New to reprap---having a little difficulty...trying my patience

Posted by NoSkillzEngineer

|

New to reprap---having a little difficulty...trying my patience March 23, 2016 11:43PM |

Registered: 8 years ago Posts: 10 |

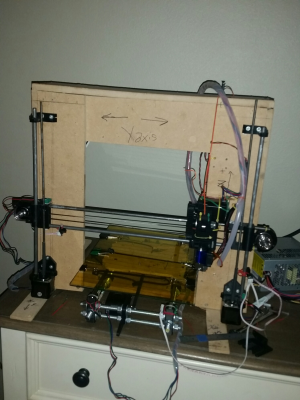

Hi all, I am extremely new to reprap. With less than two months experience, I have struggled more than I care to admit spending more than I care to admit in [something that will print] because I boldly....and ignorantly claimed I could do this no problem. Murphy's Law has kicked my butt along with my own ignorance of all this. It's a lot to take in, and I've learned a lot quickly. Just to give a perspective, I went from knowing nothing about electronics and computers six months ago, to diving into Arduino and a 3D printer about two months ago. Stubbornly, I first tried to do this without any printed parts....tried using things I had around the house....It's been....educational to say the least. I had some sense ordering parts because I have what I believe is everything....at least essential to print. Unless my wiring is incorrect, or I'm missing something I am unaware about, I only have no heated print board, and a piece of glass from an old printer that is really big but has kapton tape (if that's the right spelling).

I am a 22 year old engineering student with very electrical and electronics experience, I just switched from mechanical engineering to electrical and computer science this semester. Needless to say, the Arduino IDE is still VERY confusing to me. My print board is NOT level, I know it's not. I had hoped it was level enough for my first few prints to print a few parts to improve it rapidly and get the full dimensions I planned for to print my own bed. As a full time student, I have no job and printing has been my obsession and I know I can get my parents funding support back with what I have planned but this is more than difficult for me.

If anyone can help, I need it. I'm in over my head. I've gotten motion control but forget if it was with marlin or sprinter, and I could not figure out how to home the printer. It nearly broke itself because I hit home and it didn't stop at the photo end stop, so I bought mechanical ones....Rather my mom did because I have no more money from this. I'm proud of this, but it is FAR from perfect.

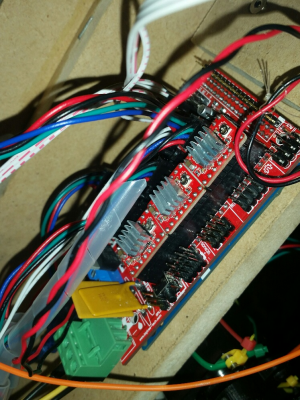

Maybe the Arduino firmware is my problem, I'm stumped because I have tried everything I understand how to do. I've gotten motion in every direction at least once. I've tried marlin and sprinter, I [think] marlin worked the best. Using pronterface and slic3r with an Arduino 2560 and a RAMPS 1.4 and a V6 3D Cam hot (x2 hot ends) end from amazon. Sain smart opto end stops, and easy rep rap mechanical switches (3 of each) of which I borrowed the sain smart wires along with some headers I got from one of the controller boards I have. I had a guy near me print me Prusa i3 hearingbone and matching hot end mount and extruder stepper gear. Forced to use M5 rod until first print where I plan to make the upgraded xz ends to use the m8 rails I bought, along with about 100Gb worth of files to print. Also purchased 1kg of orange 1.75 abs and 500kg of Carbon Fiber PLA (to start)

What am I doing wrong??? I don't understand why it wouldn't home.

My picture was too big to attach...I have no idea how to shrink the fine that small

End stops are in first, third, and fifth which I thought were all min slots. Ramps has all jumpers to 1/32 step but was under the impression I could default it to 1/16 if the drivers or programming could limit it.

Edited 1 time(s). Last edit at 03/24/2016 02:49AM by NoSkillzEngineer.

I am a 22 year old engineering student with very electrical and electronics experience, I just switched from mechanical engineering to electrical and computer science this semester. Needless to say, the Arduino IDE is still VERY confusing to me. My print board is NOT level, I know it's not. I had hoped it was level enough for my first few prints to print a few parts to improve it rapidly and get the full dimensions I planned for to print my own bed. As a full time student, I have no job and printing has been my obsession and I know I can get my parents funding support back with what I have planned but this is more than difficult for me.

If anyone can help, I need it. I'm in over my head. I've gotten motion control but forget if it was with marlin or sprinter, and I could not figure out how to home the printer. It nearly broke itself because I hit home and it didn't stop at the photo end stop, so I bought mechanical ones....Rather my mom did because I have no more money from this. I'm proud of this, but it is FAR from perfect.

Maybe the Arduino firmware is my problem, I'm stumped because I have tried everything I understand how to do. I've gotten motion in every direction at least once. I've tried marlin and sprinter, I [think] marlin worked the best. Using pronterface and slic3r with an Arduino 2560 and a RAMPS 1.4 and a V6 3D Cam hot (x2 hot ends) end from amazon. Sain smart opto end stops, and easy rep rap mechanical switches (3 of each) of which I borrowed the sain smart wires along with some headers I got from one of the controller boards I have. I had a guy near me print me Prusa i3 hearingbone and matching hot end mount and extruder stepper gear. Forced to use M5 rod until first print where I plan to make the upgraded xz ends to use the m8 rails I bought, along with about 100Gb worth of files to print. Also purchased 1kg of orange 1.75 abs and 500kg of Carbon Fiber PLA (to start)

What am I doing wrong??? I don't understand why it wouldn't home.

My picture was too big to attach...I have no idea how to shrink the fine that small

End stops are in first, third, and fifth which I thought were all min slots. Ramps has all jumpers to 1/32 step but was under the impression I could default it to 1/16 if the drivers or programming could limit it.

Edited 1 time(s). Last edit at 03/24/2016 02:49AM by NoSkillzEngineer.

|

Re: New to reprap---having a little difficulty...trying my patience March 24, 2016 01:02PM |

Registered: 8 years ago Posts: 24 |

I hate to say this, but you may not have the technical skills to jump into a project like this. Have you done any similar projects in the past? How much computer/technical skills do you have? If you can't provide us pictures or videos, then it's like trying to explain to my wife how to put together a RepRap printer from scratch using only text messaging (would take a million years). You need a good basic foundation of how electronics and computers work if you want to be successful with a project like this. My advice, start with a simple low cost 3D printer, like a Da Vinci Jr. and learn the very basics.

|

Re: New to reprap---having a little difficulty...trying my patience March 24, 2016 01:43PM |

Registered: 8 years ago Posts: 7 |

You really need to figure out exactly what printer you have, can you post a link to the printer? We may then be able to point you in the direction of where to find the correct firmware (if required) or where you need to start ,as at the moment you are as you say "in over your head". I will though try and help where possible.

|

Re: New to reprap---having a little difficulty...trying my patience March 24, 2016 02:38PM |

Registered: 10 years ago Posts: 211 |

Personally, I think you CAN do it with our help. It will take time. First get us some pics closeup of various views. If you have a Windows computer, us the Paint program. Open the pic, and use the resize option. I think the forum limits the pic size to 600mb. If you post your pics someplace else you can simply give us a link to the pics.

Then you need to test each item independently, and calibrate the machine. It will take time but it will be rewarding.

Then you need to test each item independently, and calibrate the machine. It will take time but it will be rewarding.

|

Re: New to reprap---having a little difficulty...trying my patience March 25, 2016 12:14AM |

Registered: 8 years ago Posts: 10 |

Thank you, I have not had to resize photos before. I paid a guy locally to make what I thought at the time was just the essentials, again I should have swallowed my pride and bought a kit. Did I have the technical skills to dive into this....hellllll no! But the fastest way to learn is through a mistake, I have also made this my school work, my hobby, and my job. To say I have learned a lot in a little amount of time is an understatement. Six months ago I knew little to nothing about physics, six months ago I could not take apart a computer, two months ago I knew nothing about additive manufacturing, last week I knew nothing about programming. I can do anything....I just have to learn how. You never get better at a job, you just get faster. I'm competent, creative and intuitive.

How does an opto end stop work?

A noticed my x axis in pronterface [hit the end stop @ .....] But it was in the middle of the rail.

However when I stuck my ruler in it, it moved. Is that the logic of the end stop?? Did I invert that? There are terms I am unfamiliar with. Where do I find an interpreter, I understand that computers do exactly what you tell then to do, it's becoming more clear as each day goes by. My problem is I started ignorantly fiddling and experimenting and cannot decipher my own data.

I believe I have been attempting to use my end stops as proximity sensors....or at least the same concept.

Is a proximity sensor expensive? I half want to stop this and and eliminate my problem with those but that will of course add new ones. I'll bury that thought.

*

Endstop pullup; pullup probe; const bool; and defining min and max Endstop positions.

*

That is my issue. What is this? In pronterface I'm getting numbers like 300 and 0.16.....have I just not paid attention to that? My end stops are all now min and set to -1 for the home direction. In the first three pins for X, skipped a set, Y, skipped a set, and Z. They are zip-tied on for now, I am hoping this is enough is it's only for homing the parts I need. I can print a build plate the third or fourth print. Does it matter which axis first? It's 12:55 am by me.....I am not sleeping until this is printing haha

....brainless move......I tried reading the language without learning the language. How could I be so stupid? Rhetorical! How does an opto end stop function. That's what I need. Also where should the origin be?

Edited 2 time(s). Last edit at 03/25/2016 01:20AM by NoSkillzEngineer.

|

Re: New to reprap---having a little difficulty...trying my patience March 25, 2016 12:30PM |

Registered: 8 years ago Posts: 24 |

Start here - [reprap.org] and here - [www.youtube.com]

After reading all that, if you still have questions then come back and ask us.

After reading all that, if you still have questions then come back and ask us.

|

Re: New to reprap---having a little difficulty...trying my patience March 28, 2016 12:58AM |

Registered: 8 years ago Posts: 10 |

I had it working, and one of my end stops weren't tight enough and the X axis kept moving so I frantically tried to cancel the print, it was less than successful.... After fiddling with the damage and swapping the end stop, now it says my min temp for the hot end was triggered. The hot end fluctuates at room temperature but doesn't reach over 25° C

[Error: Heating failed, system stopped! Heater_ID: 0

Error: Printer halted. kill () called!]

.......What did I do?

[Error: Heating failed, system stopped! Heater_ID: 0

Error: Printer halted. kill () called!]

.......What did I do?

|

Re: New to reprap---having a little difficulty...trying my patience March 28, 2016 08:47AM |

Registered: 8 years ago Posts: 24 |

|

Re: New to reprap---having a little difficulty...trying my patience March 28, 2016 10:52AM |

Registered: 8 years ago Posts: 10 |

|

Re: New to reprap---having a little difficulty...trying my patience March 28, 2016 04:51PM |

Registered: 8 years ago Posts: 10 |

I'm using an [3D Cam] metal V6 J-Head hot end with an NTC3950 Thermistor that I bought off amazon:

[3D CAM] Metal J-Head V6 Hot End for RepRap 3D Printer 1.75mm Filament Direct Feed Extruder 0.4mm Nozzle

[www.amazon.com]

(overpaid, but not crying over spilled milk) and this was an answer asking about Marlin settings:

A: This is "100k beta 3950 1% thermistor (4.7k pullup)", TEMP_SENSOR number 11 in Marlin config.

So naturally, I now have it set to 11. I fixed the connection issue into my Ramps 1.4 board. I know there is no polarity so wiring, as far as the schematic and video^ explains/shows, is not the issue. The second I plug my printer in I get this:

Printer is now online.

echo:Marlin 1. 1.0-RC4

echo: Last Updated: 2016-03-07 12:00 | Author: (none, default config)

Compiled: Mar 27 2016

echo: Free Memory: 5230 PlannerBufferBytes: 1232

echo:Hardcoded Default Settings Loaded

echo: Steps per unit:

echo: M92 X100.00 Y100.00 Z800.00 E756.67

echo:Maximum feedrates (mm/s):

echo: M203 X300.00 Y300.00 Z5.00 E25.00

echo:Maximum Acceleration (mm/s2):

echo: M201 X3000 Y3000 Z100 E10000

echo:Accelerations: P=printing, R=retract and T=travel

echo: M204 P3000.00 R3000.00 T3000.00

echo:Advanced variables: S=Min feedrate (mm/s), T=Min travel feedrate (mm/s), B=minimum segment time (ms), X=maximum XY jerk (mm/s), Z=maximum Z jerk (mm/s), E=maximum E jerk (mm/s)

echo: M205 S0.00 T0.00 B20.000 X20.00 Z0.40 E5.00

echo:Home offset (mm):

echo: M206 X0.00 Y0.00 Z0.00

echo: PID settings:

echo: M301 P22.36 I1.76 D70.88 C100.00 L20

echo:Filament settings: Disabled

echo: M200 D3.00

echo: M200 D0

Error:MAXTEMP triggered, system stopped! Heater_ID: 0

Error: Printer halted. kill() called!

Then I disconnected it and shut down my printer and have yet to find an answer other than something regarding a default thermocouple setting in Marlin? When everything worked fine, I ran [M303 E0 S200 C8] and plugged in the final values only into the default PID settings in Marlin replacing the Ultimaker defaults simply because it was already defined. These values are listed above.

What am I doing wrong? I am fully aware that computers do exactly what you tell them to, incredible things they are, but that means that this is not working correctly entirely due to my own ignorance. I am aware of this, education is the only cure, with that said, What [must] I learn before this prints? If needed, I'll copy and paste my configuration.h so I can be corrected. I did not have the technical skills to dive into this, I still may not, but I [need] this to work...this has to work...Thank you in advance.

*Edited because the "echo : P..." decided to turn into faces haha

Edited 2 time(s). Last edit at 03/28/2016 04:54PM by NoSkillzEngineer.

[3D CAM] Metal J-Head V6 Hot End for RepRap 3D Printer 1.75mm Filament Direct Feed Extruder 0.4mm Nozzle

[www.amazon.com]

(overpaid, but not crying over spilled milk) and this was an answer asking about Marlin settings:

A: This is "100k beta 3950 1% thermistor (4.7k pullup)", TEMP_SENSOR number 11 in Marlin config.

So naturally, I now have it set to 11. I fixed the connection issue into my Ramps 1.4 board. I know there is no polarity so wiring, as far as the schematic and video^ explains/shows, is not the issue. The second I plug my printer in I get this:

Printer is now online.

echo:Marlin 1. 1.0-RC4

echo: Last Updated: 2016-03-07 12:00 | Author: (none, default config)

Compiled: Mar 27 2016

echo: Free Memory: 5230 PlannerBufferBytes: 1232

echo:Hardcoded Default Settings Loaded

echo: Steps per unit:

echo: M92 X100.00 Y100.00 Z800.00 E756.67

echo:Maximum feedrates (mm/s):

echo: M203 X300.00 Y300.00 Z5.00 E25.00

echo:Maximum Acceleration (mm/s2):

echo: M201 X3000 Y3000 Z100 E10000

echo:Accelerations: P=printing, R=retract and T=travel

echo: M204 P3000.00 R3000.00 T3000.00

echo:Advanced variables: S=Min feedrate (mm/s), T=Min travel feedrate (mm/s), B=minimum segment time (ms), X=maximum XY jerk (mm/s), Z=maximum Z jerk (mm/s), E=maximum E jerk (mm/s)

echo: M205 S0.00 T0.00 B20.000 X20.00 Z0.40 E5.00

echo:Home offset (mm):

echo: M206 X0.00 Y0.00 Z0.00

echo: PID settings:

echo: M301 P22.36 I1.76 D70.88 C100.00 L20

echo:Filament settings: Disabled

echo: M200 D3.00

echo: M200 D0

Error:MAXTEMP triggered, system stopped! Heater_ID: 0

Error: Printer halted. kill() called!

Then I disconnected it and shut down my printer and have yet to find an answer other than something regarding a default thermocouple setting in Marlin? When everything worked fine, I ran [M303 E0 S200 C8] and plugged in the final values only into the default PID settings in Marlin replacing the Ultimaker defaults simply because it was already defined. These values are listed above.

What am I doing wrong? I am fully aware that computers do exactly what you tell them to, incredible things they are, but that means that this is not working correctly entirely due to my own ignorance. I am aware of this, education is the only cure, with that said, What [must] I learn before this prints? If needed, I'll copy and paste my configuration.h so I can be corrected. I did not have the technical skills to dive into this, I still may not, but I [need] this to work...this has to work...Thank you in advance.

*Edited because the "echo : P..." decided to turn into faces haha

Edited 2 time(s). Last edit at 03/28/2016 04:54PM by NoSkillzEngineer.

|

Re: New to reprap---having a little difficulty...trying my patience March 29, 2016 06:46PM |

Registered: 10 years ago Posts: 651 |

I'd unplug the hotend cartridge wires from the RAMPS, leave thermistor plugged in

If you have it unplugged, it shouldn't run away on you, it should read the room temperature

If it still goes MAXTEMP, I'd check to make sure the thermistor wires aren't shorted (exposed wire touching each other)

It could also be a bad thermistor

If it seems fine without the hotend cartridge plugged in, but gives the error when it's plugged in, I'd hover my finger near the nozzle and see if it's actually getting hot

In either case, I'd check for shorts on the cartridge wiring

If you have it unplugged, it shouldn't run away on you, it should read the room temperature

If it still goes MAXTEMP, I'd check to make sure the thermistor wires aren't shorted (exposed wire touching each other)

It could also be a bad thermistor

If it seems fine without the hotend cartridge plugged in, but gives the error when it's plugged in, I'd hover my finger near the nozzle and see if it's actually getting hot

In either case, I'd check for shorts on the cartridge wiring

|

Re: New to reprap---having a little difficulty...trying my patience March 30, 2016 02:00AM |

Registered: 8 years ago Posts: 10 |

Quote

FA-MAS

I'd unplug the hotend cartridge wires from the RAMPS, leave thermistor plugged in

If you have it unplugged, it shouldn't run away on you, it should read the room temperature

If it still goes MAXTEMP, I'd check to make sure the thermistor wires aren't shorted (exposed wire touching each other)

It could also be a bad thermistor

If it seems fine without the hotend cartridge plugged in, but gives the error when it's plugged in, I'd hover my finger near the nozzle and see if it's actually getting hot

In either case, I'd check for shorts on the cartridge wiring

It's funny you say that, I took my hot end (just unscrewed it from the heat sink) and brought it to my local electronics store (the guy has a bunch of hard to find old stuff, expensive to make a living but good for "I need this NOW" stuff)

Anyway, I took my whole hot end there, he tested my Thermistor resistance (I guess current flowing through but you know what I mean) and it seemed to measure right where he expected it to if it were good. Could the firmware not be picking it up??? I bought two of these thinking I knew what I was doing, I'd like to be able to use them in the future.

I say it's funny you say that because I was browsing [www.matterhackers.com] and noticed they sold E3D Hot ends, the actual piece I bought a fake of, the lite: [www.matterhackers.com] & V6: [www.matterhackers.com] with one of their hardened steel 0.4mm tip ($25 for one) (Carbon filament)

I know this may be a bit overboard as far as a replacement....But if it's worth doing, it's worth overdoing haha. Would I have any problem whatsoever [IF] I went that route? I'm beginning to suspect that the firmware runs fine, the Thermistor works perfectly, and my boards work as they are supposed to....But putting them together has given me issues. So eliminating a variable I thought wouldn't be a terrible idea as well as an upgrade.

I'll try what you suggested in the morning. Thank you very much,

|

Re: New to reprap---having a little difficulty...trying my patience June 27, 2016 02:13PM |

Registered: 8 years ago Posts: 10 |

I forgot to update this! Wow. I'm a jerk. I got it working! I tried using two tiny Nema17's off amazon to drive my z axis. That didn't work either! Before that, my layer height was just....terrible. Many clogged nozzles, burnt stepper motor driver, 3 different types of z-Axis lead screws, two different z/x ends...and I think $700 later? I think, maybe $800 haha. We're good though, I made A LOT of mistakes, I still do. Now I have a Prusa i3 rework (essentially) with 400mm 2mm pitch lead screws (Amazon, overpaid) and the ramps 1.4 with 2560 isn't bad now that I have the Reprap Discount Full Graphic Smart Controller. I print from SD card and don't really have problems, the performance is limited, I believe this is communication speed and/or processing power. I currently have an unheated bed, the gentleman I bought my heated bed from, sold me a good one for not much money. I have an aluminum heat spreader with a black pcb heat bed that has (i believe) a 2.2-2.6 ohm resistor, I believe my ramps will need to be modified to output the current it requires. The gentleman told me somewhere around 18 or 19 amps, with a Thermistor smack dab in the middle it the top (flush and level of course) of the aluminum heat spreader, with some kind of really strong clear protective film/tape. I cleaned it with acetone (ignorantly) and nothing happened, so it's good in my mind. I have an E3D Titan Extruder with an E3D 1.75 V6 all metal hot end with a hardened steel 0.4 mm nozzle. I am currently experimenting with carbon PLA!

As I've learned quite a lot since then^ I plan to build a new machine that is much more professional, I believe this one will be backed by my parents, considering they are pretty blown away at what i do with just the limited resolution I am limited to and the strength of some of the parts I use. I recently bought a Duet 0.8.5 controller and am going to use it for a printer that has a dedicated support material, still researching. This next one will not be a Prusa unfortunately!

I would like to thank you guys for helping me and motivating me!!! It was more difficult for me with the severe lack of knowledge and experience with electronics, I had to completely immerse myself to learn, or at least I chose to. I am now an Electrical Engineering and Computer Science Student :] soooo technically....this stuff is now my hobby...my education....and a future career my parents are sooooo pissed I found a hack to make this an educational project XD

my parents are sooooo pissed I found a hack to make this an educational project XD

As I've learned quite a lot since then^ I plan to build a new machine that is much more professional, I believe this one will be backed by my parents, considering they are pretty blown away at what i do with just the limited resolution I am limited to and the strength of some of the parts I use. I recently bought a Duet 0.8.5 controller and am going to use it for a printer that has a dedicated support material, still researching. This next one will not be a Prusa unfortunately!

I would like to thank you guys for helping me and motivating me!!! It was more difficult for me with the severe lack of knowledge and experience with electronics, I had to completely immerse myself to learn, or at least I chose to. I am now an Electrical Engineering and Computer Science Student :] soooo technically....this stuff is now my hobby...my education....and a future career

my parents are sooooo pissed I found a hack to make this an educational project XD

my parents are sooooo pissed I found a hack to make this an educational project XD

Sorry, only registered users may post in this forum.