Leadscrew

Posted by Bee69

Hi guys im back with a question again.

Please bare in mind Im crap at maths.

I've just recieved new leadscrews and I need to update my firmware to suit them.

How do I work out the settings to suit them. Nema 17 with 8mm. rods 2mm spacing.

Thanks

Adrian

Edited 2 time(s). Last edit at 08/29/2017 11:38AM by Bee69.

Please bare in mind Im crap at maths.

I've just recieved new leadscrews and I need to update my firmware to suit them.

How do I work out the settings to suit them. Nema 17 with 8mm. rods 2mm spacing.

Thanks

Adrian

Edited 2 time(s). Last edit at 08/29/2017 11:38AM by Bee69.

|

Re: Leadscrew August 29, 2017 12:23PM |

Registered: 10 years ago Posts: 651 |

You can use the calculator for the math. http://www.prusaprinters.org/calculator/

It seems you know the distance between the threads. But that may not be what you need to put in the calculator, depending on how many starts it has. Look at the end of the screw and you'll see it will look like there is either 1, 2, 4 or more parts where thread starts. If it's more than 1, then you'll use 2mm as the pitch in the calculator. If it's more than 1, multiply 2mm by however many starts and use that as the pitch in the calculator.

Edited 1 time(s). Last edit at 08/29/2017 12:45PM by FA-MAS.

It seems you know the distance between the threads. But that may not be what you need to put in the calculator, depending on how many starts it has. Look at the end of the screw and you'll see it will look like there is either 1, 2, 4 or more parts where thread starts. If it's more than 1, then you'll use 2mm as the pitch in the calculator. If it's more than 1, multiply 2mm by however many starts and use that as the pitch in the calculator.

Edited 1 time(s). Last edit at 08/29/2017 12:45PM by FA-MAS.

|

Re: Leadscrew August 30, 2017 01:28AM |

Registered: 8 years ago Posts: 5,232 |

Quote

FA-MAS

You can use the calculator for the math. http://www.prusaprinters.org/calculator/

It seems you know the distance between the threads. But that may not be what you need to put in the calculator, depending on how many starts it has. Look at the end of the screw and you'll see it will look like there is either 1, 2, 4 or more parts where thread starts. If it's more than 1, then you'll use 2mm as the pitch in the calculator. If it's more than 1, multiply 2mm by however many starts and use that as the pitch in the calculator.

Is that correct?

I haven't paid much attention to this subject, but you often read about 8mm pitch / 4 start lead screws. According to your math, the real pitch is 32mm then??

|

Re: Leadscrew August 30, 2017 12:28PM |

Registered: 7 years ago Posts: 163 |

Hi guys thanks for the reply.

The problem I'm having is when I tell it to go up 5mm it goes up about 50 to 60mm.

//// MOVEMENT SETTINGS

#define NUM_AXIS 4 // The axis order in all axis related arrays is X, Y, Z, E

#define HOMING_FEEDRATE {50*60,50*60, 4*60, 0} // set the homing speeds (mm/min).

do I adjust this #define DEFAULT_AXIS_STEPS_PER_UNIT

Thanks

Adrian

// default settings

#define DEFAULT_AXIS_STEPS_PER_UNIT {78.74, 78.74, 2560, 105.0} // default steps per unit for Ultimaker

#define DEFAULT_MAX_FEEDRATE {400, 400, 2, 45} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {1400,1400,100,71000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 1400 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 5000 // X, Y, Z and E max acceleration in mm/s^2 for retracts

The problem I'm having is when I tell it to go up 5mm it goes up about 50 to 60mm.

//// MOVEMENT SETTINGS

#define NUM_AXIS 4 // The axis order in all axis related arrays is X, Y, Z, E

#define HOMING_FEEDRATE {50*60,50*60, 4*60, 0} // set the homing speeds (mm/min).

do I adjust this #define DEFAULT_AXIS_STEPS_PER_UNIT

Thanks

Adrian

// default settings

#define DEFAULT_AXIS_STEPS_PER_UNIT {78.74, 78.74, 2560, 105.0} // default steps per unit for Ultimaker

#define DEFAULT_MAX_FEEDRATE {400, 400, 2, 45} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {1400,1400,100,71000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 1400 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 5000 // X, Y, Z and E max acceleration in mm/s^2 for retracts

|

Re: Leadscrew August 30, 2017 12:56PM |

Registered: 6 years ago Posts: 1,863 |

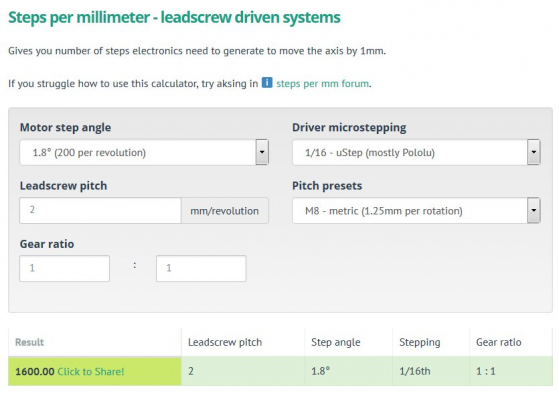

This is what you want comments lines below

// Typical stepper motors have 200 steps per full step/rev = 1.8°/step, so 1/16 microstepping = STEPS_PER_REVOLUTION_E = 3200

// X-Y Axis 3200, / 20 tooth, / 2mm pitch = 200*16 / 20 / 2 = 80 :: (STEPS_PER_REVOLUTION_X / IDLER_TEETH_X / BELT_PITCH_X)

// Z Axis 3200, / 1.25mm pitch leadscrew = 200*16 /1.25 = 2560 :: (STEPS_PER_REVOLUTION_Z / PITCH_OF_Z_ROD)

// Z Axis 3200, / 2mm pitch leadscrew = 200*16 /2 = 1600 :: (STEPS_PER_REVOLUTION_Z / PITCH_OF_Z_ROD)

// Z Axis 3200, / 8mm pitch leadscrew = 200*16 /8 = 400 :: (STEPS_PER_REVOLUTION_Z / PITCH_OF_Z_ROD)

// E-Axia 3200, / (11mm Gear OD * pi) :: (STEPS_PER_REVOLUTION_E * EXTRUDER_GEAR_RATIO / (PINCH_WHEEL_DIAMETER * PI))

And here is the RepRap Calculator Page to verify for yourself.

[www.prusaprinters.org]

Under - - - Steps per millimeter - leadscrew driven systems

LeadScrew Pitch enter 2 this will display 1600 (as there is no "pitch presets" for the T8-2 pitch LeadScrew )

I have Both T8-2 and T8-8 Pitch lead Screws, Like the T8-2 more accuracy.

If you are unsure you should measure the extruder height turn the Z-Axis one complete turn and Measure the distance Z-Axis rose.

Just finished helping a man from the UK completely setup his printer with Marlin 1.1.4 if you need further help

Edited 9 time(s). Last edit at 08/30/2017 01:39PM by Roberts_Clif.

// Typical stepper motors have 200 steps per full step/rev = 1.8°/step, so 1/16 microstepping = STEPS_PER_REVOLUTION_E = 3200

// X-Y Axis 3200, / 20 tooth, / 2mm pitch = 200*16 / 20 / 2 = 80 :: (STEPS_PER_REVOLUTION_X / IDLER_TEETH_X / BELT_PITCH_X)

// Z Axis 3200, / 1.25mm pitch leadscrew = 200*16 /1.25 = 2560 :: (STEPS_PER_REVOLUTION_Z / PITCH_OF_Z_ROD)

// Z Axis 3200, / 2mm pitch leadscrew = 200*16 /2 = 1600 :: (STEPS_PER_REVOLUTION_Z / PITCH_OF_Z_ROD)

// Z Axis 3200, / 8mm pitch leadscrew = 200*16 /8 = 400 :: (STEPS_PER_REVOLUTION_Z / PITCH_OF_Z_ROD)

// E-Axia 3200, / (11mm Gear OD * pi) :: (STEPS_PER_REVOLUTION_E * EXTRUDER_GEAR_RATIO / (PINCH_WHEEL_DIAMETER * PI))

And here is the RepRap Calculator Page to verify for yourself.

[www.prusaprinters.org]

Under - - - Steps per millimeter - leadscrew driven systems

LeadScrew Pitch enter 2 this will display 1600 (as there is no "pitch presets" for the T8-2 pitch LeadScrew )

I have Both T8-2 and T8-8 Pitch lead Screws, Like the T8-2 more accuracy.

If you are unsure you should measure the extruder height turn the Z-Axis one complete turn and Measure the distance Z-Axis rose.

Just finished helping a man from the UK completely setup his printer with Marlin 1.1.4 if you need further help

Edited 9 time(s). Last edit at 08/30/2017 01:39PM by Roberts_Clif.

|

Re: Leadscrew August 30, 2017 01:49PM |

Registered: 7 years ago Posts: 163 |

|

Re: Leadscrew August 30, 2017 03:30PM |

Registered: 7 years ago Posts: 759 |

|

Re: Leadscrew August 30, 2017 05:15PM |

Registered: 7 years ago Posts: 163 |

|

Re: Leadscrew August 30, 2017 07:33PM |

Registered: 7 years ago Posts: 267 |

Just going to jump in here and clear up a few terms. Pitch and lead are often used interchangeably but sadly this is not the case, this is only true for single starts like the threaded builders rod the early repraps were made from. Now we have jumped to using leadscrews but still use the word pitch. It would be great if the prusa calculate was updated to stop this confusion.

So just to clear things up;

Pitch - Is the distance between screw threads

Lead - Is the linear distance traveled for each complete turn of the screw

Start - Is the number of helical thread along their length

When using leadscrews the lead is equal to the pitch * the starts and this is the valve that should be used when calculating the steps (As obewan pointed out)

Some sellers dont list the number of starts but you can see by looking at the bottom of the rod (http://www.nookindustries.com/Content/image/LinearLibraryItem_Acme_Screw_Thread_Form_Terms_LinearLibraryItemImageGallery_2.png)

So just to clear things up;

Pitch - Is the distance between screw threads

Lead - Is the linear distance traveled for each complete turn of the screw

Start - Is the number of helical thread along their length

When using leadscrews the lead is equal to the pitch * the starts and this is the valve that should be used when calculating the steps (As obewan pointed out)

Some sellers dont list the number of starts but you can see by looking at the bottom of the rod (http://www.nookindustries.com/Content/image/LinearLibraryItem_Acme_Screw_Thread_Form_Terms_LinearLibraryItemImageGallery_2.png)

|

Re: Leadscrew August 31, 2017 05:37AM |

Registered: 7 years ago Posts: 163 |

|

Re: Leadscrew August 31, 2017 12:26PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Leadscrew August 31, 2017 12:36PM |

Registered: 6 years ago Posts: 1,863 |

Quote

Bee69

Thank you Clif

When I tried to use the calculator I could not do the 2mm pitch presets for the LeadScrew.

Steps per millimeter - Leadscrew driven systems

Has to be manually entered as seen in the photo.

Edited 3 time(s). Last edit at 08/31/2017 03:55PM by Roberts_Clif.

|

Re: Leadscrew September 02, 2017 09:43PM |

Registered: 8 years ago Posts: 165 |

Hi Guys, sorry for jumping in on another's thread, but it is appropriate for my problem.

I have just changed over my Y axis from belt drive to lead thread, and am having problems.

I entered the 400 as did Bee69, but I am getting no movement, I can hear the motor trying to turn but no movement,

I also changed the motor from nema17 to 14, maybe this is the problem, I don't know.

I checked all voltages on the drivers, and they are all 0.47 volts.

I hope someone will be able to help me here. Thanks.

Ok found part of the problem, the motor must be stuffed, changed it over and I have now got movement.

But it is not moving far enough, I jog it by 10 mm and it only reaches half way and it tells me it has gone the 200, I am assuming this is the Esteps I have 400 in there at the moment, any ideas.

Press home and it will do that

Edited 2 time(s). Last edit at 09/03/2017 01:42AM by erniehatt.

I have just changed over my Y axis from belt drive to lead thread, and am having problems.

I entered the 400 as did Bee69, but I am getting no movement, I can hear the motor trying to turn but no movement,

I also changed the motor from nema17 to 14, maybe this is the problem, I don't know.

I checked all voltages on the drivers, and they are all 0.47 volts.

I hope someone will be able to help me here. Thanks.

Ok found part of the problem, the motor must be stuffed, changed it over and I have now got movement.

But it is not moving far enough, I jog it by 10 mm and it only reaches half way and it tells me it has gone the 200, I am assuming this is the Esteps I have 400 in there at the moment, any ideas.

Press home and it will do that

Edited 2 time(s). Last edit at 09/03/2017 01:42AM by erniehatt.

|

Re: Leadscrew September 03, 2017 01:41AM |

Registered: 6 years ago Posts: 1,863 |

Quote

erniehatt

Hi Guys, sorry for jumping in on another's thread, but it is appropriate for my problem.

I have just changed over my Y axis from belt drive to lead thread, and am having problems.

I entered the 400 as did Bee69, but I am getting no movement, I can hear the motor trying to turn but no movement,

I also changed the motor from nema17 to 14, maybe this is the problem, I don't know.

I checked all voltages on the drivers, and they are all 0.47 volts.

I hope someone will be able to help me here. Thanks.

A questions for you then?

Have you adjusted the stepper current for the New stepper motor. As different steppers are going to require different stepper currents.

Below is an example on You-Tube of how to adjust the stepper current. This may not be your board is is only a sample, as most adjustments are similar.

you should look up how to adjust stepper motor current for your controller card.

[www.youtube.com]

Another problem could be that different stepper motors require different wiring, I recently purchased two steppers to replace my Z-Axis lead-screws steppers.

And they had a completely different wiring scheme had to change the rewire and move pins around in the housings.

Some Steppers have a non-polarized plug It may be plugged in backwards.

So included is a how to wire it video video.

[www.youtube.com]

|

Re: Leadscrew September 03, 2017 05:11AM |

Registered: 7 years ago Posts: 163 |

|

Re: Leadscrew September 03, 2017 10:56AM |

Registered: 7 years ago Posts: 759 |

Quote

erniehatt

Hi Guys, sorry for jumping in on another's thread, but it is appropriate for my problem.

I have just changed over my Y axis from belt drive to lead thread, and am having problems.

I entered the 400 as did Bee69, but I am getting no movement, I can hear the motor trying to turn but no movement,

I also changed the motor from nema17 to 14, maybe this is the problem, I don't know.

I checked all voltages on the drivers, and they are all 0.47 volts.

I hope someone will be able to help me here. Thanks.

Ok found part of the problem, the motor must be stuffed, changed it over and I have now got movement.

But it is not moving far enough, I jog it by 10 mm and it only reaches half way and it tells me it has gone the 200, I am assuming this is the Esteps I have 400 in there at the moment, any ideas.

Press home and it will do that

Sounds like you motor is strugling with the extra speed.

So, basically you have gone from ~82 steps/mm upto now 400 steps/mm , you will have to also lower the max speed so you are not trying to drive the motor too fast (ie the buzzing noise you hear)

X Y Z E

#define DEFAULT_MAX_FEEDRATE { 300, 300, 5, 25 }

try changeing the Y 300 to about 75.

you may also need to reduce the Y acceleration setting

Edited 1 time(s). Last edit at 09/03/2017 02:07PM by obewan.

|

Re: Leadscrew September 03, 2017 01:48PM |

Registered: 6 years ago Posts: 1,863 |

Quote

obewan

Sounds like you motor is struggling with the extra speed.

So, basically you have gone from ~82 steps/mm up to now 400 steps/mm , you will have to also lower the max speed so you are not trying to drive the motor too fast (ie the buzzing noise you here)

X Y Z E

#define DEFAULT_MAX_FEEDRATE { 300, 300, 5, 25 }

try changing the Y 300 to about 75.

you may also need to reduce the Y acceleration setting

Let that slip right by me. I knew this somehow missed it big time.

Thanks obewan

|

Re: Leadscrew September 03, 2017 10:56PM |

Registered: 8 years ago Posts: 165 |

Thanks Guys changed those figures, but bigger problems has arisen.

The first layer prints fine, but from then on problems.

Before I made those changes, the first layer printed fine, then on the second layer it jumped from front to back 16mm.

After the changes things got worse, the second layer jumped around 50mm

Got me puzzled.

The first layer prints fine, but from then on problems.

Before I made those changes, the first layer printed fine, then on the second layer it jumped from front to back 16mm.

After the changes things got worse, the second layer jumped around 50mm

Got me puzzled.

|

Re: Leadscrew September 03, 2017 11:26PM |

Registered: 6 years ago Posts: 1,863 |

We should start from scratch. What lead screw are you using for your Y-axis. is it the same as your Z-Axis lead screws.

What were your number before you changed to the Y Leadscrew.

Show your numbers for the following Lines

#define DEFAULT_AXIS_STEPS_PER_UNIT { , , , }

#define DEFAULT_MAX_FEEDRATE { , , ,}

#define DEFAULT_MAX_ACCELERATION { , , , }

#define DEFAULT_ACCELERATION

#define DEFAULT_RETRACT_ACCELERATION

#define DEFAULT_TRAVEL_ACCELERATION

What were your number before you changed to the Y Leadscrew.

Show your numbers for the following Lines

#define DEFAULT_AXIS_STEPS_PER_UNIT { , , , }

#define DEFAULT_MAX_FEEDRATE { , , ,}

#define DEFAULT_MAX_ACCELERATION { , , , }

#define DEFAULT_ACCELERATION

#define DEFAULT_RETRACT_ACCELERATION

#define DEFAULT_TRAVEL_ACCELERATION

|

Re: Leadscrew September 03, 2017 11:48PM |

Registered: 8 years ago Posts: 165 |

Yes using the same lead screw..

I have just got it printing ok so far, No jumping as yet.

The original acceleration was 250, that seemed to make it jump 16mm, changed as suggested it jumped almost 50mm, so I increased it to 300 now it works.

I think I will leave it at that for the time being, its a bit squeaky while laying the out lines, I can live with that.

Thanks for the help.

I have just got it printing ok so far, No jumping as yet.

The original acceleration was 250, that seemed to make it jump 16mm, changed as suggested it jumped almost 50mm, so I increased it to 300 now it works.

I think I will leave it at that for the time being, its a bit squeaky while laying the out lines, I can live with that.

Thanks for the help.

|

Re: Leadscrew September 03, 2017 11:53PM |

Registered: 6 years ago Posts: 1,863 |

Quote

erniehatt

Yes using the same lead screw..

I have just got it printing ok so far, No jumping as yet.

The original acceleration was 250, that seemed to make it jump 16mm, changed as suggested it jumped almost 50mm, so I increased it to 300 now it works.

I think I will leave it at that for the time being, its a bit squeaky while laying the out lines, I can live with that.

Thanks for the help.

Have you tried the Prusa Calculator to see what numbers it will give you.

[www.prusaprinters.org]

|

Re: Leadscrew September 04, 2017 04:13AM |

Registered: 7 years ago Posts: 163 |

|

Re: Leadscrew September 04, 2017 04:18AM |

Registered: 8 years ago Posts: 165 |

looks like I spoke to soon, it was printing great got about 2/3 of the way through on a fairly large print, then shifted towards the front about 5 mm.

Got me beat, I wonder if there could be a cliche in the motor,or even the ramps I wouldn't have thought so, but who knows.

Carries on like this for much longer I will have to go back to belt drive, shame as quality is good.

Edited 1 time(s). Last edit at 09/04/2017 04:19AM by erniehatt.

Got me beat, I wonder if there could be a cliche in the motor,or even the ramps I wouldn't have thought so, but who knows.

Carries on like this for much longer I will have to go back to belt drive, shame as quality is good.

Edited 1 time(s). Last edit at 09/04/2017 04:19AM by erniehatt.

|

Re: Leadscrew September 04, 2017 04:42AM |

Registered: 7 years ago Posts: 759 |

Quote

erniehatt

looks like I spoke to soon, it was printing great got about 2/3 of the way through on a fairly large print, then shifted towards the front about 5 mm.

Got me beat, I wonder if there could be a cliche in the motor,or even the ramps I wouldn't have thought so, but who knows.

Carries on like this for much longer I will have to go back to belt drive, shame as quality is good.

You mean 'layer shift', this coud be caused spurious endstop triggering from interference on the endstop wires.

Make sure the wires from the endstop are twisted along there length.

Try to route the wires away from the stepper motor wires.

In firmware, enable option to only check endstops while 'homing'

|

Re: Leadscrew September 04, 2017 08:55AM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Leadscrew September 04, 2017 07:00PM |

Registered: 8 years ago Posts: 165 |

|

Re: Leadscrew September 04, 2017 07:27PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Leadscrew September 05, 2017 02:08AM |

Registered: 8 years ago Posts: 165 |

|

Re: Leadscrew September 05, 2017 05:55PM |

Registered: 8 years ago Posts: 165 |

Ok have made the changes from Nema14 to 17, so it is a start again process.

The original settings I had with the belt drive where as such.

#define DEFAULT_AXIS_STEPS_PER_UNIT {80, 80, 410.6, 837.00} // default steps per unit for ***** MakiBox A6 *****

#define DEFAULT_MAX_FEEDRATE {60, 60, 20, 45} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {2000,2000,30,10000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000.

What I have done so far is to make small changes to the Y axix steps.

These changes range between 80 and 2100.

Anything between 80 and 350 worked nice and smooth.

Anything above is where the problem begin.

Set on 10 mm I can jog the axis to it's full length in both directions, no problem.

Set on 100 mm and the problem begins, it will jog 10 mm approx then begin to shudder and squeal as if something is stopping it from moving any further.

I have also varied the Default Acceleration settings.

I need some help here, I can't think of any more I can do.

The original settings I had with the belt drive where as such.

#define DEFAULT_AXIS_STEPS_PER_UNIT {80, 80, 410.6, 837.00} // default steps per unit for ***** MakiBox A6 *****

#define DEFAULT_MAX_FEEDRATE {60, 60, 20, 45} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {2000,2000,30,10000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000.

What I have done so far is to make small changes to the Y axix steps.

These changes range between 80 and 2100.

Anything between 80 and 350 worked nice and smooth.

Anything above is where the problem begin.

Set on 10 mm I can jog the axis to it's full length in both directions, no problem.

Set on 100 mm and the problem begins, it will jog 10 mm approx then begin to shudder and squeal as if something is stopping it from moving any further.

I have also varied the Default Acceleration settings.

I need some help here, I can't think of any more I can do.

|

Re: Leadscrew September 05, 2017 06:53PM |

Registered: 7 years ago Posts: 267 |

with the lead screws you cant move as fast.

when changing from belt to lead-screw there are a few things you need to change

1) axis steps - this should be the calculated value (an online calculate has been posted here a few times) once you have this number it does not need to be changed. If its the same leadscrew as your z then 400 steps/mm sounds right

2) feed rate - Start with 20 mm/sec as this is what you use on your Z. if you find that the motor stalls or jumps steps, reduce this number

3) Acceleration - Again start with 30 as this is what you use on your Z. Leadscrews are not designed for fast movement or quick speed changes, there are there for high torque applications.

Dont forget to update the new changes to the EEPROM, M502 will load the new firmware defaults and M500 will save.

when changing from belt to lead-screw there are a few things you need to change

1) axis steps - this should be the calculated value (an online calculate has been posted here a few times) once you have this number it does not need to be changed. If its the same leadscrew as your z then 400 steps/mm sounds right

2) feed rate - Start with 20 mm/sec as this is what you use on your Z. if you find that the motor stalls or jumps steps, reduce this number

3) Acceleration - Again start with 30 as this is what you use on your Z. Leadscrews are not designed for fast movement or quick speed changes, there are there for high torque applications.

Dont forget to update the new changes to the EEPROM, M502 will load the new firmware defaults and M500 will save.

Sorry, only registered users may post in this forum.