P802M Prusa i3 Unofficial Support Thread

Posted by gwc2795

|

Re: P802M Prusa i3 Unofficial Support Thread January 11, 2016 09:08AM |

Registered: 8 years ago Posts: 3 |

|

Re: P802M Prusa i3 Unofficial Support Thread January 11, 2016 09:44AM |

Registered: 8 years ago Posts: 35 |

|

Re: P802M Prusa i3 Unofficial Support Thread January 11, 2016 12:42PM |

Registered: 8 years ago Posts: 49 |

Quote

gwc2795

Post a link to the one you purchased. The screw holes on the ones I have found do not fit the P802.Quote

jnsbanman

Well I just ordered an aluminum Y carriage because my acrylic carriage is warping about 1/4" once it hits 115 degrees. Sometimes it would stay straight for a while and warp mid print screwing it all up... So upgrade time. I also ordered all the parts to do the Z axis upgrade to using just 1 Z axis stepper. as I found my Z was off level about by close to 2 mm frequently.

This is the one i purchased it is still on its way though... [www.ebay.ca]

I actually just made my own and now might stick with it. It is made from a building envelope material called composite. Basically it is 2 2mm aluminum sheets that sandwich a layer of plastic.. The plastic is melts at much higher then normal temps. I have now printed for about 20 hours since replacing the factory acrylic y carriage and I am happy to report that the bed has stayed nice and level between prints... no warping of the carriage.

I have also ordered all the parts to complete the Z axis upgrade to 1 Z axis motor.

I am also strongly considering upgrading the y axis linear shafts with 12mm shafts to prevent bending. I find the 8mm shafts to flexible.

|

Re: P802M Prusa i3 Unofficial Support Thread January 11, 2016 05:42PM |

Registered: 8 years ago Posts: 35 |

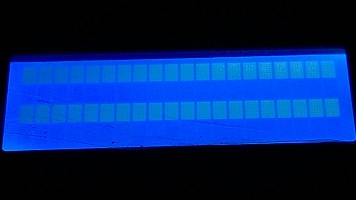

I really have quality problem, look at the attachments (and this is one of the best quality...): the area is not well covered, i notice a lot of holes; what wrong?

my current settings are:

material: PLA

bed: 70°

extruder 200-205°

I also notice that often my extruder have difficult to extrude filament but if i manually try without a complete work it has no difficult; maybe i move too fast? i'm really confused... please help

Edited 1 time(s). Last edit at 01/11/2016 07:21PM by glimpse79.

my current settings are:

material: PLA

bed: 70°

extruder 200-205°

I also notice that often my extruder have difficult to extrude filament but if i manually try without a complete work it has no difficult; maybe i move too fast? i'm really confused... please help

Edited 1 time(s). Last edit at 01/11/2016 07:21PM by glimpse79.

|

Re: P802M Prusa i3 Unofficial Support Thread January 12, 2016 03:37AM |

Registered: 8 years ago Posts: 62 |

Hello Glimpse, what are your slicer settings, especially the print speed. If I would try to print faster than 50 mm/s my nozzle ( 0,4mm) ist stucking or the extruder motor has not enough power to push the filament trough the extruder so fast. To improve that, I set the extruder motor current a little bit higher and set a cooling fan overhead the heat sinks of the drivers. If your nozzle is not stucking your prints are looking more than that the problems comes from the extruder motor driver. From time to time my nozzle is stucking because of residues of burnt or not clean filament (dust). It works a little bit better when I added a little bit sponge to clean the filament befor it is entering the extruder.

Kindly regards

Bernd

Kindly regards

Bernd

|

Re: P802M Prusa i3 Unofficial Support Thread January 12, 2016 03:46AM |

Registered: 8 years ago Posts: 35 |

Quote

bmark25116

Hello Glimpse, what are your slicer settings, especially the print speed. If I would try to print faster than 50 mm/s my nozzle ( 0,4mm) ist stucking or the extruder motor has not enough power to push the filament trough the extruder so fast. To improve that, I set the extruder motor current a little bit higher and set a cooling fan overhead the heat sinks of the drivers. If your nozzle is not stucking your prints are looking more than that the problems comes from the extruder motor driver. From time to time my nozzle is stucking because of residues of burnt or not clean filament (dust). It works a little bit better when I added a little bit sponge to clean the filament befor it is entering the extruder.

Kindly regards

Bernd

Hi Bernd,

thanks for your help; how to set the extruder motor a little bit higher? How can i check the extruder motor driver?

Thanks in advance.

Luca

|

Re: P802M Prusa i3 Unofficial Support Thread January 12, 2016 04:41AM |

Registered: 8 years ago Posts: 62 |

Hi Luca, I think you are using a Melziboard.? Try to increase the motor current of the extruder driver by turning the little potentiometer close to the axtruder driver very slowly CLOCKWISE.

Be aware to produce no short circuit on the board. It is better to use a ceramic screwdriver to avoid this. You can check the reference voltage what is an expression of the motor current by measuring

beetween GND and the middle contact on the potentiometer where you are putting the screwdriver on for turning. The reference voltage should be around 0.6 V I think, if there are Polulo drivers

on the board.

Be aware to produce no short circuit on the board. It is better to use a ceramic screwdriver to avoid this. You can check the reference voltage what is an expression of the motor current by measuring

beetween GND and the middle contact on the potentiometer where you are putting the screwdriver on for turning. The reference voltage should be around 0.6 V I think, if there are Polulo drivers

on the board.

|

Re: P802M Prusa i3 Unofficial Support Thread January 12, 2016 11:06AM |

Registered: 8 years ago Posts: 49 |

I noticed when I received mine the screws on the hobbed gear on the extruder were very loose... It would still extrude but when ever the demand increased it would slip like crazy. check that if it is clicking when printing.

I would also slow your print speeds down as well.

Post your slicer settings so we can see where the problem might be.

I would also slow your print speeds down as well.

Post your slicer settings so we can see where the problem might be.

|

Re: P802M Prusa i3 Unofficial Support Thread January 13, 2016 05:51AM |

Registered: 8 years ago Posts: 11 |

|

Re: P802M Prusa i3 Unofficial Support Thread January 13, 2016 11:36AM |

Registered: 8 years ago Posts: 43 |

Hello fellow Zonestar P802M owners!

Bought a P802M (Cstar brand) from 3D star (Aliexpress) in November, built in December and just doing wear in runs with test files. The linear bearings in the kit were VERY VERY crunchy when first slipped onto the rods. At times the Y carriage shudders as, I think, the linear bearings seriously jam and lock. :-(. That's why I haven't printed anything on it yet as I'd just be wasting filament.

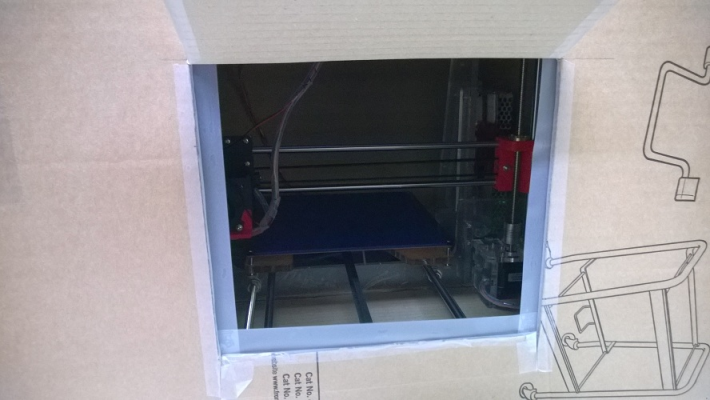

Right now the printer is housed in a card board box on my desk. I'm was thinking of making an enclosure for it so I just found the largest box I could and cut it to a snug fit and took measurements. The box also acts as a dust cover.

Just two things I'd like to bring up.

1. Dust and dirt.

While I was exploring the possibility of building a reprap from scratch I dismantled a few printers before I gave up and just bought the P802M. As you have read above I was not very impressed with the movement of the linear bearings on the rods. With time, the motion of the bearings along the rods has improved quite a bit through the shear number of wear in runs and the card board box has acted as a dust cover (it was better than nothing).

Now what I'd like to ask people what would you call the things in the pictures I've attached. What you're looking at is the bottom of a inkjet printer carriage where it is attached to the smooth rod. Can they be designed, printed and incorporated into the current version of the p802m as bearing/rod cleaners which would go some way to eliminate dust and dirt before enters and jams up the bearings. I'd do it myself or at-least I'd try but please read #2.

2. The PSU and Melzi board corruption.

Sigh..... Cold boot takes 4 - 5 power ups and downs before it will boot-up properly. Every time I boot from cold all I get is corrupt stuff on the LCD or just two bars of white blocks.

After doing my morning power up and downs today the printer wouldn't connect to the PC. I searched and hunted down what I think is the main problem. The baud rate of the melzi board always defaults to 49664! After multiple times changing the baud rate to anything else it always goes back to 49664??? so now the printer and PC won't talk to each other:-( Sigh. Although the PSU might be all powerful maybe it's not outputting clean power to the melzi board.

So near yet so far..... Need help. Has anyone else experienced this fault.

PC crashed so this message was a quick rehash...

Double checking the wiring and reading this page [reprap.org] to see if I can fix the fault.

Okay took a screw driver and re-tightened wires and then saved config to eeprom < didn't know you can do that..... and rebooted with crossed fingers for luck. The P802M is now talking to my PC!!!!!! :-D

Edited 3 time(s). Last edit at 01/13/2016 02:44PM by Gatchaman.

Bought a P802M (Cstar brand) from 3D star (Aliexpress) in November, built in December and just doing wear in runs with test files. The linear bearings in the kit were VERY VERY crunchy when first slipped onto the rods. At times the Y carriage shudders as, I think, the linear bearings seriously jam and lock. :-(. That's why I haven't printed anything on it yet as I'd just be wasting filament.

Right now the printer is housed in a card board box on my desk. I'm was thinking of making an enclosure for it so I just found the largest box I could and cut it to a snug fit and took measurements. The box also acts as a dust cover.

Just two things I'd like to bring up.

1. Dust and dirt.

While I was exploring the possibility of building a reprap from scratch I dismantled a few printers before I gave up and just bought the P802M. As you have read above I was not very impressed with the movement of the linear bearings on the rods. With time, the motion of the bearings along the rods has improved quite a bit through the shear number of wear in runs and the card board box has acted as a dust cover (it was better than nothing).

Now what I'd like to ask people what would you call the things in the pictures I've attached. What you're looking at is the bottom of a inkjet printer carriage where it is attached to the smooth rod. Can they be designed, printed and incorporated into the current version of the p802m as bearing/rod cleaners which would go some way to eliminate dust and dirt before enters and jams up the bearings. I'd do it myself or at-least I'd try but please read #2.

2. The PSU and Melzi board corruption.

Sigh..... Cold boot takes 4 - 5 power ups and downs before it will boot-up properly. Every time I boot from cold all I get is corrupt stuff on the LCD or just two bars of white blocks.

After doing my morning power up and downs today the printer wouldn't connect to the PC. I searched and hunted down what I think is the main problem. The baud rate of the melzi board always defaults to 49664! After multiple times changing the baud rate to anything else it always goes back to 49664??? so now the printer and PC won't talk to each other:-( Sigh. Although the PSU might be all powerful maybe it's not outputting clean power to the melzi board.

So near yet so far..... Need help. Has anyone else experienced this fault.

PC crashed so this message was a quick rehash...

Double checking the wiring and reading this page [reprap.org] to see if I can fix the fault.

Okay took a screw driver and re-tightened wires and then saved config to eeprom < didn't know you can do that..... and rebooted with crossed fingers for luck. The P802M is now talking to my PC!!!!!! :-D

Edited 3 time(s). Last edit at 01/13/2016 02:44PM by Gatchaman.

|

Re: P802M Prusa i3 Unofficial Support Thread January 13, 2016 04:21PM |

Registered: 8 years ago Posts: 152 |

Gatchaman

Get some 8mm felt washers at the hardware store or amazon, split one side of the washer and glue it to the side of the linear bearing. You will need 6 washers for the X axis. If you do the Y axis you will need 6 washers.

For the crunchy sounding linear bearings loosen 3 screws on each of the 2 top bearings on the X axis. Side the X axis left right until it becomes smooth and snug one screw. repeat this until all screws are tight and your bearings should be quiet and smooth.

Get some 8mm felt washers at the hardware store or amazon, split one side of the washer and glue it to the side of the linear bearing. You will need 6 washers for the X axis. If you do the Y axis you will need 6 washers.

For the crunchy sounding linear bearings loosen 3 screws on each of the 2 top bearings on the X axis. Side the X axis left right until it becomes smooth and snug one screw. repeat this until all screws are tight and your bearings should be quiet and smooth.

|

Re: P802M Prusa i3 Unofficial Support Thread January 13, 2016 07:21PM |

Registered: 8 years ago Posts: 35 |

Quote

jnsbanman

I noticed when I received mine the screws on the hobbed gear on the extruder were very loose... It would still extrude but when ever the demand increased it would slip like crazy. check that if it is clicking when printing.

I would also slow your print speeds down as well.

Post your slicer settings so we can see where the problem might be.

I notice that using Cura give me really more beautiful result, Slic3r make the model "low resolution" (i really do not why, settings seems the same)

Now my big problem is leveling the bed; i lost my "good" configuration and i cannot find the correct set. I use "paper sheet" method with bad result..

|

Re: P802M Prusa i3 Unofficial Support Thread January 14, 2016 04:01AM |

Registered: 8 years ago Posts: 23 |

dear Gatchaman,

its not exactly 3D Star's P802M problem. It is the low quality linear bearing problem, and the mistake when you insert the metal axis to the bearings, becouse very very easily drop out the bullets.

When you assemply the axis and bearing you need a litle bit twist the axis and watch inside.

If you drop out bullets you dont worry, its can be take back into bearings.

but its is not an easy movement.

i do this mistake too. and my bed jammed sometimes and creaked.

its not exactly 3D Star's P802M problem. It is the low quality linear bearing problem, and the mistake when you insert the metal axis to the bearings, becouse very very easily drop out the bullets.

When you assemply the axis and bearing you need a litle bit twist the axis and watch inside.

If you drop out bullets you dont worry, its can be take back into bearings.

but its is not an easy movement.

i do this mistake too. and my bed jammed sometimes and creaked.

|

Re: P802M Prusa i3 Unofficial Support Thread January 14, 2016 04:04AM |

Registered: 8 years ago Posts: 23 |

|

Re: P802M Prusa i3 Unofficial Support Thread January 14, 2016 04:22AM |

Registered: 8 years ago Posts: 43 |

Thanks gwc2795 and Robkadett, your replies have been taken on board and I'll get to work gluing and adjusting parts soon.

I wish I had found this place before I built the printer but ... oh well I'm here now :-).

Still haven't left a review on Aliexpress so will leave a pointer to this place when I do for other lost sheep!

Thank you once again!

I wish I had found this place before I built the printer but ... oh well I'm here now :-).

Still haven't left a review on Aliexpress so will leave a pointer to this place when I do for other lost sheep!

Thank you once again!

|

Re: P802M Prusa i3 Unofficial Support Thread January 14, 2016 05:39AM |

Registered: 8 years ago Posts: 43 |

@ gwc2795

May I suggest you edit your first post to show problems and answers.

In format such as:

Issue:

Possible cause:

Possible fix:

or which ever way you see fit

In my case it would be.

Issue: After following instructions to build the P802M the user experienced power fluctuations and corrupt LCD and baud rate set at 46994 default speed. Printer will not connect to PC or Mac com port.

Possible cause: Bearings not clean and set to right tension leading to jams and lock-ups which causes extreme juddering of the whole printer. This extreme juddering in turn leads to connections coming loose leading to a possible faulty power system and corrupt settings after following initial build instructions that came with the printer.

Possible fix: Configure linear bearings properly. "For the crunchy sounding linear bearings loosen 3 screws on each of the 2 top bearings on the X axis. Slide the X axis left right until it becomes smooth and snug one screw. Repeat this until all screws are tight and your bearings should be quiet and smooth."

Double check and re-tighten all Melzi board connections.

Without connecting to the printer to the PC or Mac change and save baud rate config to eeprom. Power down then power up after a minute or two then connect to PC or Mac. Check baud rate was saved and doesn't change after attaching the usb cable.

Edited 2 time(s). Last edit at 01/14/2016 01:39PM by Gatchaman.

May I suggest you edit your first post to show problems and answers.

In format such as:

Issue:

Possible cause:

Possible fix:

or which ever way you see fit

In my case it would be.

Issue: After following instructions to build the P802M the user experienced power fluctuations and corrupt LCD and baud rate set at 46994 default speed. Printer will not connect to PC or Mac com port.

Possible cause: Bearings not clean and set to right tension leading to jams and lock-ups which causes extreme juddering of the whole printer. This extreme juddering in turn leads to connections coming loose leading to a possible faulty power system and corrupt settings after following initial build instructions that came with the printer.

Possible fix: Configure linear bearings properly. "For the crunchy sounding linear bearings loosen 3 screws on each of the 2 top bearings on the X axis. Slide the X axis left right until it becomes smooth and snug one screw. Repeat this until all screws are tight and your bearings should be quiet and smooth."

Double check and re-tighten all Melzi board connections.

Without connecting to the printer to the PC or Mac change and save baud rate config to eeprom. Power down then power up after a minute or two then connect to PC or Mac. Check baud rate was saved and doesn't change after attaching the usb cable.

Edited 2 time(s). Last edit at 01/14/2016 01:39PM by Gatchaman.

|

Re: P802M Prusa i3 Unofficial Support Thread January 14, 2016 10:30AM |

Registered: 8 years ago Posts: 15 |

ISSUE: Screen flickering on Zonestar Prusa / Reboot mid-print. When not printing it is fine, as soon as heated bed is on, extruder on and print in progress, my LCD would flicker and sometimes the printer reboots.

POSSIBLE CAUSE: The issue is the 5v step down voltage regulator on the Melzi print control board. When I measured the voltage output of the regulator when not printing it was fine, when measured during a print, the voltage fluctuated a lot and sagged, causing the printer to reboot. I suspect the cause is either a faulty regulator or something consuming excessive current. See my youtube video [www.youtube.com]

SOLUTION: There are multiple solutions, solution 1 is the easiest and its what I do now, printer works perfectly.

1) Change the Melzi jumper switch to power the control board through the USB circuit and not the voltage regulator, and plug in a USB cable to the computer or mains adapter.

2) Unplug the LCD screen and print using USB cable (some people have reported that this works)

3) Replace the voltage regulator on the control board with one which can handle higher current.

POSSIBLE CAUSE: The issue is the 5v step down voltage regulator on the Melzi print control board. When I measured the voltage output of the regulator when not printing it was fine, when measured during a print, the voltage fluctuated a lot and sagged, causing the printer to reboot. I suspect the cause is either a faulty regulator or something consuming excessive current. See my youtube video [www.youtube.com]

SOLUTION: There are multiple solutions, solution 1 is the easiest and its what I do now, printer works perfectly.

1) Change the Melzi jumper switch to power the control board through the USB circuit and not the voltage regulator, and plug in a USB cable to the computer or mains adapter.

2) Unplug the LCD screen and print using USB cable (some people have reported that this works)

3) Replace the voltage regulator on the control board with one which can handle higher current.

|

Re: P802M Prusa i3 Unofficial Support Thread January 14, 2016 02:49PM |

Registered: 8 years ago Posts: 11 |

Hello,

I hope i am doing it right. I have a problem with my zonestar p802m.

It was printing along fine. i did put fan voor cooling of the board. lcd was flickerling. Suddenly the printer stopped. It was not responding to anything. So i had to pull the main power cord. When connected again. the printer keeps resetting. En when its getting past the boot sequens the printer is not responding to the G-codes. It is leading its own live.

I am in contact with the dutch suplyer. the want to solve my problem. but their supplyer dont want to.

I have a few qwestions. a i look in to the problem is it safe to assume that de melzi board is defective?

is there a replacement board avalibele for my printer?. my splyer wants to buy it for me.

Hope that u can help me out.

I hope i am doing it right. I have a problem with my zonestar p802m.

It was printing along fine. i did put fan voor cooling of the board. lcd was flickerling. Suddenly the printer stopped. It was not responding to anything. So i had to pull the main power cord. When connected again. the printer keeps resetting. En when its getting past the boot sequens the printer is not responding to the G-codes. It is leading its own live.

I am in contact with the dutch suplyer. the want to solve my problem. but their supplyer dont want to.

I have a few qwestions. a i look in to the problem is it safe to assume that de melzi board is defective?

is there a replacement board avalibele for my printer?. my splyer wants to buy it for me.

Hope that u can help me out.

|

Re: P802M Prusa i3 Unofficial Support Thread January 14, 2016 08:20PM |

Registered: 8 years ago Posts: 152 |

I can not over emphasize that you make sure the power wires from the power supply to the Melzi board are firmly attached at both the power supply the Melzi board. The Amount of power drawn by the extruder and the bed heater will cause rebooting if the connections are not tight. How do I know this? I have 4 of these printers and it drove me partially insane until I discovered a loose connection.

Good Luck

Good Luck

|

Re: P802M Prusa i3 Unofficial Support Thread January 15, 2016 01:50AM |

Registered: 8 years ago Posts: 35 |

My battle for better printing continue

I improve quality using cura, i improve quality tension better the cords and leveling better the bed.... now my issue is: (again)

first layer!

Even with a good leveling and heating bed (70°) i can't "tie" well PLA on bed (200° extruded)

Any best practice? or solution?

and.... during my last print fall the little (2mm) black screw near the nozzle! OMG! What's it?!?

I improve quality using cura, i improve quality tension better the cords and leveling better the bed.... now my issue is: (again)

first layer!

Even with a good leveling and heating bed (70°) i can't "tie" well PLA on bed (200° extruded)

Any best practice? or solution?

and.... during my last print fall the little (2mm) black screw near the nozzle! OMG! What's it?!?

|

Re: P802M Prusa i3 Unofficial Support Thread January 15, 2016 02:01AM |

Registered: 8 years ago Posts: 62 |

|

Re: P802M Prusa i3 Unofficial Support Thread January 15, 2016 02:13AM |

Registered: 8 years ago Posts: 35 |

Quote

bmark25116

Hi Glimpse, the little screw may be the one to fix the heater cartridge in the nozzle heater block. There ist often one screw for clamping and one for fixing. Make sure that both

are tight and secure.

Bernd

The missing one is in photo ...

|

Re: P802M Prusa i3 Unofficial Support Thread January 15, 2016 02:23AM |

Registered: 8 years ago Posts: 62 |

Hi Glimpse, thanx for the picture. I was right, the missing screw is the one which fix the heater cartridge to prevent that it is slipping out of or turning inside the heater block.

Screw in a new one and tight it careful. If you want it is a good idea to secure it with some loctite or similar.

Bernd

Edited 1 time(s). Last edit at 01/15/2016 02:25AM by bmark25116.

Screw in a new one and tight it careful. If you want it is a good idea to secure it with some loctite or similar.

Bernd

Edited 1 time(s). Last edit at 01/15/2016 02:25AM by bmark25116.

|

Re: P802M Prusa i3 Unofficial Support Thread January 15, 2016 02:25AM |

Registered: 8 years ago Posts: 11 |

Quote

gwc2795

I can not over emphasize that you make sure the power wires from the power supply to the Melzi board are firmly attached at both the power supply the Melzi board. The Amount of power drawn by the extruder and the bed heater will cause rebooting if the connections are not tight. How do I know this? I have 4 of these printers and it drove me partially insane until I discovered a loose connection.

Good Luck

i did check all connections. The problem remains.

[www.dropbox.com] video of the problem

[www.dropbox.com] picture of the problem

[www.dropbox.com] picture of the problem

Edited 1 time(s). Last edit at 01/15/2016 02:26AM by Patrisio.

|

Re: P802M Prusa i3 Unofficial Support Thread January 15, 2016 04:07AM |

Registered: 8 years ago Posts: 35 |

|

Re: P802M Prusa i3 Unofficial Support Thread January 15, 2016 06:14AM |

Registered: 8 years ago Posts: 43 |

@ gwc2795

Thinking about it I think it would be better if instead of posting all the stuff I typed in my previous posts about problems and answers just post a link to it from your very first post #1 but with a short summery of the issue.

Would still be helpful if the final post of the issue with conclusion was in.

Issue:

Possible cause:

Possible fix / solution:

Personally after tweaking the bearings I'm still stuck with

Issue: Cold boot / blank LCD / one red flash of the LED on the Melzi pcb......

Starting to think it would be better to leave it powered up 24/7 but I don't have a power meter to tell me how much juice the P802M sucks up in idle mode all with everything off. Can anyone out there tell us how much power the P802M sucks from the wall?

Possible cause: Dead / corrupt board.

Possible fix / solution: Checked the wiring and it's all good. Maybe re-flash the firmware? Haven't got a clue how though.

Edited 2 time(s). Last edit at 01/15/2016 01:56PM by Gatchaman.

Thinking about it I think it would be better if instead of posting all the stuff I typed in my previous posts about problems and answers just post a link to it from your very first post #1 but with a short summery of the issue.

Would still be helpful if the final post of the issue with conclusion was in.

Issue:

Possible cause:

Possible fix / solution:

Personally after tweaking the bearings I'm still stuck with

Issue: Cold boot / blank LCD / one red flash of the LED on the Melzi pcb......

Starting to think it would be better to leave it powered up 24/7 but I don't have a power meter to tell me how much juice the P802M sucks up in idle mode all with everything off. Can anyone out there tell us how much power the P802M sucks from the wall?

Possible cause: Dead / corrupt board.

Possible fix / solution: Checked the wiring and it's all good. Maybe re-flash the firmware? Haven't got a clue how though.

Edited 2 time(s). Last edit at 01/15/2016 01:56PM by Gatchaman.

|

Re: P802M Prusa i3 Unofficial Support Thread January 15, 2016 07:48AM |

Registered: 8 years ago Posts: 5 |

@Glimpse

If you don't have a perfectly leveled bed you can wet the painters tape with isopropanol, and the prints will stick very well. The only problem is that they can be hard to remove if there is a large surface touching the bed. I used isopropanol in the start because I had the same problems as you, but properly leveling the bed enabled me to just print on the painters tape without isopropanol.

The filament being extruded when heated is normal, just use a 1-2 width skirt and the extra filament will stick to the bed. You could probably also use some sort of custom g-code in the start of every print that wipes the nozzle in one of the corners.

If you don't have a perfectly leveled bed you can wet the painters tape with isopropanol, and the prints will stick very well. The only problem is that they can be hard to remove if there is a large surface touching the bed. I used isopropanol in the start because I had the same problems as you, but properly leveling the bed enabled me to just print on the painters tape without isopropanol.

The filament being extruded when heated is normal, just use a 1-2 width skirt and the extra filament will stick to the bed. You could probably also use some sort of custom g-code in the start of every print that wipes the nozzle in one of the corners.

|

Re: P802M Prusa i3 Unofficial Support Thread January 15, 2016 07:54AM |

Registered: 8 years ago Posts: 35 |

Quote

Brenne

@Glimpse

If you don't have a perfectly leveled bed you can wet the painters tape with isopropanol, and the prints will stick very well. The only problem is that they can be hard to remove if there is a large surface touching the bed. I used isopropanol in the start because I had the same problems as you, but properly leveling the bed enabled me to just print on the painters tape without isopropanol.

The filament being extruded when heated is normal, just use a 1-2 width skirt and the extra filament will stick to the bed. You could probably also use some sort of custom g-code in the start of every print that wipes the nozzle in one of the corners.

Thanks a lot!

Isopropanol work on 3m blue tape?

I notice that in cura i have the "initial Layer thickness" the same high of all other layers; maybe i have to double it?

|

Re: P802M Prusa i3 Unofficial Support Thread January 15, 2016 08:01AM |

Registered: 8 years ago Posts: 5 |

@Glimpse79

The isopropanol worked for me on both the included blue tape and the one I bought at a general store. I haven't tried to mess with layer thickness settings yet though. I just wet a cloth with isopropanol and rub it on the tape, but I must warn you that some of the prints gets really hard to remove.

The isopropanol worked for me on both the included blue tape and the one I bought at a general store. I haven't tried to mess with layer thickness settings yet though. I just wet a cloth with isopropanol and rub it on the tape, but I must warn you that some of the prints gets really hard to remove.

|

Re: P802M Prusa i3 Unofficial Support Thread January 15, 2016 08:23AM |

Registered: 8 years ago Posts: 35 |

Quote

Brenne

@Glimpse79

The isopropanol worked for me on both the included blue tape and the one I bought at a general store. I haven't tried to mess with layer thickness settings yet though. I just wet a cloth with isopropanol and rub it on the tape, but I must warn you that some of the prints gets really hard to remove.

Do you use heated bed? I read that with blue tape it's better to not use; it's correct?

Sorry, only registered users may post in this forum.