RepRapPro's new printer kit (off-topic)

Posted by dc42

|

Re: Fisher Delta : PETG printing July 18, 2015 04:41PM |

Registered: 8 years ago Posts: 475 |

Video of Fisher printing PETG here: [rouzeau.net]

It is real time !

layer height 0.2mm, width 0.4 mm extrusion coefficient 1.08, infill rectilinear 50%

Speed perimeters 150 mm/s , infill 190 mm/s, acceleration 5000 mm.sec2

Temperature is 275 °C, which is a bit too much, I had some blobs carried by the hotend and I had to pause the print twice to remove these blobs. For ending print, I reduced to 270°C and 125 mm/s

That was a bit too high in temp and speed, but now, with these parameters the part is more translucent, which is a good sign of adhesion on PETG and it is visibly much stronger.

The PETG is unwinding more easily than PLA, there is no extrusion problem, good !

The only problem is that, as it is much more fexible than PLA (~twice), parts with supports are difficult to clean.

Edited 1 time(s). Last edit at 07/18/2015 05:05PM by PRZ.

It is real time !

layer height 0.2mm, width 0.4 mm extrusion coefficient 1.08, infill rectilinear 50%

Speed perimeters 150 mm/s , infill 190 mm/s, acceleration 5000 mm.sec2

Temperature is 275 °C, which is a bit too much, I had some blobs carried by the hotend and I had to pause the print twice to remove these blobs. For ending print, I reduced to 270°C and 125 mm/s

That was a bit too high in temp and speed, but now, with these parameters the part is more translucent, which is a good sign of adhesion on PETG and it is visibly much stronger.

The PETG is unwinding more easily than PLA, there is no extrusion problem, good !

The only problem is that, as it is much more fexible than PLA (~twice), parts with supports are difficult to clean.

Edited 1 time(s). Last edit at 07/18/2015 05:05PM by PRZ.

|

Re: Fisher Delta : PETG printing July 18, 2015 06:42PM |

Registered: 9 years ago Posts: 1,699 |

One small tip to the BuildTak as I crashed one. Be aware of too great stickness. If you cannot barely remove the part you may have been too deep with the nozzle. buildTak is a little bit different The nozzle has to be kept higher than on other material. The little squeezing as you normal do (0.1mm above the bed at 0.2mm layer height for example) and you can throw away your BuildTak.

As I run different tests at the moment and as I even got stucking problems woth PLA I have to say I will have to change to BuildTak even though it is not cheap.

How does the side looks like that had contact with the BuildTak?

esun ABS seems to have some problems with that even though you printed in white so that error could not been seen..

With other distributors I did not get any white areas..

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

As I run different tests at the moment and as I even got stucking problems woth PLA I have to say I will have to change to BuildTak even though it is not cheap.

How does the side looks like that had contact with the BuildTak?

esun ABS seems to have some problems with that even though you printed in white so that error could not been seen..

With other distributors I did not get any white areas..

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: RepRapPro's new printer kit (off-topic) July 19, 2015 02:51AM |

Registered: 10 years ago Posts: 14,672 |

I have taken a look at the Fischer commissioning and troubleshooting instructions, and the SD card files. One thing that stands out is that the Z parameter in the G31 command in config.g is set to zero. This will cause Z=0 to be set when the bed is pushed down by the nozzle, breaking the switch contacts; but this is probably too low for Z=0. This appears to be confirmed by the sole troubleshooting entry "First layer too close to bed". So I think it would be better to use a Z parameter of about -0.1 or -0.2 in the G31 command.

The bed.g file only does 4-factor calibration instead of the 6-factor calibration I normally use; but perhaps the Fisher design leads to sufficiently accurate builds that 4 factor calibration is sufficient.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The bed.g file only does 4-factor calibration instead of the 6-factor calibration I normally use; but perhaps the Fisher design leads to sufficiently accurate builds that 4 factor calibration is sufficient.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: RepRapPro's new printer kit (off-topic) July 19, 2015 05:39AM |

Registered: 8 years ago Posts: 475 |

The troubleshooting entry was because I asked on IRC how to set the Z offset as I did not found it for the duet. Before they answered, I found the option of Z offset in Slic3R.

It is much better done in the configuration file as you suggest. after my tests, I think the good value is -0.2 (at least for my machine).

For the bed calibration, there is also a macro bed7 at the right of the screen. I was imagining that this is the initial calibration with 7 points and that it was recording the printer caracteristics and that you could subsequently run the other macro (bed4 or the button). Now, I understand that I am probably wrong, at least for the parameters recording, but there is nothing in the manual on this topic how to record your machine parameters.

It is much better done in the configuration file as you suggest. after my tests, I think the good value is -0.2 (at least for my machine).

For the bed calibration, there is also a macro bed7 at the right of the screen. I was imagining that this is the initial calibration with 7 points and that it was recording the printer caracteristics and that you could subsequently run the other macro (bed4 or the button). Now, I understand that I am probably wrong, at least for the parameters recording, but there is nothing in the manual on this topic how to record your machine parameters.

|

BED system - positive positioning and probing July 19, 2015 05:58AM |

Registered: 8 years ago Posts: 475 |

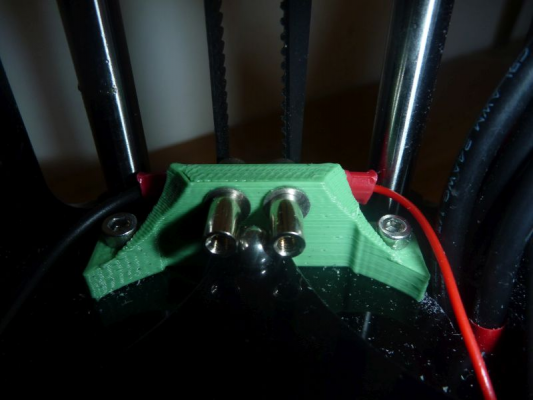

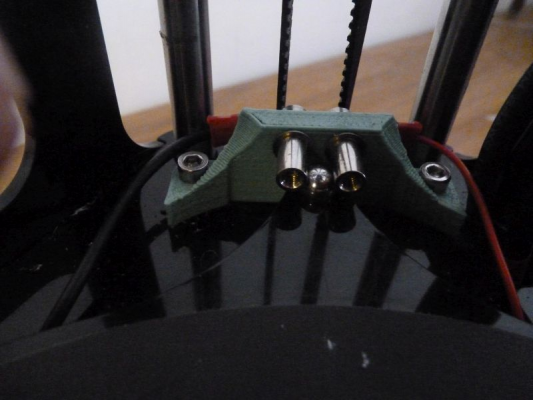

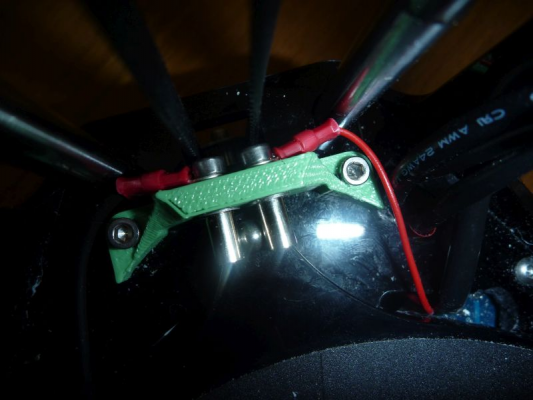

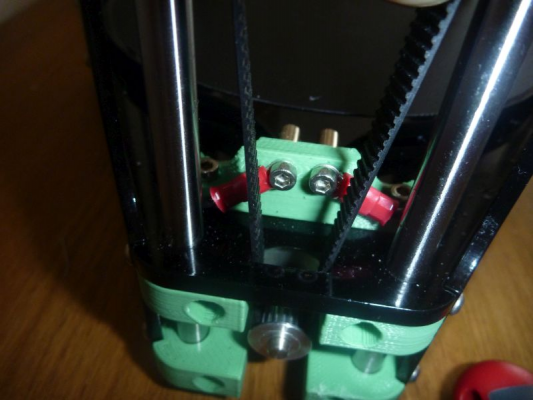

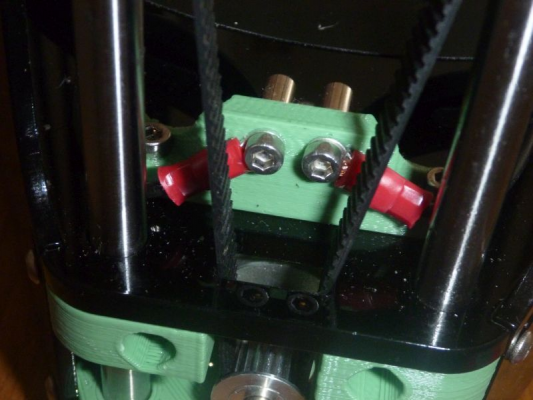

It is not very easy to understand on the photos, but the Fisher have a very special bed system.

On top of the bed plate, there are 3 balls (diam 6mm) positioned at the external bed radius at 120°.

There are three springs which push up the plate and each ball then contact two horizontal cylinders, which makes sort of a 'V' and positions sideways the ball.

The ensemble of three make a 'positive' positioning where there is a unique position for the bed plate whatever its thermal expansion or warping.

It is also used as the probe system, as the cylinders are electrically chained to the probe connector and as soon as one ball no longer touch any cylinder, the probe circuit is open. As a probe system, it is quite clever.

But there is more than that, the spring push are moderate (~200 g/spring) and the bed is easily displaced sideways as soon as there is some side load. This is a remarquable safety as after evading the parasitic load, it reposition EXACTLY at the same place. When you do have contact between the hotend and the part, as for the first layer or as printing PETG, this is really good.

My experience show that it is extremely reliable as while I got many side move during printing, the print quality and accuraccy remains constant. Particularly, while printing PETG, I got a lot of hotend scratching the part (as the PETG harden very quickly) and this never fails to reposition properly.

I don't know if it was used before the Fisher, but for me this is really an excellent setup, with the only limit that you may not have a part weight exceeding ~300g. Considering the Fisher size, this is highly unprobable.

The only moment where it does not reposition well is while removing the part, hence my former comments. More on that later.

Edited 2 time(s). Last edit at 07/19/2015 06:29AM by PRZ.

On top of the bed plate, there are 3 balls (diam 6mm) positioned at the external bed radius at 120°.

There are three springs which push up the plate and each ball then contact two horizontal cylinders, which makes sort of a 'V' and positions sideways the ball.

The ensemble of three make a 'positive' positioning where there is a unique position for the bed plate whatever its thermal expansion or warping.

It is also used as the probe system, as the cylinders are electrically chained to the probe connector and as soon as one ball no longer touch any cylinder, the probe circuit is open. As a probe system, it is quite clever.

But there is more than that, the spring push are moderate (~200 g/spring) and the bed is easily displaced sideways as soon as there is some side load. This is a remarquable safety as after evading the parasitic load, it reposition EXACTLY at the same place. When you do have contact between the hotend and the part, as for the first layer or as printing PETG, this is really good.

My experience show that it is extremely reliable as while I got many side move during printing, the print quality and accuraccy remains constant. Particularly, while printing PETG, I got a lot of hotend scratching the part (as the PETG harden very quickly) and this never fails to reposition properly.

I don't know if it was used before the Fisher, but for me this is really an excellent setup, with the only limit that you may not have a part weight exceeding ~300g. Considering the Fisher size, this is highly unprobable.

The only moment where it does not reposition well is while removing the part, hence my former comments. More on that later.

Edited 2 time(s). Last edit at 07/19/2015 06:29AM by PRZ.

|

Re: RepRapPro's new printer kit (off-topic) July 19, 2015 06:14AM |

Registered: 10 years ago Posts: 14,672 |

I've taken a look at macros/bed7.g and it does indeed do 7-factor calibration. However, I now recommend 6-factor calibration, which you can achieve by changing the S7 parameter to S6 in the last G30 command in bed7.g.

If instead you replace S7 in that file by S-1, it will print out the probe errors it finds, but not do calibration. I would be interested to know what tower angle offsets it reports, which will give an indication of the accuracy of your build.

In case you don't already know, the Auto Bed Compensation button (which should be renamed Auto Calibration on a delta) just runs sys/bed.g. So you can change it to to whatever calibration you want.

To get more accurate calibration, this is the procedure I recommend:

1. Run either 4 or 6 point auto calibration (whichever one you intend to use in future) . Then send M665 and then M666 to find the parameters it has set.

2. Repeat (1) two or more times until the reported M665 and M666 values stabilise.

3. Copy the delta radius and homed height reported by M665 into the M665 command in config.g, and the endstop corrections reported by M666 into the M666 command.

However, if the build is accurate enough, then the second and subsequent auto calibration runs won't change anything, and saving the values in config.g isn't necessary.

I did find it odd that the config.g file supplied by RRP for the Fisher includes nonzero endstop adjustments in the M666 command. I guess they may have been copied from my original file for my Mini Kossel. Or perhaps the design puts the endstop switches at slightly different heights.

Edited 1 time(s). Last edit at 07/19/2015 06:15AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If instead you replace S7 in that file by S-1, it will print out the probe errors it finds, but not do calibration. I would be interested to know what tower angle offsets it reports, which will give an indication of the accuracy of your build.

In case you don't already know, the Auto Bed Compensation button (which should be renamed Auto Calibration on a delta) just runs sys/bed.g. So you can change it to to whatever calibration you want.

To get more accurate calibration, this is the procedure I recommend:

1. Run either 4 or 6 point auto calibration (whichever one you intend to use in future) . Then send M665 and then M666 to find the parameters it has set.

2. Repeat (1) two or more times until the reported M665 and M666 values stabilise.

3. Copy the delta radius and homed height reported by M665 into the M665 command in config.g, and the endstop corrections reported by M666 into the M666 command.

However, if the build is accurate enough, then the second and subsequent auto calibration runs won't change anything, and saving the values in config.g isn't necessary.

I did find it odd that the config.g file supplied by RRP for the Fisher includes nonzero endstop adjustments in the M666 command. I guess they may have been copied from my original file for my Mini Kossel. Or perhaps the design puts the endstop switches at slightly different heights.

Edited 1 time(s). Last edit at 07/19/2015 06:15AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Redo commissioning after any cable unplug July 19, 2015 07:12AM |

Registered: 8 years ago Posts: 475 |

As I had swapped two column steppers and end-stops (Y and Z) to have non-mirrored parts, One of the pin of the end-stop cable get off the plug and was non-contacting.

As this was minor change, I did not recommissioned the machine and that ended up by high mechanical stress on the arms and columns and worse, on the hotend. No harm at the end, but I will advise you to recommission endstops and motors as soon as you unplug cables.

As this was minor change, I did not recommissioned the machine and that ended up by high mechanical stress on the arms and columns and worse, on the hotend. No harm at the end, but I will advise you to recommission endstops and motors as soon as you unplug cables.

|

Re: Calibration July 19, 2015 07:39AM |

Registered: 8 years ago Posts: 475 |

David,

The endstop position is really not precise due to building. In fact, It relies on the manual bending you do on the endstop, so the non-zero endstop is needed.

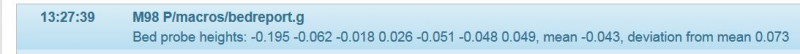

I have done the modifications you write (6 points probing) but the system does not converge. Here the screen copy.

Also, The result of the S-1 is there:

And a last question: is there any procedure that I could find on the web to access to the SD Card from the ethernet link, without removing it from the machine ? nothing yet in the manual.

Regards, Pierre

The endstop position is really not precise due to building. In fact, It relies on the manual bending you do on the endstop, so the non-zero endstop is needed.

I have done the modifications you write (6 points probing) but the system does not converge. Here the screen copy.

Also, The result of the S-1 is there:

And a last question: is there any procedure that I could find on the web to access to the SD Card from the ethernet link, without removing it from the machine ? nothing yet in the manual.

Regards, Pierre

|

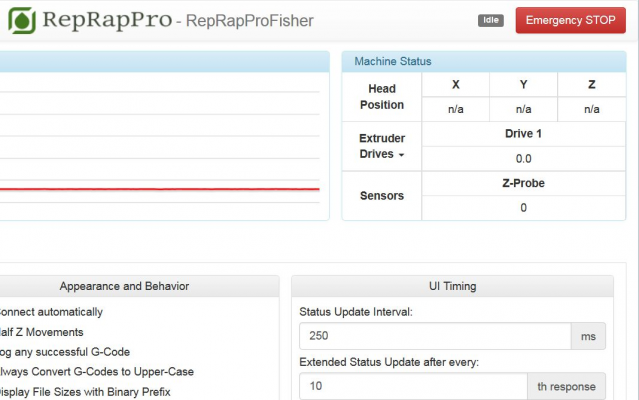

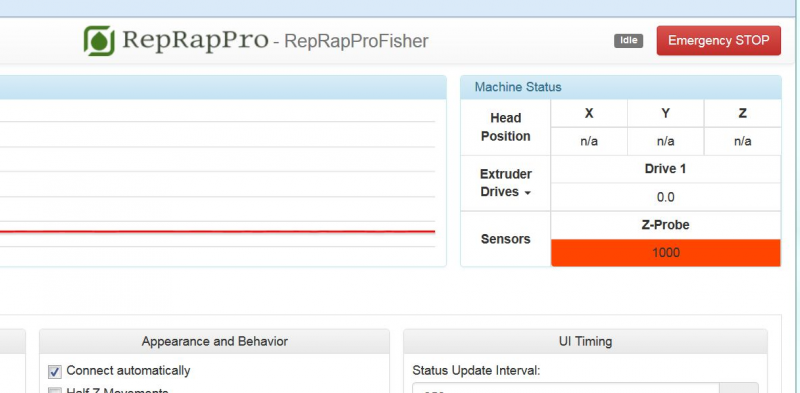

Z- Probe actuated color July 19, 2015 07:49AM |

Registered: 8 years ago Posts: 475 |

I found where the actuated Z-probe color is set :

this is in the file www/js/interface.js

I have changed the "probeTriggerColor" from "#FFF0F0" (very light rose) to "#FF4500" (orange red) which is much more visible.

That may help to notice a misplaced bed after part removing.

Web interface with Z Probe non actuated

Web interface with Z Probe actuated

Edited 1 time(s). Last edit at 07/19/2015 08:05AM by PRZ.

this is in the file www/js/interface.js

I have changed the "probeTriggerColor" from "#FFF0F0" (very light rose) to "#FF4500" (orange red) which is much more visible.

That may help to notice a misplaced bed after part removing.

Web interface with Z Probe non actuated

Web interface with Z Probe actuated

Edited 1 time(s). Last edit at 07/19/2015 08:05AM by PRZ.

|

Re: Redo commissioning after any cable unplug July 19, 2015 08:26AM |

Registered: 10 years ago Posts: 14,672 |

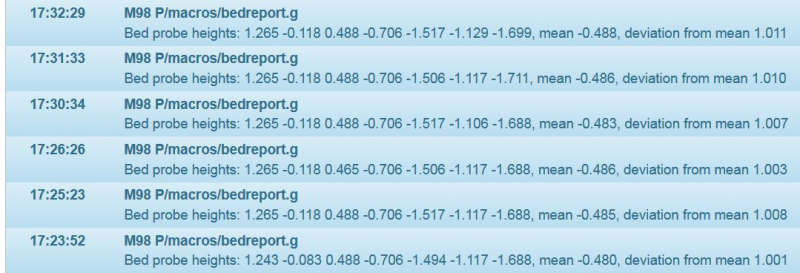

Those results are less consistent than I would hope. Try running bedreport.g multiple times and see how consistent the results are. The tower steps/mm for the Fisher are 87.489, which is 0.0114 mm/microstep. I would hope the bed probe heights would be consistent between multiple runs to within 2 or 3 microsteps, so each figure should vary over a range of about 0.05mm or less.

To improve consistency, it may be worth reducing the Z probing speed. This is set by the M210 command in config.g. I see that it is already set to a slow speed (i.e. 50). If you reduce it further, you may wish to reduce the Z dive height so that bed probing does not become too slow; this is set by the H parameter in the M558 command.

Also, check that the round spacers that form the bed probe switches are not loose.

I am assuming that the bedreport.g file does not have any homing commands in it, so the endstop switch repeatability is not relevant.

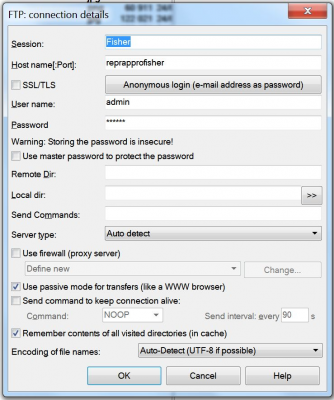

You can upload files to the SD card via the web interface. On the Settings page there is a button to upload files. Any .g files you upload using that button will go into the /sys directory. HTML, CSS or JS files will go into the relevant subdirectory in /www. There are separate buttons on the Files and Macros tabs to upload to the gcodes and macros folders. You can also use an FTP client such as FileZilla to upload/download to/from anywhere on the SD card.

Edited 1 time(s). Last edit at 07/19/2015 08:29AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

To improve consistency, it may be worth reducing the Z probing speed. This is set by the M210 command in config.g. I see that it is already set to a slow speed (i.e. 50). If you reduce it further, you may wish to reduce the Z dive height so that bed probing does not become too slow; this is set by the H parameter in the M558 command.

Also, check that the round spacers that form the bed probe switches are not loose.

I am assuming that the bedreport.g file does not have any homing commands in it, so the endstop switch repeatability is not relevant.

You can upload files to the SD card via the web interface. On the Settings page there is a button to upload files. Any .g files you upload using that button will go into the /sys directory. HTML, CSS or JS files will go into the relevant subdirectory in /www. There are separate buttons on the Files and Macros tabs to upload to the gcodes and macros folders. You can also use an FTP client such as FileZilla to upload/download to/from anywhere on the SD card.

Edited 1 time(s). Last edit at 07/19/2015 08:29AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Redo commissioning after any cable unplug July 19, 2015 11:42AM |

Registered: 8 years ago Posts: 475 |

I somewhat clean up the under bed and reposition it, then run multiple time the bedreport macro (which is bed7 macro with S7 replaced by S-1).

The results are quite consistent:

To FTP with the Duet, what is the login/password ?

The results are quite consistent:

To FTP with the Duet, what is the login/password ?

|

Re: Redo commissioning after any cable unplug July 19, 2015 12:05PM |

Registered: 10 years ago Posts: 665 |

Quote

PRZ

To FTP with the Duet, what is the login/password ?

Choose any user name you like (root, anonymous, admin, whatever) and use the password from your config.g file (default one is reprap). Also make sure you limit the number of concurrent connections to 1 if you indend to upload multiple files at once.

|

Re: Redo commissioning after any cable unplug July 19, 2015 12:52PM |

Registered: 8 years ago Posts: 475 |

Thanks; that works.

It shall be noted that there is no need to use an IP address for connection, but that the name could be 'reprapprofisher'.

And during the connection, the printer answer that it is an ormerod !

My configuration on Total Commander:

Regards, Pierre

It shall be noted that there is no need to use an IP address for connection, but that the name could be 'reprapprofisher'.

And during the connection, the printer answer that it is an ormerod !

My configuration on Total Commander:

Regards, Pierre

|

Re: Redo commissioning after any cable unplug July 19, 2015 02:41PM |

Registered: 10 years ago Posts: 14,672 |

Quote

PRZ

I somewhat clean up the under bed and reposition it, then run multiple time the bedreport macro (which is bed7 macro with S7 replaced by S-1).

The results are quite consistent:

[attachment 58398 BedReport.jpg]

To FTP with the Duet, what is the login/password ?

In that case, you should also find that auto calibration gives consistent M666 endstop corrections now.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: RepRapPro's new printer kit (off-topic) July 19, 2015 05:02PM |

Registered: 8 years ago Posts: 11 |

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 06:41AM |

Registered: 8 years ago Posts: 475 |

-> PheiPheiPhei

The printer was delivered ten days ago and at best, it is printing since 4 days. So please be a bit patient.

As you could see, there is still debugging, and as for the Z-offset, it is very basic debugging. For me, there are things which are not Ok, and shall be modified (primarily, get a more silent fan, an extruder with higher torque, a good filament guide and some modifications to improve printer stability).

There are problems which could be solved by the user, and others which are more difficult.

So, consider this printer is still beta.

As for a beginner, what does beginner mean ?

It is a kit, and a 3D printer is a complex object. If you are not technically inclined, ANY kit could be delicate. Stuff like bad connexion may need time for debugging and sometimes, it may burn the electronic.

Also, as nothing is tested prior to shipping, there could be unexpected problem of supply and you may need replacement part.

I got luck: only one ball shall be replaced and I have devised a temporary solution.

In some cases, the missing/wrong part may be a show stopper. One person tells he/she got a bad bearing on the idler. Without this bearing, the printer could not start. You have to wait the part.

Also, the aim of the manufacturer was to have a low cost printer. So what sort of compromise could you accept for low cost ? small size area, no heated bed, low speed, unbearable noise, time to build, unexpected problems, reliability, durability ?

A key on low cost is also that people doing the debugging are doing unpaid work. We got a 50 pound rebate because it is a beta printer. The extra time needed will never be worth the saving, but that is a mindset. Some people do like assembling, debugging, testing, modifying, be on the leading edge, etc.

As for the compromises, I think it is pityful for a small Delta printer with an 32 bit ARM board and very light moving part to limit the speed only because of extruder design. This 32 bit board was key in my buy and that is really one of the best selling point. The web server integrated in board is really something unique and it is well designed. (Smoothie board do have a web server but it seems people prefer using external board/computer with Octoprint).

There is some positive stuff, however, the board is on the market from two years and somewhat debugged, also there was significant software very recent improvement by volunteers (on the delta and calibration by DC42 and on the web server by ZPL).

You shall also understand that using PETG is pretty much experimental. There was ZERO data on the adherence of the PETG on Buildtak. There was some info about PET, but PETG is different material and some others get more adhesion difficulties with PETG than PET. Using PETG is very interesting for low cost printers without a heated bed, because it may replace ABS and may be less toxic. Also, On the long range, it will be lest costly than PLA. Its extra cost is only because it is a 'new' material in 3D printing.

For this sort of stuff, patience and care is key. With forum help, they may partly replace technical knowledge.

But everyone makes it own compromises, I am a 3D printer beginner, which is neither patient nor very careful, but I already have expensed hundred of hours reading docs, thinking to this stuff, evaluating printers, working on software and I have significant experience (use and design) in a comparable domain (CNC). My Slic3R profile was ready (and was working) BEFORE I get the printer. So, what's a beginner ?

Regards, Pierre

Edited 7 time(s). Last edit at 07/20/2015 07:13AM by PRZ.

The printer was delivered ten days ago and at best, it is printing since 4 days. So please be a bit patient.

As you could see, there is still debugging, and as for the Z-offset, it is very basic debugging. For me, there are things which are not Ok, and shall be modified (primarily, get a more silent fan, an extruder with higher torque, a good filament guide and some modifications to improve printer stability).

There are problems which could be solved by the user, and others which are more difficult.

So, consider this printer is still beta.

As for a beginner, what does beginner mean ?

It is a kit, and a 3D printer is a complex object. If you are not technically inclined, ANY kit could be delicate. Stuff like bad connexion may need time for debugging and sometimes, it may burn the electronic.

Also, as nothing is tested prior to shipping, there could be unexpected problem of supply and you may need replacement part.

I got luck: only one ball shall be replaced and I have devised a temporary solution.

In some cases, the missing/wrong part may be a show stopper. One person tells he/she got a bad bearing on the idler. Without this bearing, the printer could not start. You have to wait the part.

Also, the aim of the manufacturer was to have a low cost printer. So what sort of compromise could you accept for low cost ? small size area, no heated bed, low speed, unbearable noise, time to build, unexpected problems, reliability, durability ?

A key on low cost is also that people doing the debugging are doing unpaid work. We got a 50 pound rebate because it is a beta printer. The extra time needed will never be worth the saving, but that is a mindset. Some people do like assembling, debugging, testing, modifying, be on the leading edge, etc.

As for the compromises, I think it is pityful for a small Delta printer with an 32 bit ARM board and very light moving part to limit the speed only because of extruder design. This 32 bit board was key in my buy and that is really one of the best selling point. The web server integrated in board is really something unique and it is well designed. (Smoothie board do have a web server but it seems people prefer using external board/computer with Octoprint).

There is some positive stuff, however, the board is on the market from two years and somewhat debugged, also there was significant software very recent improvement by volunteers (on the delta and calibration by DC42 and on the web server by ZPL).

You shall also understand that using PETG is pretty much experimental. There was ZERO data on the adherence of the PETG on Buildtak. There was some info about PET, but PETG is different material and some others get more adhesion difficulties with PETG than PET. Using PETG is very interesting for low cost printers without a heated bed, because it may replace ABS and may be less toxic. Also, On the long range, it will be lest costly than PLA. Its extra cost is only because it is a 'new' material in 3D printing.

For this sort of stuff, patience and care is key. With forum help, they may partly replace technical knowledge.

But everyone makes it own compromises, I am a 3D printer beginner, which is neither patient nor very careful, but I already have expensed hundred of hours reading docs, thinking to this stuff, evaluating printers, working on software and I have significant experience (use and design) in a comparable domain (CNC). My Slic3R profile was ready (and was working) BEFORE I get the printer. So, what's a beginner ?

Regards, Pierre

Edited 7 time(s). Last edit at 07/20/2015 07:13AM by PRZ.

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 08:54AM |

Registered: 9 years ago Posts: 395 |

PPP From what i read, this is not yet the printer for beginner as it is intended to be eventually.

I love to read about the experienced you guys are having and, had I been inclined, I would join in. But given that I am hating anything delta every time I see my hard to finish Kossel .... I feel that fighting with one delta is enough!

Btw the smoothieboard (which I selected for my Kossel) has several nice things ... But not the web server! And definitively this community is much better!

So thanks PRZ .... For suffering all the beta issue for us who will come later :-)

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

I love to read about the experienced you guys are having and, had I been inclined, I would join in. But given that I am hating anything delta every time I see my hard to finish Kossel .... I feel that fighting with one delta is enough!

Btw the smoothieboard (which I selected for my Kossel) has several nice things ... But not the web server! And definitively this community is much better!

So thanks PRZ .... For suffering all the beta issue for us who will come later :-)

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 09:35AM |

Registered: 12 years ago Posts: 1,611 |

Hi all!

Thanks for all your efforts. We're getting lots of great feedback from Fisher beta owners, and we're working on improving the instructions and fine-tuning the configuration. We'll do a blog post in the next few days with updates. I might even get to build one in the next couple of days!

Ian

RepRapPro tech support

Thanks for all your efforts. We're getting lots of great feedback from Fisher beta owners, and we're working on improving the instructions and fine-tuning the configuration. We'll do a blog post in the next few days with updates. I might even get to build one in the next couple of days!

Ian

RepRapPro tech support

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 10:24AM |

Registered: 9 years ago Posts: 395 |

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 10:58AM |

Registered: 12 years ago Posts: 1,611 |

There hasn't been a lot of feedback suggesting mechanical changes; mostly it's about documentation. I'm pretty sure the move from beta is only going to be minor changes and polishing up the configuration and instructions, with some work to the wiring, to make it CE compliant. There isn't that much we plan on changing, but have no timescale yet. Hopefully we'll start with Fisher '1'!

There wasn't really a 'beta' release of Ormerod; we did 500 red ones for RS in December 2013, which was the first release, and then effectively the same machine continued, with tweaks here and there, until Ormerod 2 was released in September 2014. Even then, Ormerod 2 wasn't a huge change; proximity sensor, Y axis, PSU, PSU + Duet mounting, and wiring changes to comply with CE certification were the main changes. And we've been through 5 point revisions of Ormerod 2... See: [reprappro.com]

Ian

RepRapPro tech support

There wasn't really a 'beta' release of Ormerod; we did 500 red ones for RS in December 2013, which was the first release, and then effectively the same machine continued, with tweaks here and there, until Ormerod 2 was released in September 2014. Even then, Ormerod 2 wasn't a huge change; proximity sensor, Y axis, PSU, PSU + Duet mounting, and wiring changes to comply with CE certification were the main changes. And we've been through 5 point revisions of Ormerod 2... See: [reprappro.com]

Ian

RepRapPro tech support

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 11:25AM |

Registered: 9 years ago Posts: 395 |

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 12:09PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Fpex

But given that I am hating anything delta every time I see my hard to finish Kossel .... I feel that fighting with one delta is enough!

Interesting, I find my Kossel easier to print with (and faster) than my Ormerod. The only significant problem I had with it was getting the printing plane flat - mostly because the towers on my Mini Kossel leaned a little - which I solved by adding least squares auto calibration to RepRapFirmware.

Quote

Fpex

Btw the smoothieboard (which I selected for my Kossel) has several nice things ... But not the web server! And definitively this community is much better!

Yes, the Smoothie looks to me to be a well-made board, and is available in a dual extruder version. Unfortunately, Smoothieware doesn't yet do segmentation-free delta movement, or fast delta auto calibration. Also, I understand that the speed of uploading to the SD card over Ethernet is very slow. I exchanged a few emails with Arthur Wolf, and he said he intends to do a better web interface. Sadly, he rejected my suggestion of adopting DuetWebControl, but was in favour of using a common HTTP access protocol. He also intends to support PanelDue.

Quote

droftarts

I might even get to build one in the next couple of days!

Ian, I don't see how your employer can reasonably expect you to support a printer kit that you haven't had the experience of building.

Edited 2 time(s). Last edit at 07/20/2015 12:10PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 12:24PM |

Registered: 12 years ago Posts: 1,611 |

Quote

dc42

Ian, I don't see how your employer can reasonably expect you to support a printer kit that you haven't had the experience of building.Quote

droftarts

I might even get to build one in the next couple of days!

He doesn't, that's why he's answering all the Fisher emails! But I'll take over, and rewrite the instructions in more approachable language (perhaps), once my 'training' is complete!

Realistically, I have been reasonably involved in it's development, so know pretty well what's going on, and any Duet-related problems I'm obviously well aware of. However, we try to get to the point that I build a standard, shipping kit, without seeing the instructions beforehand (I have barely looked at them), so I pick up points that, as the designer of the printer wrote the instructions, may have been overlooked. Not quite 'clean room' testing, but as close as we're going to get. I'll retake photos (we've already had lots of suggestions) and rewrite descriptions if they're not clear enough.

Ian

RepRapPro tech support

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 12:32PM |

Registered: 12 years ago Posts: 1,611 |

Quote

Fpex

My understanding from the above feedback is that there some point worth changing in the design.

The above feedback is from one person, printing materials that we do not specify for the Fisher. The Fisher is what it is; a cheap PLA printer. To get it working with other filament types, or at faster speeds (though we feel going too fast causes other problems, related to trying to move a liquid at high speeds) you may have to modify it to achieve this yourself; but then that's what RepRap is all about. If you want to put a bigger motor on the extruder, feel free! Though as dc42 points out, it's better for the extruder motor to skip than strip the filament. It's not required for the specification and price point we're targetting this printer at.

I think the only other complaint is the spool mount, coupled with the feeding of filament, due to the size and weight of the spool, and the material; again, all of these aren't what we supply, so I don't really see that this is our problem! Personally, I never use a spool mount attached to the machine, except for when using the smallest, lightest spools; there are so many better ways. You need a bit of resistance to turning, to keep filament on the spool. I'm sure the community will come up with it's own ideas for handling the wide variety of spools (we can't cover all of them), and they'll all be backwards compatible.

So, like I said, we may make some small changes, but probably not either of these two. The rest are firmware/calibration issues, which we are looking at.

Ian

RepRapPro tech support

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 01:00PM |

Registered: 10 years ago Posts: 14,672 |

Quote

droftarts

If you want to put a bigger motor on the extruder, feel free!

Or perhaps adapt the Ormerod geared extruder, or VortyZA's spring-loaded version of it, for the Fisher - then there is no need to buy a new motor, just the hex bolt and hobbed insert. My delta prints PLA about twice as fast as my Ormerod for the same print quality, and it would be a shame not to realise this potential speed advantage. But I guess the direct drive extruder helps keep the price down.

Quote

droftarts

I think the only other complaint is the spool mount, coupled with the feeding of filament, due to the size and weight of the spool, and the material; again.

I hope someone will soon design a spool holder that is mounted on top of the Fisher instead of hanging on the side. I have never thought that hanging any sort of filament spool on the side of a delta printer frame is a good idea.

I don't have a Fisher, but it's great to see a low-cost, innovative delta printer design. It would be even better if it used my mini differential IR board for the Z probe!

I think the Fisher has great potential, and I won't be at all surprised if there is a Fisher 2 next year, or at least some evolutionary improvements.

I think the Fisher has great potential, and I won't be at all surprised if there is a Fisher 2 next year, or at least some evolutionary improvements.Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 01:03PM |

Registered: 8 years ago Posts: 83 |

Hi, all. Firstly, my apologies for the very bad english, it's not my mother tongue.

From my small experience in 3D printing (Replicator 2x from 06/2015 and my new Fisher since 3 days), I can tell you that the Fisher is a well thought printer when you compare it to the Makerbot (old one I agree).

After one week of Rep2x, I bought the Fisher Kit because I was disappointed. Very "febrile" when I received the Fisher, it took me some hours to build it but not too much.

The instructions were not all clear for a newbie in 3D and an ignorant in electronic. I broke some stuff (...) but nothing goes really wrong.

I made a feedback to support, and hope this will help other beginners like me.

I've printed some pieces since yesterday, some are the same as with the Rep2x, and the quality is far ahead with the Fisher "out of the box".

I read the forum since (too late to avoid some mistakes) and don't understand every post (some helps me anyway), it comforts me that I made the good choice.

I'll probably don't propose a lot of ameliorations to the material, but I already think about some.

I'm really enthusiastic and I will continue to follow these geeky guys that will probably make me go forward.

Greg

3D Newbie

From my small experience in 3D printing (Replicator 2x from 06/2015 and my new Fisher since 3 days), I can tell you that the Fisher is a well thought printer when you compare it to the Makerbot (old one I agree).

After one week of Rep2x, I bought the Fisher Kit because I was disappointed. Very "febrile" when I received the Fisher, it took me some hours to build it but not too much.

The instructions were not all clear for a newbie in 3D and an ignorant in electronic. I broke some stuff (...) but nothing goes really wrong.

I made a feedback to support, and hope this will help other beginners like me.

I've printed some pieces since yesterday, some are the same as with the Rep2x, and the quality is far ahead with the Fisher "out of the box".

I read the forum since (too late to avoid some mistakes) and don't understand every post (some helps me anyway), it comforts me that I made the good choice.

I'll probably don't propose a lot of ameliorations to the material, but I already think about some.

I'm really enthusiastic and I will continue to follow these geeky guys that will probably make me go forward.

Greg

3D Newbie

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 05:12PM |

Registered: 8 years ago Posts: 475 |

-> Ian,

There is not only the question of speed about the extruder. The biggest problem is that is got difficulties to unwind the spool and you loose parts. Indeed, in PLA, I lost 1 part on 3 due to unwinding problems.

About the spool, you write it is ok if didn't work with others manufacturer spools ? Seriously ? You are thinking to go proprietary filament ?

Your suggestion to have some braking on the spool is good, as the problem is that the filament naturally unspool and the loops then cross and are difficult to unwind. So, yes, the spool system and filament guide needs to be reviewed, especially if you intend to stay with this extruder.

About the PETG, in my own words 'it is pretty much experimental'.

However, while the tuning is more delicate than for PLA, it will constitute a good alternative to ABS at cost ZERO, because it doesn't need a heating bed. And :

1/ It is easier to extrude than PLA, so I never had any extruder skip with it

2/ The filament is more slippery and I never had any unwinding problem (with my piano wire filament guide)

I got some other problems and it need survey, but I don't loose as many parts as with PLA.

And yet for me, this printer will be 'PETG only' till PLA unwinding is solved.

till PLA unwinding is solved.

Oups, I lost a PETG part NOW :/ (surface scratching) Temperature management is delicate.

regards, Pierre

Edited 1 time(s). Last edit at 07/20/2015 05:44PM by PRZ.

There is not only the question of speed about the extruder. The biggest problem is that is got difficulties to unwind the spool and you loose parts. Indeed, in PLA, I lost 1 part on 3 due to unwinding problems.

About the spool, you write it is ok if didn't work with others manufacturer spools ? Seriously ? You are thinking to go proprietary filament ?

Your suggestion to have some braking on the spool is good, as the problem is that the filament naturally unspool and the loops then cross and are difficult to unwind. So, yes, the spool system and filament guide needs to be reviewed, especially if you intend to stay with this extruder.

About the PETG, in my own words 'it is pretty much experimental'.

However, while the tuning is more delicate than for PLA, it will constitute a good alternative to ABS at cost ZERO, because it doesn't need a heating bed. And :

1/ It is easier to extrude than PLA, so I never had any extruder skip with it

2/ The filament is more slippery and I never had any unwinding problem (with my piano wire filament guide)

I got some other problems and it need survey, but I don't loose as many parts as with PLA.

And yet for me, this printer will be 'PETG only'

till PLA unwinding is solved.

till PLA unwinding is solved.Oups, I lost a PETG part NOW :/ (surface scratching) Temperature management is delicate.

regards, Pierre

Edited 1 time(s). Last edit at 07/20/2015 05:44PM by PRZ.

|

Re: RepRapPro's new printer kit (off-topic) July 20, 2015 06:59PM |

Registered: 8 years ago Posts: 24 |

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 03:33AM |

Registered: 9 years ago Posts: 395 |

Dc42 the Kossel is very fast but it feels like any bump will let the print fail and the machine get out of calibration.

True is that i have not co spidered any bed calibration and that the choice of a moothieboard did not help, I the end I might disassemble everything and get rind of the smoothie board.

So far the original Mendel (which has been a lot customised on my version, including fw) is my workhorse printer, the ormerod is also somewhat of a pain. Apart from burned supply, I find some design choices questionable. I did not have time to change anything yet, but I might eventually.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

True is that i have not co spidered any bed calibration and that the choice of a moothieboard did not help, I the end I might disassemble everything and get rind of the smoothie board.

So far the original Mendel (which has been a lot customised on my version, including fw) is my workhorse printer, the ormerod is also somewhat of a pain. Apart from burned supply, I find some design choices questionable. I did not have time to change anything yet, but I might eventually.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 04:30AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Fpex

Dc42 the Kossel is very fast but it feels like any bump will let the print fail and the machine get out of calibration.

Interesting, I haven't had that problem. Perhaps you need a little more motor current?

Quote

Fpex

True is that i have not co spidered any bed calibration and that the choice of a moothieboard did not help, I the end I might disassemble everything and get rind of the smoothie board.

4-point calibration is not hard to do manually, see section "Calibrating the endstop positions, delta radius and homed height" in [miscsolutions.wordpress.com]. Unfortunately, 4-point calibration was insufficient for my initial Kossel build because the towers were leaning slightly.

My Kossel extruder failed yesterday, so I am back to using the Ormerod as my only printer until I fix it. My Ormerod 1 works well enough, since I upgraded the bed support, Y belt clamps, X arm and IR sensor. I find VortyZA's spring loaded version of the Ormerod extruder drive works well and I'd like to adapt it for the Kossel, but unfortunately the files are not available in OpenScad format.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.