki for the gcode commands I noticed that G29 which I had read was supposed to do a grid auto level in fact doesn't. It just probes the grid. The actual command to use dynamic Z planes from what I read is G32 however the firmware from folger doesn't have bed.g to support it. What I think is happening is that it takes the last probed point of the grid as the home for Z and that is why spreading out further made it crash. The questions I have then are, 1) Which is the right bed level code (again, official docs say it ISN'T G29) 2) Is anyone using G32 with success from a newer firmware (and just saying use the newest firmware doesn't answer whether it supports the actual bed level command or not)? Sorry, I know a couple sub comments seem to be uppity but I see a lot of stock answers of "use the newest firmware that X hacked" and that doesn't actually address the WHY I am seeking to understand.

Thanks so much for the answers and help ! I have searched for a comparison of G29 and G32 for this printer and surprisingly turned up nothing other than references to the stock (probe only) G29.

! I have searched for a comparison of G29 and G32 for this printer and surprisingly turned up nothing other than references to the stock (probe only) G29.

Thanks so much for the answers and help

! I have searched for a comparison of G29 and G32 for this printer and surprisingly turned up nothing other than references to the stock (probe only) G29.

! I have searched for a comparison of G29 and G32 for this printer and surprisingly turned up nothing other than references to the stock (probe only) G29.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2016 11:13PM |

Registered: 8 years ago Posts: 65 |

I was wondering if the X might be plugged into the wrong set of pins. Manual is very confusing about the connection and newer versions of Marlin move the pins over a row. What Version of Marlin and where is X plugged in?

Quote

[email protected]

I hope someone can help. My friend just purchased this machine and built it but we can not get the x-axis to move. I have placed it on the Y axis of the ramps board to test it and it works fine there. I tried another ramps adrino board with the same result. I have changed direction from 1 to -1. m119 shows x-max trigged. Can any one help?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 25, 2016 11:30PM |

Registered: 8 years ago Posts: 121 |

I've tried the x end stop plugged into the last spot and the one beside it (min and max). When I hit the home button the stepper twitches a little then locks in place. It's the last thing holding us up we have everything else ready to go. And as far as the x stepper plug itself the board is labled and I have tried another board i have here so it's a software issue/endstop.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2016 09:35AM |

Registered: 8 years ago Posts: 285 |

Quote

[email protected]

I've tried the x end stop plugged into the last spot and the one beside it (min and max). When I hit the home button the stepper twitches a little then locks in place. It's the last thing holding us up we have everything else ready to go. And as far as the x stepper plug itself the board is labled and I have tried another board i have here so it's a software issue/endstop.

You have to enable the pullup resistors in firmware for the endstop positions that you are not using. You also have to have settings in rep-host > printer settings > printer shape that correspond to your printer configuration. If you have your endstop on the left, it needs to be plugged into the min pins. If on the right, it's the max pins. The firmware endstop defines should be configured like this.

//#define ENDSTOPPULLUPS // Comment this out (using // at the start of the line) to disable the endstop pullup resistors <----------- make sure this is commented out #if DISABLED(ENDSTOPPULLUPS) // fine endstop settings: Individual pullups. will be ignored if ENDSTOPPULLUPS is defined //#define ENDSTOPPULLUP_XMAX <--------------------- Leave this commented out if the endstop is on the right //#define ENDSTOPPULLUP_YMAX <--------------------- Leave this commented out if the endstop is in the back //#define ENDSTOPPULLUP_ZMAX <--------------------- Leave this commented out if the endstop is at the top //#define ENDSTOPPULLUP_XMIN <--------------------- Leave this commented out if the endstop is on the left //#define ENDSTOPPULLUP_YMIN <--------------------- Leave this commented out if the endstop is in the front //#define ENDSTOPPULLUP_ZMIN <--------------------- Leave this commented out if the endstop is at the bottom //#define ENDSTOPPULLUP_ZMIN_PROBE <--------------- Leave this commented out

Folger Tech I3 2020 Wikia page: [folgertech.wikia.com]

Custom Folger Tech I3 2020 custom search

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2016 10:22AM |

Registered: 8 years ago Posts: 65 |

Mach is correct. However I have had the same problem with the X just bumping a little and not homing in some versions of Marlin. Still have not figured out what is different on some of the versions. (Sure it is just a setting I have wrong). I'm still not sure what version you are running. But if you will get the older version on the Folger Tech GetHub or the one on the Folgertech Wikia, they should work without any changes needed. Once you get it up and running then you can start upgrading things. You do not have to have the latest and greatest software to get the thing to print.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 26, 2016 12:05PM |

Registered: 8 years ago Posts: 130 |

I'm migrating to a new SSD - HDD OS-system. Can I just drag and drop the old files including cura.ini and slic3r_settings.ini into the new RepetierHost Workdirectory? It seems that there should be a better "import settings" within RepetierHost.

Hopefully I don't have to rebuild all my filament settings. Although, a clean slate has its advantages. Cue the flow-math headache. "Move over coffee, this is a job for Alcohol." Kidos don't start bad habits...

Any thoughts, gotchas? TIA

Hopefully I don't have to rebuild all my filament settings. Although, a clean slate has its advantages. Cue the flow-math headache. "Move over coffee, this is a job for Alcohol." Kidos don't start bad habits...

Any thoughts, gotchas? TIA

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 27, 2016 09:49AM |

Registered: 8 years ago Posts: 33 |

Quote

flatlander

I'm migrating to a new SSD - HDD OS-system. Can I just drag and drop the old files including cura.ini and slic3r_settings.ini into the new RepetierHost Workdirectory? It seems that there should be a better "import settings" within RepetierHost.

Hopefully I don't have to rebuild all my filament settings. Although, a clean slate has its advantages. Cue the flow-math headache. "Move over coffee, this is a job for Alcohol." Kidos don't start bad habits...

Any thoughts, gotchas? TIA

If it is the same version of the software is should work fine.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 27, 2016 03:17PM |

Registered: 8 years ago Posts: 92 |

Quote

matrimcauthon

Hi All, I have skulked on here for some time since before I bought my 2020 i3. I can't say how much i love this thing and it easily outperforms some of my printers at work that are 10x more expensive. I have also loved customizing this rig. The problem I am hitting now is autoleveling (not that that EVER comes up on here /s). I have it working with a contact switch just fine and am using the beta firmware from folgertech which is based on Marlin 1.0.2. It has the correct section to define it in configuration.h and I have everything setup just so that it prints perfectly at 300 micron which is my normal, albeit course, setting. I noticed an issue when i moved out my grid to encompass the entire bed, when i did so suddenly the head is almost crashing into the bed instead of being where I want it from the tighter spread I originally tested with. When I looked at the wiki for the gcode commands I noticed that G29 which I had read was supposed to do a grid auto level in fact doesn't. It just probes the grid. The actual command to use dynamic Z planes from what I read is G32 however the firmware from folger doesn't have bed.g to support it. What I think is happening is that it takes the last probed point of the grid as the home for Z and that is why spreading out further made it crash. The questions I have then are, 1) Which is the right bed level code (again, official docs say it ISN'T G29) 2) Is anyone using G32 with success from a newer firmware (and just saying use the newest firmware doesn't answer whether it supports the actual bed level command or not)? Sorry, I know a couple sub comments seem to be uppity but I see a lot of stock answers of "use the newest firmware that X hacked" and that doesn't actually address the WHY I am seeking to understand.

Thanks so much for the answers and help! I have searched for a comparison of G29 and G32 for this printer and surprisingly turned up nothing other than references to the stock (probe only) G29.

According to the Marlin Wiki on GitHub, G32 does not activate ABL. G29 is in fact the command to Probe the bed, and enable compensation. I can say from personal experience, this is the only command I use (after a G28) and it in fact activates ABL, as I can see the Z axis moving to compensate while printing.

The link you point to for G32 is for Repetier firmware:

Unfortunately I don't have any advice as to why you might be getting too close to the bed after expanding your grid...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 27, 2016 03:41PM |

Registered: 8 years ago Posts: 92 |

Quote

[email protected]

I've tried the x end stop plugged into the last spot and the one beside it (min and max). When I hit the home button the stepper twitches a little then locks in place. It's the last thing holding us up we have everything else ready to go. And as far as the x stepper plug itself the board is labled and I have tried another board i have here so it's a software issue/endstop.

This is common behavior when there are issues with home direction, endstopps etc. In fact, I struggled with this as well when I first got things setup. One of the key things to do is see what the firrmare thinks the status of the endstops are. M119 will echo back the status of all endstops (min and Max), and if they are triggered.

Is your X endstop on the right? then it's in the MAX position. If it's on the left, MIN.

Play with M119, while manually triggering the switches, and see that it responds as is should. If it's backwards (when pressing the switch, it reads Untriggered, then change the appropriate line from true to false or vise versa (also, make sure the ones that do not have anything plugged into them are reading untriggered, and adjust as needed and keep in mind Mach's info above, about the PULLUPs):

const bool X_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop. const bool Y_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

Make sure the home direction is set correctly: If the X endstop is on the right, this should be 1, else -1.

// ENDSTOP SETTINGS: // Sets direction of endstops when homing; 1=MAX, -1=MIN // :[-1,1] #define X_HOME_DIR -1 #define Y_HOME_DIR -1 #define Z_HOME_DIR -1

If you still are having trouble, post a message with the results of M119 when none of the end stop switches are pressed, and a copy of your configuration.h file. And we can help you further.

I know this may sound obvious, but make sure that when you make any changes, you save them, then make sure they upload successfully. I have been stung a couple times by failing to realize that the new firmware didn't upload because there was an error. To help prevent this, I change the name in the firmware to include a version number that I incriment with each change (on on v15 now). That displays on the LCD, so I know the new firmware was in fact loaded.

// Optional custom name for your RepStrap or other custom machine // Displayed in the LCD "Ready" message #define CUSTOM_MACHINE_NAME "My i3 v15"

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 28, 2016 07:49PM |

Registered: 8 years ago Posts: 314 |

Well, I thought I fixed my extruder problem but I guess not... It the middle of a print it will stop extruding. I tried tightening the threaded hotend into the heat break and the hotend into the threaded piece.

If I take it apart and put it back together it will work for abit... Then stop extruding again. Should I try heating my hotend up to around 230 and then try cleaning it with a guitar string?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

If I take it apart and put it back together it will work for abit... Then stop extruding again. Should I try heating my hotend up to around 230 and then try cleaning it with a guitar string?

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 28, 2016 11:42PM |

Registered: 8 years ago Posts: 430 |

Quote

UltiFix

Well, I thought I fixed my extruder problem but I guess not... It the middle of a print it will stop extruding. I tried tightening the threaded hotend into the heat break and the hotend into the threaded piece.

If I take it apart and put it back together it will work for abit... Then stop extruding again. Should I try heating my hotend up to around 230 and then try cleaning it with a guitar string?

If it's the stock one I would guess the liner is shot. When mine did that I upgraded to a e3d you could just replace the tube if you want to keep the stock one. [folgertech.com]

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 29, 2016 01:31PM |

Registered: 8 years ago Posts: 92 |

Quote

UltiFix

Well, I thought I fixed my extruder problem but I guess not... It the middle of a print it will stop extruding. I tried tightening the threaded hotend into the heat break and the hotend into the threaded piece.

If I take it apart and put it back together it will work for abit... Then stop extruding again. Should I try heating my hotend up to around 230 and then try cleaning it with a guitar string?

I guessing you may have a blob of plastic forming between your heatbreak and nozzle.

I looked a little closer at the before/after photos you posted a page or two back. It looks like you tightened the heatbreak tube up into the heatsink block, not down into the heater block. To ensure you have a tight seal between the heatbreak tube and the nozzle, start by backing the brass nozzle out of the heater block a full turn or so. At this point, screw the heatbreak tube all the way into the heater block (use ALL the threads). Now tighten the nozzle, until it bumps up against the tube. You should still have some thread of the nozzle visible, if not, try getting the heatbreak in a little farther down into the heater block.

Now heat up the hot end to about 240c, then once up to temp, tighten the nozzle again. You should still have a little space on the nozzle thread. It should not bottom out all the way to the heater block. This way, you know you have a good seal between the heatbreak tube and the nozzle.

If you do this, and you still have trouble, then it may be as msaeger suggests, the liner is bad, and replacing it may be needed. When replacing the heatbreak tube, make sure you follow the steps above to ensure a good seal between tube and nozzle.

I failed to do this when I purchased and installed an E3D lite6. I was having all kinds of extruder skips and jams. After much troubleshooting, and trying all kinds of different things (and more than a few choice words), I cleaned it all out, followed these steps when putting it back together, and it's been running like a champ ever since.

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 29, 2016 06:39PM |

Registered: 8 years ago Posts: 65 |

Trying to print a lens holder for my HeadPlay goggles. How can I flip the file in Repeater? I can rotate the view but not the part.

Edit: I found it. Anyone else looking it is the icons under the tabs not the ones on the far left of the screen.

Edited 1 time(s). Last edit at 06/29/2016 06:54PM by WilberMaker.

Edit: I found it. Anyone else looking it is the icons under the tabs not the ones on the far left of the screen.

Edited 1 time(s). Last edit at 06/29/2016 06:54PM by WilberMaker.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 29, 2016 06:44PM |

Registered: 8 years ago Posts: 367 |

Quote

WilberMaker

Trying to print a lens holder for my HeadPlay goggles. How can I flip the file in Repeater? I can rotate the view but not the part.

There are button in the area to the right of the object view for mirroring and rotating, close to the "+" you use for adding STL files.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 30, 2016 09:11AM |

Registered: 8 years ago Posts: 130 |

My x-axis is behaving erratically. It will move violently, in the middle of a print, from the print/part area to beyond the x-max position and then continue the print as if nothing happened. Something is causing a signal to the stepper driver to move the x position a great distance for no reason. So far I have changed the A4988 (it's still messing up.) It's probably time to change out boards. I don't think this is Marlin settings because, other than the glitch, the print goes normally. Does this sound like a power supply issue? USB issue? Is the mosfet bad on the Ramps?

I've been through the "shifted layers" troubleshooting page at: [reprap.org].

#31. Power interruptions seems the most likely but, wow, it could be anything...It seems like a stray "on" signal through the x-axis system, most likely starting on the Mega board.

Update: I put a new Mega board on and now it prints!

Edited 1 time(s). Last edit at 06/30/2016 10:45AM by flatlander.

I've been through the "shifted layers" troubleshooting page at: [reprap.org].

#31. Power interruptions seems the most likely but, wow, it could be anything...It seems like a stray "on" signal through the x-axis system, most likely starting on the Mega board.

Update: I put a new Mega board on and now it prints!

Edited 1 time(s). Last edit at 06/30/2016 10:45AM by flatlander.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 30, 2016 04:58PM |

Registered: 8 years ago Posts: 314 |

I could not get the nossle to screw off... Even tried vice grips. I took it apart and here are some pics of the ptfe tube, does it look shot?Quote

iamquestar

Quote

UltiFix

Well, I thought I fixed my extruder problem but I guess not... It the middle of a print it will stop extruding. I tried tightening the threaded hotend into the heat break and the hotend into the threaded piece.

If I take it apart and put it back together it will work for abit... Then stop extruding again. Should I try heating my hotend up to around 230 and then try cleaning it with a guitar string?

I guessing you may have a blob of plastic forming between your heatbreak and nozzle.

I looked a little closer at the before/after photos you posted a page or two back. It looks like you tightened the heatbreak tube up into the heatsink block, not down into the heater block. To ensure you have a tight seal between the heatbreak tube and the nozzle, start by backing the brass nozzle out of the heater block a full turn or so. At this point, screw the heatbreak tube all the way into the heater block (use ALL the threads). Now tighten the nozzle, until it bumps up against the tube. You should still have some thread of the nozzle visible, if not, try getting the heatbreak in a little farther down into the heater block.

Now heat up the hot end to about 240c, then once up to temp, tighten the nozzle again. You should still have a little space on the nozzle thread. It should not bottom out all the way to the heater block. This way, you know you have a good seal between the heatbreak tube and the nozzle.

If you do this, and you still have trouble, then it may be as msaeger suggests, the liner is bad, and replacing it may be needed. When replacing the heatbreak tube, make sure you follow the steps above to ensure a good seal between tube and nozzle.

I failed to do this when I purchased and installed an E3D lite6. I was having all kinds of extruder skips and jams. After much troubleshooting, and trying all kinds of different things (and more than a few choice words), I cleaned it all out, followed these steps when putting it back together, and it's been running like a champ ever since.

--Andrew

[imgur.com]

To remove the nozzle should I soak it in acetone to clean it?

Quote

msaeger

Quote

UltiFix

Well, I thought I fixed my extruder problem but I guess not... It the middle of a print it will stop extruding. I tried tightening the threaded hotend into the heat break and the hotend into the threaded piece.

If I take it apart and put it back together it will work for abit... Then stop extruding again. Should I try heating my hotend up to around 230 and then try cleaning it with a guitar string?

If it's the stock one I would guess the liner is shot. When mine did that I upgraded to a e3d you could just replace the tube if you want to keep the stock one. [folgertech.com]

Folger Tech 2020 i3 Wiki

Custom google search for the Folger Tech 2020 i3 forum topic by Animoose

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 30, 2016 05:42PM |

Registered: 8 years ago Posts: 92 |

Quote

UltiFix

I could not get the nossle to screw off... Even tried vice grips. I took it apart and here are some pics of the ptfe tube, does it look shot?Quote

iamquestar

Quote

UltiFix

Well, I thought I fixed my extruder problem but I guess not... It the middle of a print it will stop extruding. I tried tightening the threaded hotend into the heat break and the hotend into the threaded piece.

If I take it apart and put it back together it will work for abit... Then stop extruding again. Should I try heating my hotend up to around 230 and then try cleaning it with a guitar string?

I guessing you may have a blob of plastic forming between your heatbreak and nozzle.

I looked a little closer at the before/after photos you posted a page or two back. It looks like you tightened the heatbreak tube up into the heatsink block, not down into the heater block. To ensure you have a tight seal between the heatbreak tube and the nozzle, start by backing the brass nozzle out of the heater block a full turn or so. At this point, screw the heatbreak tube all the way into the heater block (use ALL the threads). Now tighten the nozzle, until it bumps up against the tube. You should still have some thread of the nozzle visible, if not, try getting the heatbreak in a little farther down into the heater block.

Now heat up the hot end to about 240c, then once up to temp, tighten the nozzle again. You should still have a little space on the nozzle thread. It should not bottom out all the way to the heater block. This way, you know you have a good seal between the heatbreak tube and the nozzle.

If you do this, and you still have trouble, then it may be as msaeger suggests, the liner is bad, and replacing it may be needed. When replacing the heatbreak tube, make sure you follow the steps above to ensure a good seal between tube and nozzle.

I failed to do this when I purchased and installed an E3D lite6. I was having all kinds of extruder skips and jams. After much troubleshooting, and trying all kinds of different things (and more than a few choice words), I cleaned it all out, followed these steps when putting it back together, and it's been running like a champ ever since.

--Andrew

[imgur.com]

To remove the nozzle should I soak it in acetone to clean it?

Quote

msaeger

Quote

UltiFix

Well, I thought I fixed my extruder problem but I guess not... It the middle of a print it will stop extruding. I tried tightening the threaded hotend into the heat break and the hotend into the threaded piece.

If I take it apart and put it back together it will work for abit... Then stop extruding again. Should I try heating my hotend up to around 230 and then try cleaning it with a guitar string?

If it's the stock one I would guess the liner is shot. When mine did that I upgraded to a e3d you could just replace the tube if you want to keep the stock one. [folgertech.com]

The lining looks OK. but judging by the look of char around the edge of the tube on the first pic, it confirms to me that the seal between the tube and your nozzle is an issue. You can try to soak in acetone, but you'd probably be better off heating it up, then try unscrewing the nozzle. The heat expands the aluminum heater block a bit more than the brass, making the threads a little looser (this is the reason you want to heat it up before tightening things down). I had a nozzle I couldn't move when cold, but when hot, it would have come out by hand. To increase this effect, you can clamp on some channel locks to the nozzle, and they will act as a heat sink, keeping it cooler, and should make things even looser. Just be careful not to use a crazy amount of clamping force, as brass is on the softer side, and can be crushed/deformed.

If all else fails, and you just can't unscrew the nozzle, heat up the block to 240c and screw in the heatbreak tube as hard as you can, and you should be able to get a reasonable seal between the tube and the nozzle.

--Andrew

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 30, 2016 06:51PM |

Registered: 8 years ago Posts: 130 |

Quote

UltiFix

I could not get the nossle to screw off... Even tried vice grips. I took it apart and here are some pics of the ptfe tube, does it look shot?

[imgur.com]

To remove the nozzle should I soak it in acetone to clean it?

If it's a pain to reinstall the heater cartridge stick it in a 475 deg F toaster oven for 15-20 min. All my ovens are in Fahrenheit. I use big ole channel locks when I'm fiddling with my hotend.

I also split PTFE plumbing tape and wrap all my threads going into the hot end, both the tip and the feed tube.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) June 30, 2016 07:05PM |

Registered: 8 years ago Posts: 130 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 04, 2016 08:30PM |

Registered: 8 years ago Posts: 65 |

I am trying to install a Inductive sensor on my printer. The sensor is working. If I put the head in the center of the bed and do a normal Z home it works like a regular endstop. Problem comes when I try a G28 it Homes X and W normal then trys to home Z with the sensor hanging off the bed. What settings do I change to get it to home Z in the center of the bed?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 05, 2016 06:47AM |

Registered: 8 years ago Posts: 46 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 05, 2016 09:30AM |

Registered: 8 years ago Posts: 33 |

Quote

WilberMaker

I am trying to install a Inductive sensor on my printer. The sensor is working. If I put the head in the center of the bed and do a normal Z home it works like a regular endstop. Problem comes when I try a G28 it Homes X and W normal then trys to home Z with the sensor hanging off the bed. What settings do I change to get it to home Z in the center of the bed?

I had this issue also when I updated to the newest version of

Marlin. If you are still having issues I can send you my firmware settings when I get done with class.

Sorry, only registered users may post in this forum.