P802M Prusa i3 Unofficial Support Thread

Posted by gwc2795

|

Re: P802M Prusa i3 Unofficial Support Thread March 16, 2016 10:39AM |

Registered: 8 years ago Posts: 49 |

Hello again all..

I am getting slightly out of round holes on the Z axis. I have done the Z axis upgrade to 1 stepper/belt on my printer. The pulleys on the motor and 2 lead screws are all the same number of teeth, belt is reasonable tight. My steps per mm is set to 400 as per all the calculators. I have my Z offset at 0 but i set the nozzle to approximately 0.127mm above the bed... should that number be in the offset since the bed is 0.127mm below what it thinks 0 is? Should that be a negative number in the offset? I have never quite fully understood how the z offset works.

I dont have a picture handy but it looks like that they may be out of round by a couple layers... Its not much. I did some other poking around and dropped my Z axis acceleration to 100mm/s from 500mm/s and z axis travel acceleration to 50mm/s I think it was at 100.

I have yet to test with these new settings but does anyone have any other ideas.

Edited 3 time(s). Last edit at 03/16/2016 11:00AM by jnsbanman.

I am getting slightly out of round holes on the Z axis. I have done the Z axis upgrade to 1 stepper/belt on my printer. The pulleys on the motor and 2 lead screws are all the same number of teeth, belt is reasonable tight. My steps per mm is set to 400 as per all the calculators. I have my Z offset at 0 but i set the nozzle to approximately 0.127mm above the bed... should that number be in the offset since the bed is 0.127mm below what it thinks 0 is? Should that be a negative number in the offset? I have never quite fully understood how the z offset works.

I dont have a picture handy but it looks like that they may be out of round by a couple layers... Its not much. I did some other poking around and dropped my Z axis acceleration to 100mm/s from 500mm/s and z axis travel acceleration to 50mm/s I think it was at 100.

I have yet to test with these new settings but does anyone have any other ideas.

Edited 3 time(s). Last edit at 03/16/2016 11:00AM by jnsbanman.

|

Re: P802M Prusa i3 Unofficial Support Thread March 18, 2016 01:47AM |

Registered: 8 years ago Posts: 8 |

Quote

jnsbanman

Hello again all..

I am getting slightly out of round holes on the Z axis. I have done the Z axis upgrade to 1 stepper/belt on my printer. The pulleys on the motor and 2 lead screws are all the same number of teeth, belt is reasonable tight. My steps per mm is set to 400 as per all the calculators. I have my Z offset at 0 but i set the nozzle to approximately 0.127mm above the bed... should that number be in the offset since the bed is 0.127mm below what it thinks 0 is? Should that be a negative number in the offset? I have never quite fully understood how the z offset works.

I dont have a picture handy but it looks like that they may be out of round by a couple layers... Its not much. I did some other poking around and dropped my Z axis acceleration to 100mm/s from 500mm/s and z axis travel acceleration to 50mm/s I think it was at 100.

I have yet to test with these new settings but does anyone have any other ideas.

Just set your Z0 close as much as possible to the surface of bed, normally when start printing the nozzle will auto lift up equal to your z-layer thickness setup (example, if you set 0.1mm z-layer, then when start printing the nozzle will lift up 0.1 mm from your Z0 setup)

Edited 2 time(s). Last edit at 03/18/2016 01:50AM by minhtri.sm.

|

Re: P802M Prusa i3 Unofficial Support Thread March 25, 2016 09:01AM |

Registered: 8 years ago Posts: 152 |

Quote

jnsbanman

Hello again all..

I am getting slightly out of round holes on the Z axis. I have done the Z axis upgrade to 1 stepper/belt on my printer. The pulleys on the motor and 2 lead screws are all the same number of teeth, belt is reasonable tight. My steps per mm is set to 400 as per all the calculators. I have my Z offset at 0 but i set the nozzle to approximately 0.127mm above the bed... should that number be in the offset since the bed is 0.127mm below what it thinks 0 is? Should that be a negative number in the offset? I have never quite fully understood how the z offset works.

I dont have a picture handy but it looks like that they may be out of round by a couple layers... Its not much. I did some other poking around and dropped my Z axis acceleration to 100mm/s from 500mm/s and z axis travel acceleration to 50mm/s I think it was at 100.

I have yet to test with these new settings but does anyone have any other ideas.

Either your X and/or Y axis has the incorrect steps set in the printer firmware. Print the YACO file that is attached. It should measure 60mm in all directions. Let us know the results. You can google yaco and find a lot of information on setting the steps. I also attached the instructions for the YACO calibration

|

Anonymous User

Re: P802M Prusa i3 Unofficial Support Thread March 25, 2016 09:35AM |

Just came across this thread. What amazes me if why people come with such complex solution for simple problems ????

You don't need all this intricate collection of idlers one wrongly set.

And better use Al pulleys, they are cheap and better than printed one !

Also, no auto bed level, useless on a properly built cartesian machine and likely to introduce problems as the Z axis will have to move up and down during one layer print instead of just up once for each layer. Therefore, with ABL the leadscrew/nut blacklash will matter.

I got a Geetech Al, see here how it can be done. Geetech Al modifications

Has to be adapted as the Prusa is a bit different and the Acylic frame upper is less rigid

Edited 2 time(s). Last edit at 03/25/2016 09:41AM by MKSA.

You don't need all this intricate collection of idlers one wrongly set.

And better use Al pulleys, they are cheap and better than printed one !

Also, no auto bed level, useless on a properly built cartesian machine and likely to introduce problems as the Z axis will have to move up and down during one layer print instead of just up once for each layer. Therefore, with ABL the leadscrew/nut blacklash will matter.

I got a Geetech Al, see here how it can be done. Geetech Al modifications

Has to be adapted as the Prusa is a bit different and the Acylic frame upper is less rigid

Edited 2 time(s). Last edit at 03/25/2016 09:41AM by MKSA.

|

Re: P802M Prusa i3 Unofficial Support Thread March 28, 2016 04:18AM |

Registered: 8 years ago Posts: 3 |

|

Re: P802M Prusa i3 Unofficial Support Thread April 02, 2016 03:32PM |

Registered: 8 years ago Posts: 12 |

I have Prusa i3 P802M 7th generation from Zonestar (transparent acrylic)

It was working fine.

1 month ago, printer started to behave strangely.

For few minutes it was printing fine. Then an offset was introduced on X and y axis (see attached photo).

Printing from USB was giving me the following error logs:

22:41:58.737 : Printing layer 1 of 500

22:42:19.701 : X:-45.00 Y:-5.00 Z:0.00 E:0.00

22:47:58.172 : Resend:431

22:48:02.603 : Error:expected line 60910 got 494

22:48:02.603 : Resend:494

22:48:05.713 : Warning: Seems like we missed a ok, got a wait - continue sending.

22:48:05.733 : Error:expected line 494 got 500

22:48:05.733 : Resend:494

22:48:31.896 : Error:Wrong checksum

22:48:31.896 : Resend:843

22:48:31.926 : Error:Wrong checksum

22:48:31.926 : Resend:843

22:48:34.947 : Warning: Seems like we missed a ok, got a wait - continue sending.

22:48:34.967 : Error:expected line 843 got 849

22:48:34.967 : Resend:843

22:48:35.607 : Error:Wrong checksum

22:48:35.607 : Resend:871

22:48:35.627 : Resend:871

22:48:35.647 : Resend:871

22:48:38.707 : Warning: Seems like we missed a ok, got a wait - continue sending.

22:48:38.717 : Resend:871

22:48:38.737 : Resend:871

another example :

22:38:45.632 : Printing layer 1 of 42

22:38:58.074 : X:-45.00 Y:-5.00 Z:0.00 E:0.00

22:41:49.019 : Printing layer 2 of 42

22:42:32.189 : Printing layer 3 of 42

22:43:08.927 : Printing layer 4 of 42

22:43:42.473 : Printing layer 5 of 42

22:44:14.083 : Printing layer 6 of 42

22:44:45.459 : Printing layer 7 of 42

22:45:03.543 : Printing layer 8 of 42

22:45:21.236 : Printing layer 9 of 42

22:45:38.901 : Printing layer 10 of 42

22:45:57.246 : Printing layer 11 of 42

22:46:15.108 : Printing layer 12 of 42

22:46:33.232 : Printing layer 13 of 42

22:46:51.095 : Printing layer 14 of 42

22:46:52.695 : Error:Wrong checksum

22:46:52.695 : Resend:5593

22:47:09.308 : Printing layer 15 of 42

22:47:27.281 : Printing layer 16 of 42

22:47:45.415 : Printing layer 17 of 42

22:48:03.217 : Printing layer 18 of 42

22:48:10.088 : Error:Wrong checksum

22:48:10.088 : Resend:6841

22:48:21.371 : Printing layer 19 of 42

22:48:39.214 : Printing layer 20 of 42

22:49:05.068 : Printing layer 21 of 42

22:49:31.152 : Printing layer 22 of 42

22:49:57.555 : Printing layer 23 of 42

22:50:23.505 : Printing layer 24 of 42

22:50:49.241 : Printing layer 25 of 42

22:51:22.396 : Printing layer 26 of 42

22:51:50.945 : Printing layer 27 of 42

22:52:07.826 : Resend:10926

22:52:19.759 : Printing layer 28 of 42

22:52:49.032 : Printing layer 29 of 42

22:52:53.732 : Error:Wrong checksum

22:52:53.732 : Resend:11719

22:53:18.318 : Printing layer 30 of 42

22:53:47.595 : Printing layer 31 of 42

22:54:13.983 : Error:Wrong checksum

22:54:13.983 : Resend:13512

22:54:14.884 : Printing layer 32 of 42

22:54:18.996 : 86

22:54:31.939 : Printing layer 33 of 42

22:54:39.251 : No start signal detected - forcing start

Then steppers stops but extruder and heatbed temperatures stay at their defined limit. In 3 cases the temperature increased well beyond the defined limit.

I've noticed that the X, Y, Z steppers drivers on the Melzi board were very hot.

Printing from SD card is not better.

I've contacted the Aliexpress seller. He was cooperative but unfortunately only providing basic debugging eg. well aligining the rods, checking the connectors on the Melzi board. playing with the potentiometers ... I've spent 3 weeks with him without success.

I've asked him to provide the recommended firmware. He provided me with a link, I downloaded it (version 1.6 ; repetier 0.91).

After burning this firmaware for the first time, nothing changed, same issues. After burning this firmware for the second time, the X, Y and Z axis move only in one direction (right) until they hit the max.

I've connected the X axis motor to the extruder socket, using repetier-host I was able to move it left and right.

So the motors are fine.

I've searched on internet. Many users pointed out to the Configuration.h settings of endstop section. The problem is that I have only a .HEX. I know how to program Arduinos. But which sketch is compatible with the P802M 7th generation ? what would be the recommended settings of endstops for this printer ? What about the eemprom configuration ?

I've also burned a 0.92.8 firmaware .HEX compatible with LCD having 5 buttons, still the X, Y and Z axis move only to the right.

My gut feeling is that the X, Y, Z stepper drivers are out of order.

Before ordering a new Melzi board, I would be grateful to have you expert eye on this issue. Do you think that it is a firmware issue ?

BTW, would you recommend a Melzi or Ramps board for this P802M 7th generation ?

Is there is a Ramps compatible firmware that works with Repetier-host (slic3r or cura) ?

It was working fine.

1 month ago, printer started to behave strangely.

For few minutes it was printing fine. Then an offset was introduced on X and y axis (see attached photo).

Printing from USB was giving me the following error logs:

22:41:58.737 : Printing layer 1 of 500

22:42:19.701 : X:-45.00 Y:-5.00 Z:0.00 E:0.00

22:47:58.172 : Resend:431

22:48:02.603 : Error:expected line 60910 got 494

22:48:02.603 : Resend:494

22:48:05.713 : Warning: Seems like we missed a ok, got a wait - continue sending.

22:48:05.733 : Error:expected line 494 got 500

22:48:05.733 : Resend:494

22:48:31.896 : Error:Wrong checksum

22:48:31.896 : Resend:843

22:48:31.926 : Error:Wrong checksum

22:48:31.926 : Resend:843

22:48:34.947 : Warning: Seems like we missed a ok, got a wait - continue sending.

22:48:34.967 : Error:expected line 843 got 849

22:48:34.967 : Resend:843

22:48:35.607 : Error:Wrong checksum

22:48:35.607 : Resend:871

22:48:35.627 : Resend:871

22:48:35.647 : Resend:871

22:48:38.707 : Warning: Seems like we missed a ok, got a wait - continue sending.

22:48:38.717 : Resend:871

22:48:38.737 : Resend:871

another example :

22:38:45.632 : Printing layer 1 of 42

22:38:58.074 : X:-45.00 Y:-5.00 Z:0.00 E:0.00

22:41:49.019 : Printing layer 2 of 42

22:42:32.189 : Printing layer 3 of 42

22:43:08.927 : Printing layer 4 of 42

22:43:42.473 : Printing layer 5 of 42

22:44:14.083 : Printing layer 6 of 42

22:44:45.459 : Printing layer 7 of 42

22:45:03.543 : Printing layer 8 of 42

22:45:21.236 : Printing layer 9 of 42

22:45:38.901 : Printing layer 10 of 42

22:45:57.246 : Printing layer 11 of 42

22:46:15.108 : Printing layer 12 of 42

22:46:33.232 : Printing layer 13 of 42

22:46:51.095 : Printing layer 14 of 42

22:46:52.695 : Error:Wrong checksum

22:46:52.695 : Resend:5593

22:47:09.308 : Printing layer 15 of 42

22:47:27.281 : Printing layer 16 of 42

22:47:45.415 : Printing layer 17 of 42

22:48:03.217 : Printing layer 18 of 42

22:48:10.088 : Error:Wrong checksum

22:48:10.088 : Resend:6841

22:48:21.371 : Printing layer 19 of 42

22:48:39.214 : Printing layer 20 of 42

22:49:05.068 : Printing layer 21 of 42

22:49:31.152 : Printing layer 22 of 42

22:49:57.555 : Printing layer 23 of 42

22:50:23.505 : Printing layer 24 of 42

22:50:49.241 : Printing layer 25 of 42

22:51:22.396 : Printing layer 26 of 42

22:51:50.945 : Printing layer 27 of 42

22:52:07.826 : Resend:10926

22:52:19.759 : Printing layer 28 of 42

22:52:49.032 : Printing layer 29 of 42

22:52:53.732 : Error:Wrong checksum

22:52:53.732 : Resend:11719

22:53:18.318 : Printing layer 30 of 42

22:53:47.595 : Printing layer 31 of 42

22:54:13.983 : Error:Wrong checksum

22:54:13.983 : Resend:13512

22:54:14.884 : Printing layer 32 of 42

22:54:18.996 : 86

22:54:31.939 : Printing layer 33 of 42

22:54:39.251 : No start signal detected - forcing start

Then steppers stops but extruder and heatbed temperatures stay at their defined limit. In 3 cases the temperature increased well beyond the defined limit.

I've noticed that the X, Y, Z steppers drivers on the Melzi board were very hot.

Printing from SD card is not better.

I've contacted the Aliexpress seller. He was cooperative but unfortunately only providing basic debugging eg. well aligining the rods, checking the connectors on the Melzi board. playing with the potentiometers ... I've spent 3 weeks with him without success.

I've asked him to provide the recommended firmware. He provided me with a link, I downloaded it (version 1.6 ; repetier 0.91).

After burning this firmaware for the first time, nothing changed, same issues. After burning this firmware for the second time, the X, Y and Z axis move only in one direction (right) until they hit the max.

I've connected the X axis motor to the extruder socket, using repetier-host I was able to move it left and right.

So the motors are fine.

I've searched on internet. Many users pointed out to the Configuration.h settings of endstop section. The problem is that I have only a .HEX. I know how to program Arduinos. But which sketch is compatible with the P802M 7th generation ? what would be the recommended settings of endstops for this printer ? What about the eemprom configuration ?

I've also burned a 0.92.8 firmaware .HEX compatible with LCD having 5 buttons, still the X, Y and Z axis move only to the right.

My gut feeling is that the X, Y, Z stepper drivers are out of order.

Before ordering a new Melzi board, I would be grateful to have you expert eye on this issue. Do you think that it is a firmware issue ?

BTW, would you recommend a Melzi or Ramps board for this P802M 7th generation ?

Is there is a Ramps compatible firmware that works with Repetier-host (slic3r or cura) ?

|

Re: P802M Prusa i3 Unofficial Support Thread April 03, 2016 07:51AM |

Registered: 8 years ago Posts: 8 |

Check your wire plug into the right place first, reinstall slicer program with default setting and default print config.

This is my config for repetier 0.92.8 (running good with my zonestar 3d printer) [dl.dropboxusercontent.com]

By this link, you must install Sanguino for Arduino IDE by this link [lauszus.github.io] and have a USBasp as programmer to burn the right bootloader for Zonestar Melzi board or you can only flash firmware with at1284p 8MHz which is not right and will cause baudrate problem (this melzi board is at1284p 16 MHz)

1. Make sure your computer have install driver for USBasp - [www.fischl.de] and Melzi board driver

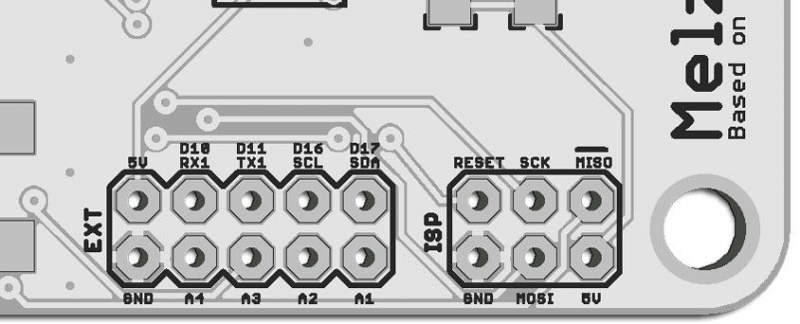

2. Check USPasp pin out and connect it to Melzi ISP right pin, connect USBasp usb head to your computer

3. Connect Melzi board to your computer by USB cable (power supply)

4. Open Arduino IDE, check

- Board: Sanguino,

- Processor: ATmega 1284 or ATmega 1284p 16 Mhz,

- Port: .... ,

- Programmer: USBasp

- Then press Burn Bootloader and pray for miracle

- After flash right Bootloader, you can flash new firmware freely on Zonestar Melzi as ATmega 1284p 16 MHz by Arduino IDE

By this link, which i have compile above firmware to .hex file and following zonestar guide to flash by avrdude [dl.dropboxusercontent.com]

p/s: Im choose baudrate 250000

This is my config for repetier 0.92.8 (running good with my zonestar 3d printer) [dl.dropboxusercontent.com]

By this link, you must install Sanguino for Arduino IDE by this link [lauszus.github.io] and have a USBasp as programmer to burn the right bootloader for Zonestar Melzi board or you can only flash firmware with at1284p 8MHz which is not right and will cause baudrate problem (this melzi board is at1284p 16 MHz)

1. Make sure your computer have install driver for USBasp - [www.fischl.de] and Melzi board driver

2. Check USPasp pin out and connect it to Melzi ISP right pin, connect USBasp usb head to your computer

3. Connect Melzi board to your computer by USB cable (power supply)

4. Open Arduino IDE, check

- Board: Sanguino,

- Processor: ATmega 1284 or ATmega 1284p 16 Mhz,

- Port: .... ,

- Programmer: USBasp

- Then press Burn Bootloader and pray for miracle

- After flash right Bootloader, you can flash new firmware freely on Zonestar Melzi as ATmega 1284p 16 MHz by Arduino IDE

By this link, which i have compile above firmware to .hex file and following zonestar guide to flash by avrdude [dl.dropboxusercontent.com]

p/s: Im choose baudrate 250000

|

Re: P802M Prusa i3 Unofficial Support Thread April 04, 2016 06:10PM |

Registered: 8 years ago Posts: 12 |

Thanks minhtri for your help

My arduino IDE is 1.5.8.1. I've configured it to support Sanguino 1284P 16MHz. Bootloader is OK.

I've uploaded to Melzi board your 0.92.8 HEX, same issue : X, Y, Z axis move in one direction only.

I've played with Configuration.h as follows and uploaded the corresponding .HEX to Melzi board:

#define ENDSTOP_PULLUP_X_MIN true

#define ENDSTOP_X_MIN_INVERTING false

#define MIN_HARDWARE_ENDSTOP_X true

#define ENDSTOP_PULLUP_Y_MIN true

#define ENDSTOP_Y_MIN_INVERTING false

#define MIN_HARDWARE_ENDSTOP_Y true

#define ENDSTOP_PULLUP_Z_MIN true

#define ENDSTOP_Z_MIN_INVERTING false

#define MIN_HARDWARE_ENDSTOP_Z true

#define ENDSTOP_PULLUP_X_MAX false

#define ENDSTOP_X_MAX_INVERTING false

#define MAX_HARDWARE_ENDSTOP_X false

#define ENDSTOP_PULLUP_Y_MAX false

#define ENDSTOP_Y_MAX_INVERTING false

#define MAX_HARDWARE_ENDSTOP_Y false

#define ENDSTOP_PULLUP_Z_MAX false

#define ENDSTOP_Z_MAX_INVERTING false

#define MAX_HARDWARE_ENDSTOP_Z false

#define max_software_endstop_r true

#define min_software_endstop_x false

#define min_software_endstop_y false

#define min_software_endstop_z false

#define max_software_endstop_x true

#define max_software_endstop_y true

#define max_software_endstop_z true

#define ENDSTOP_X_BACK_MOVE 5

#define ENDSTOP_Y_BACK_MOVE 5

#define ENDSTOP_Z_BACK_MOVE 2

#define ENDSTOP_X_RETEST_REDUCTION_FACTOR 3

#define ENDSTOP_Y_RETEST_REDUCTION_FACTOR 3

#define ENDSTOP_Z_RETEST_REDUCTION_FACTOR 3

#define ENDSTOP_X_BACK_ON_HOME 1

#define ENDSTOP_Y_BACK_ON_HOME 1

#define ENDSTOP_Z_BACK_ON_HOME 0

#define ALWAYS_CHECK_ENDSTOPS 1

now X axis moves always to the right. Activating manually the X end switch doesn't stop X axis from moving

Y axis moved to the right and the left. Homing Y axis: doesn't stop when hitting Y end stop, have to make an emergency stop

Z axis moves up and down. Homing Z axis: doesn't stop when hitting Z end stop, have to make an emergency stop

I've tested with a multimeter the end stops, they work.

I've connect the connector of X axis in the place of Y axis on the Melzi board, X axis was able to move in both directions. So X axis motor is working fine.

So there is a progress : Y and Z axis moving in both directions.

Buy why the X, Y and Z end stops seem to be ignored ?

Why the X axis still doesn't move in both directions ?

What would be the correct settings of end stops in Configuration.h ?

Does the eeprom .EEP need to be uploaded also to Melzi board

My arduino IDE is 1.5.8.1. I've configured it to support Sanguino 1284P 16MHz. Bootloader is OK.

I've uploaded to Melzi board your 0.92.8 HEX, same issue : X, Y, Z axis move in one direction only.

I've played with Configuration.h as follows and uploaded the corresponding .HEX to Melzi board:

#define ENDSTOP_PULLUP_X_MIN true

#define ENDSTOP_X_MIN_INVERTING false

#define MIN_HARDWARE_ENDSTOP_X true

#define ENDSTOP_PULLUP_Y_MIN true

#define ENDSTOP_Y_MIN_INVERTING false

#define MIN_HARDWARE_ENDSTOP_Y true

#define ENDSTOP_PULLUP_Z_MIN true

#define ENDSTOP_Z_MIN_INVERTING false

#define MIN_HARDWARE_ENDSTOP_Z true

#define ENDSTOP_PULLUP_X_MAX false

#define ENDSTOP_X_MAX_INVERTING false

#define MAX_HARDWARE_ENDSTOP_X false

#define ENDSTOP_PULLUP_Y_MAX false

#define ENDSTOP_Y_MAX_INVERTING false

#define MAX_HARDWARE_ENDSTOP_Y false

#define ENDSTOP_PULLUP_Z_MAX false

#define ENDSTOP_Z_MAX_INVERTING false

#define MAX_HARDWARE_ENDSTOP_Z false

#define max_software_endstop_r true

#define min_software_endstop_x false

#define min_software_endstop_y false

#define min_software_endstop_z false

#define max_software_endstop_x true

#define max_software_endstop_y true

#define max_software_endstop_z true

#define ENDSTOP_X_BACK_MOVE 5

#define ENDSTOP_Y_BACK_MOVE 5

#define ENDSTOP_Z_BACK_MOVE 2

#define ENDSTOP_X_RETEST_REDUCTION_FACTOR 3

#define ENDSTOP_Y_RETEST_REDUCTION_FACTOR 3

#define ENDSTOP_Z_RETEST_REDUCTION_FACTOR 3

#define ENDSTOP_X_BACK_ON_HOME 1

#define ENDSTOP_Y_BACK_ON_HOME 1

#define ENDSTOP_Z_BACK_ON_HOME 0

#define ALWAYS_CHECK_ENDSTOPS 1

now X axis moves always to the right. Activating manually the X end switch doesn't stop X axis from moving

Y axis moved to the right and the left. Homing Y axis: doesn't stop when hitting Y end stop, have to make an emergency stop

Z axis moves up and down. Homing Z axis: doesn't stop when hitting Z end stop, have to make an emergency stop

I've tested with a multimeter the end stops, they work.

I've connect the connector of X axis in the place of Y axis on the Melzi board, X axis was able to move in both directions. So X axis motor is working fine.

So there is a progress : Y and Z axis moving in both directions.

Buy why the X, Y and Z end stops seem to be ignored ?

Why the X axis still doesn't move in both directions ?

What would be the correct settings of end stops in Configuration.h ?

Does the eeprom .EEP need to be uploaded also to Melzi board

|

Re: P802M Prusa i3 Unofficial Support Thread April 04, 2016 10:34PM |

Registered: 8 years ago Posts: 8 |

My endstop config in configuration.h is like the orginal. You don't need to upload .eep to Melzi board

Base on your describe and use method of exclusion.

Firmware is good (My normally running firmware, i gave it to you)

Mechanical component (tooth belt, thread rod, machine body,...) is good

Wire is good

Stepper motor and stepper driver is good too (If stepper driver mess up, you cant control motor by repetier host)

Endstop is good

Only the Melzi board left.

Check the endstop pin soldered on Melzi board by multimeter.

If everything good then what not working happen inside the Melzi board

Base on your describe and use method of exclusion.

Firmware is good (My normally running firmware, i gave it to you)

Mechanical component (tooth belt, thread rod, machine body,...) is good

Wire is good

Stepper motor and stepper driver is good too (If stepper driver mess up, you cant control motor by repetier host)

Endstop is good

Only the Melzi board left.

Check the endstop pin soldered on Melzi board by multimeter.

If everything good then what not working happen inside the Melzi board

|

Re: P802M Prusa i3 Unofficial Support Thread April 05, 2016 02:33AM |

Registered: 8 years ago Posts: 14 |

good afternoon. I had a problem that after flashing all axes motors move only in one direction. the thing is that you need to flash the right loader . after I flashed right loader and native firmware , I have all earned the right immediately . The loader of Sanguino is not correct . here's the link will have everything that you need to solve the problem

[drive.google.com] firmware for use arduino-1.0.6. I apologize for my bad English.

[drive.google.com] firmware for use arduino-1.0.6. I apologize for my bad English.

|

Re: P802M Prusa i3 Unofficial Support Thread April 05, 2016 05:51PM |

Registered: 8 years ago Posts: 12 |

Hi Kasper. With arduino ide 1.0.6, I'm not able to burn the bootloader on the Melzi.

I have an arduino mega 2560 which I used as ISP programmer.

I'm getting always the error :

avrdude: verification error, first mismatch at byte 0x0e02

0xff != 0xef

avrdude: verification error; content mismatch

I have an arduino mega 2560 which I used as ISP programmer.

I'm getting always the error :

avrdude: verification error, first mismatch at byte 0x0e02

0xff != 0xef

avrdude: verification error; content mismatch

|

Re: P802M Prusa i3 Unofficial Support Thread April 06, 2016 01:57AM |

Registered: 8 years ago Posts: 14 |

Hey. I gathered here a programmer to LPT [webhamster.ru]. You need to alter the boot loader is obligatory ( referred to above is written ) . The fact that you have flashed boot loader and takes a lot of memory to Atmega , therefore gives this error . just do not have enough memory for firmware .

Now I have a programmer ) ) ) ) ) ) )

[drive.google.com]

I have everything turned out) ) )

Edited 1 time(s). Last edit at 04/06/2016 01:58AM by kasper.

Now I have a programmer ) ) ) ) ) ) )

[drive.google.com]

I have everything turned out) ) )

Edited 1 time(s). Last edit at 04/06/2016 01:58AM by kasper.

|

Re: P802M Prusa i3 Unofficial Support Thread April 06, 2016 03:52AM |

Registered: 8 years ago Posts: 8 |

The older version of Arduino IDE can't compressed latest repetier firmware light enough to flash it to melzi memory. I use Arduino 1.6.7 to flash firmware, any version older always get "memory not enough" error. By the way buy an USBasp with cable, everything will be more easy to re-burn bootloader

|

Re: P802M Prusa i3 Unofficial Support Thread April 06, 2016 05:14AM |

Registered: 8 years ago Posts: 14 |

the fact is , Sanguino loader size is very large , so do not have enough memory . I was not able to solve the problem is not asking [drive.google.com] loader

|

Re: P802M Prusa i3 Unofficial Support Thread April 06, 2016 08:58AM |

Registered: 8 years ago Posts: 49 |

|

Re: P802M Prusa i3 Unofficial Support Thread April 07, 2016 07:21AM |

Registered: 8 years ago Posts: 8 |

Quote

jnsbanman

Quick poll... What is everyone using as their steps per mm for their extruder (original mk8). Mine is currently set to 90 but it is grossly over extruding on solid layers.

I leave it 90 too but increase extrusion multiply to 1.04 and extrusion width 115% with feedrate about 12-16 mm/s. My external perimeter face and infill solid face is very nice.

|

Re: P802M Prusa i3 Unofficial Support Thread April 07, 2016 08:41AM |

Registered: 8 years ago Posts: 49 |

Well as it turns out my X and Y axis were out about 0.2 - 0.5 out on their movement over 50mm... So i have a tuning session last night and got it to with 0.01 - 0.05mm on both X and Y axis. My Z axis was almost dead on 49.99mm moved when told to move 50mm. After tuning that up and levelling the bed to 0.2mm using a feeler gauge (previously was at 0.127mm) I printed a 20mm test cube and it came out as perfect as I am going to get it I think. The bottom solid layers did not over flow and mush upwards and the dimensions were x - 19.98, y - 20.00, z - 19.98. Previously my bottom solid layers were always slightly wider then the rest of the model.. That has stopped too.

|

Re: P802M Prusa i3 Unofficial Support Thread April 08, 2016 04:43AM |

Registered: 8 years ago Posts: 12 |

Flashing Melzi board to correct the issue of axes moving in one direction:

I've installed Arduino1.6.8. I added the MightyCore Boards.

I used an Arduino Mega256 as programmer

In Arduino 1.6.8 I selected "Arduino as ISP (MightyCore)".

In Arduino 1.6.8, I selected : Board : ATmega1284 / Variant : 1284P / B.O.D : 2.7v / Clock : 16MHz external

I flashed the bootloader through Tools -> Burn Bootloader. The first attempt didn't work. the second one worked.

Then I tried to upload a .HEX to the Melzi board using avrdude-GUI. I'm getting the following error message :

---------------------------------------

avrdude.exe: stk500_getsync(): not in sync: resp=0x00

avrdude.exe done. Thank you.

--------------------------------------

I've also tried in Arduino 1.6.8 I to select "Arduino as ISP", I get the same error as above

It seems that the bootloader isn't working fine. Any idea how to address this issue ?

I've installed Arduino1.6.8. I added the MightyCore Boards.

I used an Arduino Mega256 as programmer

In Arduino 1.6.8 I selected "Arduino as ISP (MightyCore)".

In Arduino 1.6.8, I selected : Board : ATmega1284 / Variant : 1284P / B.O.D : 2.7v / Clock : 16MHz external

I flashed the bootloader through Tools -> Burn Bootloader. The first attempt didn't work. the second one worked.

Then I tried to upload a .HEX to the Melzi board using avrdude-GUI. I'm getting the following error message :

---------------------------------------

avrdude.exe: stk500_getsync(): not in sync: resp=0x00

avrdude.exe done. Thank you.

--------------------------------------

I've also tried in Arduino 1.6.8 I to select "Arduino as ISP", I get the same error as above

It seems that the bootloader isn't working fine. Any idea how to address this issue ?

|

Re: P802M Prusa i3 Unofficial Support Thread April 09, 2016 03:49PM |

Registered: 8 years ago Posts: 12 |

As with MightyCore it wasn't working, I've switched to Sanguino under Arduino IDE 1.6.8

I was able to burn the bootloader (although the verification at the end fired an error of mismatch between the bootloader that was burnt and the bootloader file.

Afterwards I was able to upload the 0.92.8 firmware. But same issue all axis move in one direction.

I've compared the HW pin settings of a Melzi board (as per official schematic) with the pins.h (under Repetier-Firmware-2016-03-14\Repetier-Firmware\Repetier). I found many differences:

/****************************************************************************************

* Melzi pin assignment

*

****************************************************************************************/

#if MOTHERBOARD == 63

#define KNOWN_BOARD 1

#ifndef __AVR_ATmega644P__

#ifndef __AVR_ATmega1284P__

//#error Oops! Make sure you have 'Sanguino' selected from the 'Tools -> Boards' menu.

#endif

#endif

#define ORIG_X_STEP_PIN 15 16 <--- what it should be as per Melzi board schematic

#define ORIG_X_DIR_PIN 21 24

#define ORIG_X_MIN_PIN 18 21

#define ORIG_X_MAX_PIN -1 -1

#define ORIG_Y_STEP_PIN 22 25

#define ORIG_Y_DIR_PIN 23 26

#define ORIG_Y_MIN_PIN 19 22

#define ORIG_Y_MAX_PIN -1 -1

#define ORIG_Z_STEP_PIN 3 43

#define ORIG_Z_DIR_PIN 2 42

#define ORIG_Z_MIN_PIN 20 23

#define ORIG_Z_MAX_PIN -1 -1

#define ORIG_E0_STEP_PIN 1 41

#define ORIG_E0_DIR_PIN 0 40

Which pins.h should I use ?

I was able to burn the bootloader (although the verification at the end fired an error of mismatch between the bootloader that was burnt and the bootloader file.

Afterwards I was able to upload the 0.92.8 firmware. But same issue all axis move in one direction.

I've compared the HW pin settings of a Melzi board (as per official schematic) with the pins.h (under Repetier-Firmware-2016-03-14\Repetier-Firmware\Repetier). I found many differences:

/****************************************************************************************

* Melzi pin assignment

*

****************************************************************************************/

#if MOTHERBOARD == 63

#define KNOWN_BOARD 1

#ifndef __AVR_ATmega644P__

#ifndef __AVR_ATmega1284P__

//#error Oops! Make sure you have 'Sanguino' selected from the 'Tools -> Boards' menu.

#endif

#endif

#define ORIG_X_STEP_PIN 15 16 <--- what it should be as per Melzi board schematic

#define ORIG_X_DIR_PIN 21 24

#define ORIG_X_MIN_PIN 18 21

#define ORIG_X_MAX_PIN -1 -1

#define ORIG_Y_STEP_PIN 22 25

#define ORIG_Y_DIR_PIN 23 26

#define ORIG_Y_MIN_PIN 19 22

#define ORIG_Y_MAX_PIN -1 -1

#define ORIG_Z_STEP_PIN 3 43

#define ORIG_Z_DIR_PIN 2 42

#define ORIG_Z_MIN_PIN 20 23

#define ORIG_Z_MAX_PIN -1 -1

#define ORIG_E0_STEP_PIN 1 41

#define ORIG_E0_DIR_PIN 0 40

Which pins.h should I use ?

|

Re: P802M Prusa i3 Unofficial Support Thread April 09, 2016 09:45PM |

Registered: 8 years ago Posts: 8 |

* Melzi pin assignment * ****************************************************************************************/ #if MOTHERBOARD == 63 #define KNOWN_BOARD 1 #ifndef __AVR_ATmega644P__ #ifndef __AVR_ATmega1284P__ //#error Oops! Make sure you have 'Sanguino' selected from the 'Tools -> Boards' menu. #endif #endif #define ORIG_X_STEP_PIN 15 #define ORIG_X_DIR_PIN 21 #define ORIG_X_MIN_PIN 18 #define ORIG_X_MAX_PIN -2 #define ORIG_Y_STEP_PIN 22 #define ORIG_Y_DIR_PIN 23 #define ORIG_Y_MIN_PIN 19 #define ORIG_Y_MAX_PIN -1 #define ORIG_Z_STEP_PIN 3 #define ORIG_Z_DIR_PIN 2 #define ORIG_Z_MIN_PIN 20 #define ORIG_Z_MAX_PIN -1 #define ORIG_E0_STEP_PIN 1 #define ORIG_E0_DIR_PIN 0 #define ORIG_E0_ENABLE_PIN 14 //29 on Melzi1284p A2 #define PROBE_PIN -1 #define LED_PIN 27 #define ORIG_FAN_PIN 4 #define ORIG_PS_ON_PIN -1 // (extruder) #define HEATER_0_PIN 13 #define HEATER_2_PIN -1 // bed (change to 12 for breakout pin on header) #define HEATER_1_PIN 10 #define ORIG_X_ENABLE_PIN 14 #define ORIG_Y_ENABLE_PIN 14 #define ORIG_Z_ENABLE_PIN 26 // MUST USE ANALOG INPUT NUMBERING NOT DIGITAL OUTPUT NUMBERING!!!!!!!!! (pin 33 extruder) #define TEMP_0_PIN 7 // MUST USE ANALOG INPUT NUMBERING NOT DIGITAL OUTPUT NUMBERING!!!!!!!!! (pin 34 bed) #define TEMP_1_PIN 6 #define TEMP_2_PIN -1 #define SDPOWER -1 // 31 [reprap.org] says 31, schamtic show pin 37 = PA0 which is arduino pin 31! #define SDSS 31 #define SCK_PIN 7 #define MISO_PIN 6 #define MOSI_PIN 5 #define SDSUPPORT 1 // sd card reader on board #define ORIG_SDCARDDETECT -1 #define E0_PINS ORIG_E0_STEP_PIN,ORIG_E0_DIR_PIN,ORIG_E0_ENABLE_PIN, #define E1_PINS #endif

This is my in pins.h

|

Re: P802M Prusa i3 Unofficial Support Thread April 10, 2016 01:22AM |

Registered: 8 years ago Posts: 12 |

I've checked on my Melzi board, with a multimeter:

- X end stop (ORIG_X_MIN_PIN) is connected to pin 21

- Y end stop (ORIG_Y_MIN_PIN) is connected to pin 22

- Z end stop (ORIG_Z_MIN_PIN) is connected to pin 23

This corresponds the attached Melzi schematic

Something is strange : many pin assignment have an offset of 3 between pins.h and Melzi schematic

Could you please check with a multimeter to which pin your end stops are connected ?

- X end stop (ORIG_X_MIN_PIN) is connected to pin 21

- Y end stop (ORIG_Y_MIN_PIN) is connected to pin 22

- Z end stop (ORIG_Z_MIN_PIN) is connected to pin 23

This corresponds the attached Melzi schematic

Something is strange : many pin assignment have an offset of 3 between pins.h and Melzi schematic

Could you please check with a multimeter to which pin your end stops are connected ?

|

Re: P802M Prusa i3 Unofficial Support Thread April 10, 2016 06:16AM |

Registered: 8 years ago Posts: 8 |

Quote

miro_mar

I've checked on my Melzi board, with a multimeter:

- X end stop (ORIG_X_MIN_PIN) is connected to pin 21

- Y end stop (ORIG_Y_MIN_PIN) is connected to pin 22

- Z end stop (ORIG_Z_MIN_PIN) is connected to pin 23

This corresponds the attached Melzi schematic

Something is strange : many pin assignment have an offset of 3 between pins.h and Melzi schematic

Could you please check with a multimeter to which pin your end stops are connected ?

My endstop pin was correct as Melzi schematic

|

Re: P802M Prusa i3 Unofficial Support Thread April 11, 2016 03:42PM |

Registered: 8 years ago Posts: 12 |

I've compared pins.h with the Atmel1284P datasheet.

It seems that pins.h is using the PCINTXX numbering convention.

I couldn't find the exact rule used by arduino

Nevertheless, with this explanation, I can exclude a pin assignment error resulting in the issue of end stops not being triggered.

It seems that the interruptions on the pins handling the end stops are not working either because of a HW issue in the Atmega1284P, or because of a bad initiation of specific registers

I have experience in PIC programming, not in Atmega. Do you have any idea why interrupts are not triggered although I'm not modifying the arduino code ?

It seems that pins.h is using the PCINTXX numbering convention.

I couldn't find the exact rule used by arduino

Nevertheless, with this explanation, I can exclude a pin assignment error resulting in the issue of end stops not being triggered.

It seems that the interruptions on the pins handling the end stops are not working either because of a HW issue in the Atmega1284P, or because of a bad initiation of specific registers

I have experience in PIC programming, not in Atmega. Do you have any idea why interrupts are not triggered although I'm not modifying the arduino code ?

|

Re: P802M Prusa i3 Unofficial Support Thread April 11, 2016 04:10PM |

Registered: 12 years ago Posts: 13 |

|

Re: P802M Prusa i3 Unofficial Support Thread April 12, 2016 02:56PM |

Registered: 8 years ago Posts: 12 |

|

Re: P802M Prusa i3 Unofficial Support Thread April 12, 2016 03:01PM |

Registered: 12 years ago Posts: 13 |

[github.com]

That is what I did: installed Sanguino support (link is in the README) and flashed it to the Melzi board using ISP programmer and Arduino IDE "Flash bootloader" option (I used USBasp from Hobbyking).

Edited 1 time(s). Last edit at 04/12/2016 03:01PM by osnwt.

That is what I did: installed Sanguino support (link is in the README) and flashed it to the Melzi board using ISP programmer and Arduino IDE "Flash bootloader" option (I used USBasp from Hobbyking).

Edited 1 time(s). Last edit at 04/12/2016 03:01PM by osnwt.

|

Re: P802M Prusa i3 Unofficial Support Thread April 15, 2016 11:49AM |

Registered: 8 years ago Posts: 12 |

I found on internet that, before flashing the bootloader, I need to change the configuration of some fuses in boards.txt as follows:

atmega1284.bootloader.low_fuses=0xD6

atmega1284.bootloader.high_fuses=0xDA

atmega1284.bootloader.extended_fuses=0xFD

But now, when flashing a bootloader using an ArduinoMega2560 as "Arduino As ISP", I'm getting the following error:

-------------------------------------------------------

avrdude: Device signature = 0x000000

avrdude: Yikes! Invalid device signature.

Double check connections and try again, or use -F to override

this check.

------------------------------------------------------

Before I was able to flash the bootloader .. will try not to give up ...

atmega1284.bootloader.low_fuses=0xD6

atmega1284.bootloader.high_fuses=0xDA

atmega1284.bootloader.extended_fuses=0xFD

But now, when flashing a bootloader using an ArduinoMega2560 as "Arduino As ISP", I'm getting the following error:

-------------------------------------------------------

avrdude: Device signature = 0x000000

avrdude: Yikes! Invalid device signature.

Double check connections and try again, or use -F to override

this check.

------------------------------------------------------

Before I was able to flash the bootloader .. will try not to give up ...

|

Re: P802M Prusa i3 Unofficial Support Thread April 20, 2016 04:19AM |

Registered: 8 years ago Posts: 12 |

Finally I've ordered a new Melzi board. 3D printing is working fine now. So it seems that the problem was due to the old Melzi.

Once I'll have some free time, I will change the Atmega1284P in the old Melzi, burn bootloader with suggested fuses, load firmware and test to see if the root cause was in the 1284P processor or not

Once I'll have some free time, I will change the Atmega1284P in the old Melzi, burn bootloader with suggested fuses, load firmware and test to see if the root cause was in the 1284P processor or not

|

Re: P802M Prusa i3 Unofficial Support Thread April 20, 2016 05:26AM |

Registered: 7 years ago Posts: 2 |

Good day! Hope for your help, how can i enable HE0 pin in program ? I tried to use dual extruder (chimera clone), but it works only with HE1 and Fan pin (marlin software from Mendel). But it's not the correct solution. (attached photo)

MKS Gen. 1.4.

Thank you !!!

MKS Gen. 1.4.

Thank you !!!

|

Re: P802M Prusa i3 Unofficial Support Thread April 28, 2016 08:41AM |

Registered: 7 years ago Posts: 18 |

I have adjusted the Marlin RC5 code to run on P802M with 5-button ADC keypad. I like it more than Repetier 0.92. It is configured already to use inductor sensor instead of Zmin endstop (I used LJ12A3-4-Z). You are to adjust Z_PROBE_OFFSET_FROM_EXTRUDER which is a distance from bed to nozzle tip at the point where sensor switches. Or you may set it later by M851 z-1.23 command (replace 1.23 with your offset in mm). If you don't have auto bed leveling you will have to disable it in Configuration.h and select proper endstop pullups. Just in case I have attached my sensor mount which is a remix from here.

To enable keypad support ADC_KEYPAD should be defined. Configuration.h file also introduces a type 501 100K thermistor B3950 which comes with Zonestar, disable it if you don't need ones.

I have attached a path to official RC5 version, so it should be easier to adapt future Marlin releases.

PS Most credits go to "jfd" from here for ideas and Marlin support for our keypad. However I had some problems with his firmware and Repetier-Host (since it was older Marlin version) and had to move to the latest RC.

To enable keypad support ADC_KEYPAD should be defined. Configuration.h file also introduces a type 501 100K thermistor B3950 which comes with Zonestar, disable it if you don't need ones.

I have attached a path to official RC5 version, so it should be easier to adapt future Marlin releases.

PS Most credits go to "jfd" from here for ideas and Marlin support for our keypad. However I had some problems with his firmware and Repetier-Host (since it was older Marlin version) and had to move to the latest RC.

Sorry, only registered users may post in this forum.