Thinking of buying a P3Steel kit from Orballo

Posted by paulhurleyuk

|

Re: Thinking of buying a P3Steel kit from Orballo January 12, 2016 08:51PM |

Registered: 8 years ago Posts: 7 |

I have a couple questions for your orballo builds. For the x axis idler adjustment, did you have to use 2 623 bearings in the plastic pieces? One seems too lose for me and two won't fit without some filing down.

The other question is the end stops don't fit at all. Anyone have a source for some holders that actually fit properly?

The other question is the end stops don't fit at all. Anyone have a source for some holders that actually fit properly?

|

Re: Thinking of buying a P3Steel kit from Orballo January 14, 2016 01:48AM |

Registered: 8 years ago Posts: 35 |

Quote

Justsomeguy1983

I have a couple questions for your orballo builds. For the x axis idler adjustment, did you have to use 2 623 bearings in the plastic pieces? One seems too lose for me and two won't fit without some filing down.

My kit didn't come with the smaller 623 bearings (although it did have the plastic pieces for them ??). It had an idler gear with wide rims, although that was also a little loose, but has been fine in operation.

Quote

Justsomeguy1983

The other question is the end stops don't fit at all. Anyone have a source for some holders that actually fit properly?

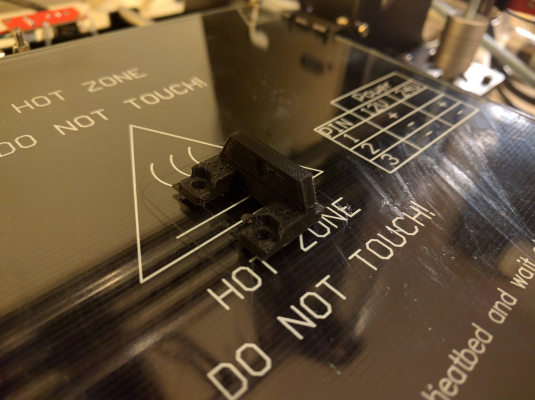

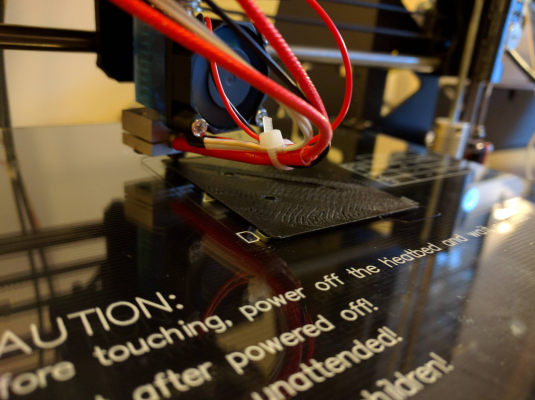

I also had problems with the endstop holders provided. I used them for the X axis (clipped to the top smooth rod, secured with a cable tie) and initially the Z axis (again, clipped to the smooth rod, held with a cable tie) although I later printed a new holder, and for the Y axis I ended up super gluing the end stop to the side of the plastic holder, then super gluing that to the bottom of the Y carriage.

Here's the new Z axis endstop holder I printed ( [www.thingiverse.com] and the screw holder from [www.thingiverse.com] )

Paul.

--

[www.paulhurley.co.uk]

--

Paul Hurley

[www.paulhurley.co.uk]

|

Re: Thinking of buying a P3Steel kit from Orballo January 20, 2016 11:31AM |

Registered: 8 years ago Posts: 24 |

Hi all,

I got my kit last week, 6 weeks after ordering it from Orballo. I had to talk to them three times and ask for a tracking number, before I finally got one. Once I got it, it turns out the package had been stuck in the post system (according to orballo anyway), and the shipping was actually started after five weeks....

After unboxing and looking through the parts being very confused, the kit looked good to me. However, as I progressed through the build, several pieces were missing. I'll try to summarize my build...

Frame:

Frame is of decent quality - perfectly fine. I got version 2.5 of the P3Steel frame which is nice. Black paint. The supplied M3 nuts that goes inside to assemble the frame were locking nuts, which is good. They the nuts require some force to insert, I started out with a hammer but eventually found pliers to be better. There was one metal piece missing from the frame, fortunately, it was just the Y-axis idler holder (one of the 2 pieces), and I was able to improvise a temporary solution to hold the belt.

Rods:

Two of the threaded rods (the z axis ones) were of incorrect length. They were 1cm too short (version 2.0 size...) so they were useless. I went to a local shop and bought a new rod and cut to the right length so that was solved as well.

3D printed parts:

The 3d printed parts were thick and stable. Unfortunately, I got two X-axis motor holder pieces instead of one motor holder and one idler. The printed parts were also of the wrong color, I had ordered white pieces but got black. There were also some pieces that I don't know what they are for, but they look like they might be part of a previous X-idler or Y-idler design, with smaller bearings inside...? Also, the x-axis motor holder pieces were inverted compared to all other pictures, which was kinda weird, but didn't really seem to matter (I just put the x-motor on the right side instead). I was able to fashion a temporary solution for the X-idler by converting one of the motor holders to a x-axis idler.

Bearings:

There were four large bearings, one for the idler and three for the extruder. Then there was one spool belt holder for the x-axis idler. The kitprinter3d instructions mention a smaller variant of bearings (and orballo lists them as part of the package contents in the web shop), but they have been removed and replaced by the thread-spool looking thing (orballo also confirmed this over chat)

Extruder:

Extruder works ok, but one bolt was missing from the kit, luckily, i could borrow one m4 bolt from my door handle, hehe. I had a really bad time trying to get a m3 nut inside of the small gear piece as the hole was a bit small. Once inside, it was crooked somehow, and the bolt was stripped and got stuck, the nut just rotates inside the hole. Luckily, the gear is stuck on the stepper so hard, it stays in the same position anyway. The smaller gear design could be improved a bit, it could have one "slotted" side to fit with the stepper motor design.

Electronics:

Everything as expected, the 30mm fan was 12v, not 5v as yours paul. The wires need to be lengthened.

Hotend:

Not much to say, it all works, I got a 0.2mm nozzle in my kit, might be good to know.

Heatbed:

Heatbed is only printed on one side (maybe this is normal for the aluminum variant?), so I put it with the printed side on top, moving the thermistor cables to the opposite side. I also put a cork mat under the heatbed to isolate it and the cables underneath better. The design could be improved a bit here too, it would be good if the solder pads were on the opposite side (facing the back), but that's a minor concern

Endstops:

Like others have mentioned in this thread, the supplied endstop holders are absolute shit. I've bootstrapped my printer by putting them up with plastic straps for now so I can print new ones. You will need to make new endstop holders for sure.

One thing I don't like is the solution with office clips holding the glass plate, though that seems like a common solution in the community. Due to them, the printable area has to be reduced about 2cm (only an issue if you want to print something huge). Anyone have any ideas how that can be improved?

I did my first build yesterday and printed a endstop holder (the one paul linked). I set up the firmware from kitprinter3d and didn't change any settings. I configured Slic3r and ran the .stl file though it. Then I used repetier to run the gcode.

In my first attempt, the heatbed was too far away from the nozzle or something I think, and the PLA plastic wouldn't stick properly. Some parts did stick but lost adhesion after the printhead came around for another layer. I adjusted the space between and added some hairspray. For my second attempt, the heatbed was too close to the nozzle, and as a result no filament came out at first. Afraid the nozzle would scratch into the glass, in a state of panic I pushed down on the headbed a bit to create a gap, and the print then continued successfully. After about half the print, the printer mysteriously stopped and sat with the nozzle touching one end of the print. I pressed pause and continue, and then it did continue and finished the build.

The build ended up really nice except for the first layer, and some kind of line/hollow area appeared at the point where the printer paused for a bit. The precision was really good, way better than I was expecting. Here's an image:

So I have my printer running, now it's time to do some upgrades, starting with endstop holders...

Orballo has agreed to send me replacement/additional missing parts, so we'll see when they arrive....

All in all it has been a lot of fun building the kit and the feeling of satisfaction of seeing your first ever 3d print taking shape is hard to beat! Looking forward to cooperating with all of you to improve our printers.

I got my kit last week, 6 weeks after ordering it from Orballo. I had to talk to them three times and ask for a tracking number, before I finally got one. Once I got it, it turns out the package had been stuck in the post system (according to orballo anyway), and the shipping was actually started after five weeks....

After unboxing and looking through the parts being very confused, the kit looked good to me. However, as I progressed through the build, several pieces were missing. I'll try to summarize my build...

Frame:

Frame is of decent quality - perfectly fine. I got version 2.5 of the P3Steel frame which is nice. Black paint. The supplied M3 nuts that goes inside to assemble the frame were locking nuts, which is good. They the nuts require some force to insert, I started out with a hammer but eventually found pliers to be better. There was one metal piece missing from the frame, fortunately, it was just the Y-axis idler holder (one of the 2 pieces), and I was able to improvise a temporary solution to hold the belt.

Rods:

Two of the threaded rods (the z axis ones) were of incorrect length. They were 1cm too short (version 2.0 size...) so they were useless. I went to a local shop and bought a new rod and cut to the right length so that was solved as well.

3D printed parts:

The 3d printed parts were thick and stable. Unfortunately, I got two X-axis motor holder pieces instead of one motor holder and one idler. The printed parts were also of the wrong color, I had ordered white pieces but got black. There were also some pieces that I don't know what they are for, but they look like they might be part of a previous X-idler or Y-idler design, with smaller bearings inside...? Also, the x-axis motor holder pieces were inverted compared to all other pictures, which was kinda weird, but didn't really seem to matter (I just put the x-motor on the right side instead). I was able to fashion a temporary solution for the X-idler by converting one of the motor holders to a x-axis idler.

Bearings:

There were four large bearings, one for the idler and three for the extruder. Then there was one spool belt holder for the x-axis idler. The kitprinter3d instructions mention a smaller variant of bearings (and orballo lists them as part of the package contents in the web shop), but they have been removed and replaced by the thread-spool looking thing (orballo also confirmed this over chat)

Extruder:

Extruder works ok, but one bolt was missing from the kit, luckily, i could borrow one m4 bolt from my door handle, hehe. I had a really bad time trying to get a m3 nut inside of the small gear piece as the hole was a bit small. Once inside, it was crooked somehow, and the bolt was stripped and got stuck, the nut just rotates inside the hole. Luckily, the gear is stuck on the stepper so hard, it stays in the same position anyway. The smaller gear design could be improved a bit, it could have one "slotted" side to fit with the stepper motor design.

Electronics:

Everything as expected, the 30mm fan was 12v, not 5v as yours paul. The wires need to be lengthened.

Hotend:

Not much to say, it all works, I got a 0.2mm nozzle in my kit, might be good to know.

Heatbed:

Heatbed is only printed on one side (maybe this is normal for the aluminum variant?), so I put it with the printed side on top, moving the thermistor cables to the opposite side. I also put a cork mat under the heatbed to isolate it and the cables underneath better. The design could be improved a bit here too, it would be good if the solder pads were on the opposite side (facing the back), but that's a minor concern

Endstops:

Like others have mentioned in this thread, the supplied endstop holders are absolute shit. I've bootstrapped my printer by putting them up with plastic straps for now so I can print new ones. You will need to make new endstop holders for sure.

One thing I don't like is the solution with office clips holding the glass plate, though that seems like a common solution in the community. Due to them, the printable area has to be reduced about 2cm (only an issue if you want to print something huge). Anyone have any ideas how that can be improved?

I did my first build yesterday and printed a endstop holder (the one paul linked). I set up the firmware from kitprinter3d and didn't change any settings. I configured Slic3r and ran the .stl file though it. Then I used repetier to run the gcode.

In my first attempt, the heatbed was too far away from the nozzle or something I think, and the PLA plastic wouldn't stick properly. Some parts did stick but lost adhesion after the printhead came around for another layer. I adjusted the space between and added some hairspray. For my second attempt, the heatbed was too close to the nozzle, and as a result no filament came out at first. Afraid the nozzle would scratch into the glass, in a state of panic I pushed down on the headbed a bit to create a gap, and the print then continued successfully. After about half the print, the printer mysteriously stopped and sat with the nozzle touching one end of the print. I pressed pause and continue, and then it did continue and finished the build.

The build ended up really nice except for the first layer, and some kind of line/hollow area appeared at the point where the printer paused for a bit. The precision was really good, way better than I was expecting. Here's an image:

So I have my printer running, now it's time to do some upgrades, starting with endstop holders...

Orballo has agreed to send me replacement/additional missing parts, so we'll see when they arrive....

All in all it has been a lot of fun building the kit and the feeling of satisfaction of seeing your first ever 3d print taking shape is hard to beat! Looking forward to cooperating with all of you to improve our printers.

|

Re: Thinking of buying a P3Steel kit from Orballo January 21, 2016 06:01PM |

Registered: 8 years ago Posts: 11 |

My printer is all up and working now after a number of significant hotend and extruder clogs, both now fixed. Learning from these I can recommend the following changes.

1/ The hotend supplied was a low quality Chinese copy, I gave up on it after a few days and bought an original, all I can say is the £40 is worth every penny.

I got my from [e3d-online.com] and is a different design, one of the differences is for the PTFE which goes all the way into the heatbeak and then can be cut to fit just below the extruder hob bolt, so one continuous filament feed. The thermistor came with heat resistant sleeving, so it could be screwed to the heat block with out shorting the wires. Next is the fan, this being the most important item IMHO to change on the supplied hotend should you keep with the Chinese version. The E3D fan runs faster, with less noise and more importantly in my case when compared to the copy wasn't intermittent after 20-30 minutes. I tested the old fan after changing it on a regulated bench PSU and noted how it varied speed before finally stopping, once power was recycled it would run again for 20 mins, so just a very low quality fan.

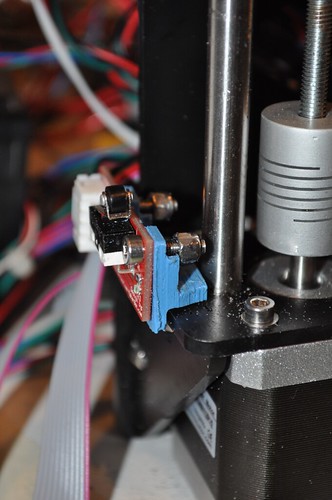

2/ Next to Extruder. With the new hotend fitted and continuous PTFE running up through the extruder, I fitted some aluminum tubing to stop the PTFE moving and to centralise it in the extruder, this was fitted from the top of the hotend opening (bottom of extruder) to the opening under the hob bolt. Once fitted this provides a very stable housing for the PTFE tube, I then noticed how far off center my hob bolt 'V' or filament tooth gear was. By using a micrometer and having a good selection of washers, 3 were selected and placed between the main gear wheel and extruder housing, this placed the hot bolt 'V' perfectly above the PTFE aperture, see attached pics. Next the filament roller needed adjusting, after some filing of the extruder housing and fitting of some more spacer washers, the center of roller was brought into line with the filament.

3/ I then updated my spool hubs so to allow easy deployment of the filament from the filament reel and added some bearing to the design. The design can be downloaded from [www.thingiverse.com]

4/ For the problems others have had with end stops, I had gone past the construction phase were the supplied end stop holders should have been fitted. My answer was to buy some plastic blocks from a hardware store, split them so they could be clamped to either side of the 8mm rods, drill a 8mm hole to accommodate the rods, then screw the two half's together to made a simple, adjustable + stable solution. The only exception was for the Y axis end stop which, again using plastic blocks was bolted to the rear of the chassis.

Like Paul I have a fan blowing over the stepper motor drivers as these get very hot, currently a 12v 120mm PC fan, so this will be another 3D design for a bracket to position a smaller 80mm fan over the board. The main heat removal for the drivers isn't via the glued on mini heat sinks but via the PCB, so to have some air moving under the PCB will provide for better cooling.

The wring can be tidied up with spiral cable wrap, Maplins in the UK sell this and it makes for a safer cabling system from the moving extruder / hotend cables.

If I was to give any advise, it would be to change the hotend fan ASAP and while ordering a new one get the original blue casing it screws to, my Orballo version was loose when fitted to the heat break. The cost is less than £10.00 to get the original parts. But it worth noting, if the Chinese Orballo fan fails then you have the potential for thermal runaway which could be a fire hazard, especially if the printer is left running unattended for short periods. As a final note, my Orballo supplied thermistor failed during the last clog, this meant it did not signal an over temperature alarm which then led to the hotend heater not turning off at the correct temperature, so it just cooked. Fortunately I pulled the mains plug before any serious damage was done, the result was a ruined hot end. So if you get a new fan add an original thermistor for a few pounds more, as these should IMHO be viewed as critical safety items.

Happy printing.

1/ The hotend supplied was a low quality Chinese copy, I gave up on it after a few days and bought an original, all I can say is the £40 is worth every penny.

I got my from [e3d-online.com] and is a different design, one of the differences is for the PTFE which goes all the way into the heatbeak and then can be cut to fit just below the extruder hob bolt, so one continuous filament feed. The thermistor came with heat resistant sleeving, so it could be screwed to the heat block with out shorting the wires. Next is the fan, this being the most important item IMHO to change on the supplied hotend should you keep with the Chinese version. The E3D fan runs faster, with less noise and more importantly in my case when compared to the copy wasn't intermittent after 20-30 minutes. I tested the old fan after changing it on a regulated bench PSU and noted how it varied speed before finally stopping, once power was recycled it would run again for 20 mins, so just a very low quality fan.

2/ Next to Extruder. With the new hotend fitted and continuous PTFE running up through the extruder, I fitted some aluminum tubing to stop the PTFE moving and to centralise it in the extruder, this was fitted from the top of the hotend opening (bottom of extruder) to the opening under the hob bolt. Once fitted this provides a very stable housing for the PTFE tube, I then noticed how far off center my hob bolt 'V' or filament tooth gear was. By using a micrometer and having a good selection of washers, 3 were selected and placed between the main gear wheel and extruder housing, this placed the hot bolt 'V' perfectly above the PTFE aperture, see attached pics. Next the filament roller needed adjusting, after some filing of the extruder housing and fitting of some more spacer washers, the center of roller was brought into line with the filament.

3/ I then updated my spool hubs so to allow easy deployment of the filament from the filament reel and added some bearing to the design. The design can be downloaded from [www.thingiverse.com]

4/ For the problems others have had with end stops, I had gone past the construction phase were the supplied end stop holders should have been fitted. My answer was to buy some plastic blocks from a hardware store, split them so they could be clamped to either side of the 8mm rods, drill a 8mm hole to accommodate the rods, then screw the two half's together to made a simple, adjustable + stable solution. The only exception was for the Y axis end stop which, again using plastic blocks was bolted to the rear of the chassis.

Like Paul I have a fan blowing over the stepper motor drivers as these get very hot, currently a 12v 120mm PC fan, so this will be another 3D design for a bracket to position a smaller 80mm fan over the board. The main heat removal for the drivers isn't via the glued on mini heat sinks but via the PCB, so to have some air moving under the PCB will provide for better cooling.

The wring can be tidied up with spiral cable wrap, Maplins in the UK sell this and it makes for a safer cabling system from the moving extruder / hotend cables.

If I was to give any advise, it would be to change the hotend fan ASAP and while ordering a new one get the original blue casing it screws to, my Orballo version was loose when fitted to the heat break. The cost is less than £10.00 to get the original parts. But it worth noting, if the Chinese Orballo fan fails then you have the potential for thermal runaway which could be a fire hazard, especially if the printer is left running unattended for short periods. As a final note, my Orballo supplied thermistor failed during the last clog, this meant it did not signal an over temperature alarm which then led to the hotend heater not turning off at the correct temperature, so it just cooked. Fortunately I pulled the mains plug before any serious damage was done, the result was a ruined hot end. So if you get a new fan add an original thermistor for a few pounds more, as these should IMHO be viewed as critical safety items.

Happy printing.

Attachments:

open | download - 5 hour printout.jpg (257.6 KB)

open | download - cabling .jpg (292.9 KB)

open | download - Extruder alignment 2.jpg (308.6 KB)

open | download - Extruder alignment 3.jpg (312 KB)

open | download - extruder alignment.jpg (315.9 KB)

open | download - Hub fitted.jpg (267.2 KB)

open | download - Hubs + bearings.jpg (242.8 KB)

open | download - New hot end with interal PTFE.jpg (292.3 KB)

open | download - 5 hour printout.jpg (257.6 KB)

open | download - cabling .jpg (292.9 KB)

open | download - Extruder alignment 2.jpg (308.6 KB)

open | download - Extruder alignment 3.jpg (312 KB)

open | download - extruder alignment.jpg (315.9 KB)

open | download - Hub fitted.jpg (267.2 KB)

open | download - Hubs + bearings.jpg (242.8 KB)

open | download - New hot end with interal PTFE.jpg (292.3 KB)

|

Re: Thinking of buying a P3Steel kit from Orballo January 22, 2016 03:07AM |

Registered: 8 years ago Posts: 24 |

|

Re: Thinking of buying a P3Steel kit from Orballo January 22, 2016 05:00AM |

Registered: 8 years ago Posts: 11 |

Hi ade2, attached is a pic of the Orballo fan, this has a different manufacture sticker on the inside part that goes next to the hotend heat sink. It also came with a blue holder but is a poor copy and is lose when clipped to the hotend heatsink. I suspect the bearing are of simple construction, so using a tie-wrap to keep the holder in place might take the fan bearings off center. When I spoke with E3D the original hotend manufacturer, they don't have Orballo on their list, so further confirmation for the copy hotend. You might be OK just changing the fan if you have problems, it's just hard to say how slow the Orballo fan is compared to E3D's, but as a guess and comparing my Orballo fan, it's somewhere near 50% less rpm. Also, check the insulation fitted over the thermistor leads, my Orballo type was clear or white plastic, it should be heat resistant type, the E3D being a woven blue material.

After making the changes I noted in my past post, my printer is now working every time with no issues so I see them as good upgrades. I also bought the glass sheet to sit on the hotbed so will try that next, So far I have only used PLA with painter's blue tape on the hotbed, results are good but I occasionally get some warping as the print layers increase above 0.5cm, some more experimentation needed.

As a side note E3D also sell a range of nozzles from 0.25 through to 0.8mm, I have 0.4mm at the moment, so by going to a smaller diameter nozzle finer prints could be made, with a trade off for printing time. Conversely, if quality is less important a 0.8mm nozzle could half the print time. If you do change nozzles its worth checking out the instructions for doing this as its best they are not removed from a cold hotend.

After making the changes I noted in my past post, my printer is now working every time with no issues so I see them as good upgrades. I also bought the glass sheet to sit on the hotbed so will try that next, So far I have only used PLA with painter's blue tape on the hotbed, results are good but I occasionally get some warping as the print layers increase above 0.5cm, some more experimentation needed.

As a side note E3D also sell a range of nozzles from 0.25 through to 0.8mm, I have 0.4mm at the moment, so by going to a smaller diameter nozzle finer prints could be made, with a trade off for printing time. Conversely, if quality is less important a 0.8mm nozzle could half the print time. If you do change nozzles its worth checking out the instructions for doing this as its best they are not removed from a cold hotend.

|

Re: Thinking of buying a P3Steel kit from Orballo January 22, 2016 09:30AM |

Registered: 8 years ago Posts: 24 |

Thanks dvx, looks like I got the same hotend/fan package. However, it's working OK for me so far. The thermistor is worrying me because the plastic is clear like you said. Perhaps it's a ptfe plastic or something? It's still working for me, but i've only ever had my hotend up to 210C.

I have a question for you guys. When making a flat surface as I was printing a larger X-axis part, the second layer had this weird pattern in about 70% of the areas while the remaining 30% had a impeccably smooth surface. Is it a heatbed temperature problem, or Z axis too low, or feed rate thing maybe? What do you think....? The next layer after that looked perfect though....

I have a question for you guys. When making a flat surface as I was printing a larger X-axis part, the second layer had this weird pattern in about 70% of the areas while the remaining 30% had a impeccably smooth surface. Is it a heatbed temperature problem, or Z axis too low, or feed rate thing maybe? What do you think....? The next layer after that looked perfect though....

|

Re: Thinking of buying a P3Steel kit from Orballo January 22, 2016 09:35AM |

Registered: 8 years ago Posts: 24 |

Also I want to mention for anyone that has not started printing yet, you really must follow good instructions when it comes to these things: Bed leveling, Z-axis "gap" height from bed, and other factors that influence the first layer. If you can't get the first layer to stick, read up on how to do these things. A tenth of a millimeter will make a difference.... Otherwise you'll end up wasting a few hours like me trying various methods (hairspray, tape or whatever) to make first layer stick....

|

Re: Thinking of buying a P3Steel kit from Orballo January 22, 2016 09:53AM |

Registered: 8 years ago Posts: 11 |

Hi Ade2, the patterning might be the infill generated at the slicing stage, typically a slicer will generate a mesh or infill pattern for internal parts of a print which do not get seen, this saves printing time and filament. The bottom, top and sides should be 100% printed. Check your slicer settings to see what infill is being used.

Btw I have used Cura with good success, this software will take a STL file and generate any slicing and then print the object in one operation, you can change many preferences, like the size of the print nozzle and retraction time, prints speed and bed + hotend temps, etc, it is very fast for complex shapes. Pronterface with Slic3r is also good and provides closer control for the printer. Meshmixer is also worth checking out as it can analyse an STL file and correct design problems which if not corrected could appear as none printed areas on the final object.

What I really need is to find a way to pause the print, there are many times I need to stop the printing and then to resume a few minutes or so later. Is this possible to do?

Btw I have used Cura with good success, this software will take a STL file and generate any slicing and then print the object in one operation, you can change many preferences, like the size of the print nozzle and retraction time, prints speed and bed + hotend temps, etc, it is very fast for complex shapes. Pronterface with Slic3r is also good and provides closer control for the printer. Meshmixer is also worth checking out as it can analyse an STL file and correct design problems which if not corrected could appear as none printed areas on the final object.

What I really need is to find a way to pause the print, there are many times I need to stop the printing and then to resume a few minutes or so later. Is this possible to do?

|

Re: Thinking of buying a P3Steel kit from Orballo January 22, 2016 10:01AM |

Registered: 8 years ago Posts: 24 |

Hi dvx, I don't think it's the infill, the infill is set to 40% honeycomb (in slic3r) and the honeycomb prints OK, in fact, it's super tiny and quite impressive how symmetric it is  Maybe I had my bed temperature too high for this print, I started at 75c for first layer as I was experimenting with getting the first layer right, and then went down to 55c for second layer, so I guess there could have been warping due to that...

Maybe I had my bed temperature too high for this print, I started at 75c for first layer as I was experimenting with getting the first layer right, and then went down to 55c for second layer, so I guess there could have been warping due to that...

I use Repetier host to print (the app, not the web interface), I really like it, it lets you view the print process visually while printing and it seems very stable for me. You can pause the print in Repetier, but I haven't really tried that feature...

Maybe I had my bed temperature too high for this print, I started at 75c for first layer as I was experimenting with getting the first layer right, and then went down to 55c for second layer, so I guess there could have been warping due to that...

Maybe I had my bed temperature too high for this print, I started at 75c for first layer as I was experimenting with getting the first layer right, and then went down to 55c for second layer, so I guess there could have been warping due to that...I use Repetier host to print (the app, not the web interface), I really like it, it lets you view the print process visually while printing and it seems very stable for me. You can pause the print in Repetier, but I haven't really tried that feature...

|

Re: Thinking of buying a P3Steel kit from Orballo January 24, 2016 09:37AM |

Registered: 8 years ago Posts: 35 |

Quote

ade2

I have a question for you guys. When making a flat surface as I was printing a larger X-axis part, the second layer had this weird pattern in about 70% of the areas while the remaining 30% had a impeccably smooth surface. Is it a heatbed temperature problem, or Z axis too low, or feed rate thing maybe? What do you think....? The next layer after that looked perfect though....

Could it be the extruder nozzle tip dragging on the previous layer and melting it a little. I think that can be caused by slight over extrusion (so the layer will be slightly higher than it should be and the next layer will dig in slightly). ? Try checking the extruder and Z axis e-steps are right, and that your slicer is set to the right nozzle/filament width.

Paul.

--

Paul Hurley

[www.paulhurley.co.uk]

|

Re: Thinking of buying a P3Steel kit from Orballo January 25, 2016 06:36AM |

Registered: 8 years ago Posts: 24 |

Quote

paulhurleyuk

Quote

ade2

I have a question for you guys. When making a flat surface as I was printing a larger X-axis part, the second layer had this weird pattern in about 70% of the areas while the remaining 30% had a impeccably smooth surface. Is it a heatbed temperature problem, or Z axis too low, or feed rate thing maybe? What do you think....? The next layer after that looked perfect though....

Could it be the extruder nozzle tip dragging on the previous layer and melting it a little. I think that can be caused by slight over extrusion (so the layer will be slightly higher than it should be and the next layer will dig in slightly). ? Try checking the extruder and Z axis e-steps are right, and that your slicer is set to the right nozzle/filament width.

Paul.

Thanks, I'll have a look at those settings, I haven't done a proper step/mm calibration yet on any steppers. Everything else prints very good now otherwise, apart from some warping in the corners of my objects. I lowered the temperature on the bed and re-printed an object I had that had catastrophic warping, and it was a lot better, but there was still some warping in all corners...

I also have a problem with my bed (or the glass piece on it?), the middle-left (mid Y, low X) appears to be a little sunk in, as the nozzle becomes more separated/higher from bed than in the other areas. More investigation needed....

|

Re: Thinking of buying a P3Steel kit from Orballo January 29, 2016 07:36AM |

Registered: 8 years ago Posts: 5 |

This thread makes me wonder should I go for kitprinter3d kit instead?

It is more expensive compared with orballo, but I feel like there will be less troubles during build. Another downside of kitprinter3d kit is that they don't offer MK3 alu bed, all updates like DRV8825 and LCD add a lot of money! Not sure about their E3D v6 hot end, is it also chinese copy or original?

It is more expensive compared with orballo, but I feel like there will be less troubles during build. Another downside of kitprinter3d kit is that they don't offer MK3 alu bed, all updates like DRV8825 and LCD add a lot of money! Not sure about their E3D v6 hot end, is it also chinese copy or original?

|

Re: Thinking of buying a P3Steel kit from Orballo January 29, 2016 08:09AM |

Registered: 8 years ago Posts: 24 |

Well, you may get unlucky, but you should get a better deal from orballo to be honest. Comparing the kits, here's what I can see:

Black frame vs galvanized steel frame (matter of taste, I prefer black).

They do have an drv8825 option in their configurator (not sure about if they make a big difference though)

No mk3 alu heatbed option

No ramps 1.4sb option (this seems important...)

For their p3steel kit, Kitprinter3d gives you a mk8 direct drive extruder, whereas orballo gives you a e3d v6 clone with greg's wade's ultimate bowden extruder. I don't know which is better.

The kitprinter3d arduino is a clone, whereas the one from orballo is a genuine arduino afaik, this could also possibly make a difference...

My p3steel frame was version 2.5, kitprinter3d doesn't say which version they have have. If you really want a 2.5 frame from orballo make sure you ask for it specifically because I think they had both 2.01 and 2.5

You can also choose igus bearings on orballo (i got 4 igus for bed and 8 lm8uu for others)

if you want e3d v6 it says E3D specifically in their configurator so that's what you should get. I don't know what extruder you would get with that though, but I guess you get the same or similar as orballo...

So I can't really see any benefits with kitprinter3d, other than the genuine hotend. I haven't tried a genuine yet but my clone seems to be working OK so far.

Black frame vs galvanized steel frame (matter of taste, I prefer black).

They do have an drv8825 option in their configurator (not sure about if they make a big difference though)

No mk3 alu heatbed option

No ramps 1.4sb option (this seems important...)

For their p3steel kit, Kitprinter3d gives you a mk8 direct drive extruder, whereas orballo gives you a e3d v6 clone with greg's wade's ultimate bowden extruder. I don't know which is better.

The kitprinter3d arduino is a clone, whereas the one from orballo is a genuine arduino afaik, this could also possibly make a difference...

My p3steel frame was version 2.5, kitprinter3d doesn't say which version they have have. If you really want a 2.5 frame from orballo make sure you ask for it specifically because I think they had both 2.01 and 2.5

You can also choose igus bearings on orballo (i got 4 igus for bed and 8 lm8uu for others)

if you want e3d v6 it says E3D specifically in their configurator so that's what you should get. I don't know what extruder you would get with that though, but I guess you get the same or similar as orballo...

So I can't really see any benefits with kitprinter3d, other than the genuine hotend. I haven't tried a genuine yet but my clone seems to be working OK so far.

|

Re: Thinking of buying a P3Steel kit from Orballo February 03, 2016 01:02AM |

Registered: 8 years ago Posts: 3 |

hello

sorry but Orballo is not a good seller at all...

I paid my printer the 17 December

I received it the 13 January...with missing part.... no pinion for the X and Y motor and missing part for the frame...

I send a email to orballo and 2 weeks later he said that he send it....and still nothing here...

the printed parts are poor quality really, lot of work to put everything together...

and the arduino is a clone too

the frame... painted in black is cool but it's painted with a lot of burr...and if you have all the part...

my opinion... stay away from this "seller"...

ps: sorry for my poor english...

sorry but Orballo is not a good seller at all...

I paid my printer the 17 December

I received it the 13 January...with missing part.... no pinion for the X and Y motor and missing part for the frame...

I send a email to orballo and 2 weeks later he said that he send it....and still nothing here...

the printed parts are poor quality really, lot of work to put everything together...

and the arduino is a clone too

the frame... painted in black is cool but it's painted with a lot of burr...and if you have all the part...

my opinion... stay away from this "seller"...

ps: sorry for my poor english...

|

Re: Thinking of buying a P3Steel kit from Orballo February 03, 2016 04:42AM |

Registered: 8 years ago Posts: 7 |

Hi all,

I must agree with "the dude", and essentially everyone else in this thread.

My experience with Orballo was as bad as everyone else's. They took about a month to ship out my order and they also lied about the actual shipping date; said it was shipped 2 days before it actually was.

I only ended up ordering the frame, hardware, heated bed and printed parts (since I had an i3 sunhokey and wanted to upgrade the frame) and I feel that I can say that they did a decent job with the first three things (even though I used a bench vice to insert the nylocs into the frame).

The printed parts however were horrible!, my x-carriage was missing (thank god I had my older x-carriage, else I would need to contact a local 3D printing shop to get it a new one printed), the z-axis bearing holders wouldn't fit my LM8UU bearings, and when I managed to force them in, they weren't at all level; so the rod wouldn't actually slide, or even go in for that matter. I managed to fix it by re-drilling the bearing hole with a 15mm drill bit and securing the bearings on the inside with duct tape.

As I previously mentioned, I didn't order any of the electronics, so I can't speak for their quality. I did recently order a ramps v1.4 and arduino board from the Italian open source hardware since my old MKS v1.1 gave up on me, so if anyone is interested, I could let you all know how that goes.

Overall, if you really want a decent quality frame and hardware (screws, nuts, smoothrods, bearings, etc) you could order those from orballo...but be prepared to wait for a long time until you get your things. Everything else; electronics, motors, printed parts, etc, get elsewhere.

I must agree with "the dude", and essentially everyone else in this thread.

Quote

the dude

sorry but Orballo is not a good seller at all...

My experience with Orballo was as bad as everyone else's. They took about a month to ship out my order and they also lied about the actual shipping date; said it was shipped 2 days before it actually was.

I only ended up ordering the frame, hardware, heated bed and printed parts (since I had an i3 sunhokey and wanted to upgrade the frame) and I feel that I can say that they did a decent job with the first three things (even though I used a bench vice to insert the nylocs into the frame).

The printed parts however were horrible!, my x-carriage was missing (thank god I had my older x-carriage, else I would need to contact a local 3D printing shop to get it a new one printed), the z-axis bearing holders wouldn't fit my LM8UU bearings, and when I managed to force them in, they weren't at all level; so the rod wouldn't actually slide, or even go in for that matter. I managed to fix it by re-drilling the bearing hole with a 15mm drill bit and securing the bearings on the inside with duct tape.

As I previously mentioned, I didn't order any of the electronics, so I can't speak for their quality. I did recently order a ramps v1.4 and arduino board from the Italian open source hardware since my old MKS v1.1 gave up on me, so if anyone is interested, I could let you all know how that goes.

Overall, if you really want a decent quality frame and hardware (screws, nuts, smoothrods, bearings, etc) you could order those from orballo...but be prepared to wait for a long time until you get your things. Everything else; electronics, motors, printed parts, etc, get elsewhere.

|

Re: Thinking of buying a P3Steel kit from Orballo February 03, 2016 07:52AM |

Registered: 8 years ago Posts: 24 |

Sorry to hear about your troubles. I'm still waiting for my spare parts, the package seems to have been lost in transit. They have now shipped me the parts again, with a tracking id this time. Make sure you ask them for help with new parts as they will send you replacements/missing parts for sure. Hopefully they have learned something and the kits will be better in the future...

In other news,

In other news,

- i've decided to replace my 0.2mm nozzle with a 0.4mm one as it seems to have been a bit of a mistake to start with such as small nozzle... The margins for calibration are really small, print speed is very slow, extrusion flow is less reliable...

- i've put my printer inside a metal cabinet, that fits it perfectly. I was having severe problems with printing ABS before, the layers would warp and separate, causing catastrophic print failures after reaching about 5mm in height. After putting the printer in the cabinet, the ambient temperature inside goes up to around 30-40 C and i've not had any of these problems anymore!

- i've ordered a BuildTak printing surface as I'm getting real tired of messing with glue stick and the glass plate to get the first layer to stick.... the adhesion is really good with a glue stick if applied correctly, but getting it smoothly applied is very tedious... I will report back with my results with this new surface.

|

Re: Thinking of buying a P3Steel kit from Orballo February 03, 2016 10:46AM |

Registered: 9 years ago Posts: 76 |

I was looking at their site, but it is down..hmm

We make a variant in the US, with no printed parts (all steel carriage parts)

It's sad to see trouble with companies and shipping these days.

Making it better for Makers!

[makerfront.com]

We make a variant in the US, with no printed parts (all steel carriage parts)

It's sad to see trouble with companies and shipping these days.

Making it better for Makers!

[makerfront.com]

|

Re: Thinking of buying a P3Steel kit from Orballo February 11, 2016 10:43AM |

Registered: 8 years ago Posts: 24 |

Was disappointed yet again when receiving replacement/missing parts, as one of the parts requested were missing, and even the compensation fans I was offered weren't in the package. Two and a half months since ordering and I still don't have all parts. Going to get the rest myself now. Can't recommend ordering from there.

|

Re: Thinking of buying a P3Steel kit from Orballo February 11, 2016 01:15PM |

Registered: 8 years ago Posts: 4 |

I just ordered a complete kit from orballoprinting two weeks ago. I received it in 5 days the printer. The quality frame is very good. I recommend the ramps SB. I received new endstops holders that fits perfect and the x axis pieces have a z-axis level adjust. I think they have made improvents.

I recommend the site.

I recommend the site.

|

Re: Thinking of buying a P3Steel kit from Orballo February 11, 2016 10:41PM |

Registered: 8 years ago Posts: 3 |

Quote

ade2

Was disappointed yet again when receiving replacement/missing parts, as one of the parts requested were missing, and even the compensation fans I was offered weren't in the package. Two and a half months since ordering and I still don't have all parts. Going to get the rest myself now. Can't recommend ordering from there.

same for me.... I just received the piece yesterday... and it's look like a joke

I had 2 pinions (it was missing..), and a end stop holder (don't need).... but not the missing frame part.... and a candy bag...... really ???

if you want to try your luck, try to buy something from orballo, if you get it you're a really lucky person.....

|

Re: Thinking of buying a P3Steel kit from Orballo February 12, 2016 03:19AM |

Registered: 8 years ago Posts: 9 |

There's these guys (in US) with steel frame, though I have not ordered from them: [www.makerfront.com]

They also have 200x300 frame (XL size).

The frame is nicely painted and has less plastic parts than others.

But you can't order it separately from the rest of the printer.

I did myself order from KitPrinter3d (it's in Spain, and I'm in US).

I had great communication from them (they answered questions promptly) and they shipped it as soon as it was back in stock.

However, after shipping, because of their or shipment company mess up and miscommunication, printer got stuck in customs, and now US customs wants 500$ of fee to get it from there (kit spent there over a month).

kitprinter3d doesn't handle the situation well at all.

Other than this "minor" issue, they do have the kit very configurable (including good hotends like e3d v6 and others), and it might so happen that if I finally get the kit, it will be in a good shape with no missing parts.

They also have 200x300 frame (XL size).

They also have 200x300 frame (XL size).

The frame is nicely painted and has less plastic parts than others.

But you can't order it separately from the rest of the printer.

I did myself order from KitPrinter3d (it's in Spain, and I'm in US).

I had great communication from them (they answered questions promptly) and they shipped it as soon as it was back in stock.

However, after shipping, because of their or shipment company mess up and miscommunication, printer got stuck in customs, and now US customs wants 500$ of fee to get it from there (kit spent there over a month).

kitprinter3d doesn't handle the situation well at all.

Other than this "minor" issue, they do have the kit very configurable (including good hotends like e3d v6 and others), and it might so happen that if I finally get the kit, it will be in a good shape with no missing parts.

They also have 200x300 frame (XL size).

|

Re: Thinking of buying a P3Steel kit from Orballo February 12, 2016 10:51AM |

Registered: 8 years ago Posts: 4 |

Quote

the dude

Quote

ade2

Was disappointed yet again when receiving replacement/missing parts, as one of the parts requested were missing, and even the compensation fans I was offered weren't in the package. Two and a half months since ordering and I still don't have all parts. Going to get the rest myself now. Can't recommend ordering from there.

same for me.... I just received the piece yesterday... and it's look like a joke

I had 2 pinions (it was missing..), and a end stop holder (don't need).... but not the missing frame part.... and a candy bag...... really ???

if you want to try your luck, try to buy something from orballo, if you get it you're a really lucky person.....

I received a candy bag too. I think is a gift! I was thinking buy from kitprinter but the the frame is galvanized before lasecut and the edges will rust!

I'm very happy with the kit from Orballo and the communication is good.

|

Re: Thinking of buying a P3Steel kit from Orballo February 12, 2016 04:33PM |

Registered: 8 years ago Posts: 39 |

So what was the customs outcome??

I ordered a kit from HTA3D,, (I am in the USA) they shipped within 2 days, it left Spain in 2 days, USPS shows the tracking number as "received notice"

But it has been stuck in limbo for almost 2 weeks,, Left Spain, but not in the USA,, I am told something about EEUU customs,,, ???

I am not paying any custom fee, I can tell you that much

Slack

I ordered a kit from HTA3D,, (I am in the USA) they shipped within 2 days, it left Spain in 2 days, USPS shows the tracking number as "received notice"

But it has been stuck in limbo for almost 2 weeks,, Left Spain, but not in the USA,, I am told something about EEUU customs,,, ???

I am not paying any custom fee, I can tell you that much

Slack

Quote

biocomp

There's these guys (in US) with steel frame, though I have not ordered from them: [www.makerfront.com]

They also have 200x300 frame (XL size).

The frame is nicely painted and has less plastic parts than others.

But you can't order it separately from the rest of the printer.

I did myself order from KitPrinter3d (it's in Spain, and I'm in US).

I had great communication from them (they answered questions promptly) and they shipped it as soon as it was back in stock.

However, after shipping, because of their or shipment company mess up and miscommunication, printer got stuck in customs, and now US customs wants 500$ of fee to get it from there (kit spent there over a month).

kitprinter3d doesn't handle the situation well at all.

Other than this "minor" issue, they do have the kit very configurable (including good hotends like e3d v6 and others), and it might so happen that if I finally get the kit, it will be in a good shape with no missing parts.

They also have 200x300 frame (XL size).

|

Re: Thinking of buying a P3Steel kit from Orballo February 12, 2016 04:51PM |

Registered: 8 years ago Posts: 9 |

Quote

Slackdaddy

So what was the customs outcome??

I ordered a kit from HTA3D,, (I am in the USA) they shipped within 2 days, it left Spain in 2 days, USPS shows the tracking number as "received notice"

But it has been stuck in limbo for almost 2 weeks,, Left Spain, but not in the USA,, I am told something about EEUU customs,,, ???

They sent it to me via TNT, and that got to LA in two days and then is stuck there for a month. I did pay the fee myself, and we discussed with them that they will reimburse half to me themselves, and the rest when they get money from TNT (who is supposedly at fault).

Well, the printer has arrived (though I did not look at it yet), but they refuse to reimburse me any money w/o seeing invoice from TNT (which TNT is supposed to mail to me, but I haven't received it yet).

Obviously, I should have just refused to pay, but for some reason I decided to give these guys a chance as there was good communication and even as small discount from them at the beginning of this.

If I were you, I'd call these HTA3d guys and shipping company (USPS in this case?) over the phone to figure everything out quicker )

|

Re: Thinking of buying a P3Steel kit from Orballo February 12, 2016 06:04PM |

Registered: 8 years ago Posts: 10 |

I received a kit from orballoprinting.com via FedEx IP in USA. They shipped to me 2 days after made the order ( I made one week ago). The transit time was 3 days! I didn't pay any custom fee. I'm very impressed with the quality of the black frame. I chose with the IGUS bearings and the noise reduction is very good.

10/10

10/10

Quote

biocomp

Quote

Slackdaddy

So what was the customs outcome??

I ordered a kit from HTA3D,, (I am in the USA) they shipped within 2 days, it left Spain in 2 days, USPS shows the tracking number as "received notice"

But it has been stuck in limbo for almost 2 weeks,, Left Spain, but not in the USA,, I am told something about EEUU customs,,, ???

They sent it to me via TNT, and that got to LA in two days and then is stuck there for a month. I did pay the fee myself, and we discussed with them that they will reimburse half to me themselves, and the rest when they get money from TNT (who is supposedly at fault).

Well, the printer has arrived (though I did not look at it yet), but they refuse to reimburse me any money w/o seeing invoice from TNT (which TNT is supposed to mail to me, but I haven't received it yet).

Obviously, I should have just refused to pay, but for some reason I decided to give these guys a chance as there was good communication and even as small discount from them at the beginning of this.

If I were you, I'd call these HTA3d guys and shipping company (USPS in this case?) over the phone to figure everything out quicker )

|

Re: Thinking of buying a P3Steel kit from Orballo February 12, 2016 06:09PM |

Registered: 8 years ago Posts: 9 |

Quote

sam_t

I didn't pay any custom fee.

Just to be clear, this was an extra charge (or fine), which customs were asking only because there were problems with address and the kit was sent to custom's storage. Had everything been OK with address, there would be no extra charge.

Other than that, I'm glad for you

|

Re: Thinking of buying a P3Steel kit from Orballo February 15, 2016 04:11PM |

Registered: 8 years ago Posts: 6 |

I ordered a P3 Steel frame kit from Orballo over a week ago. The payment has been accepted and has drawn from my account, but no mention of shipping details, and no response to my inquiries on their website.

I am concerned that I may have to file a complaint with PAYPAL if they do not communicate any shipping info to me. It seems, along with reading this, that they may not be a good supplier.

We will see.

Edited 1 time(s). Last edit at 02/15/2016 04:20PM by wesleyweber.

I am concerned that I may have to file a complaint with PAYPAL if they do not communicate any shipping info to me. It seems, along with reading this, that they may not be a good supplier.

We will see.

Edited 1 time(s). Last edit at 02/15/2016 04:20PM by wesleyweber.

|

Re: Thinking of buying a P3Steel kit from Orballo February 15, 2016 06:52PM |

Registered: 8 years ago Posts: 4 |

Hi!

I ordered a Prusa Steel 3d printer from Orballo. I received it in about 5-6 days and well packaged ( candy bag included! )

)

I'm very impressive with the laser quality of the frame. The parts fits correctly and is very robust.

I'm doing my firsts prints. I will share my progress.

Greetings!

I ordered a Prusa Steel 3d printer from Orballo. I received it in about 5-6 days and well packaged ( candy bag included!

)

)I'm very impressive with the laser quality of the frame. The parts fits correctly and is very robust.

I'm doing my firsts prints. I will share my progress.

Greetings!

|

Re: Thinking of buying a P3Steel kit from Orballo February 15, 2016 10:09PM |

Registered: 8 years ago Posts: 6 |

Update: Orballo sent the order processing information just a few moments ago, excited to get this new frame

Update#2: They sent me several responses via the website apologizing for the delay, and sent tracking info on the shipment. I will likely recommend them to my friends if this kit works well.

Edited 1 time(s). Last edit at 02/16/2016 06:46PM by wesleyweber.

Update#2: They sent me several responses via the website apologizing for the delay, and sent tracking info on the shipment. I will likely recommend them to my friends if this kit works well.

Edited 1 time(s). Last edit at 02/16/2016 06:46PM by wesleyweber.

Sorry, only registered users may post in this forum.