Thinking of buying a P3Steel kit from Orballo

Posted by paulhurleyuk

|

Thinking of buying a P3Steel kit from Orballo November 14, 2015 07:43AM |

Registered: 8 years ago Posts: 35 |

I'm thinking of pulling the trigger on this P3Steel kit from Orballo, mainly because of a cosmic alignment of some spare money, WAF and someone at home for receving.

[orballoprinting.com]

Its my first printer, so I'd prefer a kit to buying parts individually, and I think a Mendel style rather than CoreXY or Delta. Looking at the range of Prusa style kits out there, I like the P3Steel best, because of the extra rigidity (and weight), and the way (I hope) it keeps square better.

Any thoughts/comments/tips on this before I hit go ?

Thanks

Paul.

[orballoprinting.com]

Its my first printer, so I'd prefer a kit to buying parts individually, and I think a Mendel style rather than CoreXY or Delta. Looking at the range of Prusa style kits out there, I like the P3Steel best, because of the extra rigidity (and weight), and the way (I hope) it keeps square better.

Any thoughts/comments/tips on this before I hit go ?

Thanks

Paul.

|

Re: Thinking of buying a P3Steel kit from Orballo November 16, 2015 08:38AM |

Registered: 10 years ago Posts: 444 |

|

Re: Thinking of buying a P3Steel kit from Orballo November 16, 2015 06:47PM |

Registered: 8 years ago Posts: 9 |

|

Re: Thinking of buying a P3Steel kit from Orballo November 19, 2015 05:37PM |

Registered: 8 years ago Posts: 35 |

|

Re: Thinking of buying a P3Steel kit from Orballo November 20, 2015 07:01AM |

Registered: 10 years ago Posts: 444 |

|

Re: Thinking of buying a P3Steel kit from Orballo November 25, 2015 08:43AM |

Registered: 8 years ago Posts: 4 |

I also ordered the printer two weeks ago. Hope to receive it by the end of this week (took 3 weeks instead of the 3-5 days that was told me when i was placing the order).

Because i have to wait so long for the printer to arrive i found a review from somebody that is assembling the printer from orballo: [www.mygoogleplus.com]

Unfortunately she is pointing out some issues..

I also found someone on this site: [www.reddit.com] who has bad experiences with the printed parts delivered by orballo. Since this was posted 5 months ago i confronted Orballo with this issue and they said they have improved this.

Im curious about your update Paul, and i will do the same when my kit arrives.

Marcel

Because i have to wait so long for the printer to arrive i found a review from somebody that is assembling the printer from orballo: [www.mygoogleplus.com]

Unfortunately she is pointing out some issues..

I also found someone on this site: [www.reddit.com] who has bad experiences with the printed parts delivered by orballo. Since this was posted 5 months ago i confronted Orballo with this issue and they said they have improved this.

Im curious about your update Paul, and i will do the same when my kit arrives.

Marcel

|

Re: Thinking of buying a P3Steel kit from Orballo November 25, 2015 02:39PM |

Registered: 8 years ago Posts: 1 |

|

Re: Thinking of buying a P3Steel kit from Orballo November 25, 2015 05:48PM |

Registered: 8 years ago Posts: 4 |

|

Re: Thinking of buying a P3Steel kit from Orballo December 02, 2015 07:21PM |

Registered: 8 years ago Posts: 9 |

Took exactly two weeks for delivery for me. Some of the printed parts were messy, lots of sanding/filing needed. They weren't weak/crumbly though.

End stops supplied are impossible to fit in a way which works with the included mounting pieces. Fortunately, it's relatively easy to bodge them in place with duct tape and then print out proper endstop holders.

Edited 1 time(s). Last edit at 12/04/2015 11:12AM by nallar.

End stops supplied are impossible to fit in a way which works with the included mounting pieces. Fortunately, it's relatively easy to bodge them in place with duct tape and then print out proper endstop holders.

Edited 1 time(s). Last edit at 12/04/2015 11:12AM by nallar.

|

Re: Thinking of buying a P3Steel kit from Orballo December 05, 2015 09:15AM |

Registered: 8 years ago Posts: 7 |

I too ordered the frame from Orballo On Nov-22. Still not shipped, however, I had asked which frame version they were going to ship. They responded with "it's v2.01 but we're having v2.5 cut and should have them next week". I then asked for the v2.5 version to be assigned/shipped on my order, just in case I want to do a Bowden at some point. So I can understand why my particular order is taking a while.

Also, anyone know a US quality supplier for smooth rod? The v2.5 rods are a little longer and I'm having issues sourcing them. I heard orballos rods weren't very good so I didn't order them there.

Thanks! And good luck with your builds!

Also, anyone know a US quality supplier for smooth rod? The v2.5 rods are a little longer and I'm having issues sourcing them. I heard orballos rods weren't very good so I didn't order them there.

Thanks! And good luck with your builds!

|

Re: Thinking of buying a P3Steel kit from Orballo December 08, 2015 05:22PM |

Registered: 8 years ago Posts: 35 |

So my printer arrived after two weeks. All parts appear there, although packaging wasn't amazing. Also, no instructions, although I've emailed Orballo and they've replied that they will send some.

Initial unboxing pics here https://flic.kr/s/aHskpxMLyc .

I'll be posting some assembly pics somewhere, and will update this thread.

Paul.

--

www.paulhurley.co.uk

Initial unboxing pics here https://flic.kr/s/aHskpxMLyc .

I'll be posting some assembly pics somewhere, and will update this thread.

Paul.

--

www.paulhurley.co.uk

|

Re: Thinking of buying a P3Steel kit from Orballo December 09, 2015 09:46AM |

Registered: 8 years ago Posts: 24 |

|

Re: Thinking of buying a P3Steel kit from Orballo December 09, 2015 01:49PM |

Registered: 8 years ago Posts: 9 |

Quote

paulhurleyuk

So my printer arrived after two weeks. All parts appear there, although packaging wasn't amazing. Also, no instructions, although I've emailed Orballo and they've replied that they will send some.

Initial unboxing pics here https://flic.kr/s/aHskpxMLyc .

I'll be posting some assembly pics somewhere, and will update this thread.

Paul.

--

www.paulhurley.co.uk

Assembly playlist for the P3Steel here: [www.youtube.com]

It's in Spanish, but still helpful.

The kitprinter3d instructions here: [www.kitprinter3d.com] also mostly match the kit.

Quote

ade2

Hi! Please keep us posted. I've also ordered this kit from Orballo, last week, and I'm waiting for it to be sent. It would be interesting to learn about your experiences with the kit.

My configuration is:

- 1.75mm

- Ramps 1.4sb

- Heatbed MK3 ALU 12V/24V

- DRV8825 drivers

"Ramps 1.4sb" was probably a good choice, I ordered the same configuration as you but with standard/cheap clone RAMPS and it failed yesterday. The MOSFET for the heated bed failed spectacularly, it heated up so much that it desoldered itself from the board, despite being cooled reasonably well. (120mm fan at full speed very close to it).

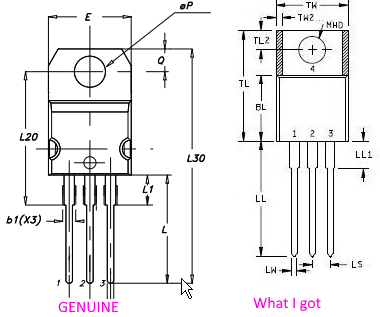

It looks like the "STP55NF06" they've used are fake. The on resistance is about 0.05 ohms (hard to measure precisely, sorry), far too high. The package doesn't match the one shown in the datasheet - the top of the tab is flat with mine, the edges are chamfered(?) in the datasheet:

Left package is from STP55NF06 datasheet, right is from an unrelated part's datasheet and matches the possible counterfeit. In this image of the RAMPS 1.3, the MOSFETs also have the chamfered tabs, unlike the possible fake.

I suspect they've just ordered the cheapest RAMPS board from alibaba and sent them out without noticing that their supplier has started using fake parts.

|

Re: Thinking of buying a P3Steel kit from Orballo December 20, 2015 10:38AM |

Registered: 8 years ago Posts: 35 |

OK, so using a combination of guessing, and other peoples instructions from the web as linked above I've started the build.

Paul.

--

Paul Hurley

www.paulhurley.co.uk

- Assembling the frame went easily, the frame seems straight, the paint hasn't chipped and there's not too many sharp edges or flash. I haven't used washers for most of the captive fastenings. https://flic.kr/p/Bpyven

- Assembling the Y axis motor and idler went ok. The kit includes four printed spacers, that could either all be for the motor, or could all be to mount the RAMPS later, or half and half. In the end I mounted the motor to one plate, then mounted the gear, then attached the other plate and two spacers. This eems to work, although the belt squeezes against it at the motor end. I also didn't follow the reprap wiki suggestion to 'tap' the y axis smooth rods in from one end completely, instead removing one end, placing the y axis rods, then re-attaching the end plate. I think this is less likely to scratch the rods and everything still seems square.

- Assembling the X axis took longer than expected, the kit includes a different X idler than the wiki or most videos show that includes a built in tensioner. it took me a while to work out what hardware to use and in what order (https://flic.kr/p/BNrkzV). Eventually I also found the BQ Prusa instructions which do resemble the X Axis.

- I attached the X axis to the Z axis which went well. I ended up attaching the Z motors three times (connectors should face the frame, and cables need to be connected before mounting the motor)

- I assembled the Extruder, which went ok. The hobbed bolt has threads on either end so I could turn the nuts on each end to align the hobbing with the filament hole.

- I also assembled the hot end. It seems to be an E3D 'style' v5 or v6. The thermistor is held in with a screw, and I added a m3 washer to hold it better. I'll need to extend the wires for the hot end fan.

- The hot end attaches to the extruder with two m3 bolts to 'pinch' it in place, however the kit also includes a short length of plastic tube (polypropylene, deffo not PTFE) with a bevel on one end. The tube is too long to fit in the extruder, and the hot end doesn't have a large enough bore to hold it, so I suspect the tube goes inside the extruder but needs trimming, but I'm not sure. (answers on a postcard...)

- I haven't attached the ramps yet. the Arduino has 4 mouting holes, but neither of the top two will take a m3 hex bolt head without interfering with a connector. Not sure if people mount another way or file the side of the bolt ?

- I've also got to wire the Mk3 alu heat bed and mount it.

- I've also got to mount the end stops, and I'm not sure what hardware to use, I'm out of m3 8mm bolts, and 15mm are a little long.

Paul.

--

Paul Hurley

www.paulhurley.co.uk

|

Re: Thinking of buying a P3Steel kit from Orballo December 24, 2015 08:02AM |

Registered: 8 years ago Posts: 35 |

Next update

Paul.

--

Paul Hurley

www.paulhurley.co.uk

Edited 1 time(s). Last edit at 12/24/2015 08:03AM by paulhurleyuk.

- So, got a reply both on the forum and direct from Orballo, Yes, the plastic tube goes inside the extruder body above and flush with the hot end. The hot end is then secured in place being pinched by two M3 bolts.

- I installed the end stops. the clips provided aren't great, for the X and Z axis they work, but not great (https://flic.kr/p/CsYpFX). For the Y axis they just didn't work so I ended up supergluing the endstop to the side of the clip, then supergluing that clip to the bottom of the Y carriage where it would strike the rear frame. (https://flic.kr/p/BUsQxM)

- Wired up the frame. The initial wiring was really messy, until I saw this video (https://youtu.be/7l1rb2gWsZM) that totally worked for all of my cable bundles to keep them together. (https://flic.kr/p/BvA9xc)

- I initially wired up the arduino on the bench to check everything worked, which it did. But I think the combination of being there, the tangle of wires and my massive labels on cables stopped any airflow, and the drivers got very hot. I moved the arduino and mounted it to the frame, filing a bolt on two edges for the top left hole and re-wired. much neater (https://flic.kr/p/BUtddk)

- I extended the cable for the fan, and following lots of advice on the net, connected it to the connector just behind the power connector. This worked and the fan was nice and loud, for maybe thirty minutes, until it was very quiet, and smelt of burnt. T and it works.urns out the fan provided was 5V and the connector supplies 12V. Oops. need to get a new fan, and make sure its 12V !

- Setup Marlin on the arduino. I pulled the latest RC from git and configured everything (LCD, endstops, heat etc)

- Setup Pronterface and Slic3r (and Skeinforge if I want to try that) and connected succesfully. Homed all the axis and heated things up, all working apart from the fan. (https://flic.kr/p/C1QDxS)

Paul.

--

Paul Hurley

www.paulhurley.co.uk

Edited 1 time(s). Last edit at 12/24/2015 08:03AM by paulhurleyuk.

|

Re: Thinking of buying a P3Steel kit from Orballo December 26, 2015 07:22PM |

Registered: 8 years ago Posts: 11 |

I have also bought an orballo Prusa i3 steel printer kit and I am having some problems. I have yet to start the build, mainly as I think there are some parts missing. Attached are some recieved files which might help anyone who has started the build. What would be useful to know is how many DVR8825 driver modules are needed, I have x 4 of these. Also, should there be a fan for the extruder?

I have been in 2 minds to return the printer but having found this forum and seeing other people starting the build, if I can confirm if I have all the required parts, I am happy to start constructing.

Paul, thanks for your many posts, I will study your pictures in more details as they should be usefull when identifying all the parts. The attached instructions make a reference to Leapto3D, tracking the www.leapto3D.com website shows it no longer exists, which is a pity as more instructions might have been found there. Now to find a way to translate the PDF to English....

Michael

I have been in 2 minds to return the printer but having found this forum and seeing other people starting the build, if I can confirm if I have all the required parts, I am happy to start constructing.

Paul, thanks for your many posts, I will study your pictures in more details as they should be usefull when identifying all the parts. The attached instructions make a reference to Leapto3D, tracking the www.leapto3D.com website shows it no longer exists, which is a pity as more instructions might have been found there. Now to find a way to translate the PDF to English....

Michael

|

Re: Thinking of buying a P3Steel kit from Orballo December 26, 2015 07:37PM |

Registered: 8 years ago Posts: 9 |

Quote

dvx

What would be useful to know is how many DVR8825 driver modules are needed, I have x 4 of these. Also, should there be a fan for the extruder?

4 sounds right. Extruder, X, Y and Z. Z has two motors, but on the RAMPS board the two motors are driven by one DRV8825.

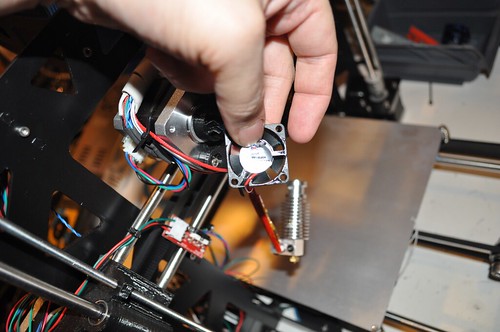

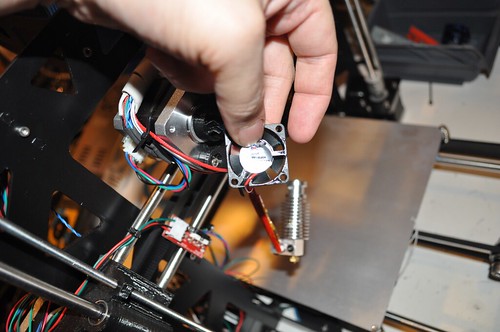

If you're using an all-metal hotend, you should have a heatsink fan which clips on like this:

Image

A layer cooling fan isn't necessary, but does help.

|

Re: Thinking of buying a P3Steel kit from Orballo December 27, 2015 05:36AM |

Registered: 8 years ago Posts: 11 |

Nallar, thanks for the feedback. Did you get your clone ramps working and printer built?

Btw, Hugo from Orballo plans to have the full instruction manual ready by 29th Dec, I have asked him if this if possible in English. Google translate works well but it's hard to cut or save text out of a protected PDF.

Btw, Hugo from Orballo plans to have the full instruction manual ready by 29th Dec, I have asked him if this if possible in English. Google translate works well but it's hard to cut or save text out of a protected PDF.

|

Re: Thinking of buying a P3Steel kit from Orballo December 27, 2015 08:10AM |

Registered: 8 years ago Posts: 3 |

|

Re: Thinking of buying a P3Steel kit from Orballo December 27, 2015 09:14AM |

Registered: 8 years ago Posts: 35 |

@DVX, I received 4 stepper drivers (also the DRV8825), so X, Y, Z and Extruder (the RAMPS board has two connectors for the Z axis so both Z steppers connect to one driver and this seems to work for me.

I did get a fan for the extruder, which was packaged with the hotend kit along with a small blue plastic fan shroud. However, my fan was a 5V fan, and I plugged it into the 12V output on the RAMPS without realising, and burned it out in 10 minutes ! I've since replaced it with a similar 12V fan.

I've also collated links to the various sets of instructions I've been using on my blog here http://paulhurley.co.uk/index.php/categories/computing-geek/29-making/85-p3steel-instructions

Regards

Paul.

--

www.paulhurley.co.uk

Edited 1 time(s). Last edit at 12/27/2015 09:15AM by paulhurleyuk.

I did get a fan for the extruder, which was packaged with the hotend kit along with a small blue plastic fan shroud. However, my fan was a 5V fan, and I plugged it into the 12V output on the RAMPS without realising, and burned it out in 10 minutes ! I've since replaced it with a similar 12V fan.

I've also collated links to the various sets of instructions I've been using on my blog here http://paulhurley.co.uk/index.php/categories/computing-geek/29-making/85-p3steel-instructions

Regards

Paul.

--

www.paulhurley.co.uk

Edited 1 time(s). Last edit at 12/27/2015 09:15AM by paulhurleyuk.

|

Re: Thinking of buying a P3Steel kit from Orballo December 28, 2015 01:27PM |

Registered: 8 years ago Posts: 4 |

kit arrived after 4 weeks. Packaging could have done better but everything was in there. I did noticed some rust on the steel frame but started building anyway.

Building the kit without a manual was easy using youtube, reprapwiki and the manual provided by kitprinter3d. (you can see some pictures of the buildt here: [klaverwm.nl] )

The parts of the buildt where you have to be a little more creative are:

1. The x-axis belt tensioner: I simply reversed the bolt, and can tensioning the belt by placing a pliers on the threaded rod.

[klaverwm.nl]

2. Placement of the Y-axis endstop: see image. (maybe there is a better solution when you place the endstop on the buildplatform, but i wanted it placed on the frame.

3. Placement of the X-axis endstop: See image. im using the green tie rips to hit the endstop switch.

Other aspects:

The threaded rods are not strait, woble alot when using but they work. The printed parts needed lots of sanding but are strong (which made me very happy since i had read a review where this was not the case..)

Somewhere this week i will try to calibrate the printer. At this point the printer works using pronterface. I used the marlin (ramps and drv8825) from Kitprinter3d. Had to comment out the lcd function to upload it to arduino. Dont know how to make this work (yet).

Regards,

Marcel

Building the kit without a manual was easy using youtube, reprapwiki and the manual provided by kitprinter3d. (you can see some pictures of the buildt here: [klaverwm.nl] )

The parts of the buildt where you have to be a little more creative are:

1. The x-axis belt tensioner: I simply reversed the bolt, and can tensioning the belt by placing a pliers on the threaded rod.

[klaverwm.nl]

2. Placement of the Y-axis endstop: see image. (maybe there is a better solution when you place the endstop on the buildplatform, but i wanted it placed on the frame.

3. Placement of the X-axis endstop: See image. im using the green tie rips to hit the endstop switch.

Other aspects:

The threaded rods are not strait, woble alot when using but they work. The printed parts needed lots of sanding but are strong (which made me very happy since i had read a review where this was not the case..)

Somewhere this week i will try to calibrate the printer. At this point the printer works using pronterface. I used the marlin (ramps and drv8825) from Kitprinter3d. Had to comment out the lcd function to upload it to arduino. Dont know how to make this work (yet).

Regards,

Marcel

|

Re: Thinking of buying a P3Steel kit from Orballo December 30, 2015 06:35AM |

Registered: 8 years ago Posts: 11 |

I have decided to use Igus plastic bearings for the hot bed rails, compared to the supplied metal bearings, which I tried as a comparison, the plastic bearings show a significant drop in bearing noise. If you need to keep your printer noise levels low this is a good option.

On closer inspection my 2 off 340mm x 8mm hotbed steel rods have significant chamfers at one end, this makes them lose when fitting to the frame. It was suggested I just hammer the lugs on the frame, but the rods chamfer is too large and I didn't want to do any hammering if possible. So I made some plastic parts with 8mm holes drilled out to hold the rods, the parts were then bolted to the frame, see pics.

There are some differences between my frame and other pictures posted here, not significant but shows the design is evolving.

Edited 1 time(s). Last edit at 12/30/2015 08:29AM by dvx.

On closer inspection my 2 off 340mm x 8mm hotbed steel rods have significant chamfers at one end, this makes them lose when fitting to the frame. It was suggested I just hammer the lugs on the frame, but the rods chamfer is too large and I didn't want to do any hammering if possible. So I made some plastic parts with 8mm holes drilled out to hold the rods, the parts were then bolted to the frame, see pics.

There are some differences between my frame and other pictures posted here, not significant but shows the design is evolving.

Edited 1 time(s). Last edit at 12/30/2015 08:29AM by dvx.

|

Re: Thinking of buying a P3Steel kit from Orballo January 01, 2016 06:39PM |

Registered: 8 years ago Posts: 35 |

Latest update from me, I got my printer all setup, and calibrated the axis, I ended up with 160 steps/mm for the X and Y axis, 8000 steps/mm for the Z axis and 1942.2716 steps/mm for the extruder. I pushed both my marlin configuration and the Slic3r configuration to github (https://github.com/paulhurleyuk/Marlin and https://github.com/paulhurleyuk/Slic3r).

I then tried a few test prints and got a succession of filament jams, I think for the following reasons (roughly in order);

I left the little plastic tube out of the extruder and the filament kinked and jammed

After reassembling the hotend I screwed the heatbreak into the hotend first instead of the heatsink leaving a gap

I had the retraction setting way to high in slicer (10mm) and it was pulling hot filament up into the heatbreak

The wire to the hotend fan broke and the heatbreak got too high

So, I've learned a lot about disassembling my hotend and clearing it out, which generally involves removing the whole hotend, unclipping the fan, unscrewing the nozzle, heatbreak and heatsink, then screwing the heatbreak back into the heater block, heating it and poking the melty filament out, cleaning the hobbed bold and then putting it all back together.

I also tried rubbing a little rapseed oil in a sponge over the filament which seems to have helped as well. I also loosened the filament slightly as the filament holder is a M8 bolt and the reel doesn't spin particularly well on it, at some point I'll add some skate bearings.

I've now got some succesfull prints, although they're a little rough;

[flic.kr]

[flic.kr]

[flic.kr]

I then tried a few test prints and got a succession of filament jams, I think for the following reasons (roughly in order);

I left the little plastic tube out of the extruder and the filament kinked and jammed

After reassembling the hotend I screwed the heatbreak into the hotend first instead of the heatsink leaving a gap

I had the retraction setting way to high in slicer (10mm) and it was pulling hot filament up into the heatbreak

The wire to the hotend fan broke and the heatbreak got too high

So, I've learned a lot about disassembling my hotend and clearing it out, which generally involves removing the whole hotend, unclipping the fan, unscrewing the nozzle, heatbreak and heatsink, then screwing the heatbreak back into the heater block, heating it and poking the melty filament out, cleaning the hobbed bold and then putting it all back together.

I also tried rubbing a little rapseed oil in a sponge over the filament which seems to have helped as well. I also loosened the filament slightly as the filament holder is a M8 bolt and the reel doesn't spin particularly well on it, at some point I'll add some skate bearings.

I've now got some succesfull prints, although they're a little rough;

[flic.kr]

[flic.kr]

[flic.kr]

|

Re: Thinking of buying a P3Steel kit from Orballo January 06, 2016 01:27PM |

Registered: 8 years ago Posts: 11 |

Paul it is good to see you have your printer working. I have now completed my biuld after tidying up the wiring and fitting a 240v IEC socket in an attempt to make the printer a bit safer. After downloading your first Marlin config and adding the display driver to arduino so it compiles OK, I uploaded the firmware to the controller. I can now via the LCD display use the home function to set the home position for each axis to the end stop positions (micro switches). It would be good to have your feedback on the following..

1/ When moving each axis, I can move 5-10cm and then the stepper motors stop, sometimes they then start again for more movement.

I can not reverse the direction back to the home position, is this normal?

2/ I have yet to fit the white tubing in the extruder, is this cut to fit in to the extruder hole with the bottom end in contact with the top of the hotend and the top end just short of the hob bolt?

3/ I loaded up Pronteface and this communicates Ok with the printer, but I don't have full axis movement

4/ How do I set up the limits to the axis movements?

5/ My DRV8225 heatsinks get very hot is this the same for yours? (it might be good to have fan blowing over them)

6/ What else do I need to do to get the printer ready for it's first print?

I noticed on my z axis the threaded rods do not run parallel to the vertical steel rods, the gap is wider at the top, so I might remove the Z axis stepper motors and elongate the fixing holes to bring the threaded rods mor into alignment.

Thanks in advance Michael

1/ When moving each axis, I can move 5-10cm and then the stepper motors stop, sometimes they then start again for more movement.

I can not reverse the direction back to the home position, is this normal?

2/ I have yet to fit the white tubing in the extruder, is this cut to fit in to the extruder hole with the bottom end in contact with the top of the hotend and the top end just short of the hob bolt?

3/ I loaded up Pronteface and this communicates Ok with the printer, but I don't have full axis movement

4/ How do I set up the limits to the axis movements?

5/ My DRV8225 heatsinks get very hot is this the same for yours? (it might be good to have fan blowing over them)

6/ What else do I need to do to get the printer ready for it's first print?

I noticed on my z axis the threaded rods do not run parallel to the vertical steel rods, the gap is wider at the top, so I might remove the Z axis stepper motors and elongate the fixing holes to bring the threaded rods mor into alignment.

Thanks in advance Michael

|

Re: Thinking of buying a P3Steel kit from Orballo January 06, 2016 04:05PM |

Registered: 8 years ago Posts: 35 |

Not sure. Is the movement quiet and smooth or loud and jerky ? Is there anything on the pronterface console (like endstop triggered or anything ? Marlin includes soft endstops where after homing, it will only move each axis the distance defined, which in my config was 190mm in each axis.Quote

DVX

1/ When moving each axis, I can move 5-10cm and then the stepper motors stop, sometimes they then start again for more movement.

I can not reverse the direction back to the home position, is this normal?

Yes, thats where it goes.Quote

2/ I have yet to fit the white tubing in the extruder, is this cut to fit in to the extruder hole with the bottom end in contact with the top of the hotend and the top end just short of the hob bolt?

Cool. see my comments for 1.Quote

3/ I loaded up Pronteface and this communicates Ok with the printer, but I don't have full axis movement

In Marlin you can set the axis limits, I think I defined it as 190,190,190mmQuote

4/ How do I set up the limits to the axis movements?

Each driver has a small adjustment screw where you can set the current it provides. Too little and the motor won't move and can skip steps, too much and the driver gets really hot and can thermal shutdown until it cools a bit. Follow the guide at http://reprap.org/wiki/Pololu_stepper_driver_board to adjust the current. I do still have a small fan blowing across the RAMPS unit.Quote

5/ My DRV8225 heatsinks get very hot is this the same for yours? (it might be good to have fan blowing over them)

Follow Triffid Hunters calibration guide to calibrate the printer, then follow the sections in the calibration guide to level the bed and adjust the Z height home position, then you're good to go. If you're anything like me you'll soon be printing all kinds of calibration thing, so make the first print something cool. (I did Marvin)Quote

6/ What else do I need to do to get the printer ready for it's first print?

How much of a deviation ? My Z axis threaded rods wobble about 5mm at the very top while revolving, which AFAIK is acceptable, especially if the top of the rods is free to move (that the X axis will run on the smooth rods and the z axis threaded rods will just move to adjust).Quote

I noticed on my z axis the threaded rods do not run parallel to the vertical steel rods, the gap is wider at the top, so I might remove the Z axis stepper motors and elongate the fixing holes to bring the threaded rods mor into alignment.

Just my two cents.

Paul.

|

Re: Thinking of buying a P3Steel kit from Orballo January 07, 2016 06:35PM |

Registered: 8 years ago Posts: 11 |

I had a number of issues when getting my first print to work, setting up the DRV8825 pots fixed most of the them. They ranged from the stepper

motors positioning in the wrong places and crashing the extruder into the Z axis threaded rods.

At one stage my extruder was running forwards and printing but then running backwards which was removing the filament from the hotend.

Integrating slic3r into Pronterface fixed it, but not sure why.

What I have been missing is a simple step by step walk through for the printer set up and PC software, by muddling through something is now printing.

I now plan to install a fan to keep the DRV8825 cooler as they run very hot.

Thanks Paul for posting your Marlin configs, these helped to get up a working, I will study the confuration.h in more detail later.

Just out of interest how long did Marvin take to print?

Edited 4 time(s). Last edit at 01/08/2016 04:25PM by dvx.

motors positioning in the wrong places and crashing the extruder into the Z axis threaded rods.

At one stage my extruder was running forwards and printing but then running backwards which was removing the filament from the hotend.

Integrating slic3r into Pronterface fixed it, but not sure why.

What I have been missing is a simple step by step walk through for the printer set up and PC software, by muddling through something is now printing.

I now plan to install a fan to keep the DRV8825 cooler as they run very hot.

Thanks Paul for posting your Marlin configs, these helped to get up a working, I will study the confuration.h in more detail later.

Just out of interest how long did Marvin take to print?

Edited 4 time(s). Last edit at 01/08/2016 04:25PM by dvx.

|

Re: Thinking of buying a P3Steel kit from Orballo January 09, 2016 07:29PM |

Registered: 8 years ago Posts: 35 |

Theres not really any good overall guides, but there's a lot of individual stuff out there, on the reprap wiki and the wider web.

The Marvin printed in about 25 minutes using standard settings, I've been slowing down my print speeds to improve the finish so that would take a little longer.

Paul.

--

www.paulhurley.co.uk

The Marvin printed in about 25 minutes using standard settings, I've been slowing down my print speeds to improve the finish so that would take a little longer.

Paul.

--

www.paulhurley.co.uk

|

Re: Thinking of buying a P3Steel kit from Orballo January 11, 2016 06:07AM |

Registered: 8 years ago Posts: 11 |

Orballo have just sent their Marlin config and this is attached, I haven't checked this out or made any comparisons.

My last 2 prints have produced some significant extruder and hotend clogging. After dissembling and cleaning the hot end and extruder I noted the white tubing material had melted at one end, so I have ordered some replacement PTFE tubing (not sure the original tubing was PTFE). The most common size appears to be 2mm inner and 4mm outer. PLA had wrapped around the hob bolt and after removal and checking the center of the 'V' alignment to the extruder hole, this was off to one side and may have caused some extra friction. With a micrometer and correct selection of washers behind the drive gear this is now close to the central position.

The thermistor had melted into the hotend, so this was drilled out and a new one is on order along with insulated tubing for the legs, the original thermistor was not supplied with insulated tubing. I have chosen to buy direct from [e3d-online.com] as their prices are the same as most other suppliers and being the hotend manufacture they ship original parts.

There is a good page for the retraction settings here [wiki.e3d-online.com] along with other useful E3D-V6 hotend info. I plan to set the retraction setting to 0.5mm and see how this works, the default Cura setting is 1.5mm and Slic3D 1mm. I am hoping it was incorrect retraction settings than have cause most of the filament jams as the extruder was in reverse for a higher percentage of the the time prior to the filament jams.

For head cleaning this site has some suggestions [bukobot.com].

Once the printer is working I plan to print some filament spool holders with bearing as I found manually rotating the filament spool helped to lower the supply off the spool and to the extruder. My first design is attached.

This is proving to be a good learning curve and hopefully result in a working printer soon....

Edited 1 time(s). Last edit at 01/11/2016 12:46PM by dvx.

My last 2 prints have produced some significant extruder and hotend clogging. After dissembling and cleaning the hot end and extruder I noted the white tubing material had melted at one end, so I have ordered some replacement PTFE tubing (not sure the original tubing was PTFE). The most common size appears to be 2mm inner and 4mm outer. PLA had wrapped around the hob bolt and after removal and checking the center of the 'V' alignment to the extruder hole, this was off to one side and may have caused some extra friction. With a micrometer and correct selection of washers behind the drive gear this is now close to the central position.

The thermistor had melted into the hotend, so this was drilled out and a new one is on order along with insulated tubing for the legs, the original thermistor was not supplied with insulated tubing. I have chosen to buy direct from [e3d-online.com] as their prices are the same as most other suppliers and being the hotend manufacture they ship original parts.

There is a good page for the retraction settings here [wiki.e3d-online.com] along with other useful E3D-V6 hotend info. I plan to set the retraction setting to 0.5mm and see how this works, the default Cura setting is 1.5mm and Slic3D 1mm. I am hoping it was incorrect retraction settings than have cause most of the filament jams as the extruder was in reverse for a higher percentage of the the time prior to the filament jams.

For head cleaning this site has some suggestions [bukobot.com].

Once the printer is working I plan to print some filament spool holders with bearing as I found manually rotating the filament spool helped to lower the supply off the spool and to the extruder. My first design is attached.

This is proving to be a good learning curve and hopefully result in a working printer soon....

Edited 1 time(s). Last edit at 01/11/2016 12:46PM by dvx.

|

Re: Thinking of buying a P3Steel kit from Orballo January 11, 2016 08:25AM |

Registered: 8 years ago Posts: 9 |

Quote

dvx

My last 2 prints have produced some significant extruder and hotend clogging. After dissembling and cleaning the hot end and extruder I noted the white tubing material had melted at one end

...

The thermistor had melted into the hotend

Possibly you went over-temperature, due to misconfiguration of the thermistor readings in firmware or a dodgy connection?

The PTFE tubing included with mine appears to be real PTFE and hasn't melted at 250*C. If you have some way of confirming the temperature readings with a thermocouple/known good thermistor that would be a good thing to do before using the hotend.

edit: fixed typo (350 =/= 250).

Edited 1 time(s). Last edit at 01/11/2016 09:45AM by nallar.

|

Re: Thinking of buying a P3Steel kit from Orballo January 11, 2016 12:54PM |

Registered: 8 years ago Posts: 11 |

...

The thermistor had melted into the hotend[/quote]

Possibly you went over-temperature, due to misconfiguration of the thermistor readings in firmware or a dodgy connection?

My Marlin is set correctly for the type of thermistor. I think / hope the most likely cause was the retraction settings as the printer worked OK when set to fast and I assumed lest retraction time. When set to normal print speed the extruder was spending as much time in faster reverse as forward, retraction of course being needed to pull back the filament when the head is moving and no printing required. A new thermistor and tubing arrives tomorrow so I will know more then. Out of interest what retraction setting do you use?

Edited 1 time(s). Last edit at 01/11/2016 02:24PM by dvx.

The thermistor had melted into the hotend[/quote]

Possibly you went over-temperature, due to misconfiguration of the thermistor readings in firmware or a dodgy connection?

My Marlin is set correctly for the type of thermistor. I think / hope the most likely cause was the retraction settings as the printer worked OK when set to fast and I assumed lest retraction time. When set to normal print speed the extruder was spending as much time in faster reverse as forward, retraction of course being needed to pull back the filament when the head is moving and no printing required. A new thermistor and tubing arrives tomorrow so I will know more then. Out of interest what retraction setting do you use?

Edited 1 time(s). Last edit at 01/11/2016 02:24PM by dvx.

Sorry, only registered users may post in this forum.