Spool on top, rotation on vertical axis

Posted by PRZ

|

Spool on top, rotation on vertical axis September 26, 2015 07:02PM |

Registered: 9 years ago Posts: 475 |

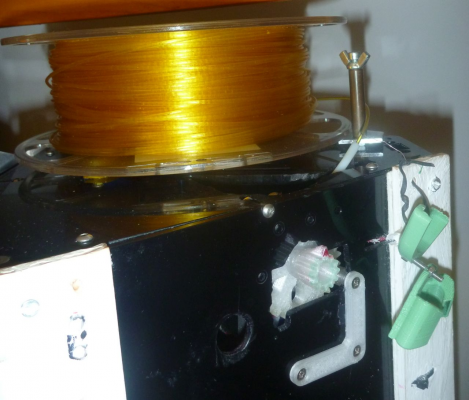

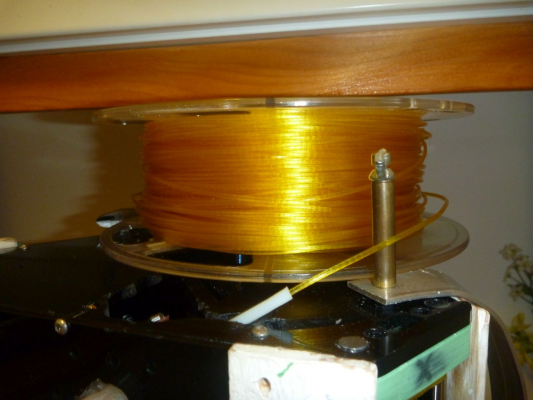

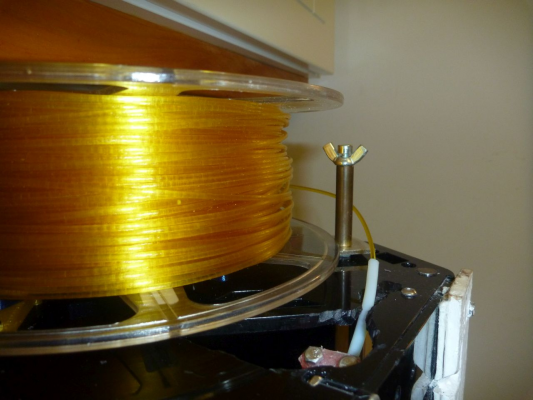

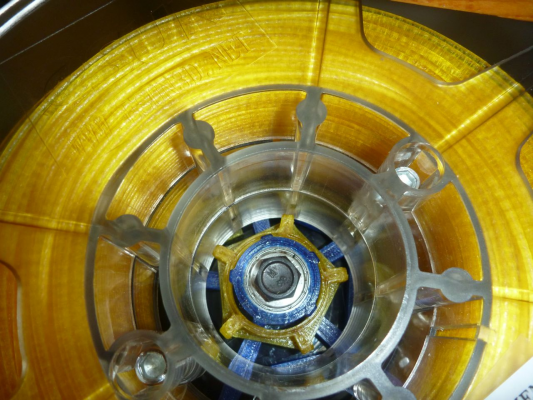

To save space, I created a new spool on top installation, with spool support done with two skate bearings (608).

This doesn't work any better than the former Fisher spool on top (on spigot): [forums.reprap.org], but is more compact and more elegant.

It does accept spool with 50mm + hole (with a ring) or 30mm + hole (without ring), but spool with 25mm holes (say small Taulman spools) cannot be installed.

While the support is only 130mm diameter, it is fairly stable with spool of 200mm diameter.

Brake is required for good unwinding as bearings makes the rotation too easy and that end up in crossed loops and knots.

If printed in PETG or ABS, the spool brake may look a bit weak but it works ok (supplied files will give a stronger brake than my own installation).

There are two "pins" underneath the brake which maintain it firmly in position. 2 holes diameter 4mm spaced 12mm shall be drilled in top plate for these pins.

As spool holes are generally larger than 50mm, the spool is never perfectly centered, but this have no effect on the operation.

BOM list :

*2 608ZZ (or 608RS) bearings

*1 M8x40 screw hex head, fully threaded

*2 M8 hex nuts

*1 M8 butterfly nut (could use an hex nut instead)

*4or 5 M8 small washers

*1 wood screw 3x10 or bolt M3x15 (for the brake)

Printed parts:

*Spool support

*Ring for 50mm spool

*Brake

Bearings are separated by an M8 nut + 2 washers.

Depending your washer thickness, you may have to set one or two washers below the bottom nut to give space for the spool brake.

Files will be supplied in next message

Fisher delta

This is a relatively large part (diameter 130mm) to print on the Fisher Delta and I experienced skipping steps at first print.

Top print it, you need :

*A reasonnably flat bed and properly calibrated machine

*To reduce the travel speed (I used 180 mm/s)

The last SD image of Fisher Delta have increased the travel speed from 200 mm/s to 250 mm/s. That may work for small parts, but with the geometry of the Fisher and its short arms, that is not ok for large parts. If still experiencing lost steps after reducing speed, you may reduce a bit the accelerations (G-Code M201 [reprap.org])

Edited 2 time(s). Last edit at 09/26/2015 08:03PM by PRZ.

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

This doesn't work any better than the former Fisher spool on top (on spigot): [forums.reprap.org], but is more compact and more elegant.

It does accept spool with 50mm + hole (with a ring) or 30mm + hole (without ring), but spool with 25mm holes (say small Taulman spools) cannot be installed.

While the support is only 130mm diameter, it is fairly stable with spool of 200mm diameter.

Brake is required for good unwinding as bearings makes the rotation too easy and that end up in crossed loops and knots.

If printed in PETG or ABS, the spool brake may look a bit weak but it works ok (supplied files will give a stronger brake than my own installation).

There are two "pins" underneath the brake which maintain it firmly in position. 2 holes diameter 4mm spaced 12mm shall be drilled in top plate for these pins.

As spool holes are generally larger than 50mm, the spool is never perfectly centered, but this have no effect on the operation.

BOM list :

*2 608ZZ (or 608RS) bearings

*1 M8x40 screw hex head, fully threaded

*2 M8 hex nuts

*1 M8 butterfly nut (could use an hex nut instead)

*4or 5 M8 small washers

*1 wood screw 3x10 or bolt M3x15 (for the brake)

Printed parts:

*Spool support

*Ring for 50mm spool

*Brake

Bearings are separated by an M8 nut + 2 washers.

Depending your washer thickness, you may have to set one or two washers below the bottom nut to give space for the spool brake.

Files will be supplied in next message

Fisher delta

This is a relatively large part (diameter 130mm) to print on the Fisher Delta and I experienced skipping steps at first print.

Top print it, you need :

*A reasonnably flat bed and properly calibrated machine

*To reduce the travel speed (I used 180 mm/s)

The last SD image of Fisher Delta have increased the travel speed from 200 mm/s to 250 mm/s. That may work for small parts, but with the geometry of the Fisher and its short arms, that is not ok for large parts. If still experiencing lost steps after reducing speed, you may reduce a bit the accelerations (G-Code M201 [reprap.org])

Edited 2 time(s). Last edit at 09/26/2015 08:03PM by PRZ.

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

|

Re: Spool on top, rotation on vertical axis September 26, 2015 07:08PM |

Registered: 9 years ago Posts: 475 |

Files

These files contains the stl file and also the OpenScad modules

SpoolOnTop.zip

Licence : Equipment OHL V1.2, documentation CC BY-SA

Position

The spool axis position shall be adjusted depending your printer. You shall resist to the temptation to install it on center, which is generally far from being the best position for good filament path.

For the Fisher Delta:

For filament path see :

spool on top (on spigot): [forums.reprap.org]

Geared extruder : [forums.reprap.org]

Edited 1 time(s). Last edit at 09/26/2015 07:22PM by PRZ.

These files contains the stl file and also the OpenScad modules

SpoolOnTop.zip

Licence : Equipment OHL V1.2, documentation CC BY-SA

Position

The spool axis position shall be adjusted depending your printer. You shall resist to the temptation to install it on center, which is generally far from being the best position for good filament path.

For the Fisher Delta:

For filament path see :

spool on top (on spigot): [forums.reprap.org]

Geared extruder : [forums.reprap.org]

Edited 1 time(s). Last edit at 09/26/2015 07:22PM by PRZ.

|

Re: Spool on top, rotation on vertical axis September 26, 2015 07:30PM |

Registered: 8 years ago Posts: 443 |

May also want to take a look at my adaptable on-top spool holder, works with any spool size, bearing components are printable taper roller bearings, non printable parts are just 3 screws and 3 elastic bands, works well in PLA, mounts well on top of fisher using just Blutak.

[www.thingiverse.com]

also a 100% printable version, but you need to print adapter rings

[www.thingiverse.com]

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

[www.thingiverse.com]

also a 100% printable version, but you need to print adapter rings

[www.thingiverse.com]

RepRapPro Mendel 3 Tricolour

RepRapPro Fisher

-Carbon Arms

-Easy adjust Carriage+effector

-axis stiffness mods

HE3D -600 delta

-Duet 0.8.5

-PanelDue

-DC42 Height probe

-RobotDigg metal components

Simplyfy3D

RS Design Spark CAD

|

Re: Spool on top, rotation on vertical axis September 26, 2015 08:54PM |

Registered: 9 years ago Posts: 475 |

The total plastic weight for the three parts is approximately 30g (fill 40to 70%)

The total printing time with layers 0.2 is approximately 2 hours. You could use thicker layers without any problems.

While it is theorically possible to set the three parts on the Fisher bed and print in one go, this is way too close to the limits for the standard Fisher and I recommend to do two prints:

- 1 print for the support

- 1 other print for the ring and brake.

If you have lengthened arms as me (170 mm), this may be workable in one go without big risks.

The total printing time with layers 0.2 is approximately 2 hours. You could use thicker layers without any problems.

While it is theorically possible to set the three parts on the Fisher bed and print in one go, this is way too close to the limits for the standard Fisher and I recommend to do two prints:

- 1 print for the support

- 1 other print for the ring and brake.

If you have lengthened arms as me (170 mm), this may be workable in one go without big risks.

Sorry, only registered users may post in this forum.