P802M Prusa i3 Unofficial Support Thread

Posted by gwc2795

|

Re: P802M Prusa i3 Unofficial Support Thread February 14, 2016 04:25PM |

Registered: 8 years ago Posts: 4 |

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 03:15AM |

Registered: 8 years ago Posts: 23 |

Quote

Bobyni

If anyone have made an enclosure for the Printer,

you should consider to print this out and add on to your printer!!!

I find it to be a must have thing!!

[www.thingiverse.com]

Cheers

And if you want upgrade your stability after assembly, you can use it too:

Thingiverse.com

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 03:21AM |

Registered: 8 years ago Posts: 30 |

Quote

Robkadett

And if you want upgrade your stability after assembly, you can use it too:

Thingiverse.com

Did you try them yourself? Did you notice any changes in your print?

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 03:46AM |

Registered: 8 years ago Posts: 23 |

Quote

ErikL

Quote

Robkadett

And if you want upgrade your stability after assembly, you can use it too:

Thingiverse.com

Did you try them yourself? Did you notice any changes in your print?

Yes, i use it. today or tomorow i upload photo to thingiverse.

I mounted my printer to 50 x 50 cm kitchen countertop (work desktop, i dont know it name), and when X moving fast than the printer not so much dancing.

without it my printer can move left or right 1-2mm. and i think now better my print result a litle bit.

my next precision upgrade will be bowden extruding. it would be better becouse loose lot of weight without NEMA motor weight moving.

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 06:59AM |

Registered: 8 years ago Posts: 23 |

Hi dears

i started to print ABS. i know its difficult.

i want to increase my temp to over 260 C, but i couldn't. whwere can i off the temp limiting ?

becouse of. if set temperature forexample 250 C it will be just 240-242 C. Every temperature settings work -10 celsius.

i do not know why?

i made PID tuning. and work my heater fast. but under 10 C every set.

why?

i started to print ABS. i know its difficult.

i want to increase my temp to over 260 C, but i couldn't. whwere can i off the temp limiting ?

becouse of. if set temperature forexample 250 C it will be just 240-242 C. Every temperature settings work -10 celsius.

i do not know why?

i made PID tuning. and work my heater fast. but under 10 C every set.

why?

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 07:10AM |

Registered: 8 years ago Posts: 91 |

Over 260C? Do you use a full metal extruder system?

Otherwise you will shortly melt/shrink the PTFE tube inside your throat!

This is the answer, why there is a temp limit given in the firmware.

[reprap.org]

Edited 1 time(s). Last edit at 02/15/2016 07:11AM by madias.

Otherwise you will shortly melt/shrink the PTFE tube inside your throat!

This is the answer, why there is a temp limit given in the firmware.

[reprap.org]

Edited 1 time(s). Last edit at 02/15/2016 07:11AM by madias.

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 07:17AM |

Registered: 8 years ago Posts: 91 |

...and about the temperature difference: Most of the china prusa i3 use the 100K ohm NTC 3950 Thermistors and nobody of the makers has done a good work to wrote down a exact temperature table, so they are about minimum 10 degrees off in high temperatures. (So did I grilled my teflon tube)

Best way is to compile your own firmware with this settings in the configuration.h:

#define NUM_TEMPS_USERTHERMISTOR0 50

#define USER_THERMISTORTABLE0 {

{1*4,8*938}, {31*4,8*314}, {41*4,8*290}, {51*4,8*272}, {61*4,8*258}, {71*4,8*247}, {81*4,8*237}, {91*4,8*229}, {101*4,8*221}, {111*4,8*215}, {121*4,8*209}, {131*4,8*204}, {141*4,8*199}, {151*4,8*195}, {161*4,8*190}, {171*4,8*187}, {181*4,8*183}, {191*4,8*179}, {201*4,8*176}, {221*4,8*170}, {241*4,8*165}, {261*4,8*160}, {281*4,8*155}, {301*4,8*150}, {331*4,8*144}, {361*4,8*139}, {391*4,8*133}, {421*4,8*128}, {451*4,8*123}, {491*4,8*117}, {531*4,8*111}, {571*4,8*105}, {611*4,8*100}, {641*4,8*95}, {681*4,8*90}, {711*4,8*85}, {751*4,8*79}, {791*4,8*72}, {811*4,8*69}, {831*4,8*65}, {871*4,8*57}, {881*4,8*55}, {901*4,8*51}, {921*4,8*45}, {941*4,8*39}, {971*4,8*28}, {981*4,8*23}, {991*4,8*17}, {1001*4,8*9}, {1021*4,8*-27}}

this is the calculated table for the 100k NTC 3950, you have to insert it manually in firmware, there is no way to use it in the online calculator (otherwise somebody wrote it into the right syntax)

Edit: Another table for the NTC 3950 (slightly different):

[www.pibot.com]

Edited 2 time(s). Last edit at 02/15/2016 07:26AM by madias.

Best way is to compile your own firmware with this settings in the configuration.h:

#define NUM_TEMPS_USERTHERMISTOR0 50

#define USER_THERMISTORTABLE0 {

{1*4,8*938}, {31*4,8*314}, {41*4,8*290}, {51*4,8*272}, {61*4,8*258}, {71*4,8*247}, {81*4,8*237}, {91*4,8*229}, {101*4,8*221}, {111*4,8*215}, {121*4,8*209}, {131*4,8*204}, {141*4,8*199}, {151*4,8*195}, {161*4,8*190}, {171*4,8*187}, {181*4,8*183}, {191*4,8*179}, {201*4,8*176}, {221*4,8*170}, {241*4,8*165}, {261*4,8*160}, {281*4,8*155}, {301*4,8*150}, {331*4,8*144}, {361*4,8*139}, {391*4,8*133}, {421*4,8*128}, {451*4,8*123}, {491*4,8*117}, {531*4,8*111}, {571*4,8*105}, {611*4,8*100}, {641*4,8*95}, {681*4,8*90}, {711*4,8*85}, {751*4,8*79}, {791*4,8*72}, {811*4,8*69}, {831*4,8*65}, {871*4,8*57}, {881*4,8*55}, {901*4,8*51}, {921*4,8*45}, {941*4,8*39}, {971*4,8*28}, {981*4,8*23}, {991*4,8*17}, {1001*4,8*9}, {1021*4,8*-27}}

this is the calculated table for the 100k NTC 3950, you have to insert it manually in firmware, there is no way to use it in the online calculator (otherwise somebody wrote it into the right syntax)

Edit: Another table for the NTC 3950 (slightly different):

[www.pibot.com]

Edited 2 time(s). Last edit at 02/15/2016 07:26AM by madias.

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 07:38AM |

Registered: 8 years ago Posts: 91 |

@JimsFlight: Can you confirm, that your thermistor values are all right? You use the standard 100k Epoc B575xxxxx in the configuration.h, if the printer (as above written) uses the 3950 NTC's this configuration is very off in the high temperature region.Quote

JimsFlight

Not saying this is a definitive guide or anything, there’s a wealth of information in previous posts, this is just what worked for me. Here is a link to a google drive with everything I used in it. Thanks again to everyone on the forum for helping me out.

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 08:04AM |

Registered: 8 years ago Posts: 14 |

No worries. I'll be back at the factory where the printer is in a few days and I will have a look then. The parts of the code about the thermistors I left as is, so there's a fair chance they're not correct. I had noticed some strange behaviour with the prints, they didn't seem to be sticking down right. I'm printing with PLA, but I thought it might be an under extrusion issue. Perhaps I can take a photo for you and upload it, because I don't really know what I'm looking for. Is the thermistor in the aluminium block where the extrusion nozzle is?

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 08:10AM |

Registered: 8 years ago Posts: 23 |

ohh

thank you Madias!

i think it is more dificcult what i mind.

i will disassemble my tube and i will watch it., i don't no what kind i have. but i think in dont have full metal. I think MK8 extruder don't have.

i think i must try other layer hight etc too.

Edited 1 time(s). Last edit at 02/15/2016 08:46AM by Robkadett.

thank you Madias!

i think it is more dificcult what i mind.

i will disassemble my tube and i will watch it., i don't no what kind i have. but i think in dont have full metal. I think MK8 extruder don't have.

i think i must try other layer hight etc too.

Edited 1 time(s). Last edit at 02/15/2016 08:46AM by Robkadett.

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 09:05AM |

Registered: 8 years ago Posts: 91 |

Ok, it seems it wasn't wrong here taking about the thermistor and values

Keep in mind Robkadett: If you experience problems while extruding (clogging...) then your teflon tube shrinked a bit. You can easily solve this, just cut a few millimeters off. There is an easy test: Take out the teflon tube and push the filament through. If you need force, than it's shrinked..

BTW: Cause I fired up my melzi board, I have started a complete conversation to RAMPS 1.4. The first testings are good, not mentioned a (real) problem since that. The only thing I regcognized: The (in many threads and forums advertised) DRV8825 aren't a good choice! So if somebody will also change, than take the A4988 or the TRV(???) Main reason: The big benefit (32 steps instead of 16) of the DRV's isn't possible with an AVR -> too slow. So the DRV are only noisy like hell (there are some hacks to solve it, but I took the A4988 to rest in peace).

Here is a cool article about the DRV8825: [plus.google.com]

Edited 1 time(s). Last edit at 02/15/2016 09:19AM by madias.

Keep in mind Robkadett: If you experience problems while extruding (clogging...) then your teflon tube shrinked a bit. You can easily solve this, just cut a few millimeters off. There is an easy test: Take out the teflon tube and push the filament through. If you need force, than it's shrinked..

BTW: Cause I fired up my melzi board, I have started a complete conversation to RAMPS 1.4. The first testings are good, not mentioned a (real) problem since that. The only thing I regcognized: The (in many threads and forums advertised) DRV8825 aren't a good choice! So if somebody will also change, than take the A4988 or the TRV(???) Main reason: The big benefit (32 steps instead of 16) of the DRV's isn't possible with an AVR -> too slow. So the DRV are only noisy like hell (there are some hacks to solve it, but I took the A4988 to rest in peace).

Here is a cool article about the DRV8825: [plus.google.com]

Edited 1 time(s). Last edit at 02/15/2016 09:19AM by madias.

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 09:34AM |

Registered: 8 years ago Posts: 23 |

Yes i think it wasn't wrong taking about thermistors.  but it may be just me

but it may be just me

Im understand your advice. very good! thank you very much.

im at now learning more and more details of all 3d printing and it's mechanical parts.

what the best advice to unplug/remove/change the filament. I usually remove the filament when it almost "luiquid" (=hot head), becouse if i cut it and extruding it will left the gear and stop drive of course

what do you advice to me , how do you make it? (you can laught, its very beginner question i know , but maybe i do it wrong

, but maybe i do it wrong  )

)

but it may be just me

but it may be just me

Im understand your advice. very good! thank you very much.

im at now learning more and more details of all 3d printing and it's mechanical parts.

what the best advice to unplug/remove/change the filament. I usually remove the filament when it almost "luiquid" (=hot head), becouse if i cut it and extruding it will left the gear and stop drive of course

what do you advice to me , how do you make it? (you can laught, its very beginner question i know

, but maybe i do it wrong

, but maybe i do it wrong  )

)

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 10:06AM |

Registered: 8 years ago Posts: 91 |

This is not a silly question

I'didn't found the best solution removing the filament either, but I use the technique:

1. Heat extruder depends on your filament (180 PLA....)

2. push the extruder spring to release the gear (do this through all steps!)

3. push the filament a bit into noozle for a second and then VERY FAST

4. pull out the whole filament in one piece.

This all depends much on your extruder system, I have one of thoose ´"MK8" clones build out of metal. Pretty shitty thing, because it costs me nervs to pull the filament INTO the extruder.

This is my one: [www.aliexpress.com]

I'didn't found the best solution removing the filament either, but I use the technique:

1. Heat extruder depends on your filament (180 PLA....)

2. push the extruder spring to release the gear (do this through all steps!)

3. push the filament a bit into noozle for a second and then VERY FAST

4. pull out the whole filament in one piece.

This all depends much on your extruder system, I have one of thoose ´"MK8" clones build out of metal. Pretty shitty thing, because it costs me nervs to pull the filament INTO the extruder.

This is my one: [www.aliexpress.com]

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 10:17AM |

Registered: 8 years ago Posts: 23 |

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 10:44AM |

Registered: 8 years ago Posts: 22 |

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 11:51AM |

Registered: 8 years ago Posts: 91 |

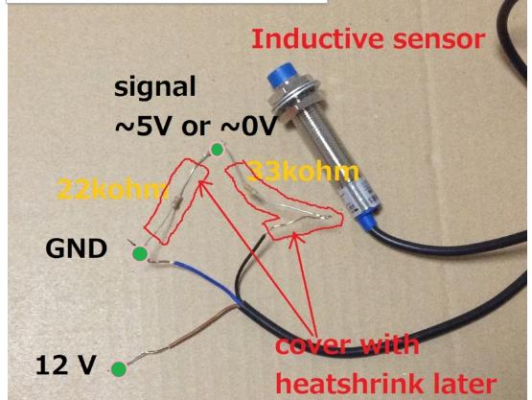

com = ground, right.

Nobody knows about the silly colors of these sensors (normally GND = black)

So here is the color table:

blue: GND or COM

brown: +12V (VCC)

black: Signal (12V Output! Use resistor dividers!)

So in my example the two resistors are lowering the voltage from 12V to 4V otherwise the MELZI board could be damaged. (4V is written as "high" state, everything above 3.3V is safe as a "high" value)

There is a better circuit I found, scroll down to last post (picture): [forum.arduino.cc]

Edited 2 time(s). Last edit at 02/15/2016 11:56AM by madias.

Nobody knows about the silly colors of these sensors (normally GND = black)

So here is the color table:

blue: GND or COM

brown: +12V (VCC)

black: Signal (12V Output! Use resistor dividers!)

So in my example the two resistors are lowering the voltage from 12V to 4V otherwise the MELZI board could be damaged. (4V is written as "high" state, everything above 3.3V is safe as a "high" value)

There is a better circuit I found, scroll down to last post (picture): [forum.arduino.cc]

Edited 2 time(s). Last edit at 02/15/2016 11:56AM by madias.

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 08:10PM |

Registered: 8 years ago Posts: 9 |

Test print for comparison - using PLA that came with printer. Looking into updating to this extruder.

|

Re: P802M Prusa i3 Unofficial Support Thread February 15, 2016 09:23PM |

Registered: 8 years ago Posts: 9 |

Hi All

This is the compiled firmware and update tool which was sent with my printer:

Marlin compiled FW and updatetool for my P802N

This is the source code FW requested from Zonestar:

Marlin Sourcecode fw for P802N

Regards

Ed

This is the compiled firmware and update tool which was sent with my printer:

Marlin compiled FW and updatetool for my P802N

This is the source code FW requested from Zonestar:

Marlin Sourcecode fw for P802N

Regards

Ed

|

Re: P802M Prusa i3 Unofficial Support Thread February 19, 2016 05:38AM |

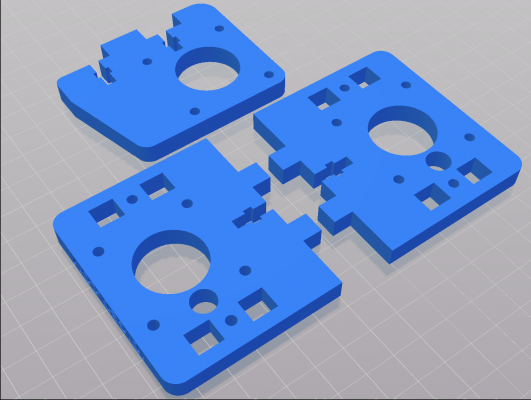

Registered: 8 years ago Posts: 22 |

if your intrested

to much belt tension made my motor mount akmust breake (see picture - red part)

so i re-desing it a bit to make it stronger

also made the z-endstop adjustable screw better and eazyer to adjust

printed in PLA, 30% infill

[www.thingiverse.com]

to much belt tension made my motor mount akmust breake (see picture - red part)

so i re-desing it a bit to make it stronger

also made the z-endstop adjustable screw better and eazyer to adjust

printed in PLA, 30% infill

[www.thingiverse.com]

|

Re: P802M Prusa i3 Unofficial Support Thread February 21, 2016 01:28PM |

Registered: 8 years ago Posts: 10 |

I'm after some help after printing in PLA I've come to use the printer again and it wont feed the PLA out of the extruder in program. When I feed it manually from the menu in the LCD it will feed no problem leaving a mess on my desk but wont on previously printed programs. Please help

The reset button on the board works a treat. Don't know why I didn't try that before

Edited 1 time(s). Last edit at 02/22/2016 02:07PM by Scottjar.

The reset button on the board works a treat. Don't know why I didn't try that before

Edited 1 time(s). Last edit at 02/22/2016 02:07PM by Scottjar.

|

Re: P802M Prusa i3 Unofficial Support Thread February 22, 2016 07:17PM |

Registered: 8 years ago Posts: 43 |

Never got feedback from you for this issue [forums.reprap.org]Quote

Scottjar

I'm after some help after printing in PLA I've come to use the printer again and it wont feed the PLA out of the extruder in program. When I feed it manually from the menu in the LCD it will feed no problem leaving a mess on my desk but wont on previously printed programs. Please help

The reset button on the board works a treat. Don't know why I didn't try that before

So what fixed your printer? It might help somebody else if you post your fix.

And to everyone else this might not come as a complete shock but I have a horrible feeling the heat sinks on the Melzi board are stuck to the IC's using silicon glue. The stuff you use in the bathroom.

I've had to burn a bootloader as my board was just blinking and wouldn't talk to the PC which left me with, yep, a blank LCD. So I did this [reprap.org], and while I was checking I pulled off a heat sink to check the paste/glue. I found the paste it to be very very rubbery. Cleaned off the silicone glue with acetone and will sandwich some proper heatsink paste in between two spots of superglue which I'll leave to set over night.

|

Re: P802M Prusa i3 Unofficial Support Thread February 23, 2016 04:57AM |

Registered: 8 years ago Posts: 11 |

|

Re: P802M Prusa i3 Unofficial Support Thread February 23, 2016 05:22AM |

Registered: 8 years ago Posts: 91 |

Javier: Unless you won't have trouble OR you need extra features like auto levelling stay at 0.91.

Yes, you have to manually add the display for update and beware of other things you have to take care of (steps mm, your rod dimension....) because there are different models and you must have luck that a firmware here in the forum posted matches your printer to 100%

Updating the firmware is like doing it from the sketch, so if you won't have the time or knowledge, be sure what you are doing. And have a HEX update of your original firmware if anything goes wrong.

Yes, you have to manually add the display for update and beware of other things you have to take care of (steps mm, your rod dimension....) because there are different models and you must have luck that a firmware here in the forum posted matches your printer to 100%

Updating the firmware is like doing it from the sketch, so if you won't have the time or knowledge, be sure what you are doing. And have a HEX update of your original firmware if anything goes wrong.

|

Re: P802M Prusa i3 Unofficial Support Thread February 23, 2016 05:24AM |

Registered: 8 years ago Posts: 91 |

|

Re: P802M Prusa i3 Unofficial Support Thread February 23, 2016 05:27AM |

Registered: 8 years ago Posts: 11 |

|

Re: P802M Prusa i3 Unofficial Support Thread February 24, 2016 08:48AM |

Registered: 11 years ago Posts: 69 |

Not a fan of acrylic. All of my motor mounts had cracks, so needed replacements. Couldn't find any files online, so I measured and made my own. Hopefully this is helpful to others.

Thingiverse: i3 z motor and y motor mount replaces acrylic

Edited 1 time(s). Last edit at 02/24/2016 08:58AM by rtideas.

Thingiverse: i3 z motor and y motor mount replaces acrylic

Edited 1 time(s). Last edit at 02/24/2016 08:58AM by rtideas.

|

Re: P802M Prusa i3 Unofficial Support Thread February 24, 2016 09:18AM |

Registered: 8 years ago Posts: 49 |

All of the sudden my printer has start to shift on the Y axis mid print after several hours of printing. Attached is a photo of what it looks like...

It will shift in the same direction it seems every time then resume printing normally for a few layers then shift again etc etc... anyone know whats going on here?

It will shift in the same direction it seems every time then resume printing normally for a few layers then shift again etc etc... anyone know whats going on here?

|

Re: P802M Prusa i3 Unofficial Support Thread February 24, 2016 09:30AM |

Registered: 11 years ago Posts: 69 |

Seems like something might be binding. Bearings dry? Does the belt have schmutz on it? Something catching? Or possibly, stepper driver voltage--but that should show skipping early on.Quote

jnsbanman

All of the sudden my printer has start to shift on the Y axis mid print after several hours of printing. Attached is a photo of what it looks like...

It will shift in the same direction it seems every time then resume printing normally for a few layers then shift again etc etc... anyone know whats going on here?

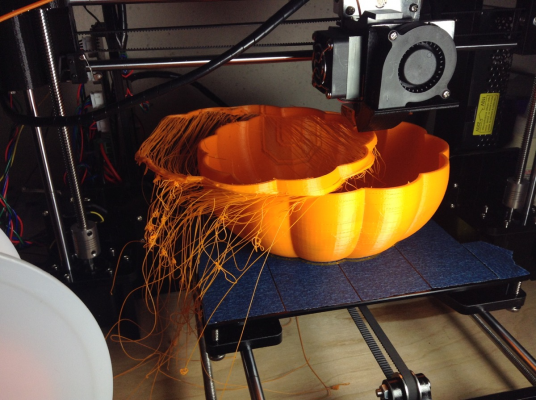

Wire bundle caught a top corner on a large print and turned my pumpkin into squash. Make sure all moving parts are free from obstructions--for the entire movement of the printer.

|

Re: P802M Prusa i3 Unofficial Support Thread February 24, 2016 09:38AM |

Registered: 8 years ago Posts: 91 |

jnsbanman: Looks like an overheating problem of the y-stepper driver if this occurs after a while of printing. (The stepper protection switches it off automatically)

At first: Check the voltage of the stepper drivers ---> [reprap.org]

Drives the bed smoothly on y-axis? Is the belt too stiff or to loose?

Edited 1 time(s). Last edit at 02/24/2016 09:41AM by madias.

At first: Check the voltage of the stepper drivers ---> [reprap.org]

Drives the bed smoothly on y-axis? Is the belt too stiff or to loose?

Edited 1 time(s). Last edit at 02/24/2016 09:41AM by madias.

|

Re: P802M Prusa i3 Unofficial Support Thread February 24, 2016 10:40AM |

Registered: 8 years ago Posts: 49 |

I had checked the voltages back when I assembled the printer in December and set them to 0.8v. But I will double check tonight.

I have not had any real issues printing until the last few days. I have not changed anything in terms of the setup. I know my belt is nice and snug as I gave it a strum to make sure it was tight when I took a pic of the failed print... maybe its too tight?

I have not had any real issues printing until the last few days. I have not changed anything in terms of the setup. I know my belt is nice and snug as I gave it a strum to make sure it was tight when I took a pic of the failed print... maybe its too tight?

Sorry, only registered users may post in this forum.