|

If you were lasering a new aluminium Y Carriage and frame, what would you change? December 30, 2016 09:22AM |

Registered: 7 years ago Posts: 5 |

Gentlefolk,

I have a Prusa i3, Aluminium Frame. The holes on the Y-axis carriage are slightly too big to tap M3, so I am thinking of getting another lasered or water-jetted. Whilst I am at it, I was considering moving the fixings for the Y-axis belt closer to the side that has the two bearings - Obviously this will require moving the cut-out in the main Z axis frame to match.

I may also put a couple of extra holes in the main frame to allow for brackets to brace it a little more firmly too, a couple of other cable clips, that kind of thing.

Likewise on the Y-axis carriage maybe cut out a little (and I mean a little!) more weight, and add a hole to mount a flag to trigger an optical end stop.

Just wondering what other changes might be a good idea whilst I am at it, and any reasons why any of the above might be a really bad idea?

Tref.

I have a Prusa i3, Aluminium Frame. The holes on the Y-axis carriage are slightly too big to tap M3, so I am thinking of getting another lasered or water-jetted. Whilst I am at it, I was considering moving the fixings for the Y-axis belt closer to the side that has the two bearings - Obviously this will require moving the cut-out in the main Z axis frame to match.

I may also put a couple of extra holes in the main frame to allow for brackets to brace it a little more firmly too, a couple of other cable clips, that kind of thing.

Likewise on the Y-axis carriage maybe cut out a little (and I mean a little!) more weight, and add a hole to mount a flag to trigger an optical end stop.

Just wondering what other changes might be a good idea whilst I am at it, and any reasons why any of the above might be a really bad idea?

Tref.

|

Re: If you were lasering a new aluminium Y Carriage and frame, what would you change? December 30, 2016 01:56PM |

Registered: 8 years ago Posts: 165 |

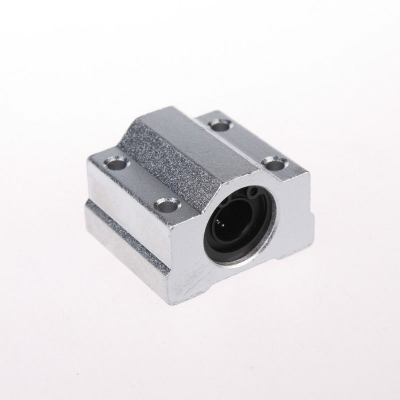

Cut holes for sc8uu or sc10uu depending which bearings you use.

This is my grieve with the Y-carriage that it does not hold a standard bracket bearing.

Instead you print a holder or use zip ties.

Not sure if optical end stops are actually needed for X and Y, because their homing does not need to be absolute precise.

Z-axis, which determines the nozzle height from the bed might be good for optical.

Can you mill your Y-carriage from magnesium?

It would be lightweight..

Edited 1 time(s). Last edit at 12/30/2016 02:24PM by Veesta.

This is my grieve with the Y-carriage that it does not hold a standard bracket bearing.

Instead you print a holder or use zip ties.

Not sure if optical end stops are actually needed for X and Y, because their homing does not need to be absolute precise.

Z-axis, which determines the nozzle height from the bed might be good for optical.

Can you mill your Y-carriage from magnesium?

It would be lightweight..

Edited 1 time(s). Last edit at 12/30/2016 02:24PM by Veesta.

|

Re: If you were lasering a new aluminium Y Carriage and frame, what would you change? December 31, 2016 04:06AM |

Registered: 7 years ago Posts: 5 |

I thought that initially, but was surprised how well the zip ties worked, and of course, getting rid of the bearing housings reduces the mass considerably. I wonder if it would work so well if there was any variation in the kurf edge or burr, but as I say, so far it has worked well for me - However, making the provision for both is really just careful placement of material and holes - so I may do that!

I don't have access to magnesium, but do know of a company that can waterjet carbon fibre for me... That is really tempting actually, but it puts me back to not being able to tap the frame directly, because as far as I am aware, it doesn't take a thread too well.

I don't have access to magnesium, but do know of a company that can waterjet carbon fibre for me... That is really tempting actually, but it puts me back to not being able to tap the frame directly, because as far as I am aware, it doesn't take a thread too well.

|

Re: If you were lasering a new aluminium Y Carriage and frame, what would you change? December 31, 2016 04:33AM |

Registered: 8 years ago Posts: 5,232 |

You can tap carbon fibre and then cure it with CA glue. Should be good enough for a one_time_only assembly.

I've got my y-frog made from aluminum sandwich plate ( IIRC it is called Dibond? ) very light and has just the right amount of springiness to allow the nozzle bump into an obstacle without loosing steps or kicking a part off the bed.

I doubt, carbon will be that nice...

Do you consider using a 3-screws bed leveling?

Edited 1 time(s). Last edit at 12/31/2016 04:35AM by o_lampe.

I've got my y-frog made from aluminum sandwich plate ( IIRC it is called Dibond? ) very light and has just the right amount of springiness to allow the nozzle bump into an obstacle without loosing steps or kicking a part off the bed.

I doubt, carbon will be that nice...

Do you consider using a 3-screws bed leveling?

Edited 1 time(s). Last edit at 12/31/2016 04:35AM by o_lampe.

|

Re: If you were lasering a new aluminium Y Carriage and frame, what would you change? December 31, 2016 05:43AM |

Registered: 7 years ago Posts: 5 |

Now you come to mention it, yes, the four screw arrangement is a pain in the... The only three screw arrangement I have seen though has the third screw on the middle of one face - the trouble with that is that it means the other two have to be adjusted first, so if I were to adopt a three-screw method, I would be inclined to just remove one of the four - that way one corner is fixed, and acts as a pivot for the other two, such that either axis can be adjusted independently - a bit like a car headlight adjustment arrangement. I wonder then if an asymmetric arrangement of the three bearings would be better, so the whole thing just becomes an "L" shape, more or less. This harks back to best practice advice from IGUS when I was last designing motion control systems, albeit bigger, heavier, and much slower moving, but I suspect the principles in this case don't change with scale.

I need to look at what weight there is on the bed itself though - with a theoretical 200 x 200 x 200mm build volume, I think that equates to a maximum of 1kg of solid PLA (which I think is heavier than ABS), but looking at typical maximum extrude rates with a 0.4mm nozzle, that would be a five day print time... I think if I work on 2kg, that will be a lot more realistic. Just thinking of what forces will be transmitted through each of the "arms".

Good stuff folks, keep it coming!

I need to look at what weight there is on the bed itself though - with a theoretical 200 x 200 x 200mm build volume, I think that equates to a maximum of 1kg of solid PLA (which I think is heavier than ABS), but looking at typical maximum extrude rates with a 0.4mm nozzle, that would be a five day print time... I think if I work on 2kg, that will be a lot more realistic. Just thinking of what forces will be transmitted through each of the "arms".

Good stuff folks, keep it coming!

|

Re: If you were lasering a new aluminium Y Carriage and frame, what would you change? December 31, 2016 10:06AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: If you were lasering a new aluminium Y Carriage and frame, what would you change? December 31, 2016 01:46PM |

Registered: 7 years ago Posts: 5 |

Putting in hole patterns is easy, and adds flexibility so long as they don't overlap - I am not sure if there is intrinsically any advantage in those guide rails or not - depends how well made they are I suppose, but certainly easy enough to keep options open by including the hole pattern - replacing the rods is on my longer term "to do" list. Are they a "standard"* linear bearing - if so, any idea what diameter mounting holes are recommended?

On my Prusa the aluminium Y-axis carriage clears the stepper. Indeed, I cannot see any reason why the linear bearings need to be so close together when using standard Prusa length 8mm rods. Am I missing something? I think it is a NEMA17 stepper, so all pretty standard there too...

Edited to add: *Standard. I was always told, "the most wonderful thing about standards, is that there are so many to choose from".

Edited 1 time(s). Last edit at 12/31/2016 01:47PM by Tref.

On my Prusa the aluminium Y-axis carriage clears the stepper. Indeed, I cannot see any reason why the linear bearings need to be so close together when using standard Prusa length 8mm rods. Am I missing something? I think it is a NEMA17 stepper, so all pretty standard there too...

Edited to add: *Standard. I was always told, "the most wonderful thing about standards, is that there are so many to choose from".

Edited 1 time(s). Last edit at 12/31/2016 01:47PM by Tref.

|

Re: If you were lasering a new aluminium Y Carriage and frame, what would you change? December 31, 2016 02:07PM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.