heatbed and ABS and ahesive

Posted by Blisk

|

heatbed and ABS and ahesive December 22, 2015 02:21PM |

Registered: 8 years ago Posts: 74 |

|

Re: heatbed and ABS and ahesive December 22, 2015 10:57PM |

Registered: 8 years ago Posts: 430 |

|

Re: heatbed and ABS and ahesive December 23, 2015 02:09AM |

Registered: 8 years ago Posts: 74 |

Quote

msaeger

Diluted elmers applied with a brush works good when I have an issue leveling the bed and getting the nozzle closer fixes it. Are you using a brim? I always use a brim too.

Sorry don't know what you mean.

Diluted elmers is that a elmer glue which is mixed with water?

Also don't know what is brim?

What temperature do you use for heatbed and extruder?

|

Re: heatbed and ABS and ahesive December 24, 2015 02:48PM |

Registered: 8 years ago Posts: 19 |

|

Re: heatbed and ABS and ahesive December 24, 2015 03:17PM |

Registered: 8 years ago Posts: 74 |

|

Re: heatbed and ABS and ahesive December 24, 2015 10:33PM |

Registered: 8 years ago Posts: 430 |

Quote

Blisk

Quote

msaeger

Diluted elmers applied with a brush works good when I have an issue leveling the bed and getting the nozzle closer fixes it. Are you using a brim? I always use a brim too.

Sorry don't know what you mean.

Diluted elmers is that a elmer glue which is mixed with water?

Also don't know what is brim?

What temperature do you use for heatbed and extruder?

Yep just white elmers with a few drops of water. I am using about the same temps as you. Here is an example of a brim. Its just adding more surface area to the first layer then when the print is done you just peel it off.

[manual.slic3r.org]

Newbie with Folgertech 2020 i3.

|

Re: heatbed and ABS and ahesive December 25, 2015 03:24AM |

Registered: 8 years ago Posts: 74 |

|

Re: heatbed and ABS and ahesive January 07, 2016 07:33AM |

Registered: 8 years ago Posts: 74 |

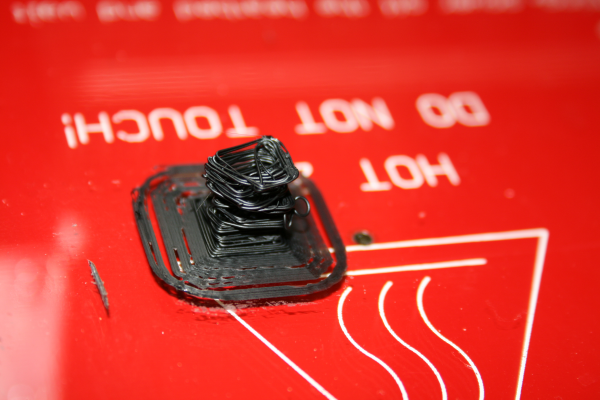

Ok I tried with glue and a brim it is alot better but latelly I have a problem with printing I get this and don't know what is wrong.

|

Re: heatbed and ABS and ahesive January 09, 2016 05:04AM |

Registered: 9 years ago Posts: 49 |

I have tried lots of different things with abs and the bed.

Kapton tape (polyamide) is by far the winner - clean it with acetone before the print, and if the model is large I use an abs/ acetone solution on the kapton tape, but normally end up ripping the tape to get it off. Other methods worked for small models but as they get larger and the stress increases they failed for me.

Your print looks like your previous layers are not firm enough to print the next layer, this can happen with small models. Possible solutions are I am aware of

Cooling fan on model

Slower print

Do multiple objects at same time

Kapton tape (polyamide) is by far the winner - clean it with acetone before the print, and if the model is large I use an abs/ acetone solution on the kapton tape, but normally end up ripping the tape to get it off. Other methods worked for small models but as they get larger and the stress increases they failed for me.

Your print looks like your previous layers are not firm enough to print the next layer, this can happen with small models. Possible solutions are I am aware of

Cooling fan on model

Slower print

Do multiple objects at same time

|

Re: heatbed and ABS and ahesive January 15, 2016 12:11PM |

Registered: 10 years ago Posts: 651 |

Looks kinda like the layers aren't close enough.

I'd say make sure that your layer height is set right in your slicing program. Eg, not equal to your nozzle size, you want it 80% or less. Say if your nozzle is a .4 for example, 80% of that would be .32. I'd just go with .30

I'd also make sure that your Z axis is moving as much as it thinks. I'd move your nozzle to within 1-2mm of the bed. Place a piece of tape right under one of the X ends. Then move the Z axis up say 30 mm with whatever software you're using. Then use calipers to measure the distance from where you put the tape to the bottom of the X end. If the software and your actual measured distance are close, that shouldn't be the issue. If they're off, it's probably the Z steps per mm.

I'd say make sure that your layer height is set right in your slicing program. Eg, not equal to your nozzle size, you want it 80% or less. Say if your nozzle is a .4 for example, 80% of that would be .32. I'd just go with .30

I'd also make sure that your Z axis is moving as much as it thinks. I'd move your nozzle to within 1-2mm of the bed. Place a piece of tape right under one of the X ends. Then move the Z axis up say 30 mm with whatever software you're using. Then use calipers to measure the distance from where you put the tape to the bottom of the X end. If the software and your actual measured distance are close, that shouldn't be the issue. If they're off, it's probably the Z steps per mm.

|

Re: heatbed and ABS and ahesive January 17, 2016 12:04AM |

Registered: 8 years ago Posts: 430 |

|

Re: heatbed and ABS and ahesive January 17, 2016 04:28AM |

Registered: 8 years ago Posts: 74 |

|

Re: heatbed and ABS and ahesive January 23, 2016 07:12AM |

Registered: 8 years ago Posts: 11 |

|

Re: heatbed and ABS and ahesive January 23, 2016 08:29AM |

Registered: 8 years ago Posts: 74 |

Sorry, only registered users may post in this forum.