Folger Tech 2020 V-Rail Upgrades

Posted by Brotherbrown831

|

Folger Tech 2020 V-Rail Upgrades June 13, 2016 12:13PM |

Registered: 8 years ago Posts: 30 |

The main FT 2020 is so big I thought I would start a thread dedicated to a more advanced level of mods and upgrades, specifically those created by Sunny Lowe. I am tweaking the X-axis now and will be adding the Y-axis with a 200 x 300mm bed next.

I have enjoyed my FT 2020 for some time now, it is constantly being upgraded as I can not stop tinkering with it. One of my most recent upgrades was to Sunny Lowe's V-rail X-Axis setup (http://www.thingiverse.com/thing:1285301).

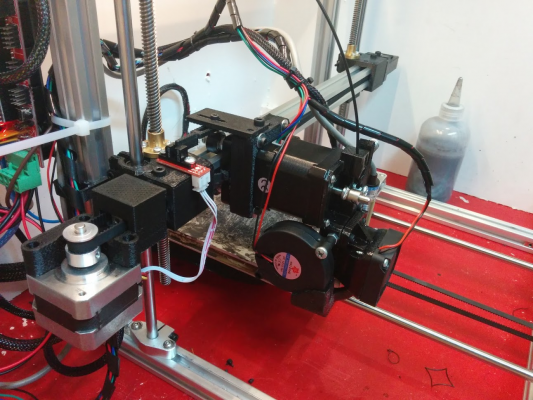

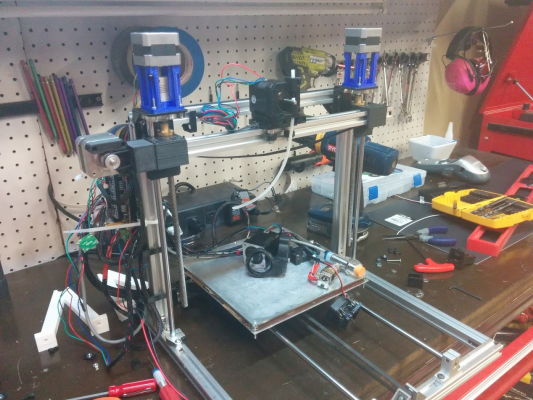

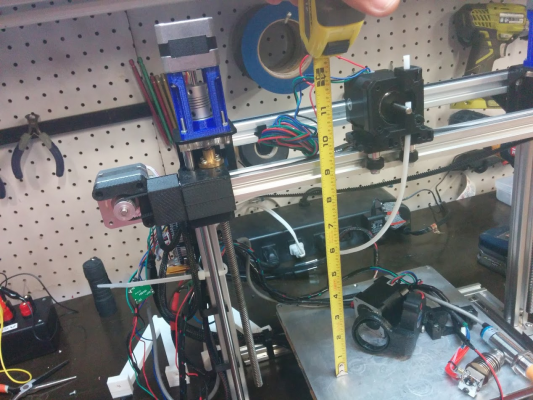

Here is my printer with the new setup:

I noticed with this setup, by placing the stepper in front of the gantry carriage this creates a rather long lever that pulls on the gantry with a bit of a twist, I'm sure the derlin wheels can tolerate this just fine, but it also lowers the nozzle of the hotend a bit. I believe if I move the gantry to the top of the 2020 extrusion this would move the center of mass for the carriage to directly over the weight bearing surfaces of the wheels and raise the nozzle significantly. Because the extrusion sits so far in front of the main support arches, the stepper can move up the Z axis without hitting the horizontal brace. By my measurements this would add approximately 46mm of movement in the Z-axis.

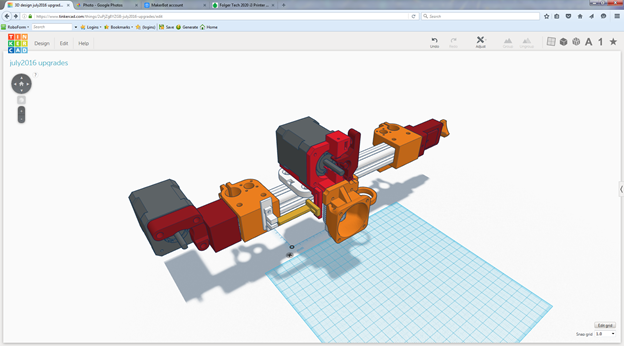

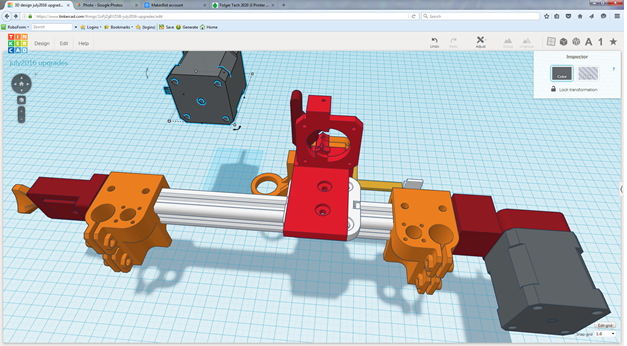

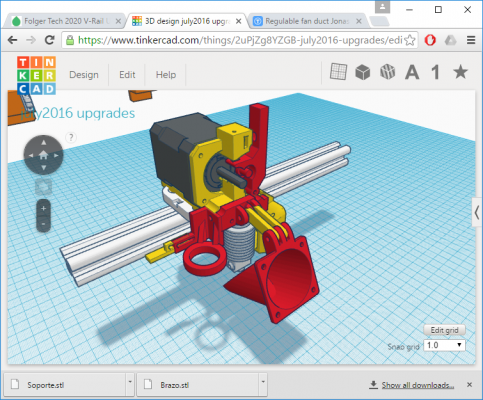

Here is a quick TinkerCad of what I'm thinking.

I still need to workout a few issues with making the new mount/extruder stronger and printable in 1 piece. I also will loose the ability to mount the centrifugal fan and will need to come up with another cooling solution.

I have enjoyed my FT 2020 for some time now, it is constantly being upgraded as I can not stop tinkering with it. One of my most recent upgrades was to Sunny Lowe's V-rail X-Axis setup (http://www.thingiverse.com/thing:1285301).

Here is my printer with the new setup:

I noticed with this setup, by placing the stepper in front of the gantry carriage this creates a rather long lever that pulls on the gantry with a bit of a twist, I'm sure the derlin wheels can tolerate this just fine, but it also lowers the nozzle of the hotend a bit. I believe if I move the gantry to the top of the 2020 extrusion this would move the center of mass for the carriage to directly over the weight bearing surfaces of the wheels and raise the nozzle significantly. Because the extrusion sits so far in front of the main support arches, the stepper can move up the Z axis without hitting the horizontal brace. By my measurements this would add approximately 46mm of movement in the Z-axis.

Here is a quick TinkerCad of what I'm thinking.

I still need to workout a few issues with making the new mount/extruder stronger and printable in 1 piece. I also will loose the ability to mount the centrifugal fan and will need to come up with another cooling solution.

|

Re: Folger Tech 2020 V-Rail Upgrades June 13, 2016 12:42PM |

Registered: 8 years ago Posts: 30 |

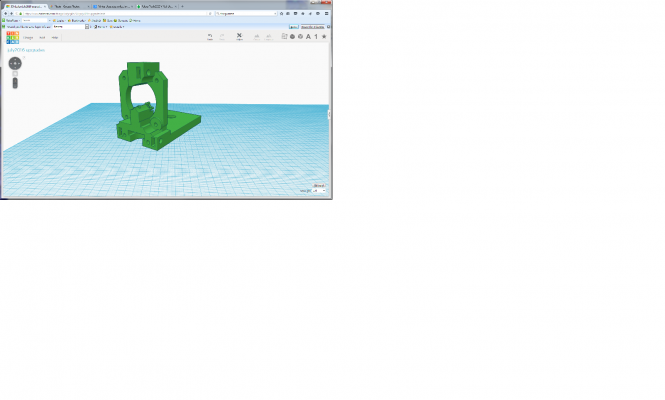

Here is the new mount/extruder: I cant think of a good way to print this. other than rotated 90 degrees on its side with support is the only way. I don't want to make it two pieces as I thing the joint will need to be as strong as possible and I want to keep the platform mount thin to maintain as much Z height as possible.

|

Re: Folger Tech 2020 V-Rail Upgrades June 14, 2016 08:08PM |

Registered: 8 years ago Posts: 430 |

I agree having the motor above the rail is a good idea. I have been using Sonny's Y setup for a few months. I didn't do anything with the X yet.

Instead of having the mount integrated into the extruder have you thought about just making something to mount the motor on the plate and mount a separate extruder to the motor. You would just need something like a 90 degree plate to mount the motor.

Newbie with Folgertech 2020 i3.

Instead of having the mount integrated into the extruder have you thought about just making something to mount the motor on the plate and mount a separate extruder to the motor. You would just need something like a 90 degree plate to mount the motor.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 V-Rail Upgrades June 14, 2016 10:55PM |

Registered: 8 years ago Posts: 30 |

I am planning to do the Y-axis upgrade next month and swap to a 200 x 300 build plate while i'm at it. There a sale going for fathers day on OpenBuilds so I might order my new rail this week.

As for separating the mount and the extruder, most secure mounting point it the stepper motor face, if the mount attached to say the back of the stepper using a 90 degree bracket then the extruder could mount to the front, that would work but it would be highly dependent on the exact length of the stepper used. By using the front face of the stepper for both the mount and the extruder the length of the stepper is not important. I am printing the last few pieces now and plan to rotate the X-axis tomorrow after work.

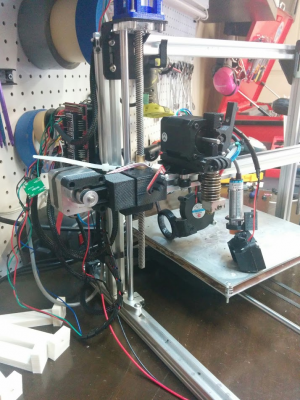

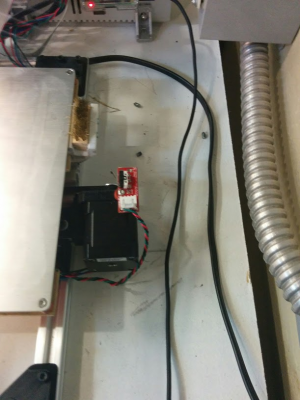

I had to change the proximity sensor location and fan setup, not sure I love this arrangement but those can me moved around anytime.

As for separating the mount and the extruder, most secure mounting point it the stepper motor face, if the mount attached to say the back of the stepper using a 90 degree bracket then the extruder could mount to the front, that would work but it would be highly dependent on the exact length of the stepper used. By using the front face of the stepper for both the mount and the extruder the length of the stepper is not important. I am printing the last few pieces now and plan to rotate the X-axis tomorrow after work.

I had to change the proximity sensor location and fan setup, not sure I love this arrangement but those can me moved around anytime.

|

Re: Folger Tech 2020 V-Rail Upgrades June 14, 2016 11:06PM |

Registered: 8 years ago Posts: 430 |

I was thinking of buying some stuff for the X axis because of the sale. Do you know when it ends? I didn't see a date.

You could still mount it on the face and have the extruder separate from the mount. I only say that because then it could be used with other extruders like the stock one, a titan, or a bulldog or something else.

I think one of those metal brackets they are using to mount the Z motors could work. They appear to be about the same size as the mini gantry plate openbuilds is selling.

Newbie with Folgertech 2020 i3.

You could still mount it on the face and have the extruder separate from the mount. I only say that because then it could be used with other extruders like the stock one, a titan, or a bulldog or something else.

I think one of those metal brackets they are using to mount the Z motors could work. They appear to be about the same size as the mini gantry plate openbuilds is selling.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 V-Rail Upgrades June 17, 2016 09:58AM |

Registered: 8 years ago Posts: 30 |

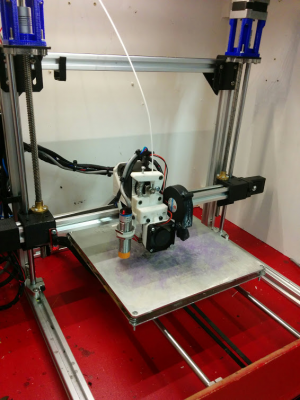

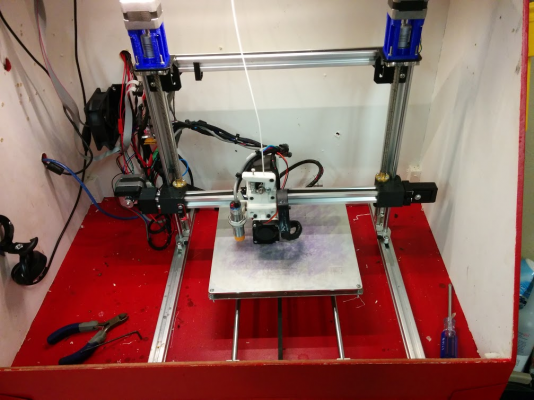

Last night I started my project to roll the X-axis and move the extruder stepper to directly above the bearing surfaces. Everything seems to be lining up and working so far. I wasnt able to get it completely back together, I will finish this evening, but at first glance I have really improved the amount of Z travel.

|

Re: Folger Tech 2020 V-Rail Upgrades June 19, 2016 09:21PM |

Registered: 8 years ago Posts: 30 |

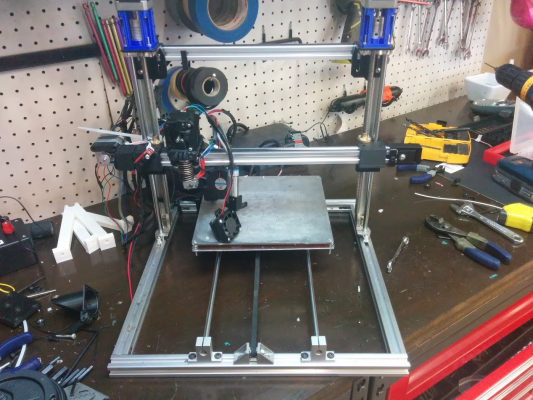

Finished! I had to rework the mount. Msaeger wqas right, it needs to be two pieces, the stepper fits snuggly into the angeled box and everything is very modular and easily adaptable.

I used this extruder: [www.thingiverse.com]

and this flexible blower hose: [www.thingiverse.com]

Here you can see the 90 degree bracket that bolts to the rear of the stepper

The trigger for the X endtop OPTO is built into the mount for the proximity sensor.

The end result is a very compact and effecient package with lots of room for expansion:

My parts arrive for the Y-Axis tomorrow, I am seriously considering increasing the height of the Z while I'm working on the Y-axis. Since i will have to rebuild my enclosure anyway, I may as well make it taller.

I used this extruder: [www.thingiverse.com]

and this flexible blower hose: [www.thingiverse.com]

Here you can see the 90 degree bracket that bolts to the rear of the stepper

The trigger for the X endtop OPTO is built into the mount for the proximity sensor.

The end result is a very compact and effecient package with lots of room for expansion:

My parts arrive for the Y-Axis tomorrow, I am seriously considering increasing the height of the Z while I'm working on the Y-axis. Since i will have to rebuild my enclosure anyway, I may as well make it taller.

|

Re: Folger Tech 2020 V-Rail Upgrades June 19, 2016 10:37PM |

Registered: 8 years ago Posts: 430 |

Looks good have fun with the Y now  This v-slot stuff is the way to go it's so much easier than the rods and bearings. I left my rail at 500mm but still am using the small bed because I was too afraid of screwing it up trying to cut it.

This v-slot stuff is the way to go it's so much easier than the rods and bearings. I left my rail at 500mm but still am using the small bed because I was too afraid of screwing it up trying to cut it.

With it all together what is the tallest thing you can print now? Do you know how much you gained?

I will defiantly be using your idea if I do the Z axis having the plate on top of the rail makes the most sense. That fan is a good find I still don't have a part cooling fan because I can never figure out how to mount it and have the duct be in the right place. With that setup you have some room to move it around to get the best placement.

Edited 1 time(s). Last edit at 06/19/2016 10:40PM by msaeger.

Newbie with Folgertech 2020 i3.

This v-slot stuff is the way to go it's so much easier than the rods and bearings. I left my rail at 500mm but still am using the small bed because I was too afraid of screwing it up trying to cut it.

This v-slot stuff is the way to go it's so much easier than the rods and bearings. I left my rail at 500mm but still am using the small bed because I was too afraid of screwing it up trying to cut it. With it all together what is the tallest thing you can print now? Do you know how much you gained?

I will defiantly be using your idea if I do the Z axis having the plate on top of the rail makes the most sense. That fan is a good find I still don't have a part cooling fan because I can never figure out how to mount it and have the duct be in the right place. With that setup you have some room to move it around to get the best placement.

Edited 1 time(s). Last edit at 06/19/2016 10:40PM by msaeger.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 V-Rail Upgrades June 22, 2016 08:06PM |

Registered: 8 years ago Posts: 30 |

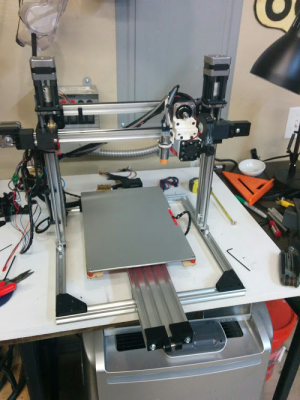

Im in the process of swapping out my Y-Axis and installing a 200x300 print bed now. I was able to raise my Z axis to 8.5 inches without interference and my new Y axis is 12.4 inches of printable space.

|

Re: Folger Tech 2020 V-Rail Upgrades June 23, 2016 06:54PM |

Registered: 8 years ago Posts: 430 |

|

Re: Folger Tech 2020 V-Rail Upgrades June 24, 2016 08:50AM |

Registered: 8 years ago Posts: 30 |

I replaced the aluminum plate and the heater PCB. I bought this combo from Amazon:

https://www.amazon.com/gp/product/B01FYDEOEK/ref=oh_aui_detailpage_o04_s00?ie=UTF8&psc=1

It was a very simple upgrade, the new Y-axis give enough range of movement to not only print on the entire 300cm of bed but also enough to go beyond 300cm to the nozzle cleaner I installed on the back of the bed.

https://www.amazon.com/gp/product/B01FYDEOEK/ref=oh_aui_detailpage_o04_s00?ie=UTF8&psc=1

It was a very simple upgrade, the new Y-axis give enough range of movement to not only print on the entire 300cm of bed but also enough to go beyond 300cm to the nozzle cleaner I installed on the back of the bed.

|

Re: Folger Tech 2020 V-Rail Upgrades June 24, 2016 11:06PM |

Registered: 8 years ago Posts: 430 |

Did you need to do something in firmware for the nozzle cleaner? I have seen those on the luzbot and it seems like a good idea. Does that bed take longer to heat up than the stock one? It must require more power.

Edited 1 time(s). Last edit at 06/24/2016 11:07PM by msaeger.

Newbie with Folgertech 2020 i3.

Edited 1 time(s). Last edit at 06/24/2016 11:07PM by msaeger.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 V-Rail Upgrades June 27, 2016 11:08PM |

Registered: 8 years ago Posts: 30 |

i just added a simple bit of Gcode to the startup script in my slicer. Very simple to do. The bed takes about the same time to heat up, is uses a larger heater pcb, i would say any larger than this and I would recommend a 120v heater on a relay.

here is my start Gcode:

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G29

M117 Cleaning...;Put Cleaning message on screen

G1 Y304.0 F{travel_speed} ;move the platform back of bed

G92 E0 ;zero the extruded length

G1 F200 E15 ;extrude 3mm of feed stock

G92 E0 ;zero the extruded length

G1 X25 F{travel_speed} ;move the platform back of bed

G1 X80 F{travel_speed} ;move the platform back of bed

G1 X25 F{travel_speed} ;move the platform back of bed

G1 X100 F{travel_speed} ;move the platform back of bed

G1 X25 F{travel_speed} ;move the platform back of bed

G1 X100 F{travel_speed} ;move the platform back of bed

G1 X25 F{travel_speed} ;move the platform back of bed

G1 X100 F{travel_speed} ;move the platform back of bed

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing...

here is my start Gcode:

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G29

M117 Cleaning...;Put Cleaning message on screen

G1 Y304.0 F{travel_speed} ;move the platform back of bed

G92 E0 ;zero the extruded length

G1 F200 E15 ;extrude 3mm of feed stock

G92 E0 ;zero the extruded length

G1 X25 F{travel_speed} ;move the platform back of bed

G1 X80 F{travel_speed} ;move the platform back of bed

G1 X25 F{travel_speed} ;move the platform back of bed

G1 X100 F{travel_speed} ;move the platform back of bed

G1 X25 F{travel_speed} ;move the platform back of bed

G1 X100 F{travel_speed} ;move the platform back of bed

G1 X25 F{travel_speed} ;move the platform back of bed

G1 X100 F{travel_speed} ;move the platform back of bed

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing...

|

Re: Folger Tech 2020 V-Rail Upgrades June 28, 2016 11:45PM |

Registered: 8 years ago Posts: 430 |

Quote

Brotherbrown831

i just added a simple bit of Gcode to the startup script in my slicer. Very simple to do. The bed takes about the same time to heat up, is uses a larger heater pcb, i would say any larger than this and I would recommend a 120v heater on a relay.

here is my start Gcode:

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G29

M117 Cleaning...;Put Cleaning message on screen

G1 Y304.0 F{travel_speed} ;move the platform back of bed

G92 E0 ;zero the extruded length

G1 F200 E15 ;extrude 3mm of feed stock

G92 E0 ;zero the extruded length

G1 X25 F{travel_speed} ;move the platform back of bed

G1 X80 F{travel_speed} ;move the platform back of bed

G1 X25 F{travel_speed} ;move the platform back of bed

G1 X100 F{travel_speed} ;move the platform back of bed

G1 X25 F{travel_speed} ;move the platform back of bed

G1 X100 F{travel_speed} ;move the platform back of bed.

G1 X25 F{travel_speed} ;move the platform back of bed

G1 X100 F{travel_speed} ;move the platform back of bed

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing...

Thanks I may have to try the brush. Looks like a brass brush right?

Newbie with Folgertech 2020 i3.

Sorry, only registered users may post in this forum.