Leadscrew upgrade

Posted by JoeK1973

|

Leadscrew upgrade May 18, 2018 08:07AM |

Registered: 6 years ago Posts: 42 |

Hi all,

I built my i3 Rework with 8mm threaded rod as it was what I had at the time - now I've got the hang of it, I'd like to reduce Z-wobble (which is what I think I'm getting - visible horizontal ripples every 1mm or so (actually about 1.25mm which is the pitch of the threaded rod perhaps?)

So I'm looking at carrying out a leadscrew upgrade. I've got 8mm single-start leadscrews complete with trapezoidal nuts, not sure what the pitch or lead is although I'm sure this is easily measured. I've printed the self-centering tapered couplers from Thingiverse, and am waiting on anti-backlash nuts before I start.

Is there anything you think I'm missing or am I wasting my time and energy?

Cheers

Joe

I built my i3 Rework with 8mm threaded rod as it was what I had at the time - now I've got the hang of it, I'd like to reduce Z-wobble (which is what I think I'm getting - visible horizontal ripples every 1mm or so (actually about 1.25mm which is the pitch of the threaded rod perhaps?)

So I'm looking at carrying out a leadscrew upgrade. I've got 8mm single-start leadscrews complete with trapezoidal nuts, not sure what the pitch or lead is although I'm sure this is easily measured. I've printed the self-centering tapered couplers from Thingiverse, and am waiting on anti-backlash nuts before I start.

Is there anything you think I'm missing or am I wasting my time and energy?

Cheers

Joe

|

Re: Leadscrew upgrade May 18, 2018 09:34AM |

Registered: 6 years ago Posts: 1,863 |

I purchased a 3D Printer with theT8-8 lead screws, and found that if you have any device close to the 3D Printer the makes a vibration the Z-Axis of the T8-8 will turn while printer is Off.

I upgraded to a T8-2 lead-screws ( 8mm and only 2 mm Rise per revelation) Was always having to adjust my Z-Axis using the T8-8 lead-screws ( 8mm and only 8 mm Rise per revelation).

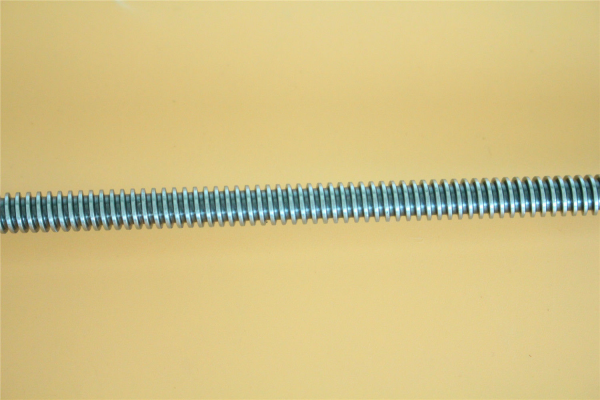

T8-2 Lead screw

This is a video of a T8-8 lead screw, you will see that just gravity will cause the nut to fall.

T8-8 Lead-screw Drop with Gravity

[youtu.be]

T8-8 Lead screw

Edited 4 time(s). Last edit at 05/18/2018 09:47AM by Roberts_Clif.

I upgraded to a T8-2 lead-screws ( 8mm and only 2 mm Rise per revelation) Was always having to adjust my Z-Axis using the T8-8 lead-screws ( 8mm and only 8 mm Rise per revelation).

T8-2 Lead screw

This is a video of a T8-8 lead screw, you will see that just gravity will cause the nut to fall.

T8-8 Lead-screw Drop with Gravity

[youtu.be]

T8-8 Lead screw

Edited 4 time(s). Last edit at 05/18/2018 09:47AM by Roberts_Clif.

|

Re: Leadscrew upgrade May 18, 2018 09:39AM |

Registered: 6 years ago Posts: 42 |

Quote

Roberts_Clif

I purchased a 3D Printer with theT8-8 lead screws, and found that if you have any device close to the 3D Printer the makes a vibration the Z-Axis of the T8-8 will turn while printer is Off.

I upgraded to a T8-2 ( 8mm and only 2 mm Rise per revelation)

This is a video of a T8-8 lead screw, you will see that just gravity will cause the nut to fall.

T8-8 Lead-screw Drop with Gravity

[youtu.be]

Does that make your upgraded leadscrews singe-start also? Thanks for the video by the way.

|

Re: Leadscrew upgrade May 18, 2018 09:47AM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Leadscrew upgrade May 18, 2018 09:52AM |

Registered: 6 years ago Posts: 42 |

|

Re: Leadscrew upgrade May 18, 2018 01:28PM |

Registered: 7 years ago Posts: 759 |

|

Re: Leadscrew upgrade May 21, 2018 09:07AM |

Registered: 6 years ago Posts: 9 |

If your ripple follows the pitch of the z lead screw, make sure your lead screw is not pushing the carriage around.

The X Y position of the carriage can only be provided by the smooth guide rod.. If the z lead screw is constrained in any way, it will if fight the guide rod and move the carriage around. Make sure the couplers between the lead screws and steppers are installed correctly (the motor shaft and lead screw should only be inserted enough for the set screws to grab) and that the far end of the lead screw isn't constrained by the frame at the top, if it is, you make have to adjust the z stepper in it's mounts to align it properly.

See my other post here:

[forums.reprap.org]

The X Y position of the carriage can only be provided by the smooth guide rod.. If the z lead screw is constrained in any way, it will if fight the guide rod and move the carriage around. Make sure the couplers between the lead screws and steppers are installed correctly (the motor shaft and lead screw should only be inserted enough for the set screws to grab) and that the far end of the lead screw isn't constrained by the frame at the top, if it is, you make have to adjust the z stepper in it's mounts to align it properly.

See my other post here:

[forums.reprap.org]

|

Re: Leadscrew upgrade May 22, 2018 03:42AM |

Registered: 8 years ago Posts: 5,232 |

Quote

Make sure the couplers between the lead screws and steppers are installed correctly (the motor shaft and lead screw should only be inserted enough for the set screws to grab)

I've placed a 4.5mm steelball between stepper shaft and leadscrew ( both are touching the ball ). That way the weight and inertia of the X-carrier can't compress the coupler, but it can still flex.

|

Re: Leadscrew upgrade May 22, 2018 03:46AM |

Registered: 6 years ago Posts: 42 |

Quote

o_lampe

Quote

Make sure the couplers between the lead screws and steppers are installed correctly (the motor shaft and lead screw should only be inserted enough for the set screws to grab)

I've placed a 4.5mm steelball between stepper shaft and leadscrew ( both are touching the ball ). That way the weight and inertia of the X-carrier can't compress the coupler, but it can still flex.

That sounds like a genius idea! Doing that!

|

Re: Leadscrew upgrade May 22, 2018 08:02AM |

Registered: 6 years ago Posts: 1,863 |

Quote

JoeK1973

I'd like to reduce Z-wobble (which is what I think I'm getting - visible horizontal ripples every 1mm or so (actually about 1.25mm which is the pitch of the threaded rod perhaps?)

Joe

On all my lead-screws, I see a little Z-wobble, I place a single wrap of electricians tape on the end of the lead-screw that slides into the coupler.

This fixes the loose fitting connections and eliminates the Z-Wobble.

|

Re: Leadscrew upgrade May 22, 2018 08:36AM |

Registered: 6 years ago Posts: 9 |

|

Re: Leadscrew upgrade May 22, 2018 04:54PM |

Registered: 8 years ago Posts: 165 |

|

Re: Leadscrew upgrade May 22, 2018 05:38PM |

Registered: 6 years ago Posts: 1,007 |

The problem is that you simply don't mount properly the motor/coupler/ leadscrew. Just do a search on the proper way to mount these. It is a basic mistake repeated over and over in the 3D amateur builders and some vendors. Resutl: wobblle and a attempt to get rid of it, some solution leading to even worse results others working by luck.

ANd there are ways to get rid of the couplers too.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

ANd there are ways to get rid of the couplers too.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Leadscrew upgrade May 22, 2018 09:00PM |

Registered: 8 years ago Posts: 165 |

|

Re: Leadscrew upgrade May 23, 2018 02:53AM |

Registered: 8 years ago Posts: 5,232 |

Quote

BrianRosenthal

Quote

o_lampe

I've placed a 4.5mm steelball between stepper shaft and leadscrew ( both are touching the ball ). That way the weight and inertia of the X-carrier can't compress the coupler, but it can still flex.

While I like the idea, what issues does coupler flex cause on the z axis?

The flexing is what we want from the coupler, but not the compression. Imagine you print with z-lift on retraction and the couplers compress/decompress everytime...

Sorry, only registered users may post in this forum.