direct drive extruder mounting idea, any good?

Posted by jimmyclarke

|

direct drive extruder mounting idea, any good? November 24, 2015 08:40AM |

Registered: 8 years ago Posts: 22 |

Hi, I after battling with clogging I am changing my hot end,

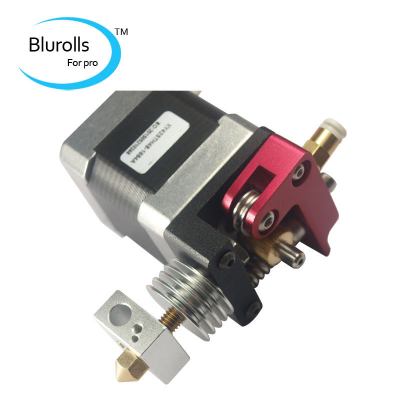

I really like the concept of the hot end being directly attached to the feeder like this:

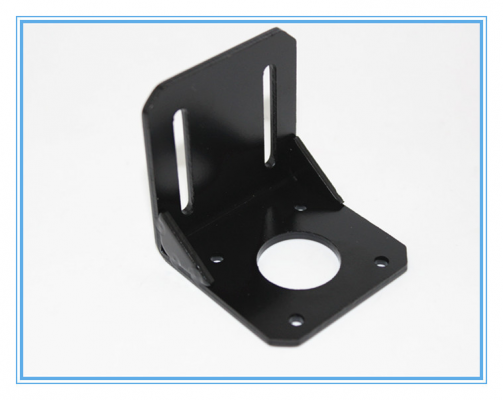

But with my printer out of action I have no way of fabricating a mount, as my carriage has 30mm spaced bolts, a metal nema holder like this:

should work perfectly.

Is this viable? Has anyone tried it and would recommend it?

Thanks

I really like the concept of the hot end being directly attached to the feeder like this:

But with my printer out of action I have no way of fabricating a mount, as my carriage has 30mm spaced bolts, a metal nema holder like this:

should work perfectly.

Is this viable? Has anyone tried it and would recommend it?

Thanks

|

Re: direct drive extruder mounting idea, any good? November 24, 2015 01:53PM |

Registered: 8 years ago Posts: 3 |

|

Re: direct drive extruder mounting idea, any good? November 24, 2015 03:40PM |

Registered: 9 years ago Posts: 722 |

Hi guys.

@jimmyclarke, the extruder you show is one of the worst money can buy.

There's a 7mm gap between the driving gear and the output hole. Rubbish.

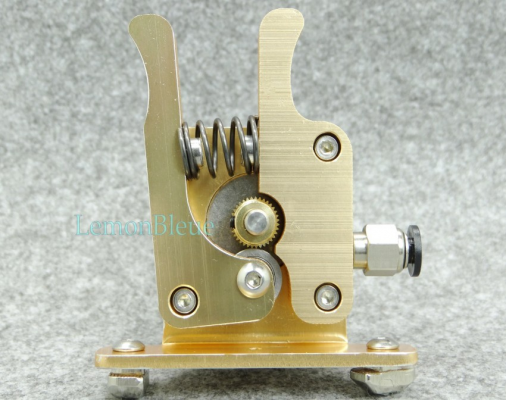

Look at this one (it's a bowden but that does not matter) :

As you can see the output hole catches the filament just out of the gear.

Seccond, the hotend have a too small heatsink and no heatbreak at all.

You want the heat to stay in the heatblock. The heatbreak parts makes it happends.

Then you need an efficient heatsink to keep the coldend cold since the thin wall of the heatbreak.

Of course, the heatsink needs to be perfectly ventilated to cool down properly.

Read about E3D V6 to understand what these parts are and understand one of the best principles of hot end architecture.

Actualy, a good hot end does not cost that much. You can find it everywhere.

Get inspiration from this kind of mounting : [www.thingiverse.com]

++JM

Edited 1 time(s). Last edit at 11/24/2015 03:41PM by J-Max.

@jimmyclarke, the extruder you show is one of the worst money can buy.

There's a 7mm gap between the driving gear and the output hole. Rubbish.

Look at this one (it's a bowden but that does not matter) :

As you can see the output hole catches the filament just out of the gear.

Seccond, the hotend have a too small heatsink and no heatbreak at all.

You want the heat to stay in the heatblock. The heatbreak parts makes it happends.

Then you need an efficient heatsink to keep the coldend cold since the thin wall of the heatbreak.

Of course, the heatsink needs to be perfectly ventilated to cool down properly.

Read about E3D V6 to understand what these parts are and understand one of the best principles of hot end architecture.

Actualy, a good hot end does not cost that much. You can find it everywhere.

Get inspiration from this kind of mounting : [www.thingiverse.com]

++JM

Edited 1 time(s). Last edit at 11/24/2015 03:41PM by J-Max.

|

Re: direct drive extruder mounting idea, any good? November 25, 2015 04:11AM |

Registered: 8 years ago Posts: 22 |

@gamma1148 Glad to hear it has been done thanks

@J-Max should have mentioned that the one I used as an example wasn't the one I was going for, just first picture that showed what I meant rather than me try and describe it.

You have won me over though and just ordered a E3D v6, that hopefully I can couple to my wade extruder long enough to print out a replacement (really liking the thingiverse one you showed!)

I have seen some where the motor bolts directly onto the carriage, wouldn't this cause vibrations that could lead to errors? Think I will stick to the bracket method.

@J-Max should have mentioned that the one I used as an example wasn't the one I was going for, just first picture that showed what I meant rather than me try and describe it.

You have won me over though and just ordered a E3D v6, that hopefully I can couple to my wade extruder long enough to print out a replacement (really liking the thingiverse one you showed!)

I have seen some where the motor bolts directly onto the carriage, wouldn't this cause vibrations that could lead to errors? Think I will stick to the bracket method.

Sorry, only registered users may post in this forum.