How to improve my cheap China Kit

Posted by studiohead

|

How to improve my cheap China Kit June 03, 2016 09:28AM |

Registered: 7 years ago Posts: 3 |

Hello All,

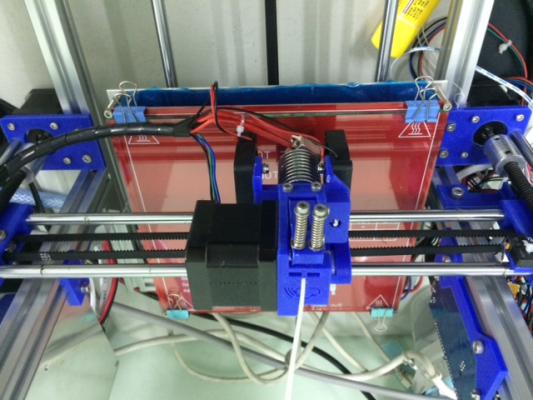

I am pretty new to to 3D Printing and gotten and assembled my first 3D Printer which is a i3 clone kit from China. and there are quite a number of issues I have. I know I went for the cheap first approach as I figure that it is best to just get my feet into the door at the lowest possible price and then proceed with upgrades from there on. I am actually located in Singapore and would be traveling to the Bay aera for work in about a week so I hope to order some of the parts online from Amazon or source from the location stores. The 2 items on my list at the moment is some Kapton Tape and the Blue Tape. I would like to know from the community what else should I be considering as well to enhance the printered especially since I cannot get the PCB heated bed above 85 degrees C. Currenlt I am doing PLA on a bare glass bed at 210 Degrees C and bed at 55 Degrees C and hope to start on ABS. I am using Cura Engine as the slicing engine with a Z-Hop of 0.4mm and tried aligning the bed so there is a slight resistance on the nozzle when I drag a sheet of paper underneath it. Attached are images of my printer.

I am pretty new to to 3D Printing and gotten and assembled my first 3D Printer which is a i3 clone kit from China. and there are quite a number of issues I have. I know I went for the cheap first approach as I figure that it is best to just get my feet into the door at the lowest possible price and then proceed with upgrades from there on. I am actually located in Singapore and would be traveling to the Bay aera for work in about a week so I hope to order some of the parts online from Amazon or source from the location stores. The 2 items on my list at the moment is some Kapton Tape and the Blue Tape. I would like to know from the community what else should I be considering as well to enhance the printered especially since I cannot get the PCB heated bed above 85 degrees C. Currenlt I am doing PLA on a bare glass bed at 210 Degrees C and bed at 55 Degrees C and hope to start on ABS. I am using Cura Engine as the slicing engine with a Z-Hop of 0.4mm and tried aligning the bed so there is a slight resistance on the nozzle when I drag a sheet of paper underneath it. Attached are images of my printer.

|

Re: How to improve my cheap China Kit June 06, 2016 09:52AM |

Registered: 7 years ago Posts: 8 |

Greetings from Germany!

The first thing i improved was the plate. I had so much problems with the adhesion at glas, so i bought a "plastic plate". In germany its called "Dauerdruckplatte". Its a special material where the filament stucks when ist hot. if it cools down, you can remove it easily.

[CsAAOSwhcJWHq8b" target="_blank" rel="nofollow">www.ebay.de]

The next thing was the extruder. Now i have a bowden extruder, so there are much less vibrations at the hotend. But the difference is minimal.

Imprtant is the calibration. you find very much threads an guids about it. In my oppinio that makes about 50% of the qualitiy.

The last thin i changed was the thin plastic plate (the carrier) under the heatbed. It wwas to thin an shaked while printing. because of that i had trouble with the edges. Now im using a wood-plate (0,5-1.0cm). That increases the stability. And i filled the gape betwen the plate and the heatbed with an insulation-matrial (wool, cotton, fabric or something like this). This will help to keep the heatbed temperature constant and it will heat much faster.

I hope you understand my tips (sory for bad grammar)

Keep me informed

I improve my I3 everytime...i spend more time in improving than in printing

The first thing i improved was the plate. I had so much problems with the adhesion at glas, so i bought a "plastic plate". In germany its called "Dauerdruckplatte". Its a special material where the filament stucks when ist hot. if it cools down, you can remove it easily.

[CsAAOSwhcJWHq8b" target="_blank" rel="nofollow">www.ebay.de]

The next thing was the extruder. Now i have a bowden extruder, so there are much less vibrations at the hotend. But the difference is minimal.

Imprtant is the calibration. you find very much threads an guids about it. In my oppinio that makes about 50% of the qualitiy.

The last thin i changed was the thin plastic plate (the carrier) under the heatbed. It wwas to thin an shaked while printing. because of that i had trouble with the edges. Now im using a wood-plate (0,5-1.0cm). That increases the stability. And i filled the gape betwen the plate and the heatbed with an insulation-matrial (wool, cotton, fabric or something like this). This will help to keep the heatbed temperature constant and it will heat much faster.

I hope you understand my tips (sory for bad grammar)

Keep me informed

I improve my I3 everytime...i spend more time in improving than in printing

|

Re: How to improve my cheap China Kit June 06, 2016 03:05PM |

Registered: 7 years ago Posts: 4 |

Hello,

I don't have any experience printing on glass, but I use blue painters tape on my aluminum heated bed and get pretty consistent results.

Something else to watch for are ambient temperature changes especially when the printer is laying down the first layers. If you have the printer near a door or window or under some vents that can affect how well the material sticks to the bed.

For printing PLA, I'd suggest heating the bed to 60-65C, as that is the glass transition temperature.

For the nozzle to bed height, I've been using a standard business card with the nozzle just coming into contact with it and that seems to work very well. I measured the thickness of the business card and bought feeler gauges, but since the bed is on springs I found that it was more difficult to use the feeler gauges than the business card because the bed would move on the springs and my height wouldn't be as consistent.

Hope this helps.

I don't have any experience printing on glass, but I use blue painters tape on my aluminum heated bed and get pretty consistent results.

Something else to watch for are ambient temperature changes especially when the printer is laying down the first layers. If you have the printer near a door or window or under some vents that can affect how well the material sticks to the bed.

For printing PLA, I'd suggest heating the bed to 60-65C, as that is the glass transition temperature.

For the nozzle to bed height, I've been using a standard business card with the nozzle just coming into contact with it and that seems to work very well. I measured the thickness of the business card and bought feeler gauges, but since the bed is on springs I found that it was more difficult to use the feeler gauges than the business card because the bed would move on the springs and my height wouldn't be as consistent.

Hope this helps.

|

Re: How to improve my cheap China Kit June 07, 2016 07:47AM |

Registered: 10 years ago Posts: 439 |

I use borosilicate glass for PLA and PETG. Increasing the bed temperature helps. If I set the heat bed to 75C then the top of the glass is about 60C which gives good adhesion.

I find clean glass important. Vinegar works for me. Standard glass cleaner somehow destroys the adhesion. For larger parts that give adhesion problems I have used balsamic vinegar on the plate.

I find clean glass important. Vinegar works for me. Standard glass cleaner somehow destroys the adhesion. For larger parts that give adhesion problems I have used balsamic vinegar on the plate.

|

Re: How to improve my cheap China Kit June 07, 2016 03:30PM |

Registered: 7 years ago Posts: 3 |

I actually have ordered the Blue Painter's Tape as well as the Kapton Tape from Amazon. Is "Dauerdruckplatte" PEI? Seems like a interesting change would be doing it during my next swing round the US. I want to do ABS and I cannot get a temperature above 85 Degrees C so I think I have a 12V 220 Watt Silicone Heater on order. Been trying to find a appropriately sized Aluminium build plate which can be a drop in replacement for the PCB heater. Any suggestions in the Bay Area? Am there for a week long technology conference.

Sorry, only registered users may post in this forum.