Prusa I3 first "print" - what am I doing wrong?

Posted by CraigMoberg

|

Prusa I3 first "print" - what am I doing wrong? May 23, 2015 04:10AM |

Registered: 8 years ago Posts: 82 |

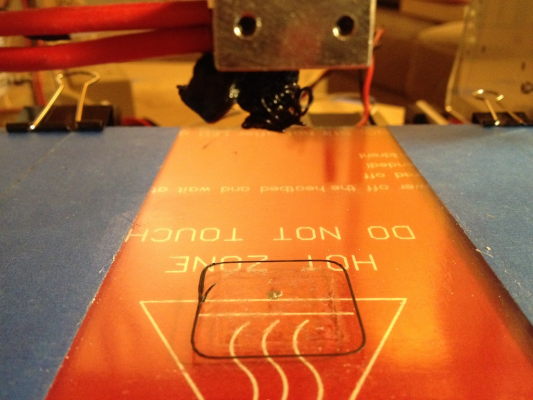

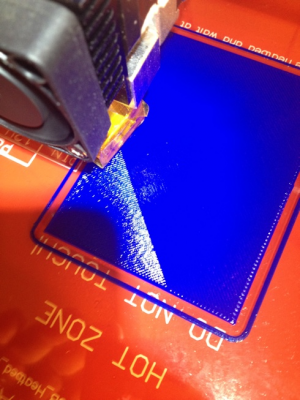

My first print isn't adhering well at all. Part of the perimeter adhered, but otherwise it's a blob on the nozzle. I've attached a picture - this is after stopping the print and raising the Z axis to see the nozzle.

I'm printing ABS on glass with glue stick. Extruder temp is 230, bed temp is 100. Extruder fan is off for the first 5 layers. Layer height and first layer height are both 0.2.

I'm thinking I may have the Z home too close to the bed. Does it look like that? I had difficulty homing it - fiddling with the end stop to get it within a paper thickness seems very crude to me. It seems like there must be a better way, since getting the first layer down is crucial.

Any suggestions? Thanks.

I'm printing ABS on glass with glue stick. Extruder temp is 230, bed temp is 100. Extruder fan is off for the first 5 layers. Layer height and first layer height are both 0.2.

I'm thinking I may have the Z home too close to the bed. Does it look like that? I had difficulty homing it - fiddling with the end stop to get it within a paper thickness seems very crude to me. It seems like there must be a better way, since getting the first layer down is crucial.

Any suggestions? Thanks.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 23, 2015 07:31AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Prusa I3 first "print" - what am I doing wrong? May 23, 2015 07:35AM |

Registered: 9 years ago Posts: 55 |

|

Re: Prusa I3 first "print" - what am I doing wrong? May 23, 2015 12:27PM |

Registered: 8 years ago Posts: 82 |

Olaf - so it looks like the nozzle is too close to the glass? You're right, I'm seeing an auto bed leveler in my future.

Laopa - it's definitely coming out of the nozzle, not the threads. I let it run for several layers to fully document the disaster. So a lot of plastic pushed up onto the block.

So a lot of plastic pushed up onto the block.

Laopa - it's definitely coming out of the nozzle, not the threads. I let it run for several layers to fully document the disaster.

So a lot of plastic pushed up onto the block.

So a lot of plastic pushed up onto the block.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 23, 2015 01:50PM |

Registered: 11 years ago Posts: 973 |

i would try using something in the bed like hairspray, i was printing with pla and had my 1st layer height set at 0.3, but i was actually squishing my 1st layer into the bed ton get it stuck, so i adjusted my z offset as i have a probe and it would not stick to the bed did same as yours just curled up and stuck to the nozzle. so i got some pritt stick and coated my glass with it now i have no issue getting it stuck down

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: Prusa I3 first "print" - what am I doing wrong? May 23, 2015 11:20PM |

Registered: 9 years ago Posts: 49 |

Glue stick is not that great for adhering abs. It works for thin objects, but I have not had any success with a bigger object. You can here it cracking off as the print gets further above the bed.

I have found kapton tape is easiest to get consistent stick ability. Wiping it with acetone to clean it before a print makes it better. Clean with the acetone after the print and it's ready to go again.

You can also use abs juice (abs dissolved in acetone) on it to make it even better, but may find that getting the prints off damages the kapton tape. Some talk about abs juice on glass, but there have been reports of people breaking the glass getting the print off.

I have found kapton tape is easiest to get consistent stick ability. Wiping it with acetone to clean it before a print makes it better. Clean with the acetone after the print and it's ready to go again.

You can also use abs juice (abs dissolved in acetone) on it to make it even better, but may find that getting the prints off damages the kapton tape. Some talk about abs juice on glass, but there have been reports of people breaking the glass getting the print off.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 24, 2015 01:31AM |

Registered: 11 years ago Posts: 661 |

For ABS a strong glue stick like UHU stick works well. Sometimes too well. I've been using it with ABS and higher temp plastics nearly a couple of years. I use hairspray for PLA and lower temp plastics. The main thing for any print is to make sure the nozzle to bed distance is set properly for the particular build/machine. You don't need a mechanism to do it. If you have a square, relatively level build you can do it by hand with a little bit of patience. For learning to print using thicker layers are more forgiving. For example using .3 layers. If your nozzle is too close you won't see the color of your material and eventually it will clog or jam. It's likely a combination of not having the right alignment of the nozzle to bed and the layer heights. For a .3 layer object I use a first layer of .25.

Even if you use an automated leveling/tramming device you are still going to have to manually level your bed initially to get it to work properly.

Even if you use an automated leveling/tramming device you are still going to have to manually level your bed initially to get it to work properly.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 24, 2015 06:34PM |

Registered: 8 years ago Posts: 82 |

So we have one vote for glue stick working well with ABS, and one vote for it not working well. It's tough being a newbie.

I think one of my problems getting a good bed level is that the acrylic Y carriage frame is a little warped. I can see that the back left corner is closer to the rails than the rest, pulling that corner down, and I have to tighten the front left corner all the way down and it's still too close to the nozzle. So I think I'll be looking into an aluminum frame along with my aluminum bed.

But I realized that I'll only be making small prints at first, and I found it much easier to level a 40x40 square in the center of the bed.

Today's experiment -- hairspray! I've heard great things about it. And I've heard that it sucks. sigh

I do wonder if hairspray can gum up the rails and other things over time. I'm going to try to find a way to keep it contained while spraying it on.

Oh - does it work better to apply the hairspray when the bed is cold, or when it's hot, or at some temperature during heating, or doesn't it matter?

Edited 1 time(s). Last edit at 05/24/2015 06:39PM by CraigMoberg.

I think one of my problems getting a good bed level is that the acrylic Y carriage frame is a little warped. I can see that the back left corner is closer to the rails than the rest, pulling that corner down, and I have to tighten the front left corner all the way down and it's still too close to the nozzle. So I think I'll be looking into an aluminum frame along with my aluminum bed.

But I realized that I'll only be making small prints at first, and I found it much easier to level a 40x40 square in the center of the bed.

Today's experiment -- hairspray! I've heard great things about it. And I've heard that it sucks. sigh

I do wonder if hairspray can gum up the rails and other things over time. I'm going to try to find a way to keep it contained while spraying it on.

Oh - does it work better to apply the hairspray when the bed is cold, or when it's hot, or at some temperature during heating, or doesn't it matter?

Edited 1 time(s). Last edit at 05/24/2015 06:39PM by CraigMoberg.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 24, 2015 07:28PM |

Registered: 8 years ago Posts: 82 |

The hairspray didn't work. I applied it when the bed was hot (100). The perimeter laid down fine and I was feeling pretty good. Then the perimeter started sliding around and the rest was a blob.

I was just reading that some have had success with sugar water, so I'm trying that next since it's easy to test. And the hummingbird feeder is empty, so I can kill two birds with one stone (so to speak.)

(I used Pantene extra strong hold. Others have recommended Aquanet.)

Edited 1 time(s). Last edit at 05/24/2015 07:29PM by CraigMoberg.

I was just reading that some have had success with sugar water, so I'm trying that next since it's easy to test. And the hummingbird feeder is empty, so I can kill two birds with one stone (so to speak.)

(I used Pantene extra strong hold. Others have recommended Aquanet.)

Edited 1 time(s). Last edit at 05/24/2015 07:29PM by CraigMoberg.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 24, 2015 09:12PM |

Registered: 8 years ago Posts: 82 |

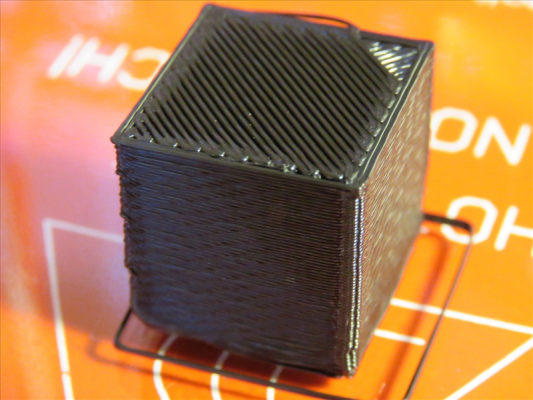

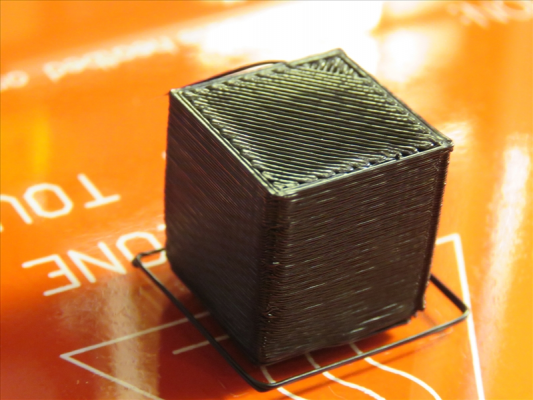

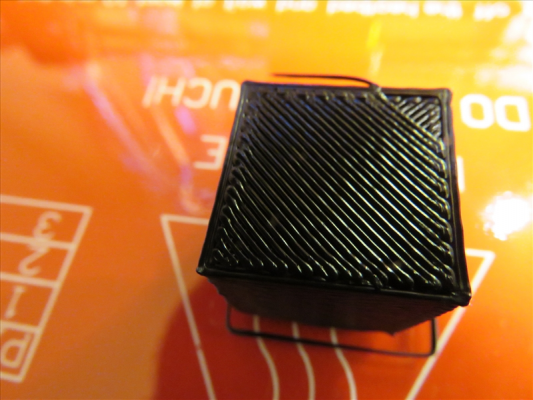

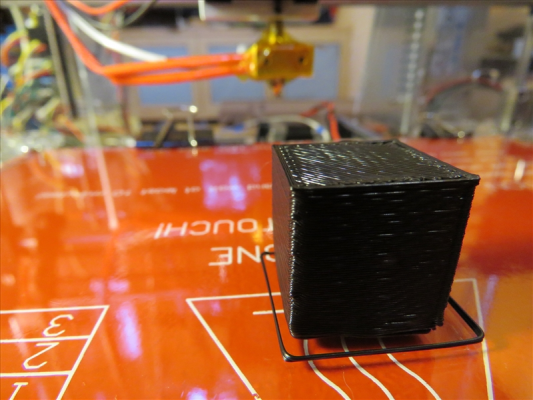

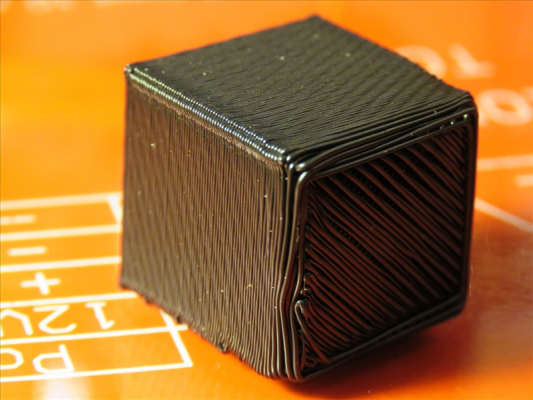

The sugar water worked! I used 10g sugar in 100ml water, dabbed it heavily with a tissue on the hot bed (100) and let it dry. I'm now the proud father of a 20mm hollow cube.

I'm not sure it worked VERY well though. At the end the cube was skewed a little relative to the perimeter, so there may have been some slippage, and the cube may have suffered some from that too. After the bed cooled, it lifted right off with no resistance.

One thing I notice is that the corners protrude a little. It's a nice effect, but not what's intended. And one corner is very jaggy, as if the width is increasing bottom to top.. It is 0.2 mm wider at the top than the bottom.

It looks like the bottom couple of layers shrunk in, and there too you can see evidence of skewing, maybe from the piece slipping on the bed. (The last picture is of the bottom.)

The sides are nice and flat and look filled in. But the top is gappy, and it forgot to finish the last corner -- or the filament pulled away when the nozzle retracted.

Does anything else jump out that could be fixed with some settings tweaks?

(Extruder temp 230, bed temp 100, layer height 0.3 at vegasloki's suggestion.)

I'm not sure it worked VERY well though. At the end the cube was skewed a little relative to the perimeter, so there may have been some slippage, and the cube may have suffered some from that too. After the bed cooled, it lifted right off with no resistance.

One thing I notice is that the corners protrude a little. It's a nice effect, but not what's intended. And one corner is very jaggy, as if the width is increasing bottom to top.. It is 0.2 mm wider at the top than the bottom.

It looks like the bottom couple of layers shrunk in, and there too you can see evidence of skewing, maybe from the piece slipping on the bed. (The last picture is of the bottom.)

The sides are nice and flat and look filled in. But the top is gappy, and it forgot to finish the last corner -- or the filament pulled away when the nozzle retracted.

Does anything else jump out that could be fixed with some settings tweaks?

(Extruder temp 230, bed temp 100, layer height 0.3 at vegasloki's suggestion.)

|

Re: Prusa I3 first "print" - what am I doing wrong? May 24, 2015 10:44PM |

Registered: 9 years ago Posts: 476 |

Quote

CraigMoberg

The sugar water worked! I used 10g sugar in 100ml water, dabbed it heavily with a tissue on the hot bed (100) and let it dry. I'm now the proud father of a 20mm hollow cube.

I'm not sure it worked VERY well though. At the end the cube was skewed a little relative to the perimeter, so there may have been some slippage, and the cube may have suffered some from that too. After the bed cooled, it lifted right off with no resistance.

One thing I notice is that the corners protrude a little. It's a nice effect, but not what's intended. And one corner is very jaggy, as if the width is increasing bottom to top.. It is 0.2 mm wider at the top than the bottom.

It looks like the bottom couple of layers shrunk in, and there too you can see evidence of skewing, maybe from the piece slipping on the bed. (The last picture is of the bottom.)

The sides are nice and flat and look filled in. But the top is gappy, and it forgot to finish the last corner -- or the filament pulled away when the nozzle retracted.

Does anything else jump out that could be fixed with some settings tweaks?

(Extruder temp 230, bed temp 100, layer height 0.3 at vegasloki's suggestion.)

[attachment 55268 cube01-800x600.JPG]

[attachment 55269 cube02-800x600.JPG]

[attachment 55270 cube03-800x600.JPG]

[attachment 55271 cube04-800x600.JPG]

[attachment 55273 cube06-800x600.JPG]

From the looks of it, 3 things came to mind, insufficient flow rate, extruder not calibrated or temperature not hot enough

|

Re: Prusa I3 first "print" - what am I doing wrong? May 25, 2015 03:41AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Prusa I3 first "print" - what am I doing wrong? May 25, 2015 05:31AM |

Registered: 8 years ago Posts: 82 |

Quote

o_lampe

I´d reduce the nozzle height a bit until you see the ABS squashed down the surface a bit.

-Olaf

You're right, that helped. On my second print, before I did that, I saw that the first layer wasn't being deposited directly on the glass.

And sarf2k4 is right, I need to calibrate my extruder... when I can wrap my head around the math.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 25, 2015 03:54PM |

Registered: 16 years ago Posts: 824 |

I've posted several times over the years on the topic of Printing on Glass. Here is a compilation.

It's all about temperature people. Adding anything to the glass, or sanding it, is just a crutch. The underlying problem not being addressed is one of the following.

1. ABS filament chemistry is not ideal. Some ABS will seem almost rubbery when warm, and will stick hard to bare glass at 110°C. Other ABS will seem very slick, and even brittle, and won't stick at any temperature. When this is the case, you can have a go at the beer/glue/hair spray/etc. All Weather Aquanet Extra Super Hold definately works, if you don't want to go completely bare.

2. Temperature of bed is too low/high. There is a temperature window for stick on bare glass. Typically it is between 105°C and 115°C (Read 110), but this depends on how accurately your thermistor is tracking the glass temperature. The ABS chemistry also affects this window's position, and range.

3. The glass surface is contaminated. Contamination can be oils from fingers, moisture residue from 30% alcohol used for cleaning, other residue from paper towels used in cleaning, and even coatings given to the glass during manufacturing. If the glass seems phobic in any way to a drop of water (ie the water beads, instead of spreading) this could be the case. Use only glass cleaner (the blue kind) with ammonia. 6mm borosilicate (Band name Pyrex). Thinner glass, whether borosilicate,or from a picture frame, will be susceptible to rapid warping when exposed to airflow. This will cause ABS prats to pop off suddenly. The thicker glass holds the heat better, and is dimensionaly stable in small breezes.

It's all about temperature people. Adding anything to the glass, or sanding it, is just a crutch. The underlying problem not being addressed is one of the following.

1. ABS filament chemistry is not ideal. Some ABS will seem almost rubbery when warm, and will stick hard to bare glass at 110°C. Other ABS will seem very slick, and even brittle, and won't stick at any temperature. When this is the case, you can have a go at the beer/glue/hair spray/etc. All Weather Aquanet Extra Super Hold definately works, if you don't want to go completely bare.

2. Temperature of bed is too low/high. There is a temperature window for stick on bare glass. Typically it is between 105°C and 115°C (Read 110), but this depends on how accurately your thermistor is tracking the glass temperature. The ABS chemistry also affects this window's position, and range.

3. The glass surface is contaminated. Contamination can be oils from fingers, moisture residue from 30% alcohol used for cleaning, other residue from paper towels used in cleaning, and even coatings given to the glass during manufacturing. If the glass seems phobic in any way to a drop of water (ie the water beads, instead of spreading) this could be the case. Use only glass cleaner (the blue kind) with ammonia. 6mm borosilicate (Band name Pyrex). Thinner glass, whether borosilicate,or from a picture frame, will be susceptible to rapid warping when exposed to airflow. This will cause ABS prats to pop off suddenly. The thicker glass holds the heat better, and is dimensionaly stable in small breezes.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 27, 2015 01:03AM |

Registered: 11 years ago Posts: 661 |

Quote

jcabrer

I've posted several times over the years on the topic of Printing on Glass. Here is a compilation.

It's all about temperature people. Adding anything to the glass, or sanding it, is just a crutch. The underlying problem not being addressed is one of the following.

I see adhesion promotion as a tool, not a crutch. For example our machines exist to print parts. Plain borofloat, even in the best conditions can be inconsistent due to variations in the heater elements or environmental factors affecting the work space. Good borofloat is much more consistent than most PCB and polyimide heater assemblies. Our volume is about 15kg/month, parts coming right off the machine as soon as they are cool enough with another job loaded right after. Most are between two and ten hour prints. The use of an adhesion promoter is cheap insurance. We can also print much faster when using a binder on the bed. The result is consistent adhesion with no difference between parts printed with a promoter or without.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 27, 2015 01:28AM |

Registered: 11 years ago Posts: 661 |

Quote

CraigMoberg

So we have one vote for glue stick working well with ABS, and one vote for it not working well. It's tough being a newbie.

Yep, it is tough knowing what to do when you're new to the process. Ultimately you have to do what works best for you. I don't see it as a vote, rather what I've been doing for the last few years. Not all glue sticks are the same just as all hairspray is not the same. As jcabrer posted, you can indeed print directly to glass. PLA can be printed to clean, unheated glass under optimum conditions and prep. For ABS a heated bed is used to prevent edge curl as the material cools and ot promote adhesion during printing.

The hairspray I use for PLA is Aquanet extra hold, purple can, applied prior to the bed heating. I don't use it for ABS or higher temp materials, I use UHU.. UHU gluestick is different than the Elmers or other glue sticks found in the US. If you use too much it will stick the part to the bed and could damage the bed when you try to remove the part.

You are going to need to experiment to find out what works best for you. But first it looks like your machine or slicing settings need some tweaking. Make sure your steps for the extruder are set properly. There are several calibration guides in the Wiki that explain it. You'll also want to look at your filament diameter and extrusion factor in your slicing settings as well as making sure the proper thermistor profile is in your firmware. If your hot end is at 230 and the other parameters are correct bump the temps up a bit. I've gone as high as 240 with some ABS. It doesn't look like you are getting enough plastic out of the nozzle. I think sarf2k4 and Olaf are pointing you in the right direction. That first layer wants to look a little smashed on the bed but not so much you can't see the color of the material. You should be able to print that cube with no adhesion promoters, bed at 110 or so and you'll know your machine config is fine.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 27, 2015 04:04AM |

Registered: 9 years ago Posts: 476 |

Now I am getting first layer too thin, probably put too much generic gluestick (artliner, blue colour) and I somehow in a rush put the glue on the bet when it is 110'c. I wonder if I really damaged bed/glass because right after print ended I tried to take the item off (most likely due to anxious newbie in successful prints). I'm going to wash the glass then put a bit of glue stick when it is dry and cold and see if my first layer will be thin or not.

Anyway, glue stick does work well with abs. strictly speaking the glue stick adds somewhat a 'rough' layer on the bed, that is why abs do stick well on bed+glue stick. Still, I need to check why my first layer are so thin

Anyway, glue stick does work well with abs. strictly speaking the glue stick adds somewhat a 'rough' layer on the bed, that is why abs do stick well on bed+glue stick. Still, I need to check why my first layer are so thin

|

Re: Prusa I3 first "print" - what am I doing wrong? May 28, 2015 04:25PM |

Registered: 9 years ago Posts: 98 |

|

Re: Prusa I3 first "print" - what am I doing wrong? May 28, 2015 04:29PM |

Registered: 9 years ago Posts: 98 |

Quote

CraigMoberg

So we have one vote for glue stick working well with ABS, and one vote for it not working well. It's tough being a newbie.

Add another for glue stick. Elmers purple disappearing works great. Ive tried Xtra strength hairspray too but have read that it can cause shrinkage which could cause lift.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 28, 2015 06:04PM |

Registered: 8 years ago Posts: 125 |

The sticking out corners are cause by printing a 90 degree turn that requires infinite decel rate and infinite accel rate in the cross direction. the head stops, wiggles a bit, and the extra gets deposited causing the bulge. Dirty trick time - round off your corners just enough to work against inertia and you can get pretty sharp corners. Yes, it's cheating the system but it does work. But remember, YMMV and if you change your rates, the amount of rounding will have to change as well.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 28, 2015 08:25PM |

Registered: 8 years ago Posts: 82 |

|

Re: Prusa I3 first "print" - what am I doing wrong? May 28, 2015 09:03PM |

Registered: 8 years ago Posts: 82 |

I'm making good progress and getting much better prints after calibrating the extruder and tweaking the layer heights, extrusion width, etc. Thanks everyone for all the suggestions!

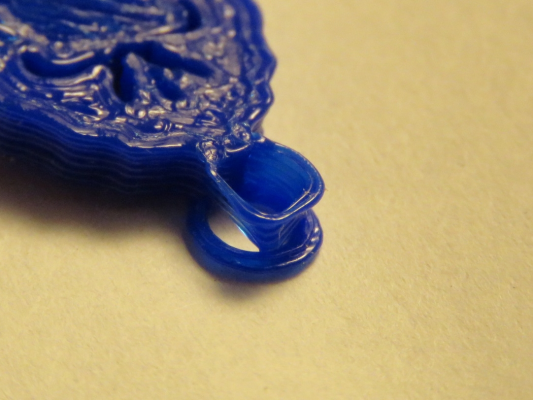

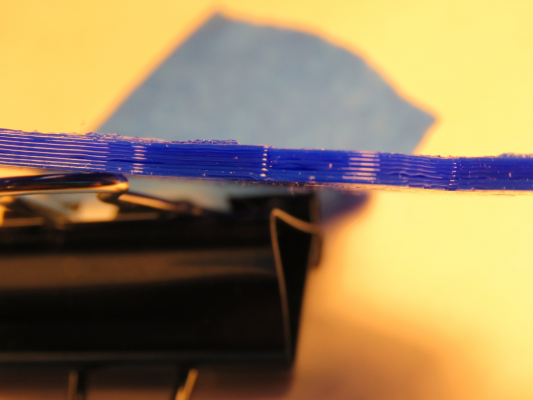

My last print came out not-so-bad, but with a couple problems.

It's a hanging pendant, and the loop for hanging didn't print well. And there's slight layer separation in some places on the perimeters.

I know I had Z homed too close to the bed, because the nozzle was scraping across the piece as it was printing. I'm going to fix that.

Any other ideas about these problems? Temperature? Layer height? Extrusion multiplier? (it's 1 now) Speed? Perimeter setting? (it's minimum 2 now)

Prusa I3 from Folgertech

1.75 PLA at 190/185 (first layer / others)

Unheated bed, with no fan on piece.

0.4 nozzle, layer height 0.4/0.3 (first layer / others)

Extrusion width = 0, first layer 200%

Glue stick on glass (generic, and it adheres very well)

on glass (generic, and it adheres very well)

My last print came out not-so-bad, but with a couple problems.

It's a hanging pendant, and the loop for hanging didn't print well. And there's slight layer separation in some places on the perimeters.

I know I had Z homed too close to the bed, because the nozzle was scraping across the piece as it was printing. I'm going to fix that.

Any other ideas about these problems? Temperature? Layer height? Extrusion multiplier? (it's 1 now) Speed? Perimeter setting? (it's minimum 2 now)

Prusa I3 from Folgertech

1.75 PLA at 190/185 (first layer / others)

Unheated bed, with no fan on piece.

0.4 nozzle, layer height 0.4/0.3 (first layer / others)

Extrusion width = 0, first layer 200%

Glue stick

on glass (generic, and it adheres very well)

on glass (generic, and it adheres very well)|

Re: Prusa I3 first "print" - what am I doing wrong? May 30, 2015 09:43AM |

Registered: 9 years ago Posts: 55 |

Hi

Look like you have more than one problem.

The first layer cannot be 0.4, if like this mean you are not pushing the material on the bed and printing in air.

Do good calibration of your bed with a paper,

After down your nose and try to get 0.25 to 0.3 mm high on first layer. Print holo Cubs like that you can measue 4 sides.

From your last pictures, you have gaps, and that cannot be possible. Mean you go too fast and strech the filament. Or your speed is correct but not feed enough.

Start at 35mm/s, and do some single wall spiral print, with layer of 0.3, you can get wall thickness at 0.43mm.

If you get consistant print, play with temp and cooling, " the problem of the loop".

Good luck

Look like you have more than one problem.

The first layer cannot be 0.4, if like this mean you are not pushing the material on the bed and printing in air.

Do good calibration of your bed with a paper,

After down your nose and try to get 0.25 to 0.3 mm high on first layer. Print holo Cubs like that you can measue 4 sides.

From your last pictures, you have gaps, and that cannot be possible. Mean you go too fast and strech the filament. Or your speed is correct but not feed enough.

Start at 35mm/s, and do some single wall spiral print, with layer of 0.3, you can get wall thickness at 0.43mm.

If you get consistant print, play with temp and cooling, " the problem of the loop".

Good luck

|

Re: Prusa I3 first "print" - what am I doing wrong? May 30, 2015 12:06PM |

Registered: 8 years ago Posts: 5,232 |

Your temp is too low, when you get layer separation. The 1st layer should not exceed 80% of nozzle diameter.

0.3 works good for me, when I have the nozzle slighty push the bed down at z-home. ( 200% extrusion sounds way too much for me?)

Other layers can be as thin as 50% with good results.

-Olaf

0.3 works good for me, when I have the nozzle slighty push the bed down at z-home. ( 200% extrusion sounds way too much for me?)

Other layers can be as thin as 50% with good results.

-Olaf

|

Re: Prusa I3 first "print" - what am I doing wrong? May 30, 2015 02:38PM |

Registered: 8 years ago Posts: 82 |

Quote

Laopa

The first layer cannot be 0.4

Quote

o_lampe

The 1st layer should not exceed 80% of nozzle diameter.

Good to know. I haven't seen that in any of the guides I've read. Most say to use a thicker first layer, and I'm using a 0.3 overall layer height, so I made the first layer 0.4.

Quote

o_lampe

200% extrusion sounds way too much for me?

I knew that as I was setting it

but I've been trying different things to get a nicely filled first layer. That's obviously not the way to go.

but I've been trying different things to get a nicely filled first layer. That's obviously not the way to go.And I'm increasing the temperature a little at a time to see what effect that has.

Quote

o_lampe

I have the nozzle slighty push the bed down at z-home.

I've tried that, but then I found the nozzle scraped the top of the piece. At first I thought it was homed too close, but then I noticed that the scraping got worse as the piece got taller, and sometimes would make a real mess. That got me thinking about my Z steps/mm. They're correct according to Prusa's calculator, but a symptom like that seems to indicate an accumulating error at each layer. I'm sure the threaded rods aren't machined to precision. So now I'm increasing that value a little at a time to see if it helps. Am I on the right track?

Quote

Laopa

Or your speed is correct but not feed enough.

I also started thinking about my extruder steps/mm. That's also "correct" but I'll be playing with that value too. These are the things they don't tell you in the brochure.

(I found this simple gadget for setting the Z endstop more precisely.)

Thanks for the help and suggestions guys!

|

Re: Prusa I3 first "print" - what am I doing wrong? May 30, 2015 03:57PM |

Registered: 8 years ago Posts: 5,232 |

You should print a complete testcube and then see, if you´d raise z-steps or better reduce e-steps to fight against the accumulating scratch-error.

Might be, your filament isn´t exactly 1.75mm but a bit more?

I don´t like the z-stop gadged, the endstop sticks out and is very exposed. But in general, I´m using the same concept with an allen-head screw.

Try to aim the screw directly to the switch, not to the "tongue".for better precision.

-Olaf

Might be, your filament isn´t exactly 1.75mm but a bit more?

I don´t like the z-stop gadged, the endstop sticks out and is very exposed. But in general, I´m using the same concept with an allen-head screw.

Try to aim the screw directly to the switch, not to the "tongue".for better precision.

-Olaf

|

Re: Prusa I3 first "print" - what am I doing wrong? May 30, 2015 07:03PM |

Registered: 8 years ago Posts: 82 |

Quote

o_lampe

raise z-steps or better reduce e-steps to fight against the accumulating scratch-error.

But I would think that even if e-steps were off, or the filament swelled, it would still be laying down the same amount of plastic per layer -- even if that's too much. And judging by the lower layers, it's not putting down enough. If the z-step was too small, the nozzle is lower than it thinks it is at each layer, and that's what would accumulate. I'm just trying to reason this through, but I'm trying all kinds of things. Increasing the z-step by a couple percent did seem to help some.

Quote

o_lampe

I don´t like the z-stop gadget, the endstop sticks out and is very exposed.

Well, the endstops are like that in this kit (from Folgertech.) It's an entry level machine. The gadget is made specifically for this kit and its endstops -- making the best of a bad situation, as it were.

You make a good point about aiming at the switch. I notice that the tongue has a lot of play while the switch is activated.

You make a good point about aiming at the switch. I notice that the tongue has a lot of play while the switch is activated.The filament is 1.75 - 1.77 by measurement (1.78 in places). How much of a difference is significant? There's also the fact that cheap digital calipers aren't super precise. I've been wondering -- how long does it take for humidity to affect PLA? Will one humid day make it swell?

And by the time the PLA is melted and laid down, won't any water content have evaporated? It seems like water absorption will result in less plastic deposited, not more.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 31, 2015 01:27AM |

Registered: 8 years ago Posts: 82 |

Here's my "raised ripples" piece from another post, printing now. As smooth and sweet as can be. You guys are the best!

(It's a raised relief, and I'm having string issues. Theories abound. Maybe ABS is better for this kind of thing.)

Maybe ABS is better for this kind of thing.)

Edited 1 time(s). Last edit at 05/31/2015 01:28AM by CraigMoberg.

(It's a raised relief, and I'm having string issues. Theories abound.

Maybe ABS is better for this kind of thing.)

Maybe ABS is better for this kind of thing.)Edited 1 time(s). Last edit at 05/31/2015 01:28AM by CraigMoberg.

|

Re: Prusa I3 first "print" - what am I doing wrong? May 31, 2015 03:18AM |

Registered: 8 years ago Posts: 5,232 |

The last one looks great!

When I mentioned the thickness of PLA, it wasn´t humidity, but fabrication tolerance I had in mind.

The z-steps are "written in stone": You have a thread with a given slope and steppers with fixed (micro)-steps. That calculates to a certain steps/mm ( 80 steps I´d guess )

The only source of z-error is : not enough current for both steppers and therefor skipped steps.

Extruder inaccuracy is much more likely.

-Olaf

When I mentioned the thickness of PLA, it wasn´t humidity, but fabrication tolerance I had in mind.

The z-steps are "written in stone": You have a thread with a given slope and steppers with fixed (micro)-steps. That calculates to a certain steps/mm ( 80 steps I´d guess )

The only source of z-error is : not enough current for both steppers and therefor skipped steps.

Extruder inaccuracy is much more likely.

-Olaf

|

Re: Prusa I3 first "print" - what am I doing wrong? May 31, 2015 04:53AM |

Registered: 8 years ago Posts: 82 |

Quote

o_lampe

The z-steps are "written in stone"

I see what you're saying. But if they were truly written in stone, there would be no need to set them or calculate them. They're really written in metal, which is imprecisely machined, and maybe the setting is to compensate for that, and get a true millimeter of height from the steps.

And I did get improvement in the scraping and the quality just by increasing the z-steps by a couple percent. After that I was playing with the e-steps too, so it's hard to say. But like I said, I'm laying down more plastic now, not less, and getting better results.

Sorry, only registered users may post in this forum.