Best place to start with calibration based on these results?

Posted by jimmyclarke

|

Best place to start with calibration based on these results? June 09, 2015 04:55AM |

Registered: 8 years ago Posts: 22 |

Hi all,

I'm new so be kind please!

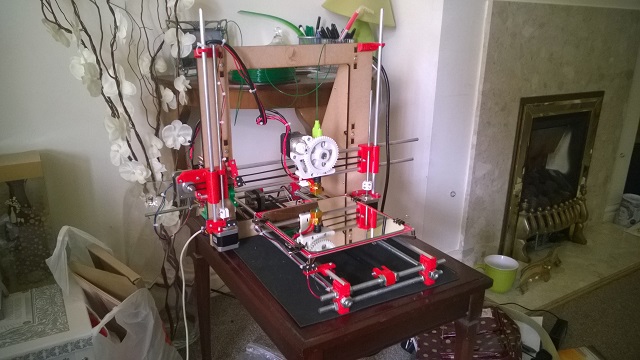

I have built up a prusa i3, nothing special nor modified (yet)

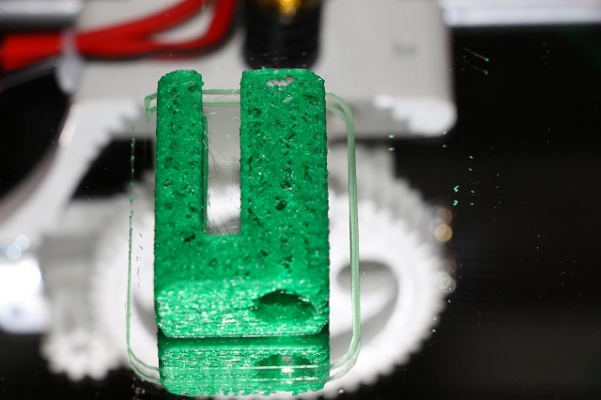

I have it at the stage where it can produce "functional" pieces, I am currently creating a spoolholder from http://www.thingiverse.com/thing:370390

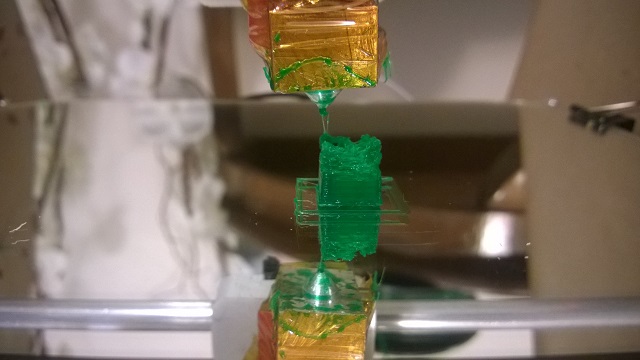

Part 1 came out with the correct dimensions, but the infill is seriously messy! All my speeds are set to 30mm/s this was at 0.28mm line height, (going to print at 0.2 for the next one to compare)

The speeds are set in slicer, but it seems the infill is quicker than the perimeters?

I've just read about using clothes peg springs as tensioners, so will do that tonight, but where would be a good place to start to get things looking neater? (I've measured 10mm of travel and feed etc and happy with the tolerence there)

Also print before this, no filament was coming out so I upped the flowrate to max 150 (I'm using repetier), but turns out the extruder gear had come loose from the motor, so I tightened that back up, but forgot to lower the flowrate back for this print : -(

I'm printing in PLA, heatbed isn't actually wired up yet, as I'd need to route some of the wires I chopped from the ATX to it

0.35mm nozzle

Hope it's not too noobish sounding! Thanks for any help! (sorry for the rushed pics)

Edited 1 time(s). Last edit at 06/09/2015 04:56AM by jimmyclarke.

I'm new so be kind please!

I have built up a prusa i3, nothing special nor modified (yet)

I have it at the stage where it can produce "functional" pieces, I am currently creating a spoolholder from http://www.thingiverse.com/thing:370390

Part 1 came out with the correct dimensions, but the infill is seriously messy! All my speeds are set to 30mm/s this was at 0.28mm line height, (going to print at 0.2 for the next one to compare)

The speeds are set in slicer, but it seems the infill is quicker than the perimeters?

I've just read about using clothes peg springs as tensioners, so will do that tonight, but where would be a good place to start to get things looking neater? (I've measured 10mm of travel and feed etc and happy with the tolerence there)

Also print before this, no filament was coming out so I upped the flowrate to max 150 (I'm using repetier), but turns out the extruder gear had come loose from the motor, so I tightened that back up, but forgot to lower the flowrate back for this print : -(

I'm printing in PLA, heatbed isn't actually wired up yet, as I'd need to route some of the wires I chopped from the ATX to it

0.35mm nozzle

Hope it's not too noobish sounding! Thanks for any help! (sorry for the rushed pics)

Edited 1 time(s). Last edit at 06/09/2015 04:56AM by jimmyclarke.

|

Re: Best place to start with calibration based on these results? June 09, 2015 05:23AM |

Registered: 9 years ago Posts: 476 |

The printer looks nice. You can ask a lot of things here, that's what this forum all about. You could try searching calibration steps or calibrating your printer under reprap wiki. I personally never really read and follow that guide. But I somewhat learned it the hard way.

Mechanical calibration comes first, especially punching in correct steps/mm then you can move on. I also saw you put y axis end stop at front, it probably gonna make your print a mirrored result on the y axis.

Your green thingy results, I would say you might have the hot end temp too high or lack of flow rate or extruder not calibrated well. I don't know if the spool mount attached to the top of the frame would be a good idea or not, from my own perspective, it would be bad, some people would say good probably would make it slightly rigid or something, for me who use almost same table size as yours I don't really recommend. I often printing at around 50-60mm/s

An offset of about 1% output e.g printing 20mm cube and turned out to be having 20.1-20.4mm for x and y, I think it's a good tolerance too because the walls aren't always perfectly aligned with the previous layers.

Unsure about infill quicker than perimeters, or did you mean walls? That one usually common but you can set the speed of printing the infills in the setting.

Mechanical calibration comes first, especially punching in correct steps/mm then you can move on. I also saw you put y axis end stop at front, it probably gonna make your print a mirrored result on the y axis.

Your green thingy results, I would say you might have the hot end temp too high or lack of flow rate or extruder not calibrated well. I don't know if the spool mount attached to the top of the frame would be a good idea or not, from my own perspective, it would be bad, some people would say good probably would make it slightly rigid or something, for me who use almost same table size as yours I don't really recommend. I often printing at around 50-60mm/s

An offset of about 1% output e.g printing 20mm cube and turned out to be having 20.1-20.4mm for x and y, I think it's a good tolerance too because the walls aren't always perfectly aligned with the previous layers.

Unsure about infill quicker than perimeters, or did you mean walls? That one usually common but you can set the speed of printing the infills in the setting.

|

Re: Best place to start with calibration based on these results? June 09, 2015 05:43AM |

Registered: 8 years ago Posts: 22 |

Hi Sarf24k

Thanks for the response!

In terms of terminology, I'm not sure if I mean perimeter or wall, I set perimeter to 3 in slic3r so figured that the part of the print that isn't the infill was called that, but wall makes sense!

I have all the speeds set to the same value, but different processes to the layer (edge vs middle) still print at different speeds.

I will try lowering the temperature, it is currently at 190

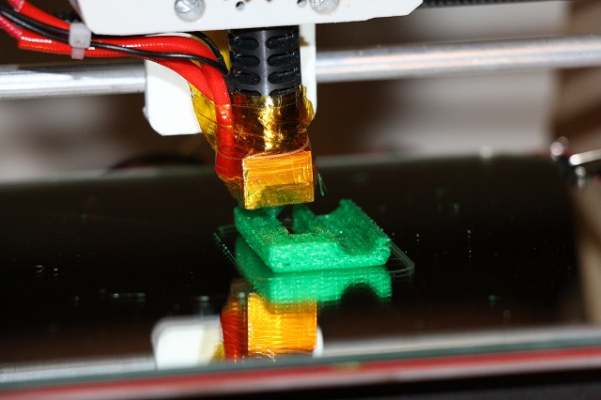

Yes during this print I was questioning adding more weight so high up, the thin part of the slice, (to the right of the hole in the pics) caused a lot of vibration due to it's size, so I was thinking an external spool would be better

I will have another look at spool holders, I saw a nice horizontal one once, if I can't find it again will knock one up

I will double check my mechanical calibration about, especially after adding the tensioner, but I am fairly confident about that, so thought my problem must be digital!

Thanks again, will report back tonight

Thanks for the response!

In terms of terminology, I'm not sure if I mean perimeter or wall, I set perimeter to 3 in slic3r so figured that the part of the print that isn't the infill was called that, but wall makes sense!

I have all the speeds set to the same value, but different processes to the layer (edge vs middle) still print at different speeds.

I will try lowering the temperature, it is currently at 190

Yes during this print I was questioning adding more weight so high up, the thin part of the slice, (to the right of the hole in the pics) caused a lot of vibration due to it's size, so I was thinking an external spool would be better

I will have another look at spool holders, I saw a nice horizontal one once, if I can't find it again will knock one up

I will double check my mechanical calibration about, especially after adding the tensioner, but I am fairly confident about that, so thought my problem must be digital!

Thanks again, will report back tonight

|

Re: Best place to start with calibration based on these results? June 09, 2015 06:19AM |

Registered: 8 years ago Posts: 5,232 |

It´s always helpful to inspect/show us the first layer. That already tells alot about the state of calibration.

The green thingi has some dark spots ( or gaps ) in it. Is it the color of the filament o do you have waterbubbles from humid filament?

The y-stop ( as min-endstop ) at the front and the x-stop at the left ( as max-endstop ) would be OK, no mirrored output.

-Olaf

The green thingi has some dark spots ( or gaps ) in it. Is it the color of the filament o do you have waterbubbles from humid filament?

The y-stop ( as min-endstop ) at the front and the x-stop at the left ( as max-endstop ) would be OK, no mirrored output.

-Olaf

|

Re: Best place to start with calibration based on these results? June 09, 2015 07:41AM |

Registered: 8 years ago Posts: 22 |

Hi Olaf,

The dark spots are indeed gaps, the filament is kept in a sealed bag with silica gel in it when not in use, and there was no popping noises when printing, so I am hoping it is not that, and simply my settings are wrong.

I will get more details on first layer etc. next time, thanks.

The dark spots are indeed gaps, the filament is kept in a sealed bag with silica gel in it when not in use, and there was no popping noises when printing, so I am hoping it is not that, and simply my settings are wrong.

I will get more details on first layer etc. next time, thanks.

|

Re: Best place to start with calibration based on these results? June 09, 2015 09:51AM |

Registered: 9 years ago Posts: 55 |

Hi JimmyClark

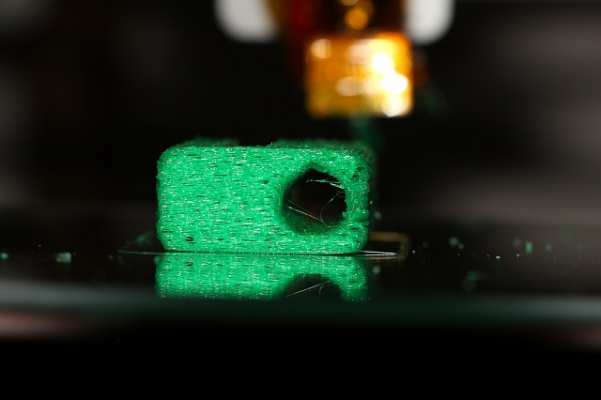

look at the first loop around your print, left and front look like your nozzle is too close to the bed and material cannot get out .

The right side, the bed is little lower so more material but very squishy.

Up you nozzle ~0.1 to 0.15mm.

Also I did not see any cooling fan near your nozzle, so you will heat too much the material.

Also you place Kapton tape Over the heat break halh high ( just over the nozzle). This will increase the heat inside the heat break, then you will have too much " liquid material", 2 solution here, print faster to avoid over heat or removed this kapton tape.

Generally PLA does not absorb as much water as ABS. from the moment you do not ear pop when you print or small bubbles on your print it is OK.

According to your cube, you are over heating, and heating too longtime.

look at the first loop around your print, left and front look like your nozzle is too close to the bed and material cannot get out .

The right side, the bed is little lower so more material but very squishy.

Up you nozzle ~0.1 to 0.15mm.

Also I did not see any cooling fan near your nozzle, so you will heat too much the material.

Also you place Kapton tape Over the heat break halh high ( just over the nozzle). This will increase the heat inside the heat break, then you will have too much " liquid material", 2 solution here, print faster to avoid over heat or removed this kapton tape.

Generally PLA does not absorb as much water as ABS. from the moment you do not ear pop when you print or small bubbles on your print it is OK.

According to your cube, you are over heating, and heating too longtime.

|

Re: Best place to start with calibration based on these results? June 09, 2015 12:08PM |

Registered: 10 years ago Posts: 477 |

Have you checked your steps per mm for the extruder?

I also file a flat spot on my extruder motor shaft to help the grub-screw have less chance of slipping.

My updated Instructable on our Prusa i3 Build

[www.instructables.com]

I also file a flat spot on my extruder motor shaft to help the grub-screw have less chance of slipping.

My updated Instructable on our Prusa i3 Build

[www.instructables.com]

|

Re: Best place to start with calibration based on these results? June 09, 2015 12:19PM |

Registered: 8 years ago Posts: 22 |

Thanks guys, My extruder came ready assembled and had the tape as you see, do you think it is worth taking this tape off then?

Unfortunately my kit did not come with anyway of mounting a fan near the extruder, this is one of the things I will be printing

Great advice coming in, looking forward to getting back to it tonight

Thanks

Oh and SteveRoy, my extruder motor does have a flat spot on the shaft, it was just really convinced it wanted to slip off I suppose!

Unfortunately my kit did not come with anyway of mounting a fan near the extruder, this is one of the things I will be printing

Great advice coming in, looking forward to getting back to it tonight

Thanks

Oh and SteveRoy, my extruder motor does have a flat spot on the shaft, it was just really convinced it wanted to slip off I suppose!

|

Re: Best place to start with calibration based on these results? June 09, 2015 08:53PM |

Registered: 9 years ago Posts: 476 |

I didn't file any part of my extruder motor shaft, that's optional but a great thing to solve a problem that kept coming back. I only tighten it snuggle fit, never ever over tighten it. The perimeter/skirt lines are normal like that, try increasing perimeter lines up to 3 lines. I always use 3 perimeter lines so that the extruder will eventually extrude plastic properly.

The left side of the picture for the perimeter looks like it is normal when starting a print and then eventually the plastic came out. Just you need to do some extruder calibration left. Tensioner won't affect the travel distance but it might affect quality of the prints and therefore you might ran into problem like motors skipping steps due to lack of current supplied

I use an external spool holder that came with my kit, but it somehow gave me bad prints on my first 1kg of plastics often due to there were no bushing and bad wobble that time. If you making some kind of stand like mine with using a cheap 20mm pipe or rods, can use this [www.thingiverse.com], I created it to be customizable to fit most things even options to add slots for bearings. I am using this spool bushing and made my filament spool rolls more smoothly than without it. I suggest you better get fast with the spool holder =D

Edited 1 time(s). Last edit at 06/09/2015 08:57PM by sarf2k4.

The left side of the picture for the perimeter looks like it is normal when starting a print and then eventually the plastic came out. Just you need to do some extruder calibration left. Tensioner won't affect the travel distance but it might affect quality of the prints and therefore you might ran into problem like motors skipping steps due to lack of current supplied

I use an external spool holder that came with my kit, but it somehow gave me bad prints on my first 1kg of plastics often due to there were no bushing and bad wobble that time. If you making some kind of stand like mine with using a cheap 20mm pipe or rods, can use this [www.thingiverse.com], I created it to be customizable to fit most things even options to add slots for bearings. I am using this spool bushing and made my filament spool rolls more smoothly than without it. I suggest you better get fast with the spool holder =D

Edited 1 time(s). Last edit at 06/09/2015 08:57PM by sarf2k4.

|

Re: Best place to start with calibration based on these results? June 10, 2015 04:43AM |

Registered: 8 years ago Posts: 22 |

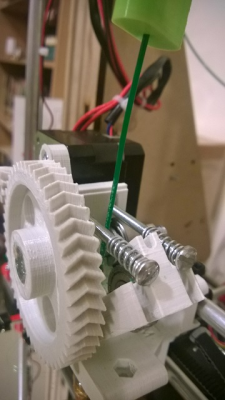

OK, well I think I have my problem diagnosed

I checked all my esteps and am happy with the calibration

So I printed out a test cube at 0% infill and got this

During the time it was looking perfect I left it, and came back to the mess at the top!

I had a look at the extruder and the whole filament had not snapped, but the hobbed bolt had cut away all the filament it could reach, so there was just a dome missing, and the hob couldn't catch it anymore,

I removed the old stuff, cleaned the nozzle and re set up, but still the the occasional crack of filament, and it often looks like this

How do I gauge how much tension to put into the extruder, I must be doing too much yes?

I will also get a little 10m test reel and put that through it, to see if my filament is just gone...

Edited 1 time(s). Last edit at 06/10/2015 04:55AM by jimmyclarke.

I checked all my esteps and am happy with the calibration

So I printed out a test cube at 0% infill and got this

During the time it was looking perfect I left it, and came back to the mess at the top!

I had a look at the extruder and the whole filament had not snapped, but the hobbed bolt had cut away all the filament it could reach, so there was just a dome missing, and the hob couldn't catch it anymore,

I removed the old stuff, cleaned the nozzle and re set up, but still the the occasional crack of filament, and it often looks like this

How do I gauge how much tension to put into the extruder, I must be doing too much yes?

I will also get a little 10m test reel and put that through it, to see if my filament is just gone...

Edited 1 time(s). Last edit at 06/10/2015 04:55AM by jimmyclarke.

|

Re: Best place to start with calibration based on these results? June 10, 2015 09:02AM |

Registered: 9 years ago Posts: 55 |

Hi

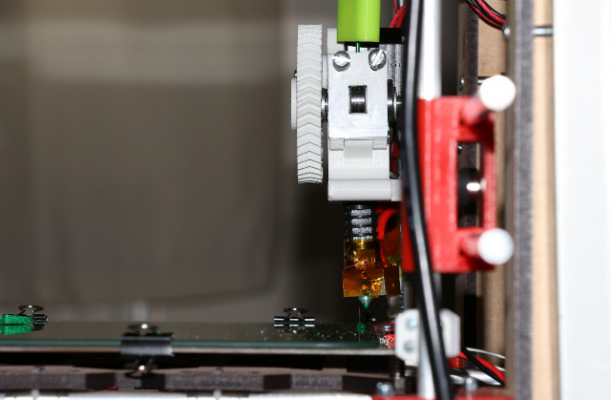

I do not know if it is my eyes, but look like your nozzle is not perpendicular to the bed!

for filament feeding, it is better to skip step than push too much, un tight and progressively adjust until no missing steps.

I will first reduce the amount of material feeding to the printer, better to have hole in the print than too much to see the problems.

can you give us your settings? speed, temps...screen copies.

Also Estep is first things to do, according to your nozzle diameter,t you must fine tune your printer. follow this, the single wall cube.

[www.youmagine.com]

Edited 2 time(s). Last edit at 06/10/2015 09:15AM by Laopa.

I do not know if it is my eyes, but look like your nozzle is not perpendicular to the bed!

for filament feeding, it is better to skip step than push too much, un tight and progressively adjust until no missing steps.

I will first reduce the amount of material feeding to the printer, better to have hole in the print than too much to see the problems.

can you give us your settings? speed, temps...screen copies.

Also Estep is first things to do, according to your nozzle diameter,t you must fine tune your printer. follow this, the single wall cube.

[www.youmagine.com]

Edited 2 time(s). Last edit at 06/10/2015 09:15AM by Laopa.

|

Re: Best place to start with calibration based on these results? June 10, 2015 09:34AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Best place to start with calibration based on these results? June 10, 2015 11:53AM |

Registered: 8 years ago Posts: 2 |

Have you calibrated your e-steps yet?

[reprap.org]

If yes, when you extrude 100mm do you see it consistently taking 100mm of filament?

In my case my extruder temperature was too low which caused inconsistent extrusion. After raising my extruder temperature from 200C to 215C I now get consistent extrusions (as measured during extrusion length calibration) and my prints look good (I'm printing PLA).

If your filament is breaking it sounds like your hotend temp may also be too low (trying to push filament that isn't fully melted in the hotend).

[reprap.org]

If yes, when you extrude 100mm do you see it consistently taking 100mm of filament?

In my case my extruder temperature was too low which caused inconsistent extrusion. After raising my extruder temperature from 200C to 215C I now get consistent extrusions (as measured during extrusion length calibration) and my prints look good (I'm printing PLA).

If your filament is breaking it sounds like your hotend temp may also be too low (trying to push filament that isn't fully melted in the hotend).

|

Re: Best place to start with calibration based on these results? June 10, 2015 09:05PM |

Registered: 9 years ago Posts: 476 |

Hmm, the cube turned out to be so messy, I also would think that your hot end are not 90' angle and thus hit the cube previous layer that hasn't fully hardened yet.

Don't tighten it too much on your extruder spring, probably the best way is that you check how much the hobbed bolt/ extruder gear has eaten the raw filament or how deep the teeth squishing the raw filament (sorry not very sure the correct word for these) or the bite marks. Another way was (during my very first 1kg with abs), I tried tightening the spring then extrude, the motor can't push the filament due to strong tension of the spring and you can hear motor losing steps or there was some click noises. When you got it, loosen it slightly more because you might printing it with filament retractions

Don't tighten it too much on your extruder spring, probably the best way is that you check how much the hobbed bolt/ extruder gear has eaten the raw filament or how deep the teeth squishing the raw filament (sorry not very sure the correct word for these) or the bite marks. Another way was (during my very first 1kg with abs), I tried tightening the spring then extrude, the motor can't push the filament due to strong tension of the spring and you can hear motor losing steps or there was some click noises. When you got it, loosen it slightly more because you might printing it with filament retractions

|

Re: Best place to start with calibration based on these results? June 12, 2015 07:17AM |

Registered: 8 years ago Posts: 22 |

Hi all!

Sorry for the delay, the sun is out in Britain and as summer only last a few days at a time, we have to make the most of it when we can!

Yes, when the filament jammed it ended up trying to push the hotend out of the way which caused it to become wonky

I have tried to adjust it back but it now seems permanently loose, so I think I will bore out one of the retaining bolts for it out to 4mm, will try a metal shim first as a non destructive method first.

This is what it looks like now

Although looking at it now and being able to draw straight lines, it also looks like my bed is not perpendicular either, so will add that to my list! : -(

As recommended I upped my temperature (lowering the temperature was a lot worse) but now at 210celcius it is printing almost beautfully, even Cura's rafts came out great!

the issue now is either the bed or hotend, as this piece (which is [www.thingiverse.com]) Starts off on an angle, but by half way it has levelled out and is the correct shape

seeing as the top half is correct this would lead me to assume the bed is the worst offender rather than the hot end?

pictured effect as best I could, but it's only from my phone

Progress is being made though, thanks everyone

Sorry for the delay, the sun is out in Britain and as summer only last a few days at a time, we have to make the most of it when we can!

Yes, when the filament jammed it ended up trying to push the hotend out of the way which caused it to become wonky

I have tried to adjust it back but it now seems permanently loose, so I think I will bore out one of the retaining bolts for it out to 4mm, will try a metal shim first as a non destructive method first.

This is what it looks like now

Although looking at it now and being able to draw straight lines, it also looks like my bed is not perpendicular either, so will add that to my list! : -(

As recommended I upped my temperature (lowering the temperature was a lot worse) but now at 210celcius it is printing almost beautfully, even Cura's rafts came out great!

the issue now is either the bed or hotend, as this piece (which is [www.thingiverse.com]) Starts off on an angle, but by half way it has levelled out and is the correct shape

seeing as the top half is correct this would lead me to assume the bed is the worst offender rather than the hot end?

pictured effect as best I could, but it's only from my phone

Progress is being made though, thanks everyone

|

Re: Best place to start with calibration based on these results? June 12, 2015 09:30AM |

Registered: 9 years ago Posts: 55 |

Hi JimmyClarke

Good you start printing

Calibration is the base for good printing.

1: X,Y,Z adjust Estep as closed as possible

2: Filament feeding Estep

3: Control your temperature for Hot Bed and nozzle. MUST do that also.

4: Bed LEVEL, MUST I will say check every time your first layer.

4: Nozzle height, this one is the base, if not good, your print will be messy.

after fine adjustment

X,Y, Z

filament adjustment (wall thickness)

temperature # for every roll of plastic.

Good prints

Good you start printing

Calibration is the base for good printing.

1: X,Y,Z adjust Estep as closed as possible

2: Filament feeding Estep

3: Control your temperature for Hot Bed and nozzle. MUST do that also.

4: Bed LEVEL, MUST I will say check every time your first layer.

4: Nozzle height, this one is the base, if not good, your print will be messy.

after fine adjustment

X,Y, Z

filament adjustment (wall thickness)

temperature # for every roll of plastic.

Good prints

Sorry, only registered users may post in this forum.