RepRapPro's new printer kit (off-topic)

Posted by dc42

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 04:43AM |

Registered: 9 years ago Posts: 395 |

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 04:52AM |

Registered: 12 years ago Posts: 1,611 |

PRZ - no, we're not going with a proprietary spool; the Fisher is designed as a small desktop printer, so we feel 0.5kg spool is the right size for it, and that's what we designed it for. If you're using 1kg spools, or even 2kg spools like we do in production, you wouldn't necessarily mount them on any machine. There is such a range of spools (diameter, width, central hole size), and such a variety of ways to mount them (and what 'fits' in people's spaces), that it's pointless us coming up with a sophisticated solution that uses more parts and increase cost (and price) of the printer. As upsch2000 points out, there's many, many spool designs on Thingiverse to choose from. See: [www.thingiverse.com]

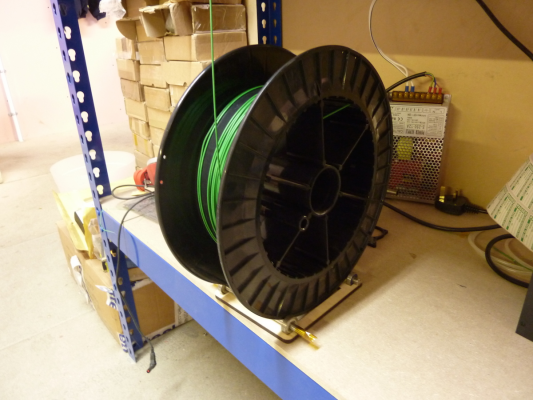

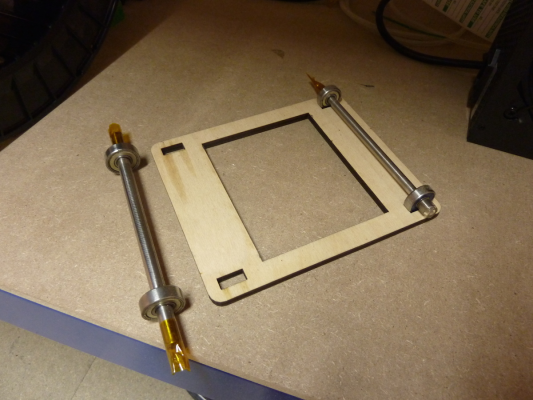

This is what we use, with the large 2kg production spools; one laser cut part (could be printed, or hand-made), four bearings (608 or 626) and two smooth rods (8mm or 6mm, depending on bearings), with something on the end of the rods to stop them walking out of the bearings (Kapton tape here). These provide good stability, and the spool can't freely spin, but the extruder has no problem pulling filament off the spool. We really should release the parametric OpenSCAD version of these... We also tend to use a PTFE 3mm OD 2mm ID tube to guide filament from the spool into the extruder smoothly, which also helps keep the filament on the spool.

We're very happy that your Fisher is capable of more than we designed it for! To avoid the nozzle striking the print, use 'lift Z' in your gcode; Slic3r > Printer Settings > Extruder 1 > Retraction > Lift Z. On a cartesian printer, where the Z axis is a screw thread, there is a penalty in using this; on a Delta, there is no penalty. Setting this to 0.4mm will lift the nozzle on travel moves, reducing chances of the nozzle hitting the print. The shape of the nozzle tip is also a bit different from our other printers; research has shown that a pointier nozzle is better at overhangs, but it does have more vertical sides, compared with our old nozzle.

Ian

RepRapPro tech support

This is what we use, with the large 2kg production spools; one laser cut part (could be printed, or hand-made), four bearings (608 or 626) and two smooth rods (8mm or 6mm, depending on bearings), with something on the end of the rods to stop them walking out of the bearings (Kapton tape here). These provide good stability, and the spool can't freely spin, but the extruder has no problem pulling filament off the spool. We really should release the parametric OpenSCAD version of these... We also tend to use a PTFE 3mm OD 2mm ID tube to guide filament from the spool into the extruder smoothly, which also helps keep the filament on the spool.

We're very happy that your Fisher is capable of more than we designed it for! To avoid the nozzle striking the print, use 'lift Z' in your gcode; Slic3r > Printer Settings > Extruder 1 > Retraction > Lift Z. On a cartesian printer, where the Z axis is a screw thread, there is a penalty in using this; on a Delta, there is no penalty. Setting this to 0.4mm will lift the nozzle on travel moves, reducing chances of the nozzle hitting the print. The shape of the nozzle tip is also a bit different from our other printers; research has shown that a pointier nozzle is better at overhangs, but it does have more vertical sides, compared with our old nozzle.

Ian

RepRapPro tech support

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 04:54AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Fpex

The bed is a real pain in the Kossel.

Why?

Quote

Fpex

What extruders design do you use ?

The one that came with my T3P3 Mini Kossel kit, which I believe is called a RepRap Mini Geared Extruder. It' looks similar to this one [reprappro.com]. It worked well until I broke it, although I find it over-geared, so depending on the motor current I get either too much torque or too little acceleration. This is using a 48mm long motor, and I suspect it will work better with a 34mm motor because of the lower rotor inertia. Even so, I think the 3:1 gearing of the Ormerod extruder is closer to the optimum.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 05:37AM |

Registered: 12 years ago Posts: 1,611 |

Just a quick note about printing speed.

On the Huxley, Mendel and Ormerod, we print at 40mm/s maximum. After this, frame stiffness and the weight of the axes start to cause problems, and backlash in the axes becomes more obvious. The Fisher has a nice, stiff frame, and the effector and carriages are much lighter, the weight is distributed around the axes evenly, and spread across three axes. So it can print faster. We print on the Fisher at up to 80mm/s. At this speed, we haven't had extrusion problems with the new extuder or hot end design.

However, going faster than this can, potentially, have problems. First, there is the increase in extrusion pressure, as the filament is pushed through faster, and has less time to melt. This isn't a failing of the extruder, it's the hot end; increasing the temperature should help, but to go really fast, you probably need a longer melt zone in the nozzle. But then this brings it's own problems of accurate control of filament, and ooze! Also, at fast speeds, overhangs and bridging will suffer; the filament is laid down and pulled around with the nozzle going so fast, causing it warp. Finally, cooling doesn't stay over the extruded filament to cool it effectively; it's still hot, and so will shrink, again leading to warping. If you're serious about wanting nice overhangs, you'll need to slow perimeters right down. This is mechanic of extruding a thermoplastic, not a problem of design of any of the printers.

Ultimaker, who for a long time was the 'fastest printer', did this by running really hot hot end temperatures (so could push the filament through fast), and no retraction (so didn't have to worry about such accurate control of the filament)! I think they have improved the quality over time, but have to go slower to do it. They were able to go fast because of the design of their machine; a strong box, with a light XY carriage that shared the weight of the hot end, and had the extruder mounted on the printer and connected to the hot end by Bowden tube. Sounds a bit like a Delta!

Ian

RepRapPro tech support

On the Huxley, Mendel and Ormerod, we print at 40mm/s maximum. After this, frame stiffness and the weight of the axes start to cause problems, and backlash in the axes becomes more obvious. The Fisher has a nice, stiff frame, and the effector and carriages are much lighter, the weight is distributed around the axes evenly, and spread across three axes. So it can print faster. We print on the Fisher at up to 80mm/s. At this speed, we haven't had extrusion problems with the new extuder or hot end design.

However, going faster than this can, potentially, have problems. First, there is the increase in extrusion pressure, as the filament is pushed through faster, and has less time to melt. This isn't a failing of the extruder, it's the hot end; increasing the temperature should help, but to go really fast, you probably need a longer melt zone in the nozzle. But then this brings it's own problems of accurate control of filament, and ooze! Also, at fast speeds, overhangs and bridging will suffer; the filament is laid down and pulled around with the nozzle going so fast, causing it warp. Finally, cooling doesn't stay over the extruded filament to cool it effectively; it's still hot, and so will shrink, again leading to warping. If you're serious about wanting nice overhangs, you'll need to slow perimeters right down. This is mechanic of extruding a thermoplastic, not a problem of design of any of the printers.

Ultimaker, who for a long time was the 'fastest printer', did this by running really hot hot end temperatures (so could push the filament through fast), and no retraction (so didn't have to worry about such accurate control of the filament)! I think they have improved the quality over time, but have to go slower to do it. They were able to go fast because of the design of their machine; a strong box, with a light XY carriage that shared the weight of the hot end, and had the extruder mounted on the printer and connected to the hot end by Bowden tube. Sounds a bit like a Delta!

Ian

RepRapPro tech support

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 05:41AM |

Registered: 10 years ago Posts: 1,230 |

Quote

PRZ

....The biggest problem is that is got difficulties to unwind the spool and you loose parts. Indeed, in PLA, I lost 1 part on 3 due to unwinding problems....

here's an easy fix that will keep the layers on the spool in order...and put a ugly neck tie to good use

1) hang a neck tie over the spool, should fit in between the sides of the spool and rest on the filament, if its to wide cut it to size

2) fasten the end of the tie on the roll-out side (outgoing) of the spool to something solid, printer or table - why outgoing?, you want the friction to be constant, not act like a pipe wrench

3 hang a suitable weight in the other end of the tie

Erik

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 08:14AM |

Registered: 10 years ago Posts: 14,672 |

As there is now a separate subforum for the Fisher at [forums.reprap.org], I suggest we close this thread. PRZ, you may wish to use your experience to assist another user who has posted a couple of questions there.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 08:18AM |

Registered: 10 years ago Posts: 2,472 |

Quote

PRZ

About the PETG, in my own words 'it is pretty much experimental'.

However, while the tuning is more delicate than for PLA, it will constitute a good alternative to ABS at cost ZERO, because it doesn't need a heating bed. And :

1/ It is easier to extrude than PLA, so I never had any extruder skip with it

2/ The filament is more slippery and I never had any unwinding problem (with my piano wire filament guide)

I got some other problems and it need survey, but I don't loose as many parts as with PLA.

It is worth mentioning that PET is a lot more dense than ABS - I couldn't find the density of PETG but imagine it is also the case with that. It won't matter for many prints, but for those of us printing quadcopters or other weight-sensitive things it needs to be taken into account because the strength advantage is more than negated by the additional weight (you could make a beefier ABS part that has more strength for less weight). I think ABS is has the best strength to weight ratio of all currently available FFF plastics (but please correct me if I am wrong - I'd love to try a better material for my quads).

Dave

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 09:20AM |

Registered: 12 years ago Posts: 1,611 |

Quote

dc42

As there is now a separate subforum for the Fisher at [forums.reprap.org], I suggest we close this thread. PRZ, you may wish to use your experience to assist another user who has posted a couple of questions there.

Hooray! My badgering finally paid off... [forums.reprap.org]

I'll get the admins to move this post, and any others, to that sub-forum. Hopefully Fisher owners will still look in this forum too, with it's wealth of information!

Ian

RepRapPro tech support

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 11:39AM |

Registered: 9 years ago Posts: 1,159 |

Quote

dc42

Quote

Fpex

Dc42 the Kossel is very fast but it feels like any bump will let the print fail and the machine get out of calibration.

Interesting, I haven't had that problem. Perhaps you need a little more motor current?

Quote

Fpex

True is that i have not co spidered any bed calibration and that the choice of a moothieboard did not help, I the end I might disassemble everything and get rind of the smoothie board.

4-point calibration is not hard to do manually, see section "Calibrating the endstop positions, delta radius and homed height" in [miscsolutions.wordpress.com]. Unfortunately, 4-point calibration was insufficient for my initial Kossel build because the towers were leaning slightly.

My Kossel extruder failed yesterday, so I am back to using the Ormerod as my only printer until I fix it. My Ormerod 1 works well enough, since I upgraded the bed support, Y belt clamps, X arm and IR sensor. I find VortyZA's spring loaded version of the Ormerod extruder drive works well and I'd like to adapt it for the Kossel, but unfortunately the files are not available in OpenScad format.

Dave

What format are they in I may be able to convert them? do you have the link to them?

Doug

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 04:01PM |

Registered: 10 years ago Posts: 14,672 |

Quote

dougal1957

Quote

dc42

My Kossel extruder failed yesterday, so I am back to using the Ormerod as my only printer until I fix it. My Ormerod 1 works well enough, since I upgraded the bed support, Y belt clamps, X arm and IR sensor. I find VortyZA's spring loaded version of the Ormerod extruder drive works well and I'd like to adapt it for the Kossel, but unfortunately the files are not available in OpenScad format.

Dave

What format are they in I may be able to convert them? do you have the link to them?

Doug

They are in .stp format, whatever that is, [www.thingiverse.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: RepRapPro's new printer kit (off-topic) July 21, 2015 06:41PM |

Registered: 9 years ago Posts: 1,699 |

Unfortunately step files cannot be converted. I only could use the geometry as I remixed the feeder. As I had to remove the tongue it only was able with the hard way as building a new block that was killing the tongue. To widen/ tighten holes means to draw a new hole.

At our company this problem is common and we use this issue if we are supplying 3D drawings of our parts as they are fixed and cannot be edited.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

At our company this problem is common and we use this issue if we are supplying 3D drawings of our parts as they are fixed and cannot be edited.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 04:44AM |

Registered: 12 years ago Posts: 1,611 |

SolidWorks can import a step file (most CAD software can), but also has a feature recognition tool (there's an automatic and manual option, I think) which can create SolidWorks features, and make the part editable. Alternatively, find out from MasonStonehenge what the CAD software he uses is, maybe ask him for the original file so you can edit it.

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 05:29AM |

Registered: 9 years ago Posts: 395 |

If you need, send the step files to me and i try to convert them.

Or make an account for Autodesk fusion360 that should allow to import step files. It is an amazing software to design stuff and free for maker and hobbyists, while profs like me need to pay for it.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

Or make an account for Autodesk fusion360 that should allow to import step files. It is an amazing software to design stuff and free for maker and hobbyists, while profs like me need to pay for it.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 06:18AM |

Registered: 12 years ago Posts: 1,611 |

Quote

Fpex

If you need, send the step files to me and i try to convert them. Or make an account for Autodesk fusion360 that should allow to import step files. It is an amazing software to design stuff and free for maker and hobbyists, while profs like me need to pay for it.

That's interesting. I've been playing around with OnShape ( [www.onshape.com] ) recently; it's a full, online, cloud-based CAD environment - I've tried it on Mac, PC and Ubuntu, and in Firefox, Chrome and Safari, and it works in all of them. I really like it, and they are adding new features all the time. It can import step, SolidWorks and many other files, and there's even an ipad/iphone app! The 'free' account will be 'free' forever: [www.onshape.com]

It is a little limited at the moment, but it is being developed by the people who worked on SolidWorks, before Dessault took over. It gets updated with new features and bug fixes every three weeks.

I haven't tried Fusion 360, mainly because it was my understanding that Fusion 360 only has a free 90-day trial, as far as I can make out. It's free for 'students & educators'. It's also not an 'in browser' application; you still have to download and install it, and you need Windows or Mac. Only your files are stored in the cloud.

Fusion 360 does have a larger and more impressive feature set, but I think OnShape is catching up.

Ian

RepRapPro tech support

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 07:39AM |

Registered: 9 years ago Posts: 395 |

Ian,

I have also used OnShape, but (given my auto cad background) it is a little confusing and it lacks yet few things i need. Still, it will catch up quickly.

As response to OnShape (I think), autodesk has made Fusion360 Ultimate free for non commercial use including personal use or use for things not being sold. Not for 90 days, forever.

As for reliability, OnShape i have not used enough to judge it ... fusion, i have found tons of bugs as i have been using it from its beta state and the support is really fast. Clearly autodesk is betting a lot on additive and subtractive manufacturing, If only they prices their resign printer lower ;-)

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

I have also used OnShape, but (given my auto cad background) it is a little confusing and it lacks yet few things i need. Still, it will catch up quickly.

As response to OnShape (I think), autodesk has made Fusion360 Ultimate free for non commercial use including personal use or use for things not being sold. Not for 90 days, forever.

As for reliability, OnShape i have not used enough to judge it ... fusion, i have found tons of bugs as i have been using it from its beta state and the support is really fast. Clearly autodesk is betting a lot on additive and subtractive manufacturing, If only they prices their resign printer lower ;-)

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 08:46AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Treito

...As I had to remove the tongue it only was able with the hard way as building a new block that was killing the tongue..

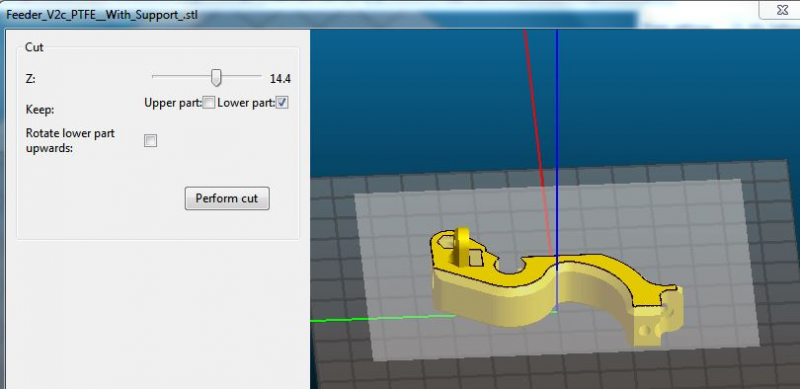

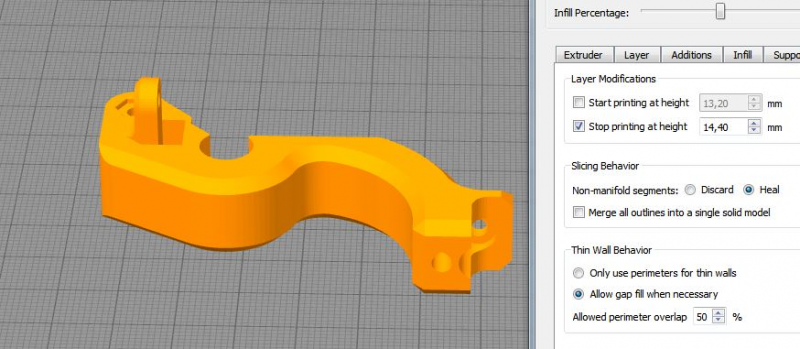

I often use Slic3r to cut of parts or to cut models in two

but in this case where the excessive part is in the z direction it would be much simpler just to stop the print at the correct hight

Erik

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 11:12AM |

Registered: 9 years ago Posts: 1,699 |

But how you change hole sizes? The step-for,at is not suitable for this as it only saves the results not the way to get those results and so you cannot change things directly. Some changes you can handle but mason offered once a version with a bigger radius of the feeder way and here I would have no chance to change this if I only have a step file or an STL file.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 11:54AM |

Registered: 12 years ago Posts: 1,611 |

Quote

Fpex

As response to OnShape (I think), autodesk has made Fusion360 Ultimate free for non commercial use including personal use or use for things not being sold. Not for 90 days, forever.

That's really interesting! Finally found this post ( [forums.autodesk.com] ) which links to this [www.autodesk.com] (see note in top right). Also, there's an FAQ explaining the difference between Fusion 360 and Fusion 360 Ultimate here: [knowledge.autodesk.com]

Looks like I might have yet another CAD package to learn! Though I still like that I can use OnShape on pretty much any operating system or device...

Ian

RepRapPro tech support

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 12:21PM |

Registered: 8 years ago Posts: 475 |

Any STL file could be reworked in OpenSCAD. You can make holes, adds parts, etc.

for OpenSCAD, there is no difference between an object it created and an object it imported in STL.

If it this is just to increase a hole, that is easy, adjust position of a hole of same size, then increase its diameter.

For structural modifications, as you do not have the structure, this is not possible.

You could scale the object, with scaling different for each direction.

Also, you could cut a part, either with the projection function in Z , or by substracting a cube, in any direction.

Use modifier '#' to help.

for OpenSCAD, there is no difference between an object it created and an object it imported in STL.

If it this is just to increase a hole, that is easy, adjust position of a hole of same size, then increase its diameter.

For structural modifications, as you do not have the structure, this is not possible.

You could scale the object, with scaling different for each direction.

Also, you could cut a part, either with the projection function in Z , or by substracting a cube, in any direction.

Use modifier '#' to help.

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 12:31PM |

Registered: 9 years ago Posts: 1,699 |

But as I described before what can you do if you want to change the sweep for example make the entrance larger? Using the step-files I can do these things with FreeCAD too, but in my eyes it is not okay as you add more commands. If you have an original file you could do the changes directly. So let me say you would like to change the size of the s-curve and nothing else. Your turn.

I am taking a look at Fusion 360 at the moment and hopefully it has something with Inventor in common as I would not have to learn much, but I am afraid it will not. It looks like 123D and the functions of that program were too simple for me but I did not reach the sketch function yet (as my Ormerod MK1 tries successfully to angry me)

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I am taking a look at Fusion 360 at the moment and hopefully it has something with Inventor in common as I would not have to learn much, but I am afraid it will not. It looks like 123D and the functions of that program were too simple for me but I did not reach the sketch function yet (as my Ormerod MK1 tries successfully to angry me)

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 01:23PM |

Registered: 9 years ago Posts: 395 |

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 01:34PM |

Registered: 9 years ago Posts: 1,699 |

I know that the features are not comparable. What I mean is the usage -> the interface itself. Would it be easy to change? FreeCAD is very similiar to Inventor according the usage. If I compare it with Medusa I would have much to learn but at FreeCAD there are only slightly differences and so I could fully concentrate on drawing and I do not waste much time with "how I can do this now?". I hope you can understand.

FreeCAD can also import .STL or step-files, but I can only use the given geometry and "catch" this gemoetry if the source file is a step-file. Using an .STL-file I have to catch structures via coordinates and that might be not as exact as catching them directly.

Fusion 360 looks interesting. Okay the usage is slightly other but you can handle it. But I could not run it on Linux that is a great disadvantage and everything is selectable via a pull-down menu so you cannot see which functions you can use. And you cannot see if a sketch is fully restricted. Okay I started my both big parts in FreeCAD and I will observe Fusion 360 but for the moment I think I stay with FreeCAD.

But as I mentioned before to come back to the topic - using a stepfile you only can add further manipulations but you cannot manipulate given structures at the root. Has anyone tried .igs-files yet? Do they have more options?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

FreeCAD can also import .STL or step-files, but I can only use the given geometry and "catch" this gemoetry if the source file is a step-file. Using an .STL-file I have to catch structures via coordinates and that might be not as exact as catching them directly.

Fusion 360 looks interesting. Okay the usage is slightly other but you can handle it. But I could not run it on Linux that is a great disadvantage and everything is selectable via a pull-down menu so you cannot see which functions you can use. And you cannot see if a sketch is fully restricted. Okay I started my both big parts in FreeCAD and I will observe Fusion 360 but for the moment I think I stay with FreeCAD.

But as I mentioned before to come back to the topic - using a stepfile you only can add further manipulations but you cannot manipulate given structures at the root. Has anyone tried .igs-files yet? Do they have more options?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 01:48PM |

Registered: 9 years ago Posts: 395 |

Did you try ti locate an investor beta? there are few around that might do what you want .... but the main issue here is linux. If linux is where yu work, onshore or professional non free sw is the way to try.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 01:50PM |

Registered: 9 years ago Posts: 1,699 |

I might get an educational version for free of Inventor but again that is not the point as .STP and .STL are limited by the file format itself and do not rebuild the model

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 04:40PM |

Registered: 9 years ago Posts: 395 |

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 04:59PM |

Registered: 9 years ago Posts: 1,699 |

But that was the question above. It seems that Mason would be so kind to offer another file format but he do not know what kind of format is suitable. And if this extruder should be changed for the Fisher or for the Kossel it would be much easier to have a file format which contains the original model. First of all I would prefer .STP over .STL as .STP provides complete structures like sweeps which can be used with FreeCAD for example or Inventor.

The question should not be which program to use it should be which file format should be preferred so most users can modify/ edit parts and if possible for free. I do not know much about .igs. Is this format also restricted like .stp?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

The question should not be which program to use it should be which file format should be preferred so most users can modify/ edit parts and if possible for free. I do not know much about .igs. Is this format also restricted like .stp?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 05:07PM |

Registered: 9 years ago Posts: 395 |

I still fail to understand the problem with step format. I provide step files to all my plastic suppliers and the can modify it without problem including dramatic changes. I can easily open step in any inventor fusion (also the free beta) program and modify it at will.

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

----- Making the world smarter @ www.xetal.eu

----- Helping entrepreneurs @ www.fralke.com

|

Re: RepRapPro's new printer kit (off-topic) July 22, 2015 05:27PM |

Registered: 9 years ago Posts: 1,699 |

So I did not say that .STP is a bad format but there must be a better solution.

I changed the diameter of the top hole. It was to wide so what did I? I draw a new sketch at the top, grabbed the center of the hole and made a donut hole (let me call it like this as it looked like a donut). The inner diameter was my destination width and the outer diameter was slightly wider than the original hole. After that I extruded this sketch and combined both parts and I was done. Time to be used less than 2 minutes.

Of course this works. But if I had had the original FreeCAD file (if exists) I could have opened the original sketch containing the hole diameter and changed it there. That is the more elegant way. So besides if the parts are freely distributed what if 100 persons try to change the hole size with my method or with the second method? Think about the file size and processing time then. Just one simple example.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I changed the diameter of the top hole. It was to wide so what did I? I draw a new sketch at the top, grabbed the center of the hole and made a donut hole (let me call it like this as it looked like a donut). The inner diameter was my destination width and the outer diameter was slightly wider than the original hole. After that I extruded this sketch and combined both parts and I was done. Time to be used less than 2 minutes.

Of course this works. But if I had had the original FreeCAD file (if exists) I could have opened the original sketch containing the hole diameter and changed it there. That is the more elegant way. So besides if the parts are freely distributed what if 100 persons try to change the hole size with my method or with the second method? Think about the file size and processing time then. Just one simple example.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: RepRapPro's new printer kit (off-topic) July 23, 2015 09:42AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: RepRapPro's new printer kit (off-topic) July 23, 2015 09:57AM |

Registered: 9 years ago Posts: 1,699 |

Hello Ian,

I did already but he did not give an answer. I ask him also some times ago. The only answer I get is the question what format we wish, but I do not know what he can offer and maybe you (not you personnel the indirect you) can switch your software favorites for a moment. For example I would also use OpenSCAD if the changes are small. I even did already. I am afraid we will not get any answer from him.

Take a look here for example (I remixed the extruder some time ago).

Forum

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

I did already but he did not give an answer. I ask him also some times ago. The only answer I get is the question what format we wish, but I do not know what he can offer and maybe you (not you personnel the indirect you) can switch your software favorites for a moment. For example I would also use OpenSCAD if the changes are small. I even did already. I am afraid we will not get any answer from him.

Take a look here for example (I remixed the extruder some time ago).

Forum

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Sorry, only registered users may post in this forum.