|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 08:04AM |

Registered: 8 years ago Posts: 430 |

Quote

wderoxas

My original x motor goes unbearably hot. Turning the voltage down caused more problems due to skipped steps. Its for these reasons i replaced it with a bigger stepper.

@ejnelson. Ill be posting them over probably by weekends.

Got a link to what motor? Did you need to make a different X carriage end?

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 09:01AM |

Registered: 8 years ago Posts: 27 |

Quote

wderoxas

Got some free time at work today. So here goes:

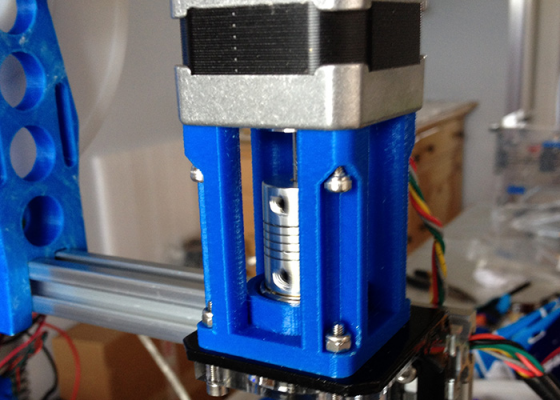

Z standoff

Modified X-Ends for 8mm lead screw. Belt tensioner derived from heartless' design.

Im dropping in here one of my GDrive folder for the inventor part files and some other stuffs im working on.

Thanks wderoxas!!!

...all of these parts makes me wonder if anyone has modeled the whole machine. Would be nice to see this guy in solidworks.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 09:50AM |

Registered: 8 years ago Posts: 81 |

Quote

msaeger

Quote

wderoxas

My original x motor goes unbearably hot. Turning the voltage down caused more problems due to skipped steps. Its for these reasons i replaced it with a bigger stepper.

@ejnelson. Ill be posting them over probably by weekends.

Got a link to what motor? Did you need to make a different X carriage end?

I bought it from a local supplier here in Singapore. This is the specs i found on the net for this model. 42HS4013A4

No modification needed on X-end as long as the motor you'll replace it with is NEMA 17 too.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 11:38AM |

Registered: 8 years ago Posts: 21 |

anybody having any issues with the bed heating up? It seems the longer i use this printer, the slower it gets when it comes to heating the bed. Lately it takes forever to get up to 100C (for abs). I checked that i soldered the bed correctly (black wire touching the 2 soldering sections) and that everything else is wired in correctly. Not sure if it's my little temp gauge not working correctly or if it's something else. I have it heating up right now and it took 20 minutes to get from 70 to 90...and it's increasing by about 1 degree every minute or two...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 12:26PM |

Registered: 11 years ago Posts: 335 |

Quote

hobbes

anybody having any issues with the bed heating up? It seems the longer i use this printer, the slower it gets when it comes to heating the bed. Lately it takes forever to get up to 100C (for abs). I checked that i soldered the bed correctly (black wire touching the 2 soldering sections) and that everything else is wired in correctly. Not sure if it's my little temp gauge not working correctly or if it's something else. I have it heating up right now and it took 20 minutes to get from 70 to 90...and it's increasing by about 1 degree every minute or two...

Could be the weather? Even small changes in ambient temperature (or drafts in the room) will significantly impact heating time.

I personally put some insulation on the bottom of the PCB and turned my power supply up to 14V for faster heating. You may have to retune the PIDs and stepper currents should you choose to do the same.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 12:36PM |

Registered: 8 years ago Posts: 18 |

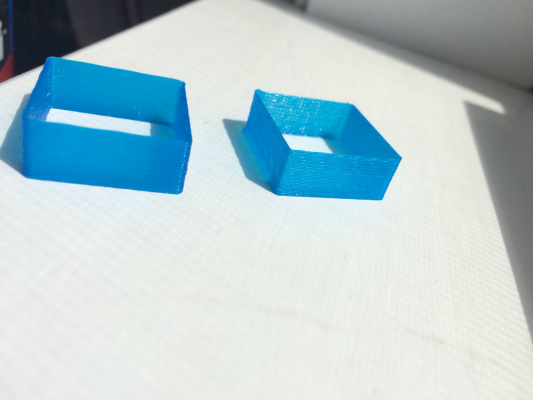

This print quality is really good. The layer height on the left is .1mm on the right is .3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 01:52PM |

Registered: 9 years ago Posts: 251 |

This sounds silly, but someone a while back mentioned just placing a piece of cardboard over the bed to reflect the heat back while its warming. I could barely get my bed over 90C, then I tried the cardboard and I can easily get to 110C in <10min with that and another piece of cardboard with kapton tape covering the top under the bed as well.Quote

hobbes

anybody having any issues with the bed heating up? It seems the longer i use this printer, the slower it gets when it comes to heating the bed. Lately it takes forever to get up to 100C (for abs). I checked that i soldered the bed correctly (black wire touching the 2 soldering sections) and that everything else is wired in correctly. Not sure if it's my little temp gauge not working correctly or if it's something else. I have it heating up right now and it took 20 minutes to get from 70 to 90...and it's increasing by about 1 degree every minute or two...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 02:41PM |

Registered: 8 years ago Posts: 95 |

Quote

sk8

This print quality is really good. The layer height on the left is .1mm on the right is .3.

Looks good sk8 I'm still working on my printer,, It was missing a lot of nut and bolts being metric I'm having problems located them.... but strangely it has extras of others? Its frustrating waiting for your printer then not being able to complete it because of missing such small parts..going to harbor freight later,, I think they sell metric nut and bolt kits..

Edited 1 time(s). Last edit at 07/22/2015 02:42PM by mike3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 03:27PM |

Registered: 8 years ago Posts: 18 |

Quote

mike3

Looks good sk8 I'm still working on my printer,, It was missing a lot of nut and bolts being metric I'm having problems located them.... but strangely it has extras of others? Its frustrating waiting for your printer then not being able to complete it because of missing such small parts..going to harbor freight later,, I think they sell metric nut and bolt kits..

Mine was also missing some, but I just winged it. Use the extras that you got, the only things i needed that weren't in the kit was some wider washers than they have provided. The ones they give you aren't great for securing the corner brackets that holds the y axis belt. And in the instructions that they had some of the wiring is wrong on the board, I can post a picture later if you want of the correct wiring.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 04:47PM |

Registered: 8 years ago Posts: 171 |

Quote

widespreaddeadhead

This sounds silly, but someone a while back mentioned just placing a piece of cardboard over the bed to reflect the heat back while its warming. I could barely get my bed over 90C, then I tried the cardboard and I can easily get to 110C in <10min with that and another piece of cardboard with kapton tape covering the top under the bed as well.Quote

hobbes

anybody having any issues with the bed heating up? It seems the longer i use this printer, the slower it gets when it comes to heating the bed. Lately it takes forever to get up to 100C (for abs). I checked that i soldered the bed correctly (black wire touching the 2 soldering sections) and that everything else is wired in correctly. Not sure if it's my little temp gauge not working correctly or if it's something else. I have it heating up right now and it took 20 minutes to get from 70 to 90...and it's increasing by about 1 degree every minute or two...

I had luck with that until I broke the glass and replaced it with a thinner one. Then, once I removed the cardboard the bed would cool off too much and the part would release from it.

I have a new piece of glass (borosilicate) I'm looking forward to trying.

Edited 1 time(s). Last edit at 07/22/2015 04:48PM by markts.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 04:48PM |

Registered: 8 years ago Posts: 35 |

Quote

mike3

Looks good sk8 I'm still working on my printer,, It was missing a lot of nut and bolts being metric I'm having problems located them.... but strangely it has extras of others? Its frustrating waiting for your printer then not being able to complete it because of missing such small parts..going to harbor freight later,, I think they sell metric nut and bolt kits..

Some of the parts might be a little differrent than what is called for in the build guide. 3Mx16 vs 3Mx18 etc There were more than enough parts included in the kit but they didn't all match up exactly to what was called for in the guide. Some of the M3s in the guide showed a different bolt head than the ones included, they were pan head instead... that kind of thing.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 07:00PM |

Registered: 8 years ago Posts: 18 |

The prints I am getting are perfect other than the overhangs, is there a way to impove the quality without printing support material?

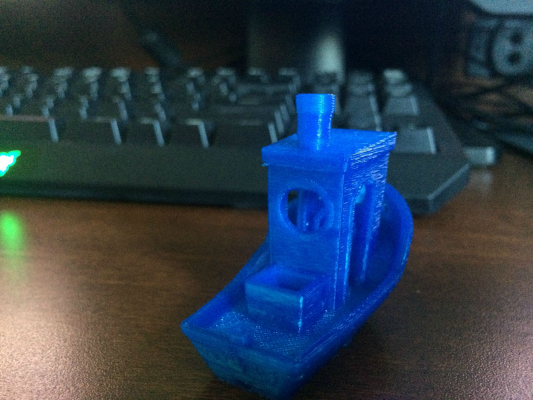

This 3Dbenchy was printed at .2mm layer height.

This 3Dbenchy was printed at .2mm layer height.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 08:10PM |

Registered: 8 years ago Posts: 135 |

Is that PLa or ABS? I print great ABS overhangs. Even with cooling fans my PLA overhangs are still subpar but thats a known flaw of PLA because it has to cool past 50C to hold the shape its in.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 08:14PM |

Registered: 8 years ago Posts: 14 |

Quote

sk8

Received my package completely smashed, looks like it was run over by something. Still got my printer completely built, but when following the config guide when I try to home the x axis it doesn't want to move more than a few inches. With manual control it doesn't want to move to the right, did I get a bad board? What could the problem be? I checked all my wiring multiple times and everything is the same as the tutorial.

My X axis is doing the same. I've found that whenever the Y axis end stop is triggered (and sometimes the Z axis) that the X axis will not home and will move the wrong way. If neither the Y nor the Z axis end stops are triggered I have no problem homing the X axis.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 08:36PM |

Registered: 8 years ago Posts: 367 |

Quote

sk8

The prints I am getting are perfect other than the overhangs, is there a way to impove the quality without printing support material?

This 3Dbenchy was printed at .2mm layer height.

Cooling and slow printing are the only ways I know of improving the overhangs. My own Benchy and a bunch of other tricky tests are posted at [moosteria.blogspot.com]

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 08:41PM |

Registered: 8 years ago Posts: 121 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 08:52PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 09:04PM |

Registered: 8 years ago Posts: 367 |

40, 40, 90% for the first three and 150 for travel speed. I have tried cranking it up quite a way from these without hurting quality in most cases.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 09:15PM |

Registered: 8 years ago Posts: 14 |

Quote

[email protected]

Got my kit today (ordered on July 12th). Ran into problems first page says to use pan head screws but they fall through the brackets for the bed idler pulley brackets . I used the 8 mm socket head screws instead and pressed onward. I have the base built but out of time tonight.

It seems they are just pulling whatever parts they have that are close. Some kits will have a pan head screw, others a socket head. For the connectors on the thermistor wires the instructions mention crimping terminals for Molex connectors. In my kit, the thermistor for the bed already had a connector on it, and for the other I had a connector with 2 short wires already attached that I had to solder to the wires on the extruder's thermistor.

My extruder carriage was printed under sized such that I had to file out the holes for bolting on the extruder by a couple milimeters each, and had to scrape away a lot of plastic to get the bearings to fit. And one of the rails for the Y axis was damaged (looks like grinder marks about 2/3 from one end). I've emailed them last week about it, but have not heard back yet.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 09:43PM |

Registered: 8 years ago Posts: 20 |

Well, got all the hardware assembled and just finished configuration. Officially up and running! Well, sort of. Did the first manual tests in Repetier, and was able to move the X,Y, and extruder steppers. However, there is absolutely no response from the Z axis motors. I've noticed that the manual communication is glitchy at best, but I'm hesitant to start a full print without at least getting the Z to respond manually first. I tuned my driver to 0.35 volts, based on a recommendation early in this thread. Absolutely zero response. Going to try swapping the driver with the extra that was provided later tonight. Until then, anyone experience a similar issue? Pictures to follow soon!

Edited 1 time(s). Last edit at 07/22/2015 09:43PM by cvanclev.

Edited 1 time(s). Last edit at 07/22/2015 09:43PM by cvanclev.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 10:14PM |

Registered: 8 years ago Posts: 367 |

Quote

cvanclev

Well, got all the hardware assembled and just finished configuration. Officially up and running! Well, sort of. Did the first manual tests in Repetier, and was able to move the X,Y, and extruder steppers. However, there is absolutely no response from the Z axis motors. I've noticed that the manual communication is glitchy at best, but I'm hesitant to start a full print without at least getting the Z to respond manually first. I tuned my driver to 0.35 volts, based on a recommendation early in this thread. Absolutely zero response. Going to try swapping the driver with the extra that was provided later tonight. Until then, anyone experience a similar issue? Pictures to follow soon!

Have you tried homing the Z motor first in Repetier? As I recall, the manual control won't drive it until you do this. If you are worried about not having the position right, click home and manually press the end stop switch so it thinks it's homed.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 10:42PM |

Registered: 8 years ago Posts: 81 |

There is also an instance when you cant home z unless x and y were homed first. Not sure though if it was there by default or it was only activated when i configured my firmware for auto bed levelling. It was safe_home or something. If i remember it right, it took effect when i enabled that option.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 22, 2015 10:54PM |

Registered: 8 years ago Posts: 18 |

Quote

Lagomorph

Quote

sk8

Received my package completely smashed, looks like it was run over by something. Still got my printer completely built, but when following the config guide when I try to home the x axis it doesn't want to move more than a few inches. With manual control it doesn't want to move to the right, did I get a bad board? What could the problem be? I checked all my wiring multiple times and everything is the same as the tutorial.

My X axis is doing the same. I've found that whenever the Y axis end stop is triggered (and sometimes the Z axis) that the X axis will not home and will move the wrong way. If neither the Y nor the Z axis end stops are triggered I have no problem homing the X axis.

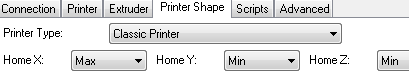

Move the X endstop connector 1 pin to the left, and set home x to max instead of min. Should fix your problem if it was like mine!

Edited 1 time(s). Last edit at 07/22/2015 10:54PM by sk8.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 12:17AM |

Registered: 8 years ago Posts: 18 |

Quote

[email protected]

Got my kit today (ordered on July 12th). Ran into problems first page says to use pan head screws but they fall through the brackets for the bed idler pulley brackets . I used the 8 mm socket head screws instead and pressed onward. I have the base built but out of time tonight.

Go out tomorrow and get some bigger washers, that way you can use the screws they provided.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 02:19AM |

Registered: 8 years ago Posts: 276 |

Confirmed: aluminum plates on the heatbed suck (the heat out and put it into the air). Went back to heatbed+glass+PEI. Can reach 110 degrees in a little under 10 minutes, so not messing with the aluminum anymore. Plan on bonding the heatbed to the glass plate using 3M 468 for better heat transfer (the plate was about 10 degrees cooler than the temperature the thermistor was reporting).

But, after two weeks of downtime, it's nice to be able to print again, even if it's just a calibration cube in ABS

But, after two weeks of downtime, it's nice to be able to print again, even if it's just a calibration cube in ABS

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 03:26AM |

Registered: 8 years ago Posts: 66 |

These cages are fantastic! I'm still using the 5mm screws but intend to upgrade later on. The hanging couplers have annoyed me from day 1 with the potential to sag and now I have an easy 170mm print height!

My stock screws are kinda shortish so they don't sit full flush with the motor shafts but there seems to be no issue as of yet. I had to drop them to get the Z axis to home without moving my bed up. I'm thinking of replacing the guide rods with longer ones as well as there's room for 25mm more space with the angle brackets.

One thing I want to do is add some length to the motor side X-bracket, 1-2mm so it can be flipped to the other side and clear the upright. I tried with the stock ones and it rubbed on the frame just a smidge.

Sigil Pickups || Stunt Monkey Pedals

My stock screws are kinda shortish so they don't sit full flush with the motor shafts but there seems to be no issue as of yet. I had to drop them to get the Z axis to home without moving my bed up. I'm thinking of replacing the guide rods with longer ones as well as there's room for 25mm more space with the angle brackets.

One thing I want to do is add some length to the motor side X-bracket, 1-2mm so it can be flipped to the other side and clear the upright. I tried with the stock ones and it rubbed on the frame just a smidge.

Sigil Pickups || Stunt Monkey Pedals

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 03:46AM |

Registered: 8 years ago Posts: 81 |

Quote

CheopisIV

These cages are fantastic! I'm still using the 5mm screws but intend to upgrade later on. The hanging couplers have annoyed me from day 1 with the potential to sag and now I have an easy 170mm print height!

My stock screws are kinda shortish so they don't sit full flush with the motor shafts but there seems to be no issue as of yet. I had to drop them to get the Z axis to home without moving my bed up. I'm thinking of replacing the guide rods with longer ones as well as there's room for 25mm more space with the angle brackets.

One thing I want to do is add some length to the motor side X-bracket, 1-2mm so it can be flipped to the other side and clear the upright. I tried with the stock ones and it rubbed on the frame just a smidge.

Glad you liked it. On my setup, the leadscrews isnt flush with the motor shaft either. I intentionally left the slotted portions of the coupler unoccupied by either the shaft or leadscrew. I was thinking that this could probably help to let the coupler absorb the wiggling if the motor and leadscrew are not straighly aligned. And also, if theres any, let the slots absorb the vibrations from the motor shaft.

I can't picture what you meant with flipping the motor side x bracket. I could probably help you do some adjustments but i need to know where the additional length should be added.

Edited 1 time(s). Last edit at 07/23/2015 03:52AM by wderoxas.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 04:04AM |

Registered: 8 years ago Posts: 66 |

Quote

wderoxas

Glad you liked it.

I can't picture what you meant with flipping the motor side x bracket. I could probably help you do some adjustments but i need to know where the additional length should be added.

I'd appreciate some help

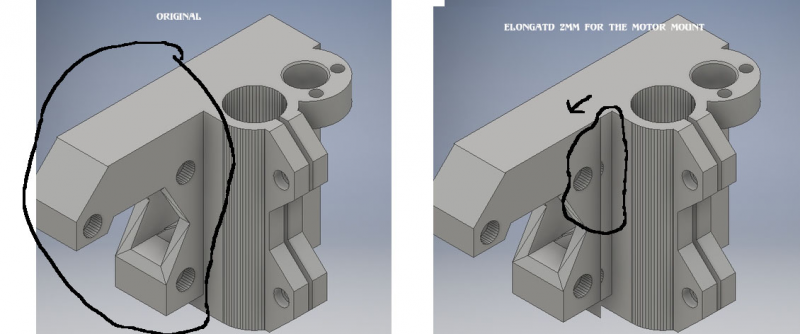

I basically want to remove the entire X-Axis carriage, rods, screws and swing it around as a whole so the right side (motor mount side) is on the left. This would put the motor behind the rail and right beside the main frame. The stock part has no room and the motor rubs on the frame when flipped around so the mount part needs to be 1-2mm further out (longer in the X axis) from the main screw/rod part right where it narrows. I just think it's a better weight distribution and would align the wires with the rest as I switched my PSU to the left already.

I basically want to remove the entire X-Axis carriage, rods, screws and swing it around as a whole so the right side (motor mount side) is on the left. This would put the motor behind the rail and right beside the main frame. The stock part has no room and the motor rubs on the frame when flipped around so the mount part needs to be 1-2mm further out (longer in the X axis) from the main screw/rod part right where it narrows. I just think it's a better weight distribution and would align the wires with the rest as I switched my PSU to the left already.This pic shows what I want to do;

and here's a quicky photoshop showing the extension of the mounting area.

I do want to upgrade to the 8mm screws for strength and am working up my dual extruder setup which I think would benefit from them.

Edited 1 time(s). Last edit at 07/23/2015 04:07AM by CheopisIV.

Sigil Pickups || Stunt Monkey Pedals

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 04:17AM |

Registered: 8 years ago Posts: 81 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 23, 2015 04:25AM |

Registered: 8 years ago Posts: 66 |

Sorry, only registered users may post in this forum.